Method for changing curing speed of raw lacquer

A technology of curing speed and raw lacquer, applied in the direction of natural resin coatings, coatings, etc., can solve the problems of reducing polymerization rate, dead paint, high labor cost, prolonging and recovering drying time, slowing curing speed, and effective drying time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 blank paint film

[0037] (1) The original raw lacquer is filtered with a filter tool to remove branches and other impurities in the original paint solution. The filter tool used is a simple filter tool assembled with 100 mesh gauze and absorbent cotton. The paint solution with a solid content of 66.25% is placed Stir in a beaker at 35°C and 120r / min until the solid content is about 75% to obtain refined lacquer, which is sealed and stored after the reaction;

[0038] (2) Using refined raw lacquer as raw material, use a 75 μm film applicator to coat the surface of the tinplate sheet so that the wet thickness of the paint film is 75 μm, and then put the obtained sample into a constant temperature and humidity box (T=25°C, RH= 80%) dry, denoted as sample RL. Before coating, the tinplate sheet was polished with 100-mesh and 240-mesh sandpaper in turn, and then cleaned with absolute ethanol.

Embodiment 2

[0039] The preparation of embodiment 2 raw lacquer and inorganic salt composite coating

[0040] (1) The original raw lacquer is filtered with a filter tool to remove branches and other impurities in the original paint solution. The filter tool used is a simple filter tool assembled with 100 mesh gauze and absorbent cotton. The paint solution with a solid content of 66.25% is placed Stir in a beaker at 35°C and 120r / min until the solid content is about 75% to obtain refined lacquer, which is sealed and stored after the reaction;

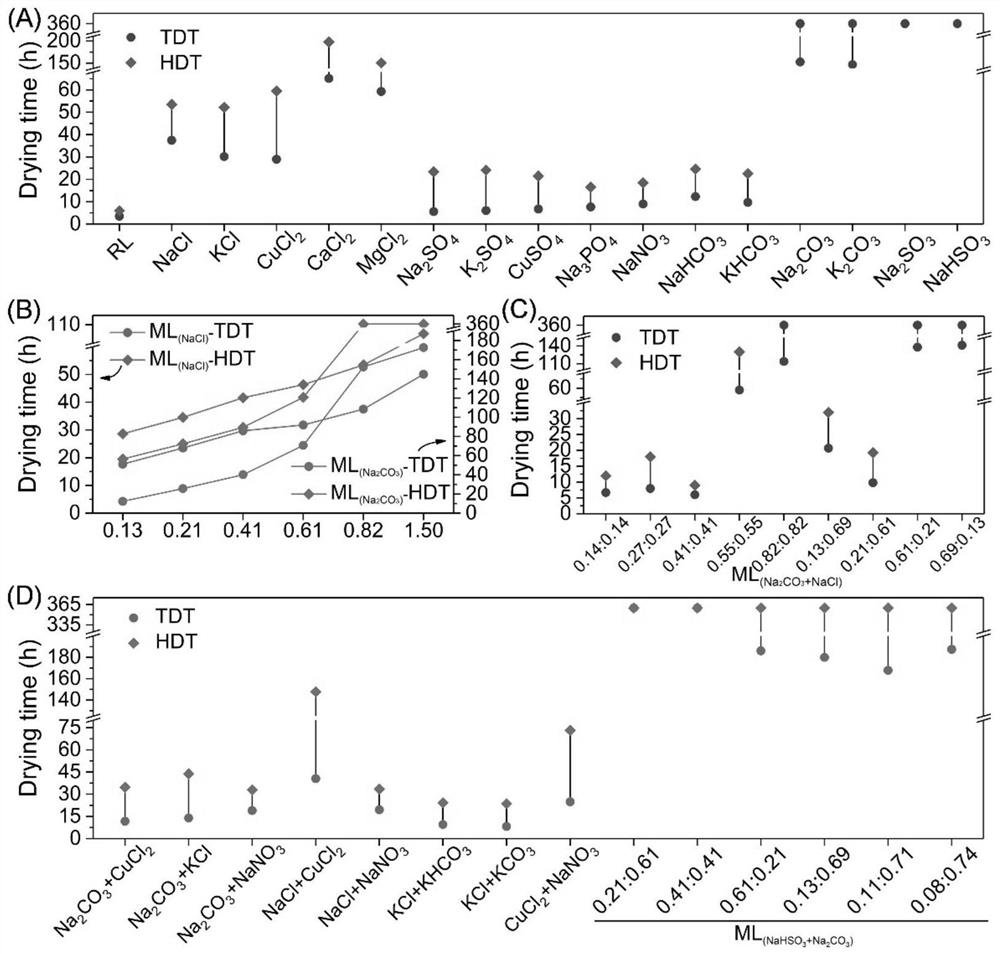

[0041] (2) Inorganic salts (sodium chloride, potassium chloride, copper chloride, calcium chloride, magnesium chloride, sodium sulfate, potassium sulfate, copper sulfate, sodium phosphate, sodium nitrate, sodium bicarbonate, sodium carbonate, potassium carbonate, Sodium sulfite or sodium bisulfite) and raw lacquer were mixed in a beaker in proportion, stirred magnetically for 1 hour at 25°C, and the obtained sample was sealed and stored as ML (无机盐) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com