Patents

Literature

36results about How to "Reduce chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical mechanical polishing solution for processing surface of sapphire or carborundum wafer for LED (Light Emitting Diode) substrate slice and preparation method thereof

InactiveCN102888193AAvoid damageNo subsurface damageSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesActive agentSilicon oxide

The invention discloses a chemical mechanical polishing solution for processing a surface of a sapphire or carborundum wafer for an LED (Light Emitting Diode) substrate slice. The chemical mechanical polishing solution comprises the following raw materials by weight: 2 to 30% of grinding material, 0.01 to 5% of chelating agent, 0.01 to 10% of surface active agent, 0.01 to 10% of dispersing agent, 0.1 to 20% of oxidant and the balance of deionized water. The preparation method comprises the steps as follows: preparing a grinding material-silica sol; then, sequentially adding the chelating agent, surface active agent, dispersing agent, oxidant and deionized water to the obtained silica sol along with agitating; and continuously uniformly agitating to obtain the chemical mechanical polishing solution for processing the surface of the sapphire or carborundum wafer for the LED substrate slice. The chemical mechanical polishing solution disclosed by the invention can not bring damage, scratching and corrosive pits to the surface of the LED substrate and has no pollution to the environment; the raw materials are cheap, and the cost is low; and the chemical mechanical polishing solution is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

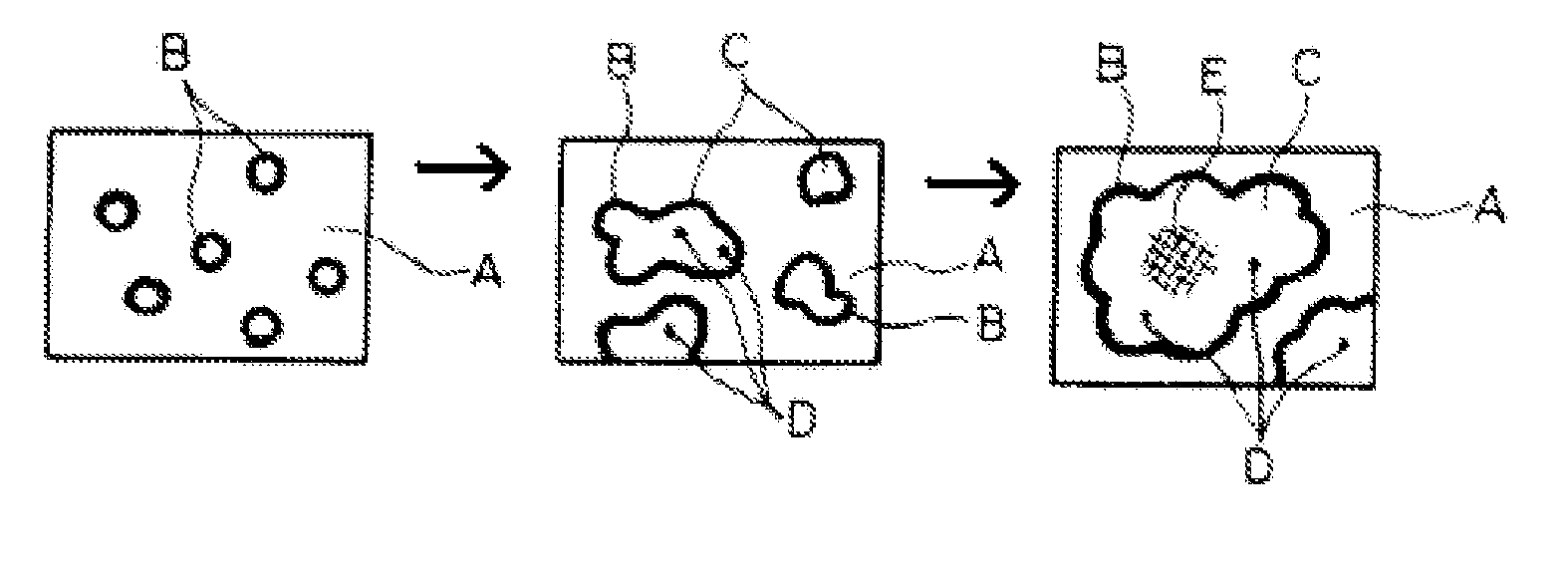

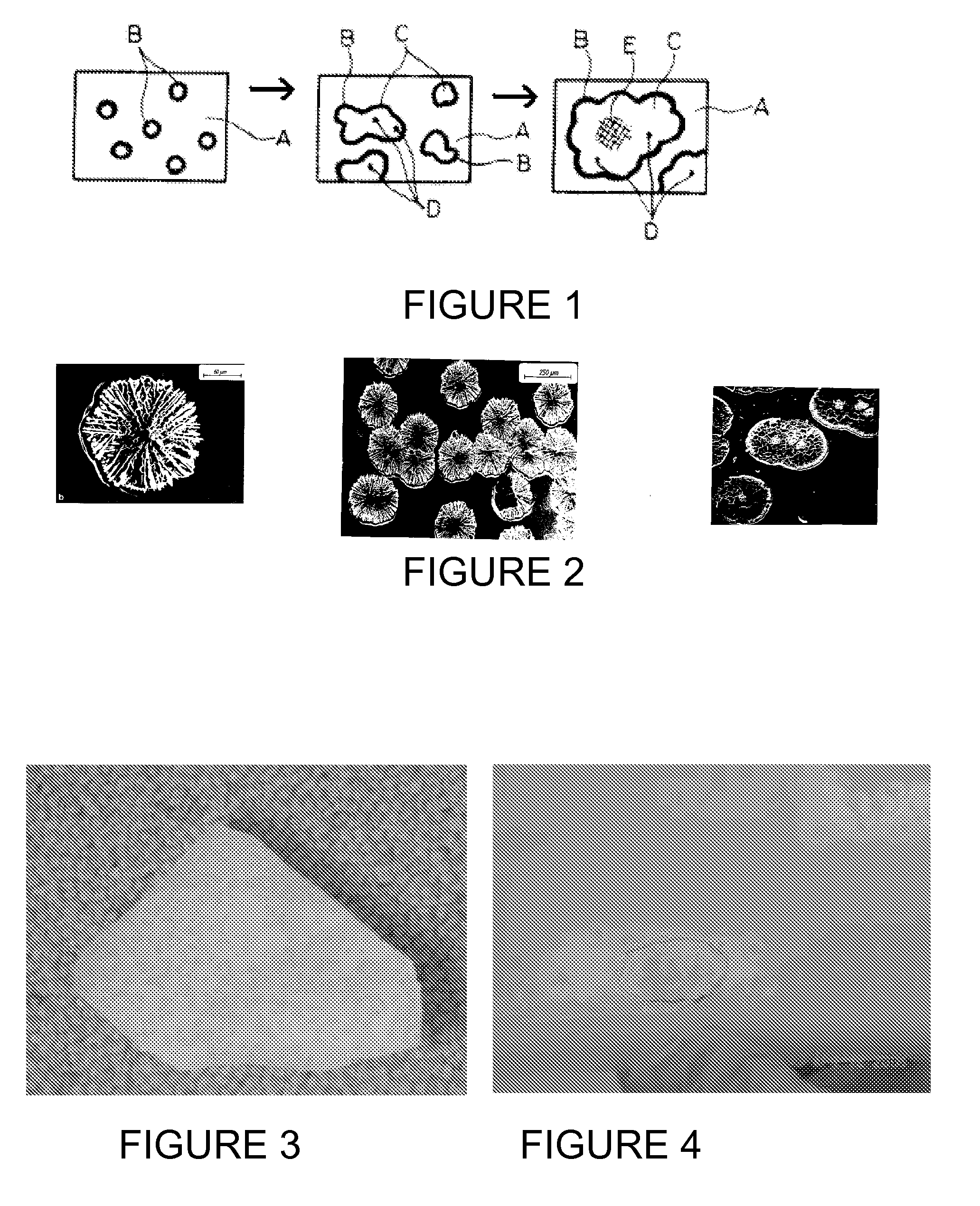

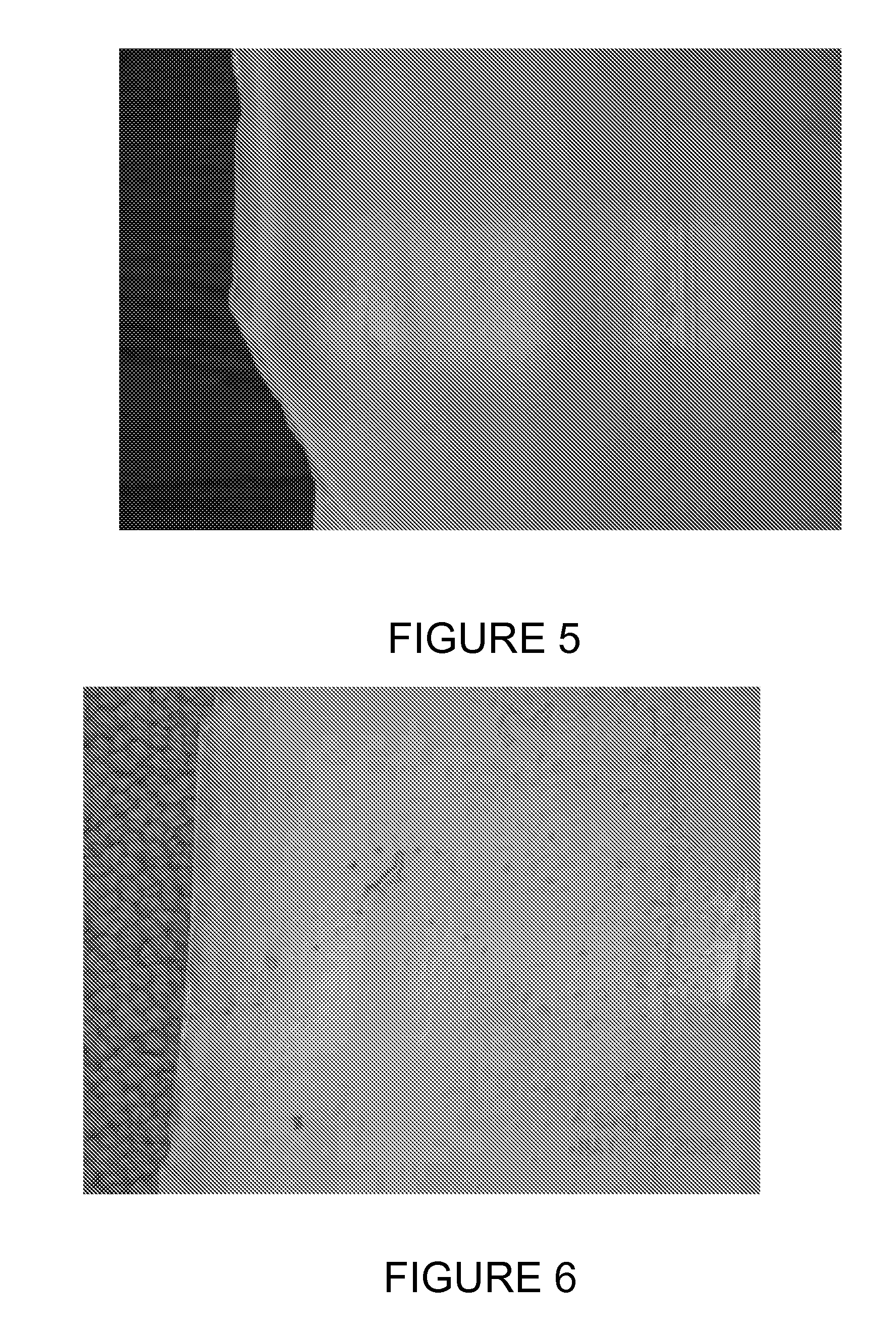

Quartz glass crucible and method for treating surface of quartz glass crucible

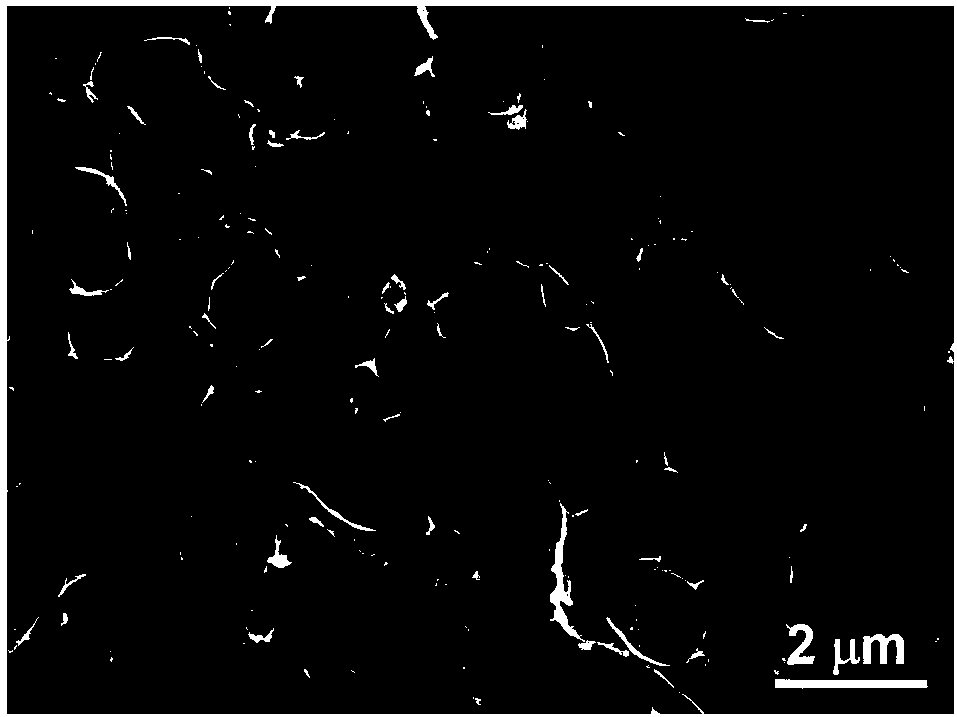

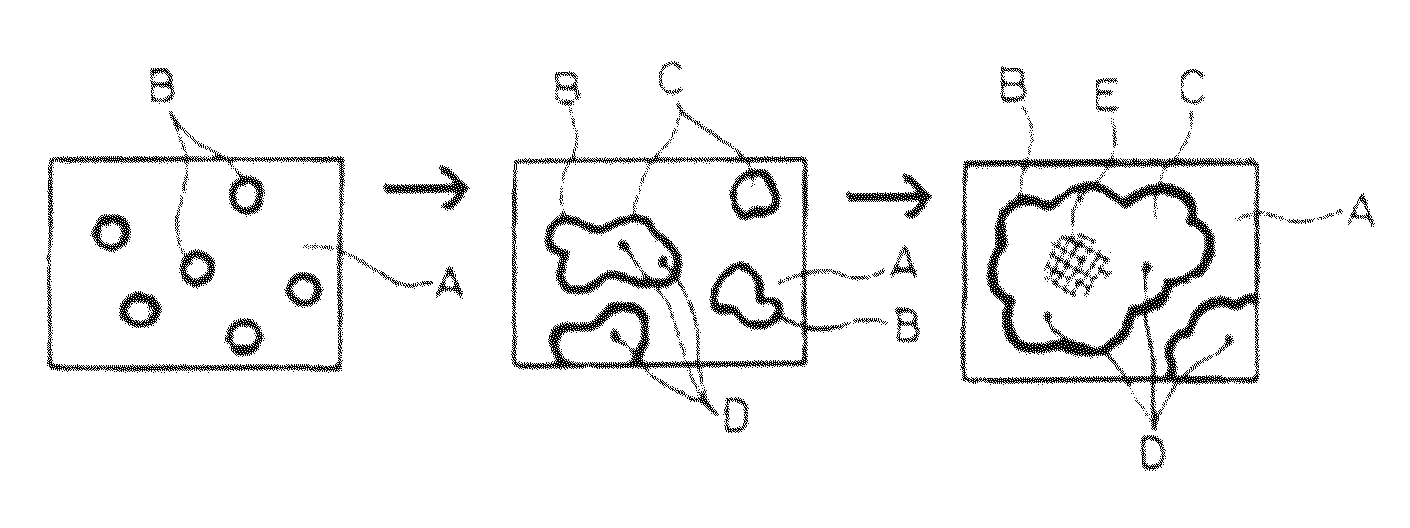

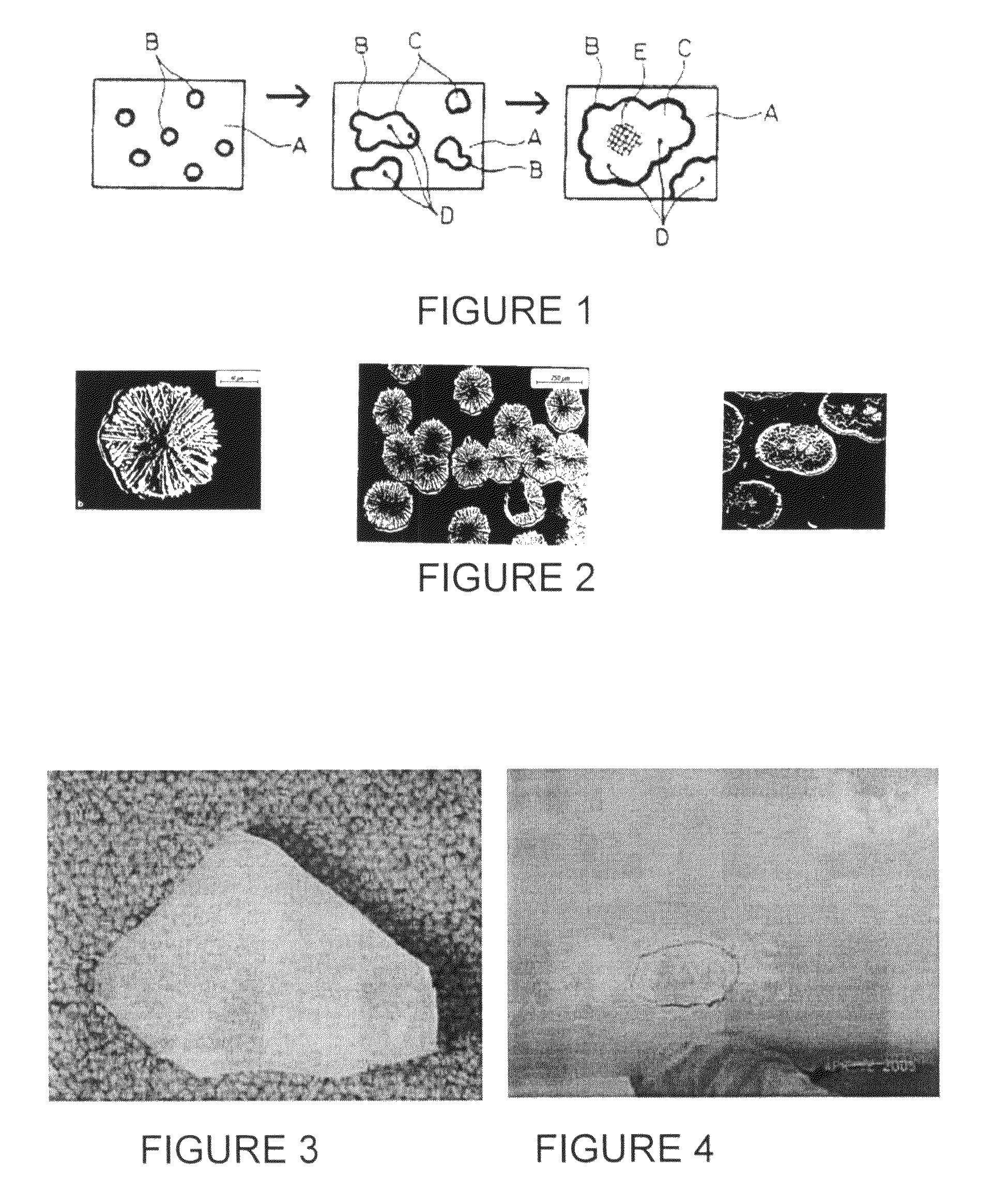

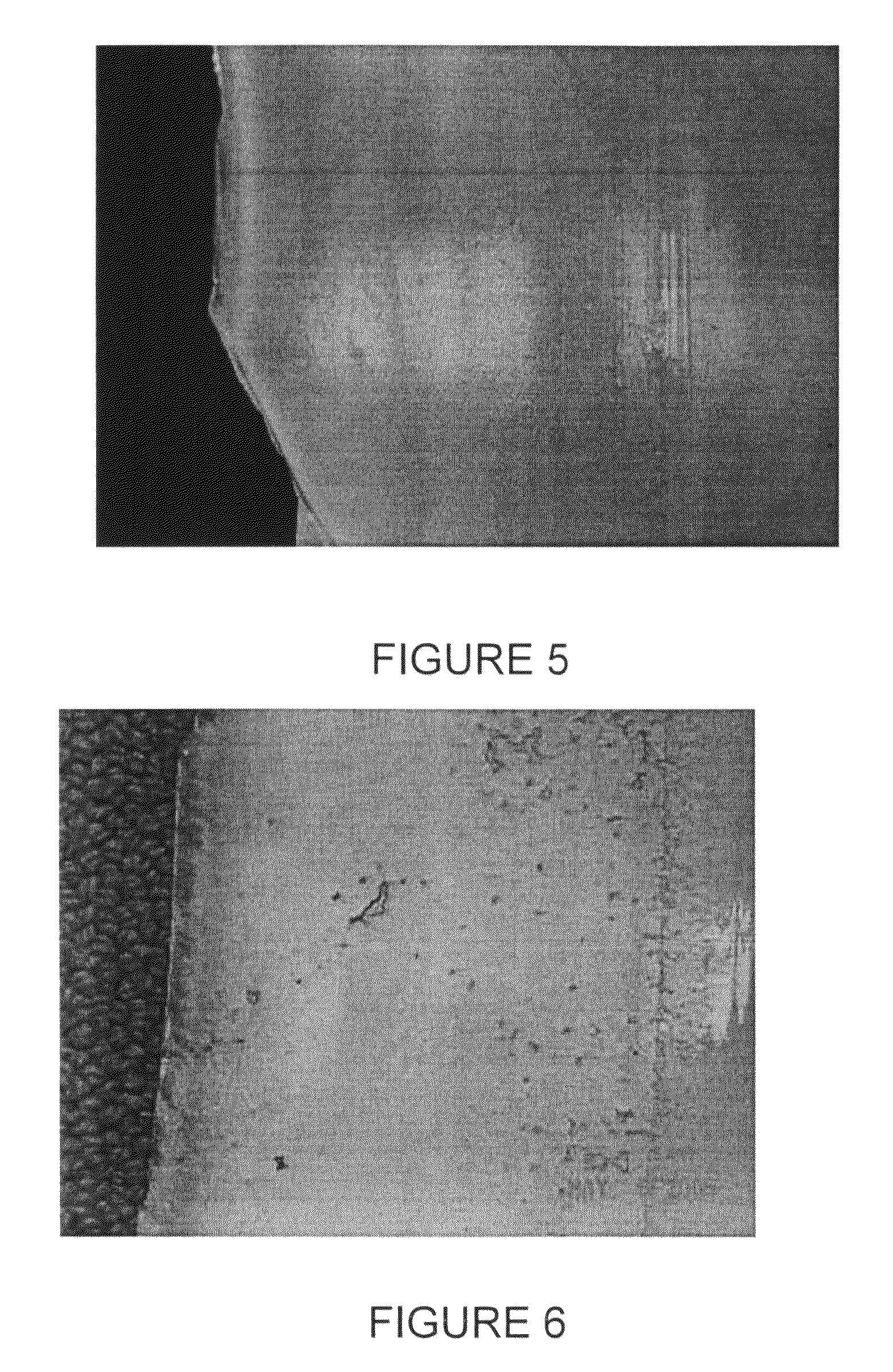

ActiveUS20080092804A1Prolong lifeReduce chemistryAfter-treatment apparatusPolycrystalline material growthCoated surfaceHalogen

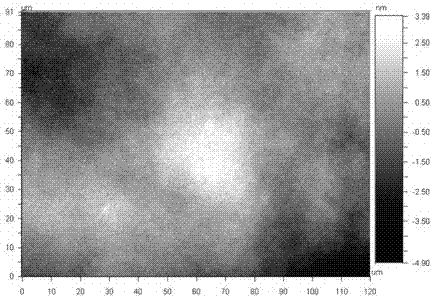

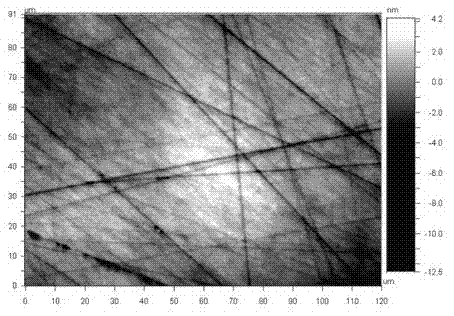

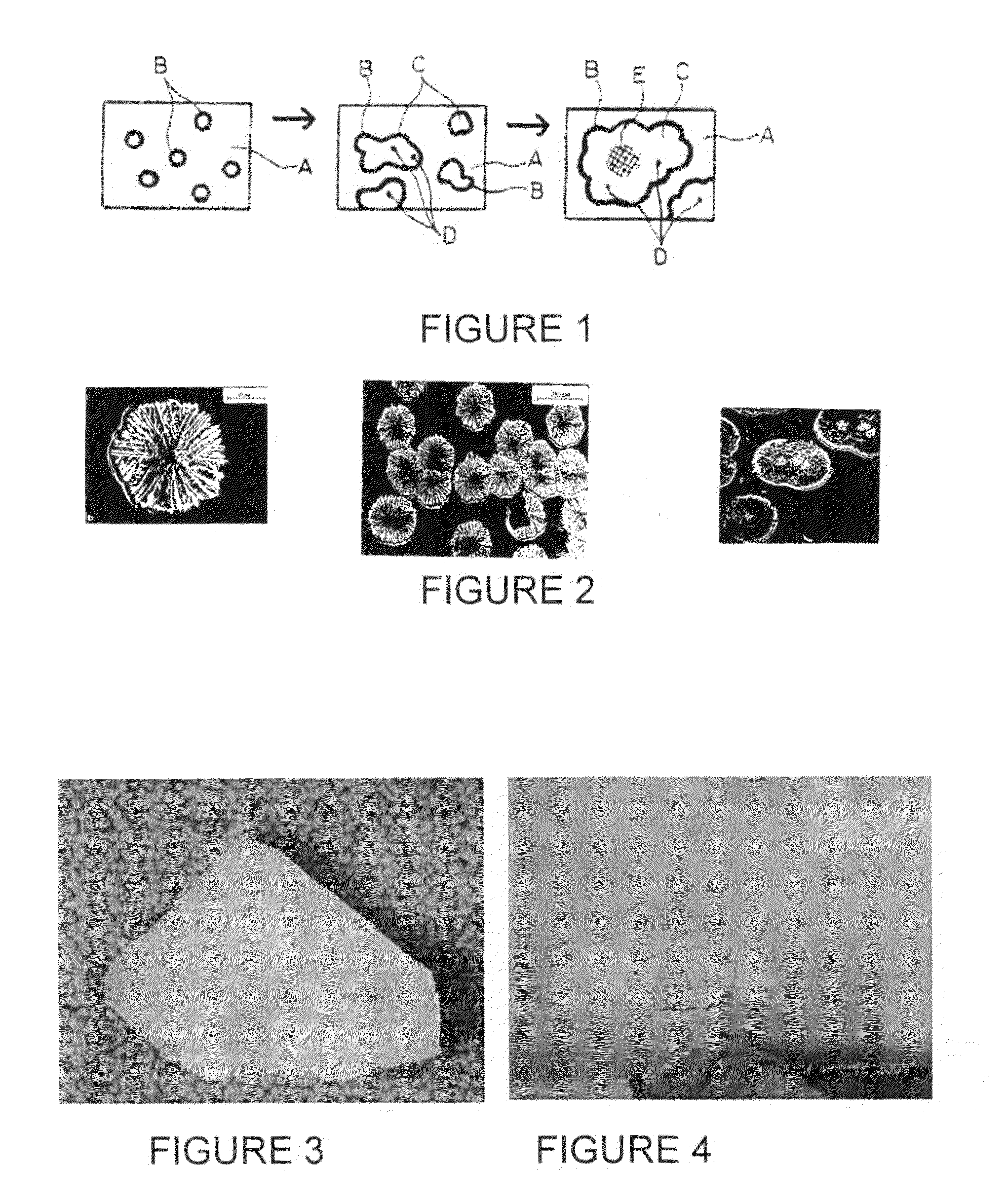

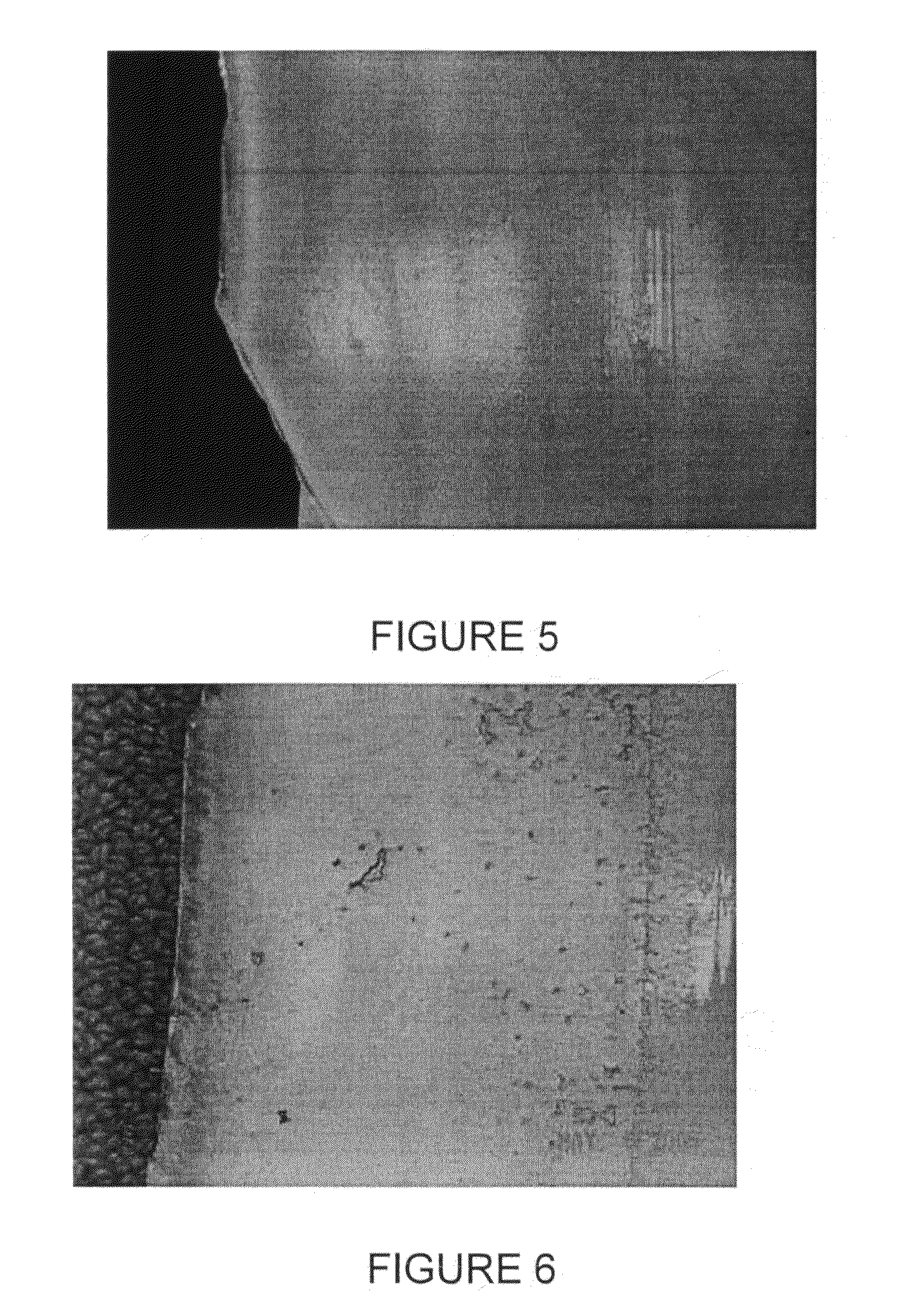

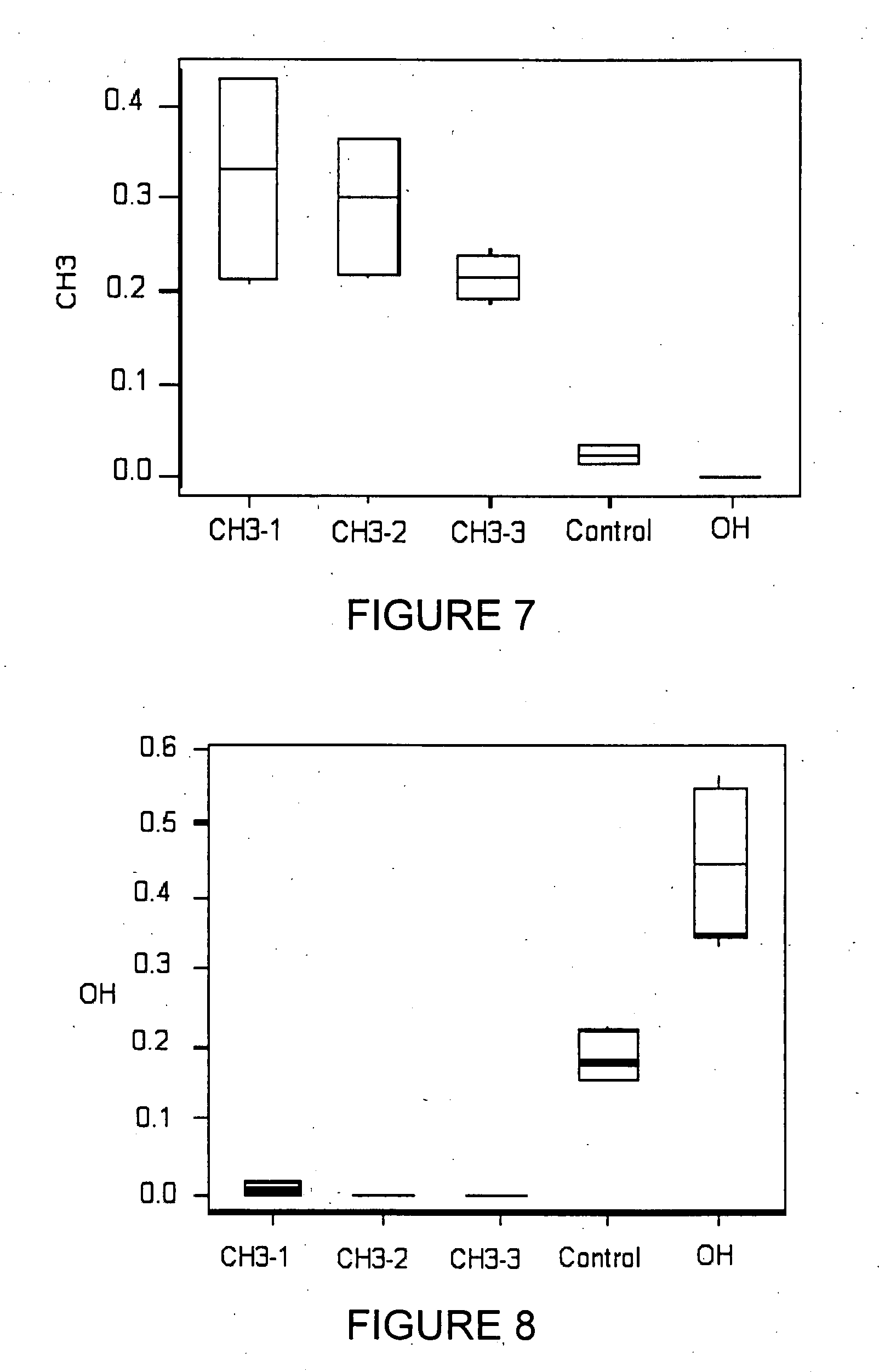

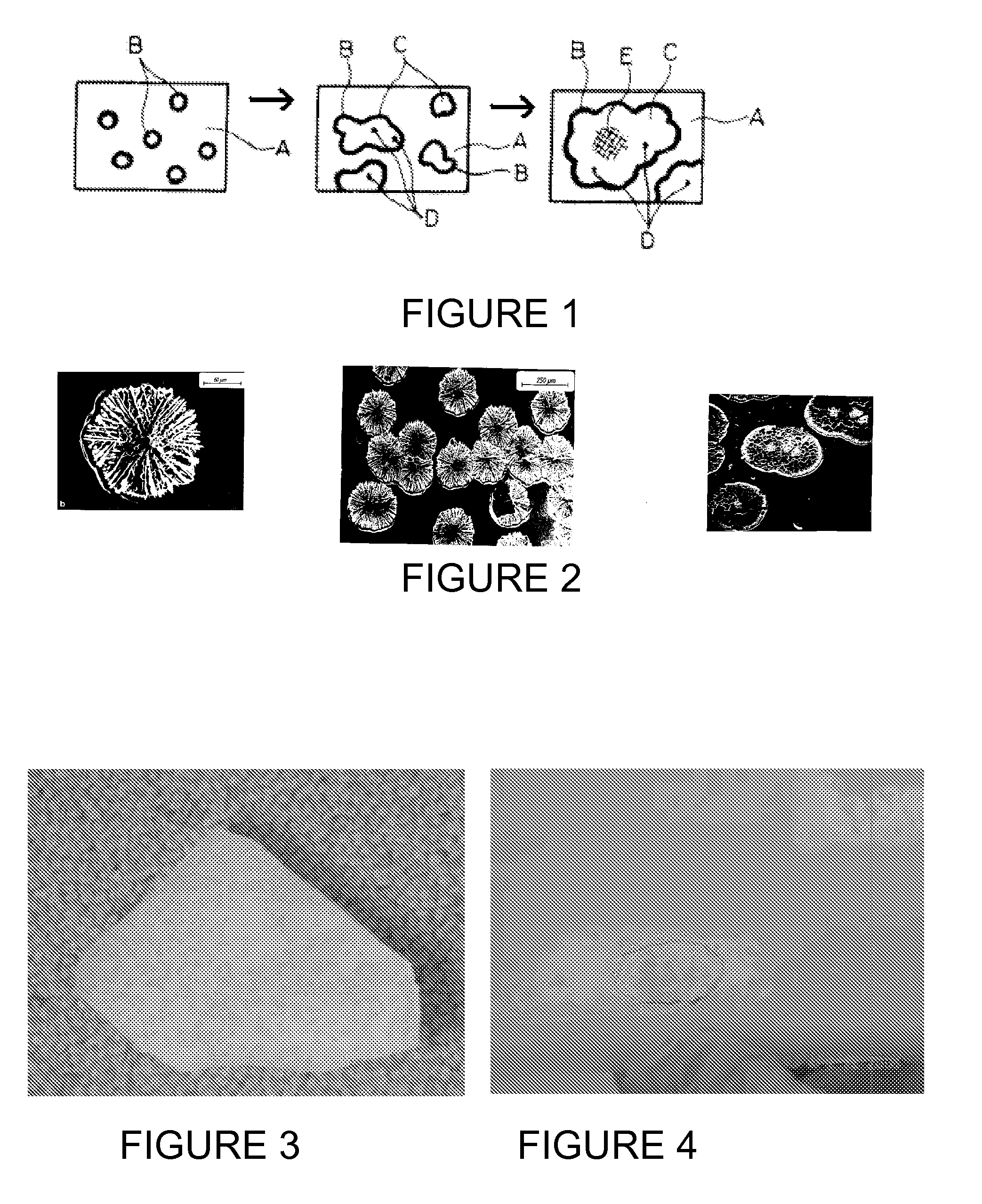

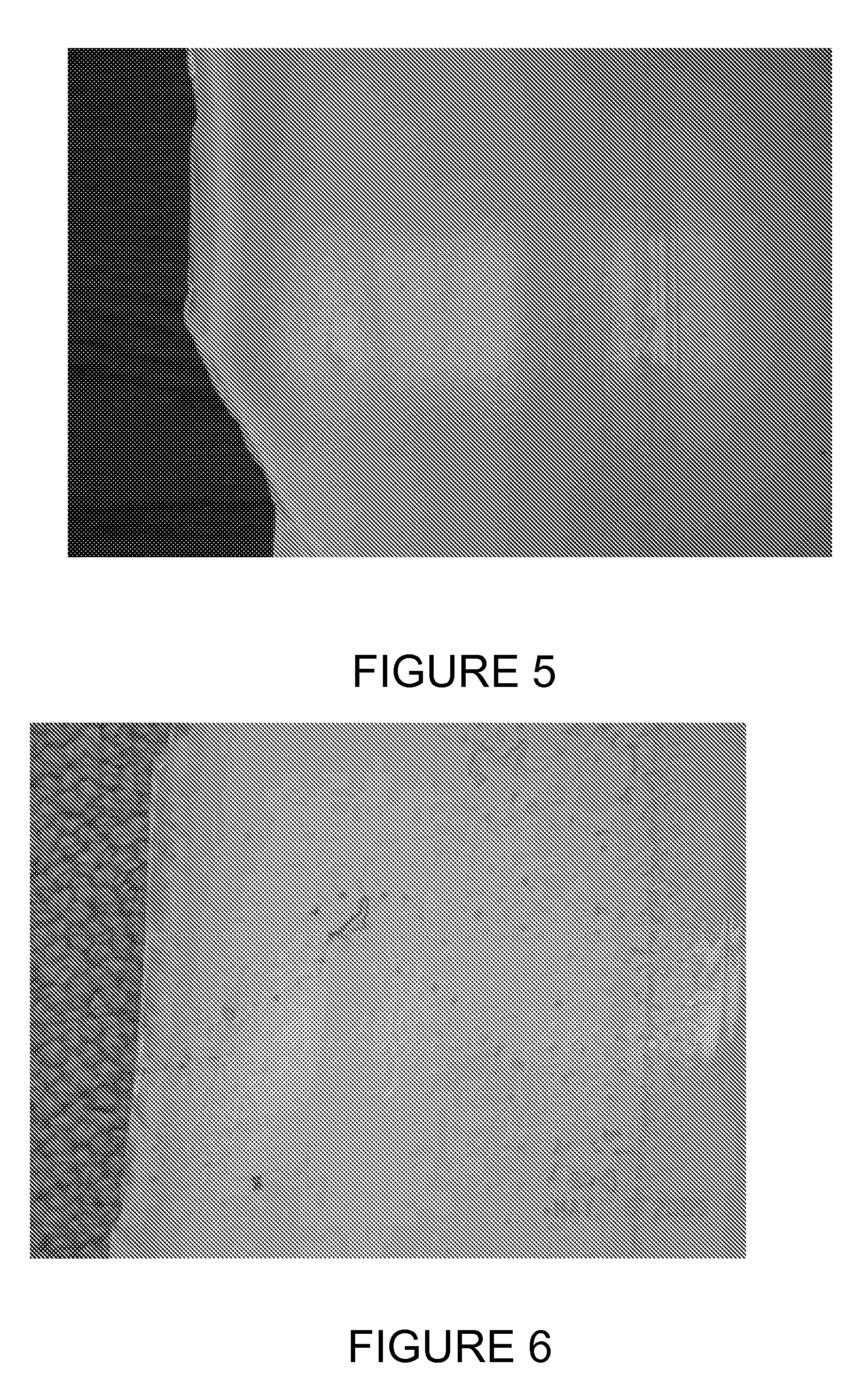

There is provided a quartz glass article having a surface treated with novel coating materials which provides a reduced chemistry, wherein the quartz glass surface having a reduced chemistry upon exposure to melted silicon or similarly corrosive environments, forms crystalline structures covering at least 30% of the coated surface of the quartz glass crucible. Said crystalline covered surface provides a more stable surface of contact with the silicon melt and the growth of single crystal silicon. In one embodiment of the invention, the coating material comprises at least a methyl group for providing at least one of a hydrogenated and a methylated surface on the coated surface, forming rosette structures, or other crystalline morphologies covering at last 80% of the coated surface. In another embodiment of the invention, the coating material is selected from at least one of an amine, an organosilane halogen and mixtures thereof.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

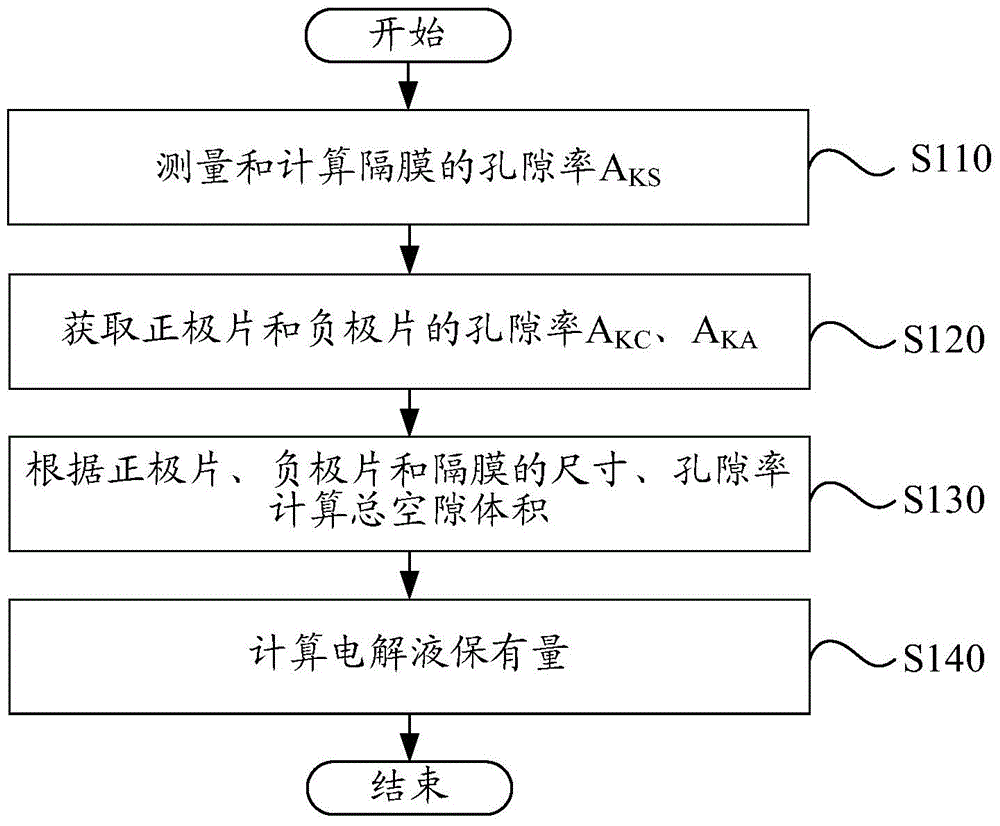

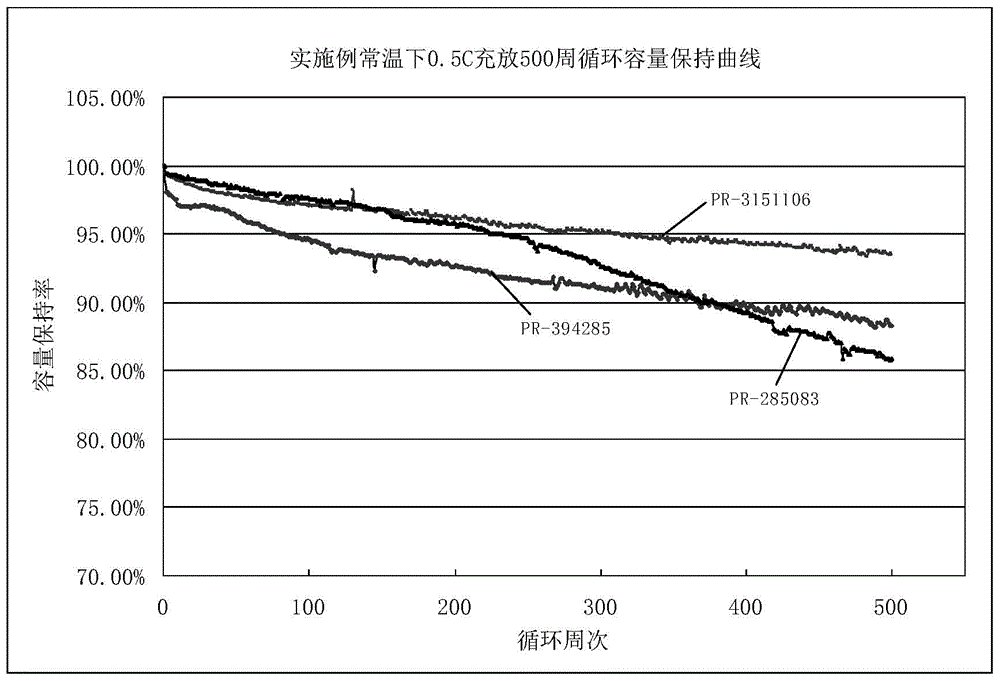

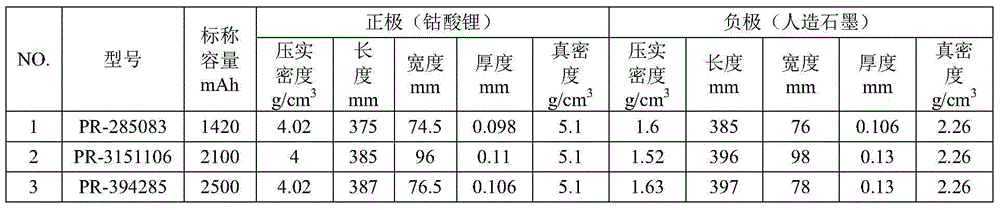

Method for determining retaining amount and injection amount of electrolyte solution of lithium ion battery

InactiveCN105787140ADecreased electrochemical performanceReduce chemistrySpecial data processing applicationsPorosityElectrochemistry

The invention relates to a method for determining a retaining amount and an injection amount of an electrolyte solution of a lithium ion battery. The method comprises the following steps of measuring and calculating the porosity AKS of a diaphragm; obtaining the porosities AKC and AKA of a positive electrode plate and a negative electrode plate; according to the length LC, width WC and thickness HC of the positive electrode plate, the length LA, width WA and thickness HA of the negative electrode plate and the length LS, width WS and thickness HS of the diaphragm, calculating the total void volume Vtotal (Vtotal=(AKC X LC X WC X HC)+(AKA X LA X WA X HA)+(AKS X LS X WS X HS)) in combination with the porosities AKS, AKC and AKA of the diaphragm, the positive electrode plate and the negative electrode plate; and calculating the retaining amount mE (mE=rho E X Vtotal) of the electrolyte solution, wherein rho E is the density of the electrolyte solution. In addition, the calculated retaining amount of the electrolyte solution can be multiplied by an injection coefficient to obtain the injection amount. According to the method, the calculation is simple, the injection amount and retaining amount of the electrolyte solution of a designed battery product can be determined in a battery product design stage, and the electrochemical performance reduction and safety risk of the battery caused by excessively large and small amount of electrolyte solutions of the soft package lithium ion battery can be prevented.

Owner:EVE HYPERPOWER BATTERIES INC

Polishing solution for silicon carbide substrate

InactiveCN102533124AAvoid damageLow subsurface damageSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSURFACTANT BLENDCorrosion

The invention relates to a chemically mechanical polishing solution for a silicon carbide substrate. The chemically mechanism polishing solution comprises the following components in percentage by weight: 1-50 percent of grinding material, 0.01-8 percent of chelant, 0.01-10 percent of surfactant, 0.01-10 percent of dispersing agent, 0.1-20 percent of oxidant and the balance of deionized water. The polishing solution has little damage to the surface of the silicon carbide substrate; the silicon carbide substrate has low roughness degree value and can reach the roughness Ra of being less than 0.5nm; no scratch and corrosion pit defect exists on the surface of the silicon carbide substrate; and the chemically mechanical polishing solution has high removing speed of scratch and corrosion pit, is easy to clean, does not corrode processing equipment and pollute the environment, and is low is price of raw materials, low in cost and easy to store. The chemically mechanical polishing solution is mainly used for chemically mechanical polishing of a silicon carbide wafer for the substrate.

Owner:上海上硅中试基地科技有限公司 +1

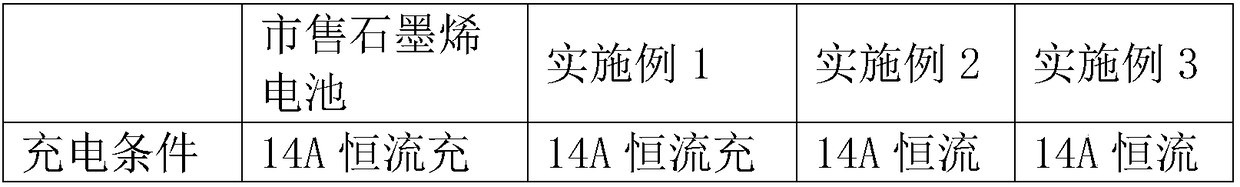

Large-capacity graphene battery capable of rapidly charging

InactiveCN108199039AImprove corrosion resistanceExtended service lifeCell electrodesSecondary cellsCorrosionEngineering

The invention provides a large-capacity graphene battery capable of rapidly charging, and relates to the technical field of batteries. The large-capacity graphene battery capable of rapidly charging,fabricated by the invention, comprises a positive pole plate, a negative pole plate, a separator, an electrolyte and a battery shell, the phenomena of small storage capacity and slow charging speed ofan existing graphene battery are solved, meanwhile, the corrosion resistance of the battery is improved, the service lifetime is prolonged, the large-capacity graphene battery is relatively good in stability, and no harm to a human body and an environment is generated; and compared with a traditional market graphene battery, it is verified that the charging time is obviously shortened by 34.94% under the same charging condition, and the charge-discharge efficiency of the battery can reach 87.73%.

Owner:长沙善道新材料科技有限公司

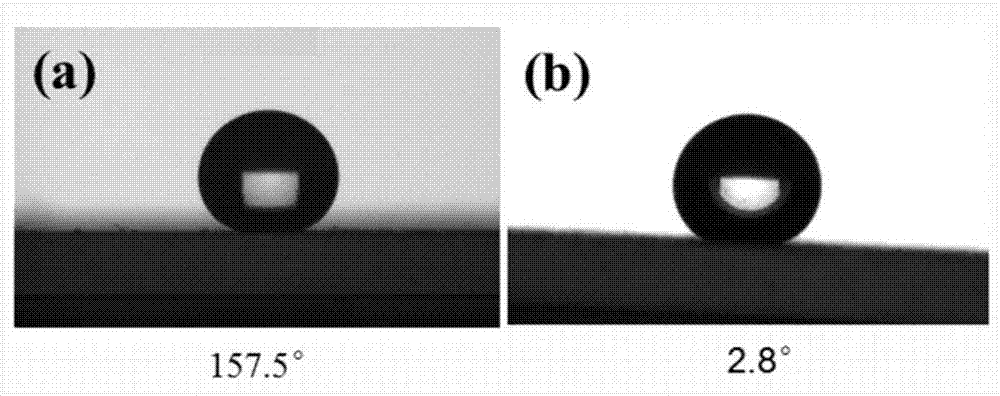

Preparation method of fluoride-free super-hydrophobic surface

InactiveCN106862032AImprove solubilityEasy to handleAnti-corrosive paintsSpecial surfacesDissolutionSolvent

The invention discloses a preparation method of a fluoride-free super-hydrophobic surface. The preparation method comprises the following steps: polymethyl methacrylate and / or polydimethylsiloxane are / is dissolved into a solvent, ultrasonic is adopted for facilitating dissolution, and super-hydrophobic coating liquid is prepared; and the super-hydrophobic coating liquid is sprayed onto a substrate, and the super-hydrophobic surface is prepared. Polymethyl methacrylate is sprayed on the surface of the substrate for building a coarse structure, and with the adoption of polydimethylsiloxane, the surface energy is further reduced and the binding force between a coating and the substrate is improved, so that the super-hydrophobic surface having the good mechanical property and the good chemical property are prepared on various substrates. On the condition that no fluorine is used, environmental protection is facilitated and better hydrophobicity can be obtained.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Wood plastic material and preparation method thereof

InactiveCN108250787AImprove flame retardant performanceImprove stabilityHazardous substancePlastic materials

The invention discloses a wood plastic material and a preparation method thereof, and relates to the technical field of wood plastic materials. The wood plastic material is prepared from the followingraw materials in parts by weight: 30 to 40 parts of wood powder, 20 to 45 parts of straw powder, 20 to 35 parts of polyvinyl chloride resin, 12 to 20 parts of polypropylene resin, 15 to 24 parts of nitrile butadiene rubber, 8 to 16 parts of polystyrene resin, 5 to 18 parts of glass fibres, 11 to 15 parts of boron carbide, 6 to 15 parts of nano-silicon carbide, 3 to 9 parts of expanded graphite, 3to 7 parts of aluminum oxide, 3 to 9 parts of a compatilizer, 2 to 6 parts of an antioxidant preservative, 1 to 3 parts of a lubricant, 2 to 8 parts of a flame retardant and 8 to 13 parts of a filling agent. The wood plastic material disclosed by the invention is good in flame retardance and stability, and high in mechanical strength, and does not fracture and deform easily; the preparation method is simple in process and high in operability, does not produce toxic or harmful substances, is environmentally friendly, and is suitable for industrial popularization.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

Quartz glass crucible and method for treating surface of quartz glass crucible

InactiveUS20070151504A1Prolong lifeReduce chemistryAfter-treatment apparatusPolycrystalline material growthCoated surfaceHalogen

Owner:GENERAL ELECTRIC CO

Adhesive film for encapsulating electronic element

InactiveCN103773257AReduce chemistryReducer physical damageNon-macromolecular adhesive additivesFilm/foil adhesivesTectorial membraneAcrylic resin

The invention discloses an adhesive film for encapsulating an electronic element. The adhesive film consists of the following components in parts by mass: 35-55 parts of organic silicon resin, 15-25 parts of acrylic resin, 12-18 parts of inorganic filler, 4-9 parts of titanium oxide, 3-7 parts of polyethylene wax and 5-9 parts of functional aid, wherein the functional aid comprises a dispersing agent, a curing agent and a film forming aid. The adhesive film for encapsulating the electronic element provided in the technical scheme of the invention can form a layer of protective film around the electronic element, so that chemical or physical damages of the external environment to the electronic element are reduced greatly. Moreover, the adhesive film is stable in property, is prevented from falling off easily, and does not damage the electronic element.

Owner:NANTONG YAOHUA MECHANICAL & ELECTRICAL

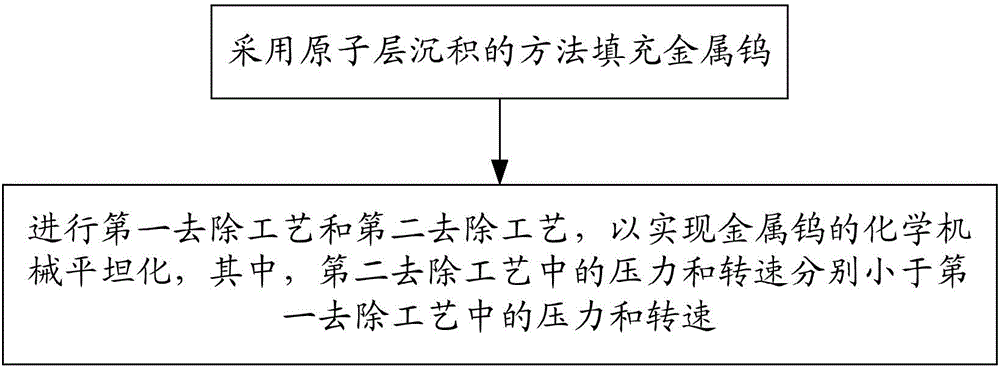

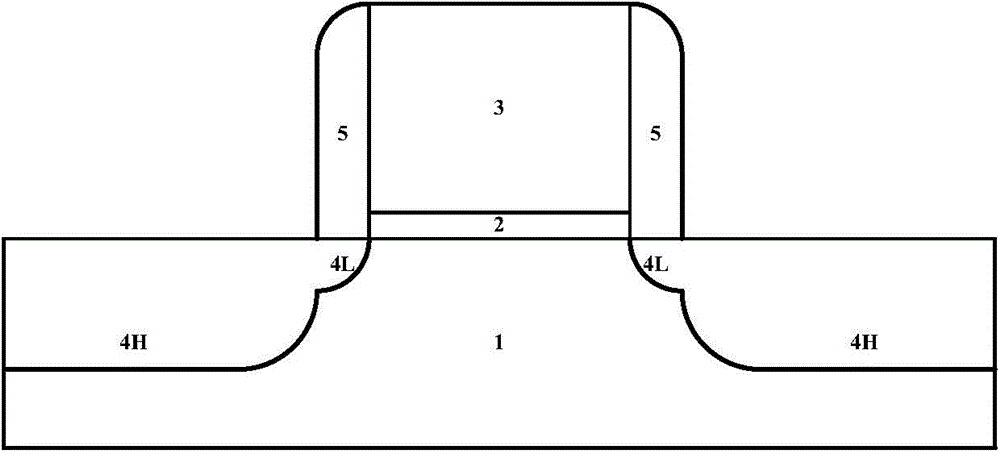

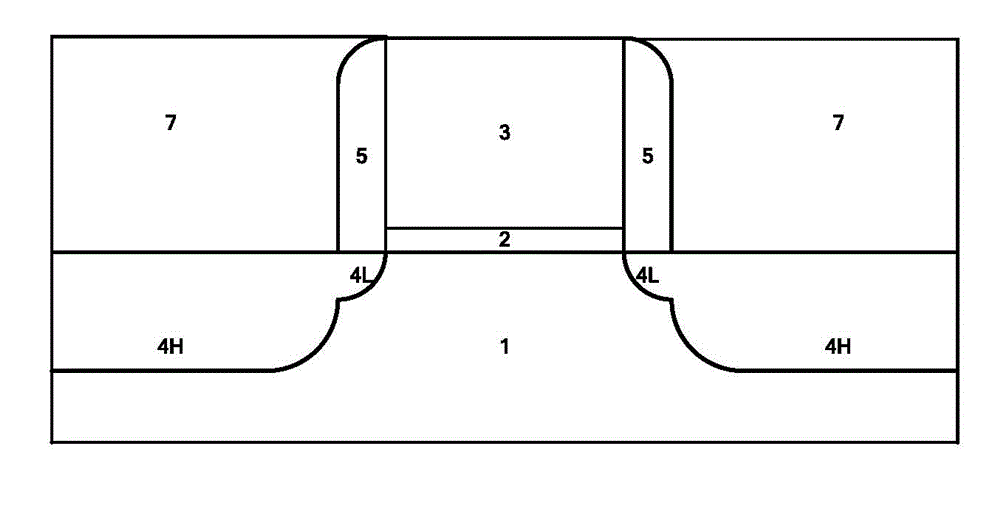

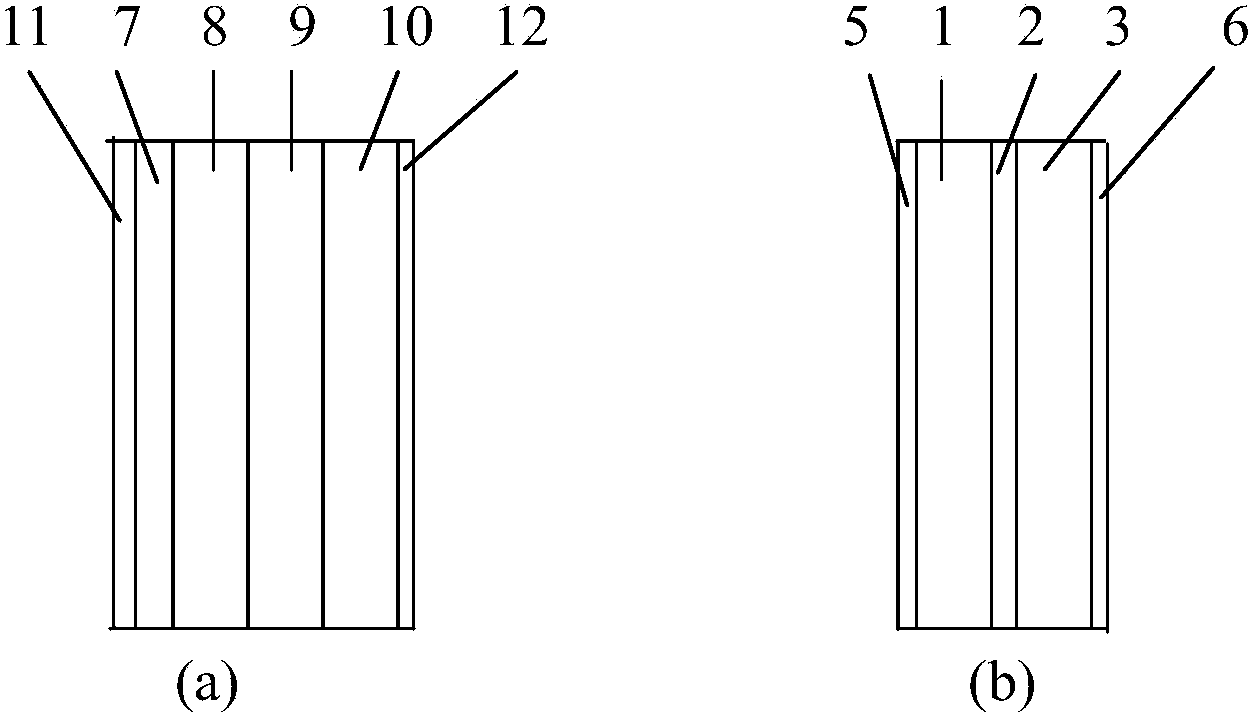

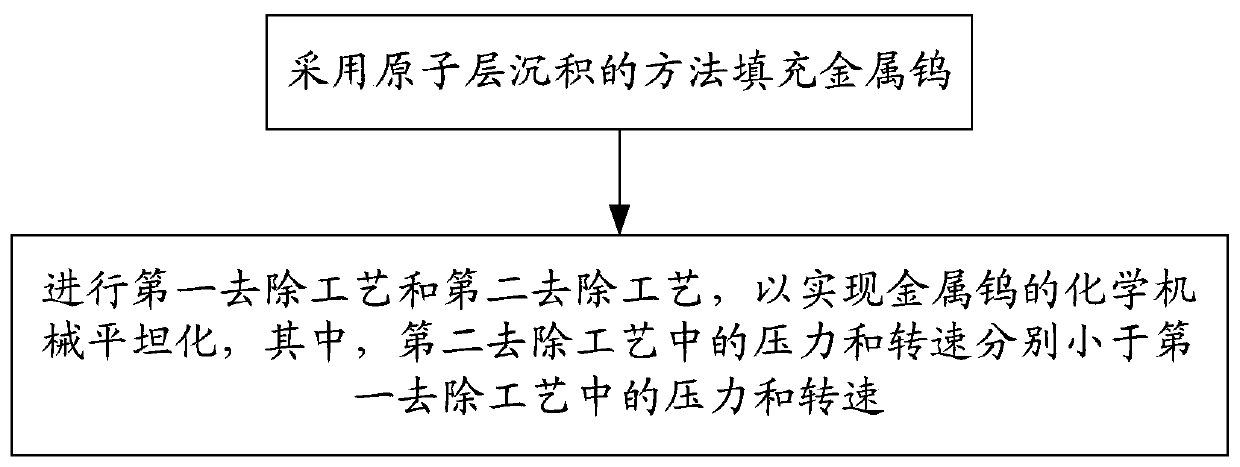

Chemical machinery planarization process method

ActiveCN104979277AReduce metal lossImprove performance and yieldSemiconductor/solid-state device manufacturingTungstenMetal

The invention provides a chemical machinery planarization process method. The method comprises the following steps: filling metallic tungsten by use of an atomic layer deposition method; carrying out a first removal process and a second removal process so as to realize chemical machinery planarization of the metallic tungsten, wherein the pressure and the rotating speed in the second removal process are respectively smaller than the pressure and the rotating speed in the first removal process. According to the invention, the chemical machinery planarization of the metallic tungsten is realized by use of a two-step removal process, and the pressure and the rotating speed in the later removal process are reduced, such that the mechanical effect in a grinding process is reduced in the second removal process, metal loss at the top of a metal gate can be reduced, and the performance and the yield of a device are improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

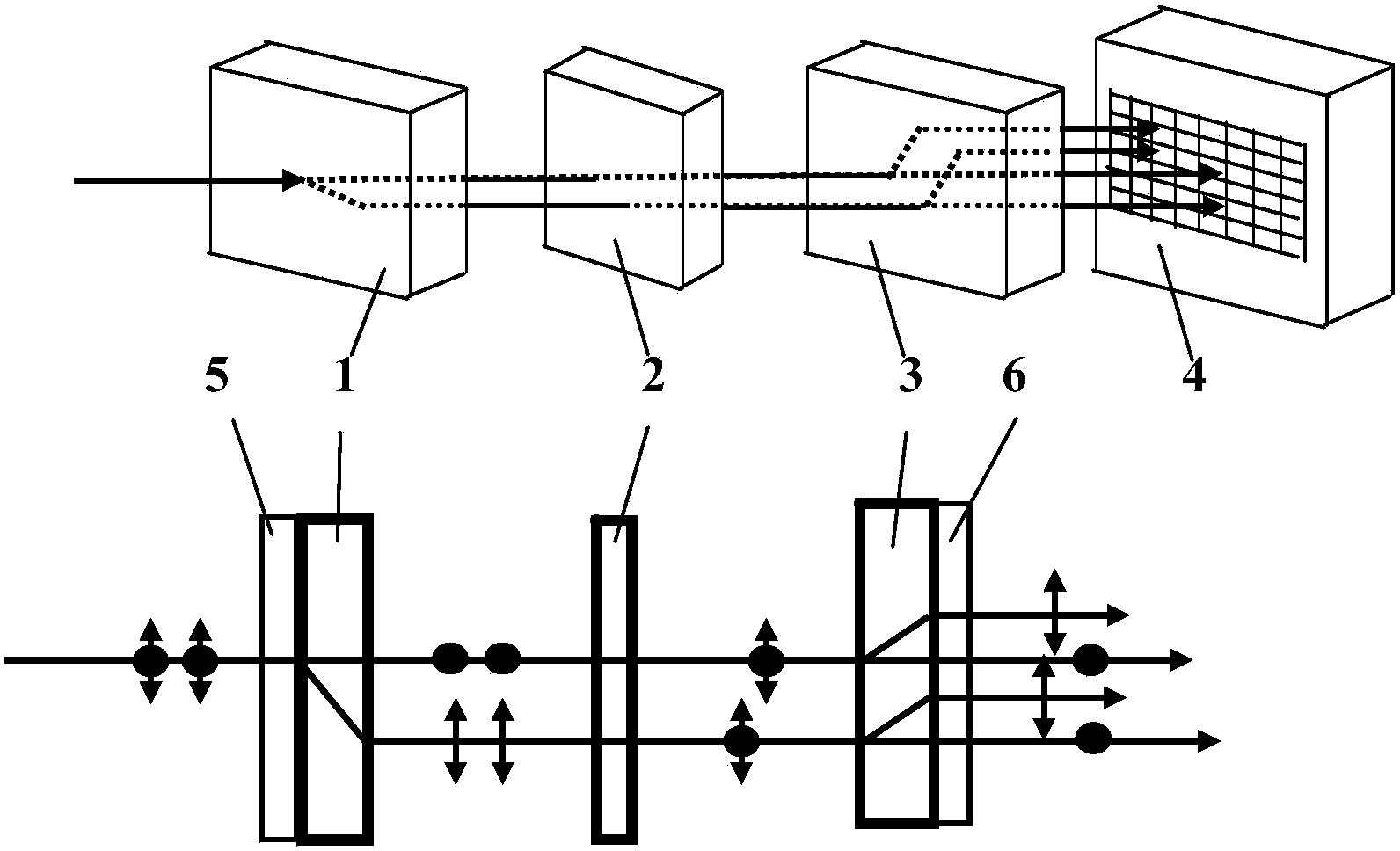

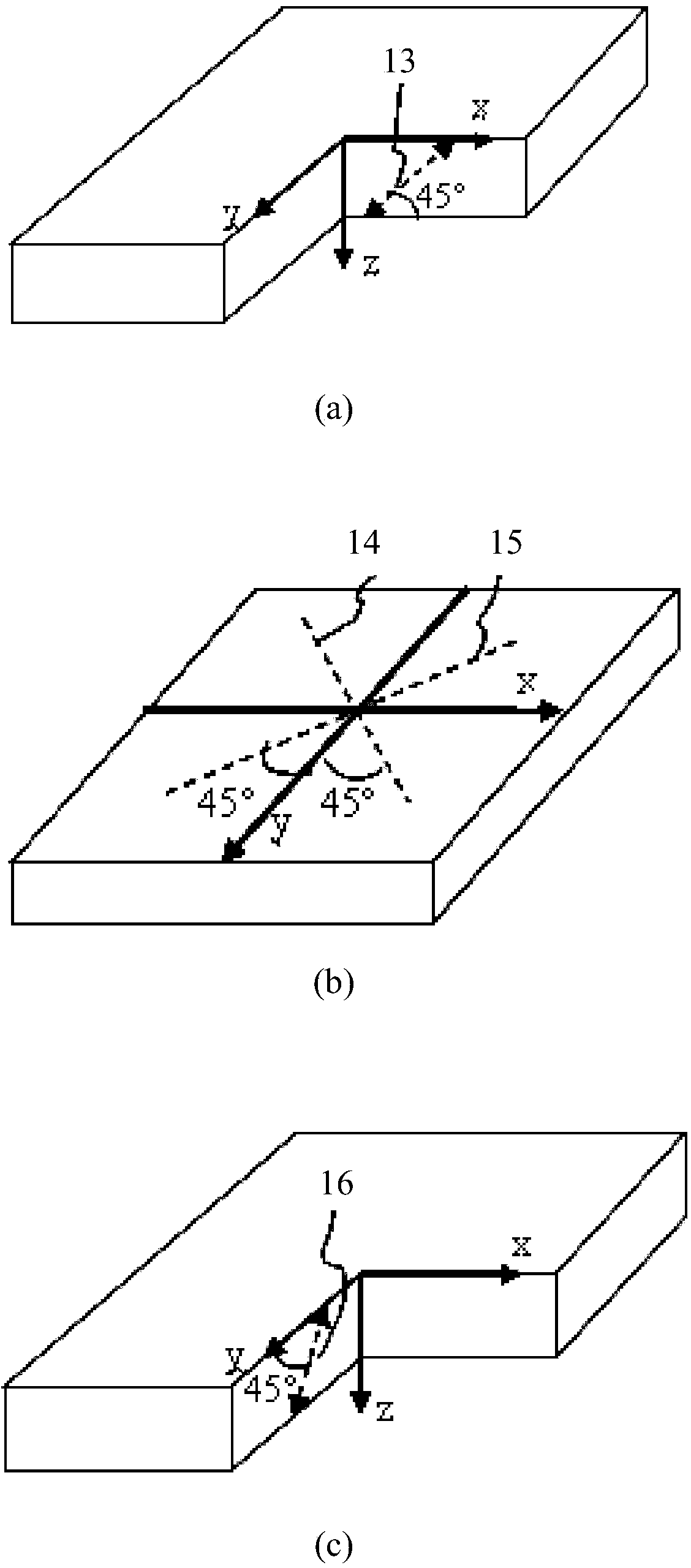

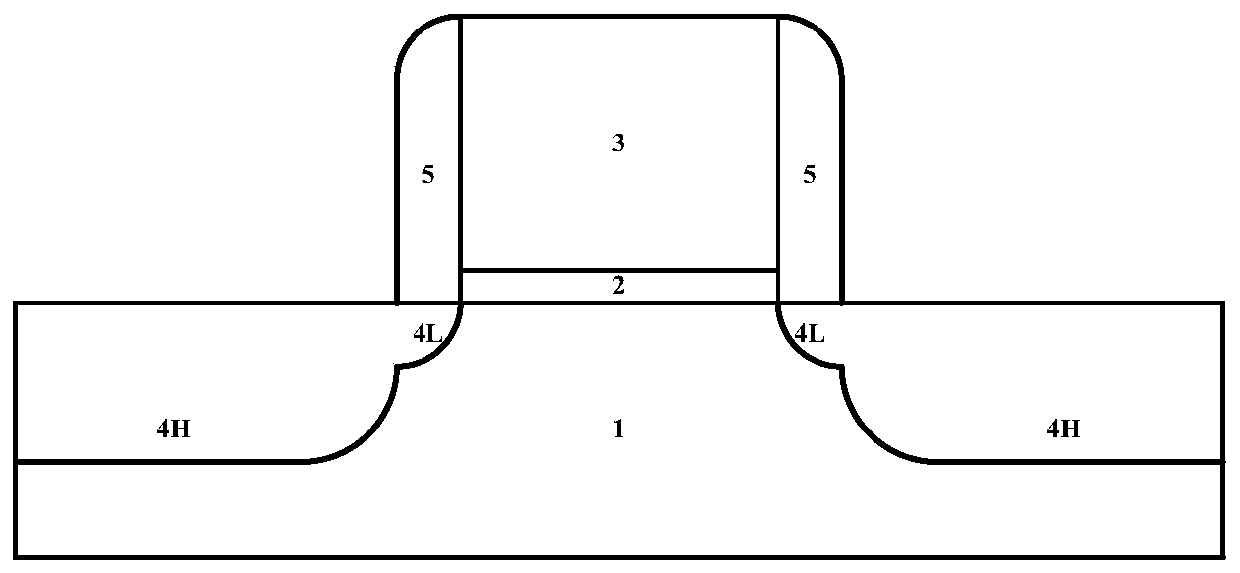

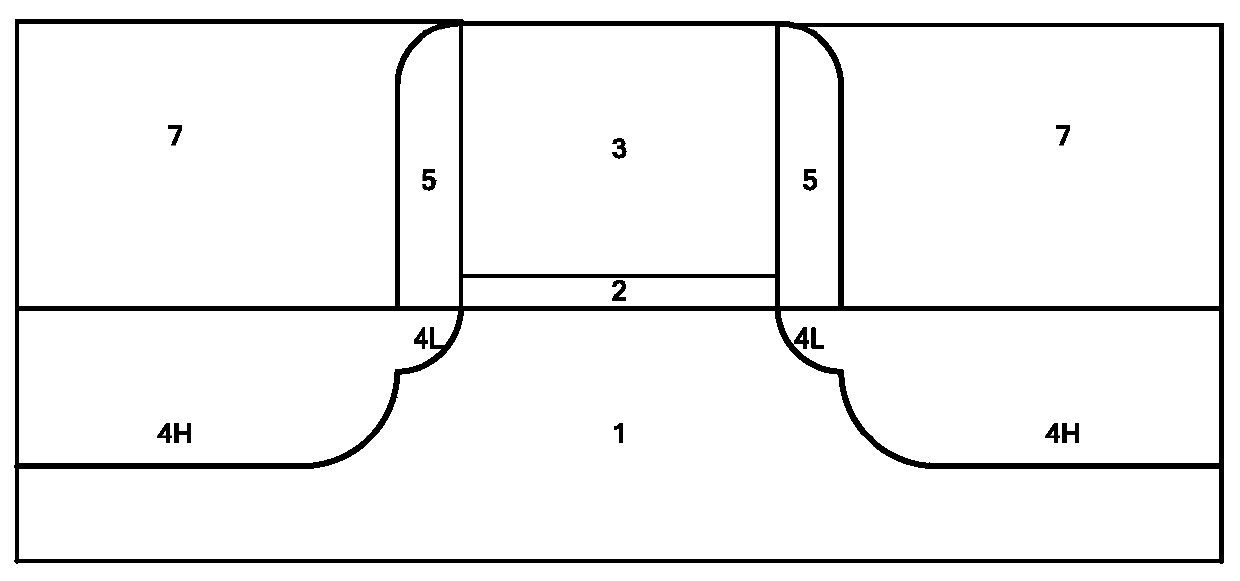

Low pass filter

ActiveCN103513314AImaging aberration reductionReduce weightLayered productsOptical filtersLow-pass filterUltraviolet

The invention discloses a low pass filter for a high-pixel image sensor. The low pass filter comprises a first quartz crystal piece, a quarter-wave plate and a second quartz crystal piece which are arranged in sequence along the light path direction. An infrared cut-off film is plated on the light incidence side surface of the first quartz crystal piece. A restrained wavelength shifting film is plated on the light outgoing side surface of the second quartz crystal piece. According to the low pass filter, the infrared cut-off film cuts off light in the infrared wave length zone, and the restrained wavelength shifting film has the advantages that ultraviolet cutting off is achieved, visible light high transmission is achieved, and wavelength shift caused by the incidence angle is small. The low pass filter is low in cost, light in weight and small in size, due to the fact that the restrained wavelength shifting film is an optics multilayer film system, performance is stable and reliable, and meanwhile a blue glass stable transmission-transition wavelength cut-off function, an ultraviolet cut-off function and an antireflection film function are achieved.

Owner:HANGZHOU KOTI OPTICAL TECH

Pig feed for improving immunity and preventing diarrhea of piglets

InactiveCN108902462APromote digestionSmooth weaningFood processingAnimal feeding stuffMicroorganismPhytase

The invention discloses a pig feed for improving immunity and preventing diarrhea of piglets. The pig feed comprises the following components in parts by weight: 80 to 100 parts of corn, 60 to 80 parts of expanded soybeans, 20 to 35 of bran, 15 to 25 parts of whey powder, 20 to 30 parts of rice bran, 2 to 5 parts of fish meal, 0.5 to 1.5 parts of calcium hydrogen phosphate, 0.1 to 0.5 parts of salt, 0.01 to 0.05 parts of phytase, 5 to 15 parts of a piglet premix, and 1 to 10 parts of a Chinese herbal medicine additive. The pig feed of the invention does not add antibiotics, can enhance the body health of the piglets, enhances the immunity of the body, enhances the resistance to microorganisms such as pathogenic bacteria, and well prevents piglet diarrhea.

Owner:ANHUI JINMU FEED

Surface cleaning method on indium antimonide wafer after alkaline chemical mechanical polishing

InactiveCN101912857APrevent local reactionUniform temperature distributionCleaning using liquidsChemistryCompound (substance)

The invention discloses a surface cleaning method on indium antimonide wafer after alkaline chemical mechanical polishing. The invention aims at providing a method which can reduce downstream processing cost of indium antimonide wafer after alkaline chemical mechanical polishing, is simple and easy and can improve surface evenness and cleanliness of wafer. Ultrapure water with the resistance of more than 18Mohm is subject to stirring while surfactant and FA / O II chelating agent are added, stirring to be uniform is carried out, so as to obtain clean solution; the clean solution is adopted to rapidly carry out polishing cleaning on indium antimonide wafer after alkaline chemical mechanical polishing for at least 30s under the conditions of high flow of 1000-5000ml / min and low pressure of 0-0.0 atmospheric pressure; ultrapure water with the resistance of more than 18Mohm is adopted to dilute corrosion inhibitor, and high flow polishing cleaning is carried out on indium antimonide wafer after cleaning for at least 30s under the condition of zero pressure; and finally ultrapure water with the resistance of more than 18Mohm is adopted to wash the indium antimonide wafer after cleaning for at least 30s under the conditions of zero pressure and high flow.

Owner:HEBEI UNIV OF TECH

A high-power LED drive power cooling device based on carbon nanotubes

InactiveCN102281744AImprove heat exchange capacityReduce weightCooling/ventilation/heating modificationsCarbon nanotubeEngineering

Owner:GUANGZHOU UNIVERSITY

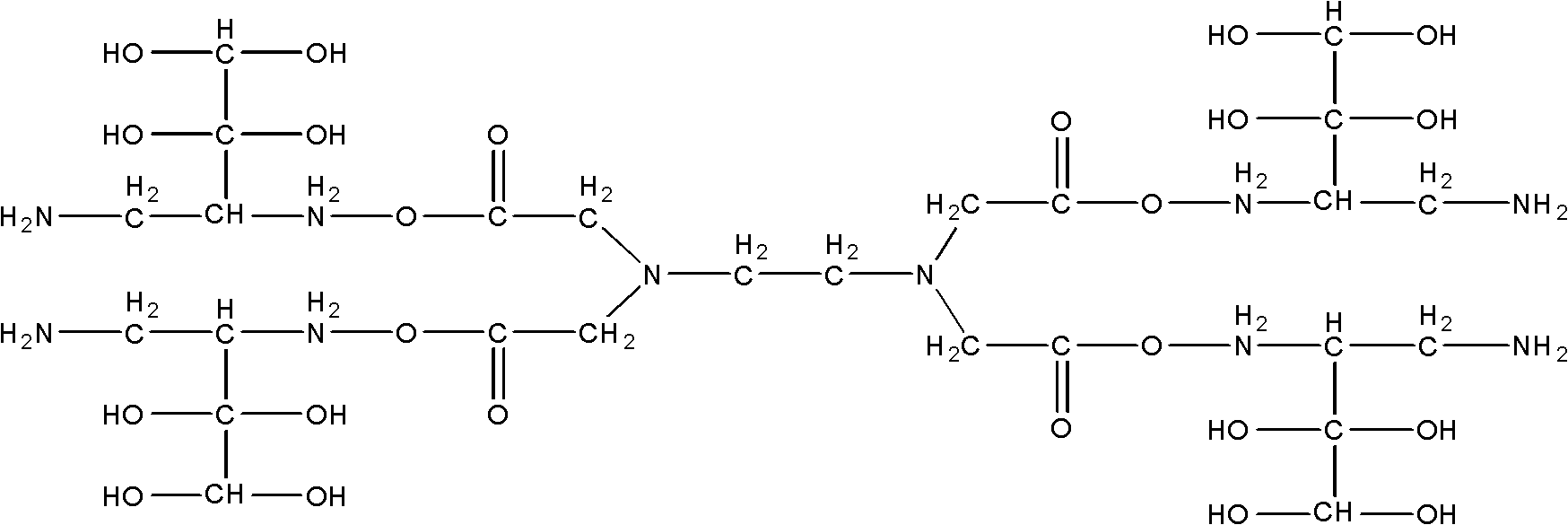

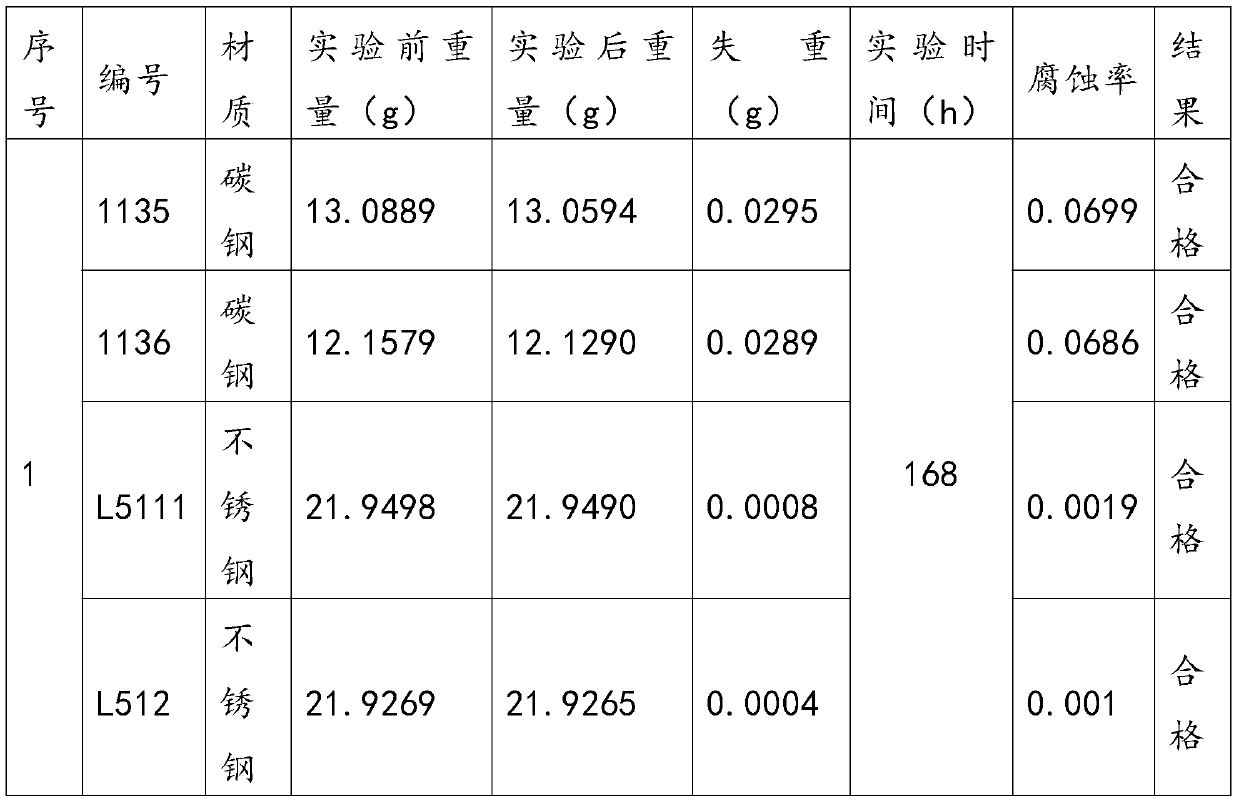

Special corrosion and scale inhibitor for high concentration index recycling water and preparation method of special corrosion and scale inhibitor

InactiveCN109761378AIncrease the concentration factorImprove water qualityTreatment using complexing/solubilising chemicalsHigh concentrationCarboxylic acid

The invention discloses a special corrosion and scale inhibitor for high concentration index recycling water and a preparation method of the special corrosion and scale inhibitor. The special corrosion and scale inhibitor is prepared from the following raw materials in percentage by weight: 15-25% of acrylic acid-acrylic ester-phosphonic acid-sulfonate quadripolymer, 20-25% of carboxylic acid-sulfoacid-acrylic ester terpolymer, 15-20% of 2-hydroxyphosphonoacetic acid, 10-20% of phosphino-carboxylic acid, 2-3% of zinc sulfate heptahydrate and the balance of deionized water. The corrosion and scale inhibitor has the excellent effects of scale inhibition, corrosion inhibition, prefilming and bacteria and algae growth inhibition, a recycling cooling water system can operate under the situationthat the concentration rate of the recycling water is 10-40 by adjusting the dosage when the inhibitor is applied to the recycling cooling water system, the water saving effect is much more higher than that of existing drugs on the market, the corrosion and scale inhibitor realizes the effect of zero drainage of the recycling water, can be widely applied to all recycling water for coking, rubber,chloro-alkali and fertilizer, and has a good effect on equipment such as carbon steel, stainless steel and copper; the corrosion and scale inhibitor has considerable economic benefits and social benefits and high popularization value.

Owner:郭福然

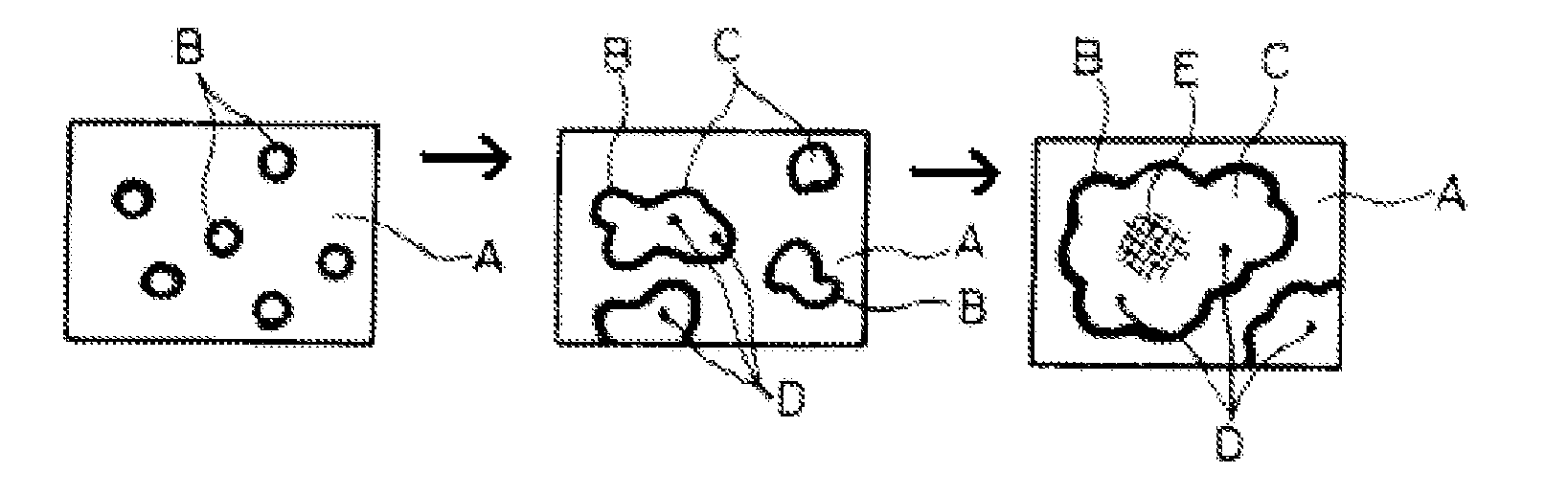

Quartz glass crucible and method for treating surface of quartz glass crucible

InactiveUS20070084400A1Prolong lifeReduce chemistryAfter-treatment apparatusPolycrystalline material growthCoated surfaceHalogen

There is provided a quartz glass article having a surface treated with novel coating materials which provides a reduced chemistry, wherein the quartz glass surface having a reduced chemistry upon exposure to melted silicon or similarly corrosive environments, forms crystalline structures covering at least 75% of the coated surface of the quartz glass crucible. Said crystalline covered surface provides a more stable surface of contact with the silicon melt and the growth of single crystal silicon. In one embodiment of the invention, the coating material comprises at least a methyl group for providing at least one of a hydrogenated and a methylated surface on the coated surface, forming rosette structures, or other crystalline morphologies covering at last 80% of the coated surface. In another embodiment of the invention, the coating material is selected from at least one of an amine, an organosilane halogen and mixtures thereof.

Owner:GENERAL ELECTRIC CO

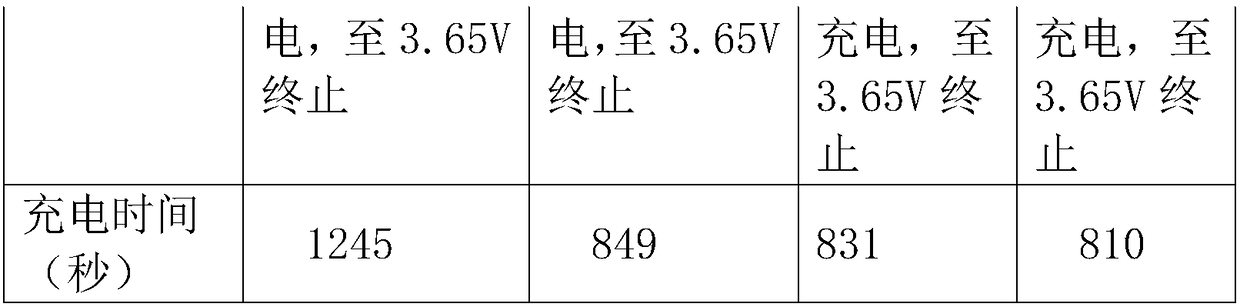

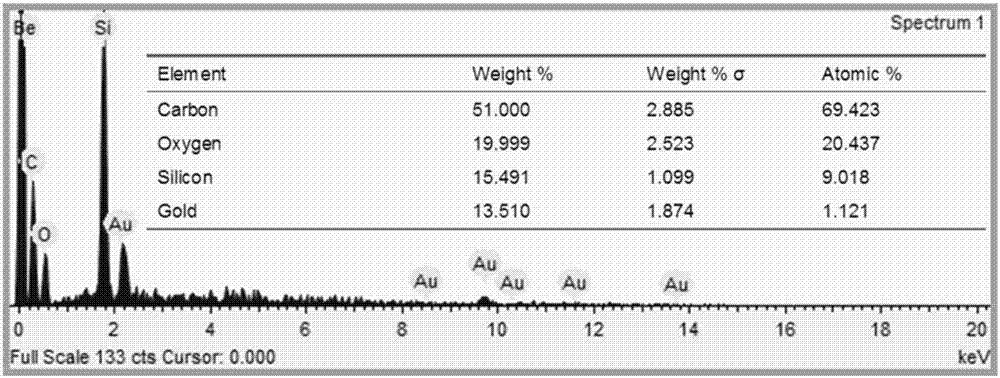

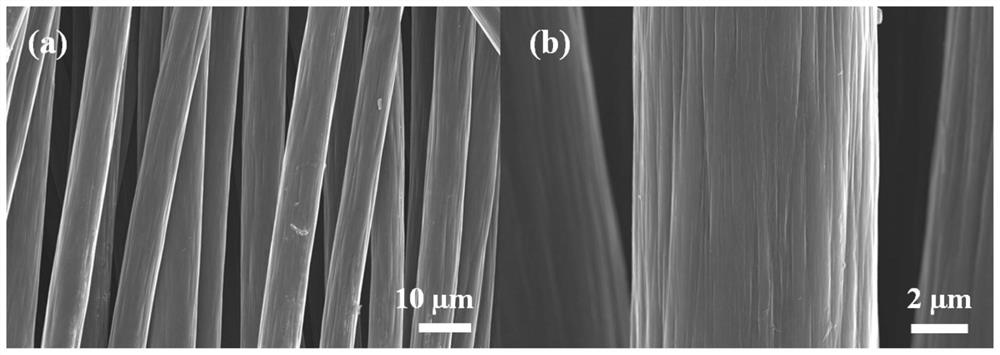

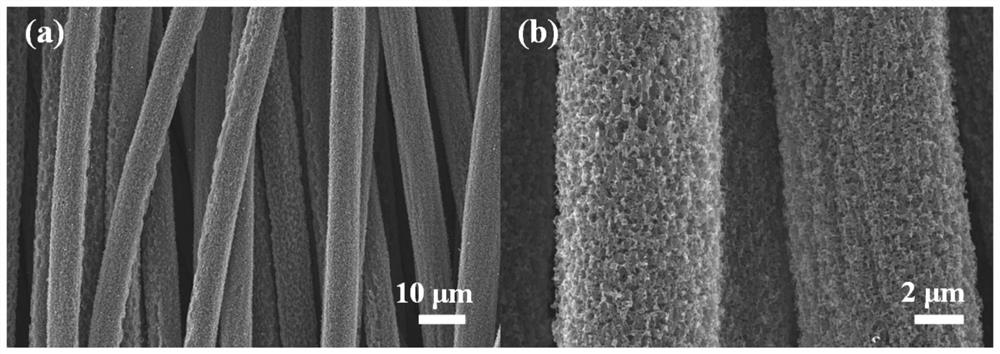

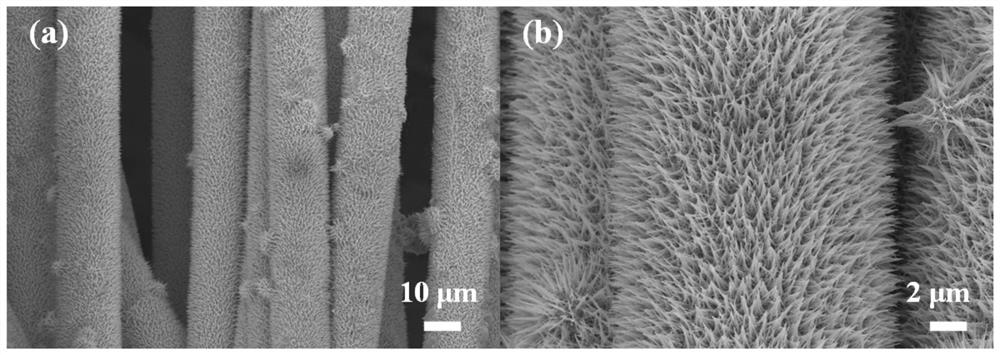

Carbon fiber/three-dimensional network graphene composite material preparation method and application thereof

ActiveCN107833756AIncrease the areaImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureFiberCapacitance

The invention discloses a carbon fiber / three-dimensional network graphene composite material preparation method and application thereof. Graphene in a porous and thin layer structure grows on the surface of carbon fiber through a method of coating and heat treatment. A three-dimensional graphene sheet layer structure and carbon fiber form a network structure. The structure has a high specific surface area, can realize rapid transmission of electrons and electrolyte ions at the same time, and improves the capacitance performance. The carbon fiber / three-dimensional network graphene composite material provided by the invention can be directly used as an electrode material, can be used as a conductive substrate, and is further applied to a super capacitor by growing other electrode materials.

Owner:HEFEI UNIV OF TECH

Quartz glass crucible and method for treating surface of quartz glass crucible

InactiveUS9139932B2Prolong lifeReduce chemistryAfter-treatment apparatusPolycrystalline material growthCoated surfaceHalogen

There is provided a quartz glass article having a surface treated with novel coating materials which provides a reduced chemistry, wherein the quartz glass surface having a reduced chemistry upon exposure to melted silicon or similarly corrosive environments, forms crystalline structures covering at least 30% of the coated surface of the quartz glass crucible. Said crystalline covered surface provides a more stable surface of contact with the silicon melt and the growth of single crystal silicon. In one embodiment of the invention, the coating material comprises at least a methyl group for providing at least one of a hydrogenated and a methylated surface on the coated surface, forming rosette structures, or other crystalline morphologies covering at last 80% of the coated surface. In another embodiment of the invention, the coating material is selected from at least one of an amine, an organosilane halogen and mixtures thereof.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Fluoride-free zinc alloy water-based release agent

InactiveCN110026527AReduce thermal and mechanical shockReduce friction and wearFoundry mouldsFoundry coresWater basedZinc alloys

The invention discloses a fluoride-free zinc alloy water-based release agent. The agent comprises the following components of, by weight, lauryl sodium sulfate, polyethylene wax, dimethyl silicone oil, hydroxyl silicone oil, isomeric alcohol-polyoxyethylene ether, a compound emulsifier, a preservative, a defoaming agent, sodium xylene sulfonate and water. The agent has the advantages that the applicability is wide, the original characteristics can still be kept when the temperature is changed hugely, the agent is not easy to oxidize, is not prone to react with most of chemical substances, hasexcellent storage stability and is easy to treat, the agent can still be very stable when the temperature of a mold is high, so that the heat shock effect and the mechanical shock effect of an aluminum alloy liquid on the surface of the mold can be effectively reduced, frictional wear of a casting on the surface of the mold can be reduced, the physical effect and the chemical effect of the aluminum alloy liquid on a mold material can be reduced, the cavity protection effect and the lubrication and mold release effect can be achieved, meanwhile, the pollution on the surface of a product causedby colloid left or residual substances is avoided, the cost is saved, the product quality is improved, and the mold release property is excellent.

Owner:广州市蓝化润滑科技有限公司

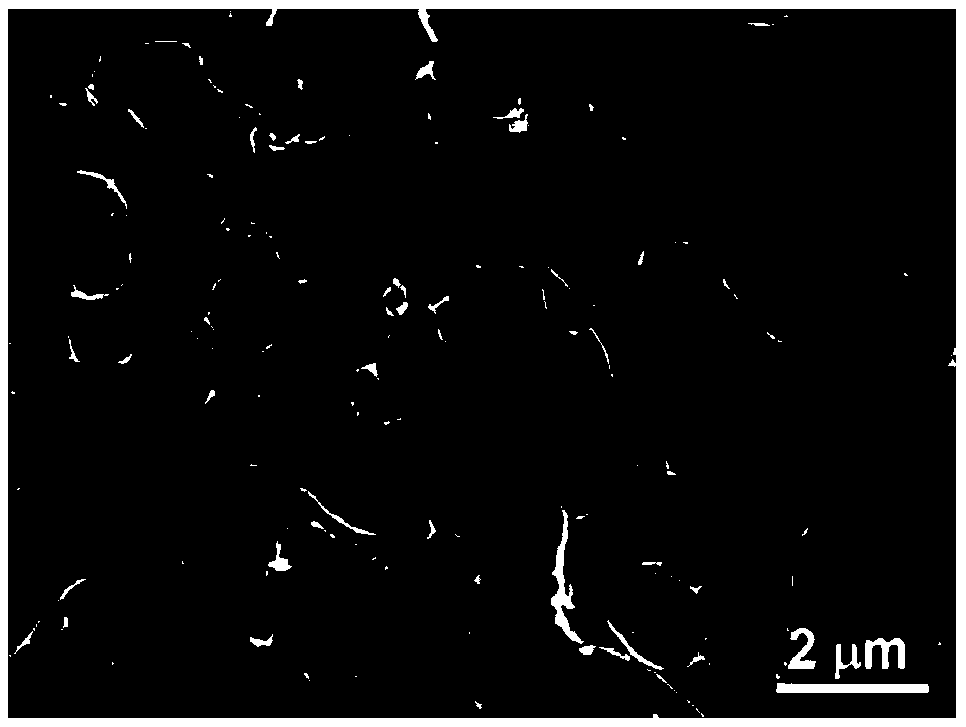

Preparation method and application of porous carbon fiber/tungsten oxide self-supporting lithium-sulfur battery positive electrode material

The invention discloses a preparation method and application of a porous carbon fiber / tungsten oxide self-supporting lithium-sulfur battery positive electrode material, and the self-supporting lithium-sulfur battery positive electrode material is composed of active sulfur and porous carbon fiber / tungsten oxide. The porous carbon fiber / tungsten oxide is a self-supporting conductive sulfur carrier which takes porous carbon fiber cloth as a substrate and then grows tungsten oxide nanorods through combination of a simple one-step hydrothermal method and low-temperature calcination treatment, and finally sulfur is loaded through a hot melting method to obtain the sulfur positive electrode. According to the self-supporting lithium-sulfur battery positive electrode material disclosed by the invention, good mechanical strength and excellent conductivity of the porous carbon fiber and an adsorption-catalysis effect of the tungsten oxide nanorod on soluble polysulfide are organically combined, so that high load of sulfur is realized, and the conductivity of the whole material is improved; and the shuttle effect can be effectively inhibited, and the volume change of the electrode can be relieved, so that the cycle performance of the lithium-sulfur battery is effectively improved.

Owner:HEFEI UNIV OF TECH

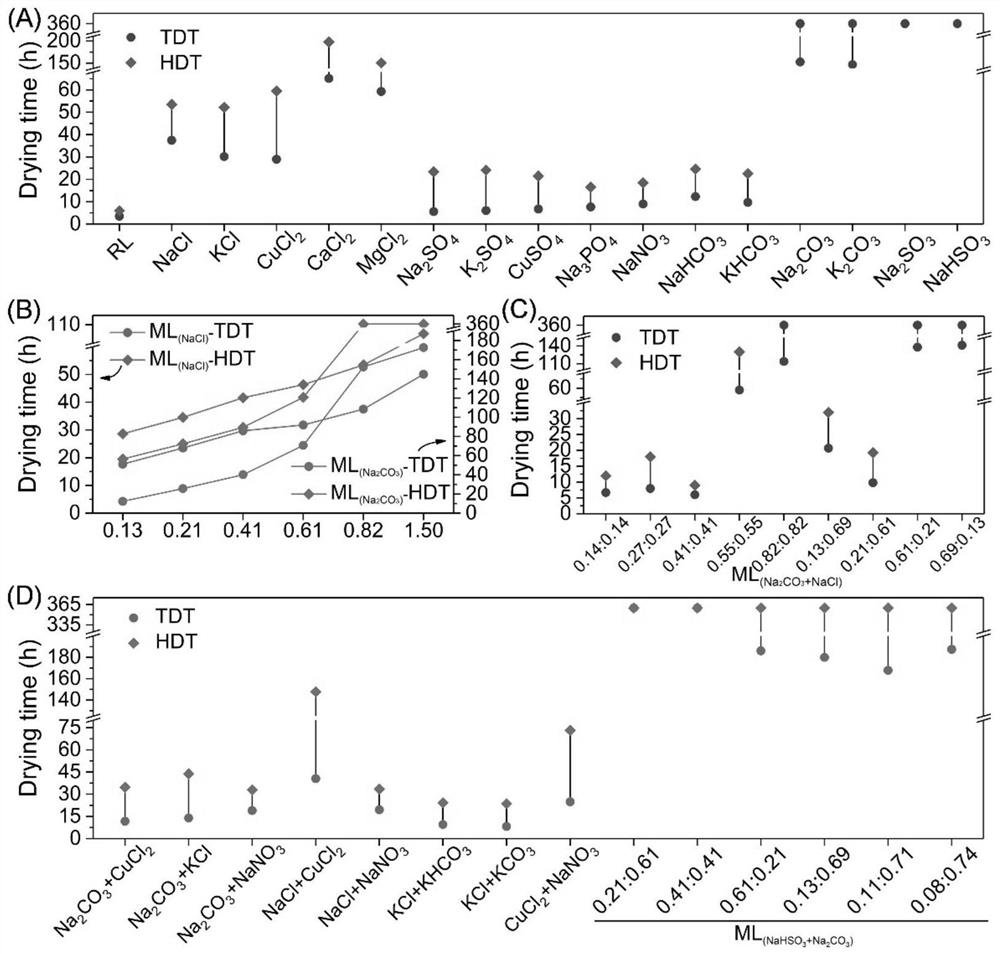

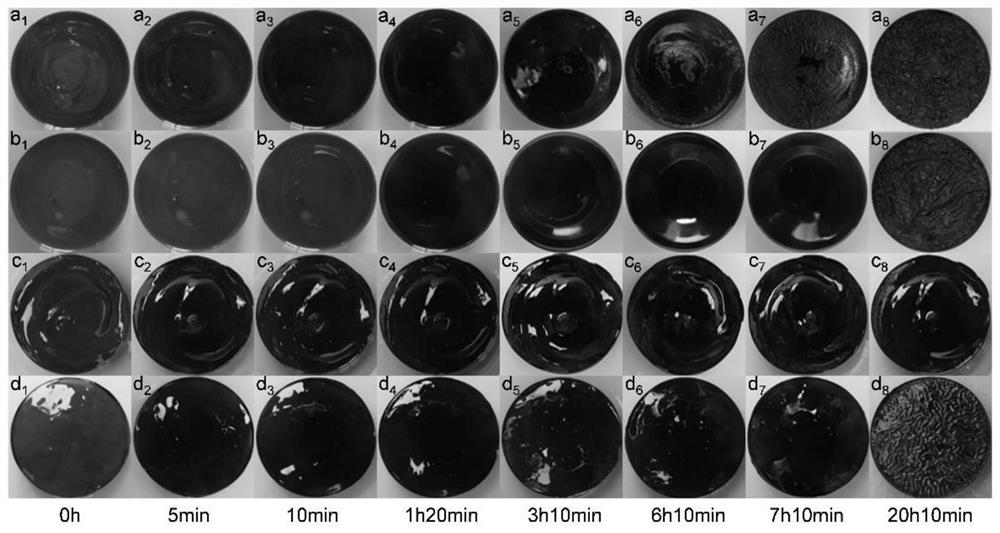

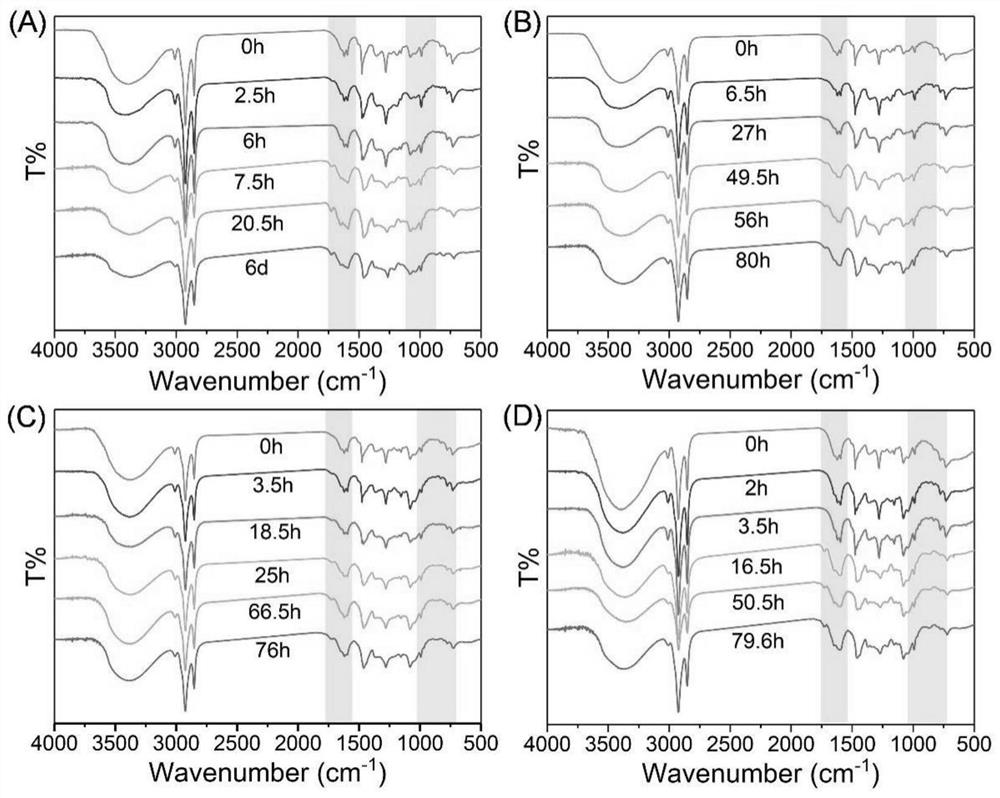

Method for changing curing speed of raw lacquer

ActiveCN113462289AExtended drying time and recoverySolve wasteNatural resin coatingsSodium bicarbonateOil emulsion

The invention discloses a method for changing the curing speed of raw lacquer, and belongs to the technical field of polymer coatings.Inorganic salt is added into the raw lacquer. The inorganic salt comprises one or more of sodium chloride, potassium chloride, copper chloride, calcium chloride, magnesium chloride, sodium sulfate, potassium sulfate, copper sulfate, sodium phosphate, sodium nitrate, sodium bicarbonate, sodium carbonate, potassium carbonate, sodium sulfite or sodium hydrogen sulfite. On the premise of not destroying the structure of the water-in-oil emulsion, the laccase activity is regulated by using inorganic salt for the first time; The drying time of the paint liquid is prolonged and recovered, the problem of film formation waste caused by long-term storage and transportation of the paint liquid can be avoided, but the drying time of the paint liquid can be recovered or shortened by adding sodium carbonate and / or sodium chloride again in actual use.

Owner:MINJIANG UNIV

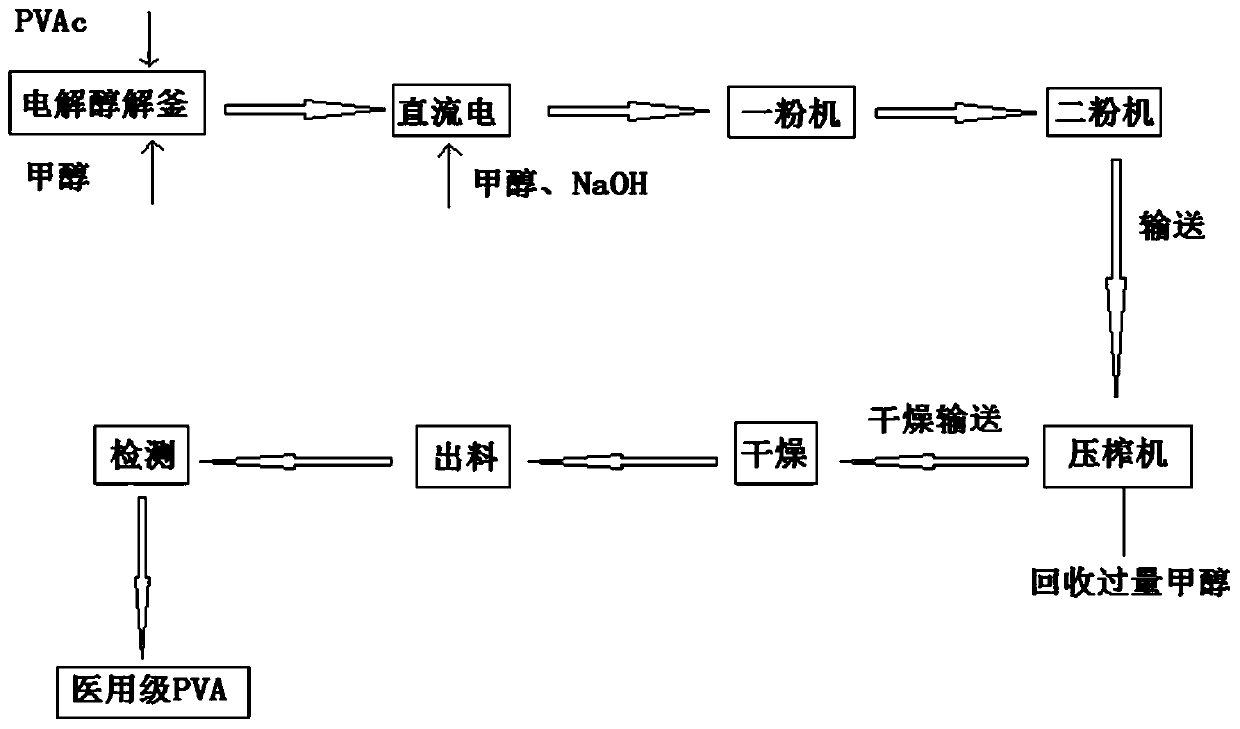

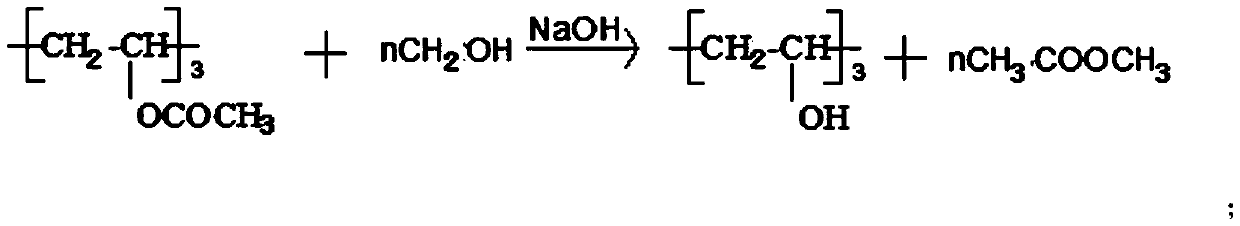

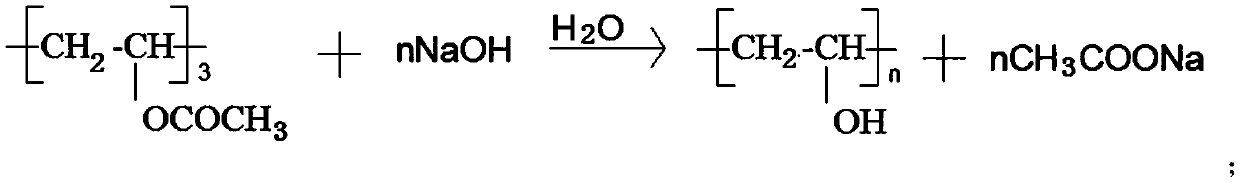

Preparation method of polyvinyl alcohol resin high in alcoholysis degree

The invention discloses a preparation method of high-alcoholysis-degree polyvinyl alcohol resin. The preparation method comprises the following steps: adding methanol into an electrolytic alcoholysiskettle, slowly adding PVAc while stirring, and heating to dissolve to obtain a PVAc / methanol solution; dissolving NaOH in methanol to obtain a NaOH-methanol solution; adding polymethylsiloxane into the electrolytic alcoholysis kettle containing the PVAc / methanol solution, and then applying direct current at a temperature kept to be 45-48 DEG C; reducing the temperature of the PVAc / methanol solution to 28-32 DEG C, and adding the NaOH-methanol solution into the electrolytic alcoholysis kettle for reaction; passing an obtained product through a pulverizer and a squeezer, and drying and discharging to obtain medical-grade polyvinyl alcohol resin. According to the preparation method, monomer residue is reduced, so that energy saving and emission reduction are realized, and the influence of monomers on the chemical and mechanical properties of polyvinyl acetate and polyvinyl alcohol is reduced, so that the product can meet the medical-grade requirements.

Owner:ZHENDE MEDICAL CO LTD

Egg prepared food with vegetables and preparation method thereof

InactiveCN104305330AReduce nutritional imbalanceNutritional balanceFood ingredient functionsFood preparationBiotechnologyMonosodium glutamate

The invention relates to egg prepared food with vegetables and a preparation method thereof. By adopting the egg prepared food with vegetables, the technical problems that traditional processes for manually preparing egg prepared food are simple, waste labor and time and cause unbalance of the proportion of nutritional ingredients of the egg prepared food and the product quality is difficult to control are solved, and the shelf life of the product can be lengthened. The egg prepared food with vegetables contains the following ingredients in parts by weight: 700-1000 parts of eggs, 300-400 parts of soup bases, 400-500 parts of bread flour, 40-50 parts of soft wheat flour, 150-200 parts of carrots and 100-150 parts of onions, wherein the soup bases comprise 8000-10000 parts of soft wheat flour, 4000-6000 parts of wheat starch, 1200-1400 parts of salt, 300-500 parts of cream, 150-200 parts of fatty acid, 300-400 parts of monosodium glutamate and 45000-50000 parts of water. The invention also provides the preparation method of the egg prepared food with vegetables. The preparation method is widely used for preparing the egg prepared food with vegetables.

Owner:RUSHAN HONGWEI FOOD

Household water-based paint and preparation method thereof

InactiveCN111961380AWell mixedRich sourcesFireproof paintsAntifouling/underwater paintsEpoxyBenzoxazole

The invention discloses household water-based paint. The household water-based paint is prepared from the following raw materials in parts by weight: 2 to 5 parts of triazine hyperbranched quaternaryammonium salt surfactant, 10 to 20 parts of water-soluble hyperbranched epoxy resin, 30 to 40 parts of a lambda-cyhalothric acid / 2-methacryloyloxyethylphosphorylcholine / allyl beta-D-glucopyranoside / chlorinated 3-ethyl-2-[2-(1-ethyl-2,5-dimethyl-1H-pyrrole-3-yl)vinyl]benzoxazole onium salt / sulfadicramide copolymer, 3 to 6 parts of polyphosphoric ferric chloride, 1 to 2 parts of a leveling agent, 10to 15 parts of an inorganic filler, 1 to 3 parts of a defoamer and 25 to 35 parts of water. The invention also discloses a preparation method of the household water-based paint. The household water-based paint disclosed by the invention is better in comprehensive performance, higher in bonding performance, better in weather resistance, flame retardance, environmental friendliness, high-temperature resistance and performance stability and longer in service life.

Owner:候伟强

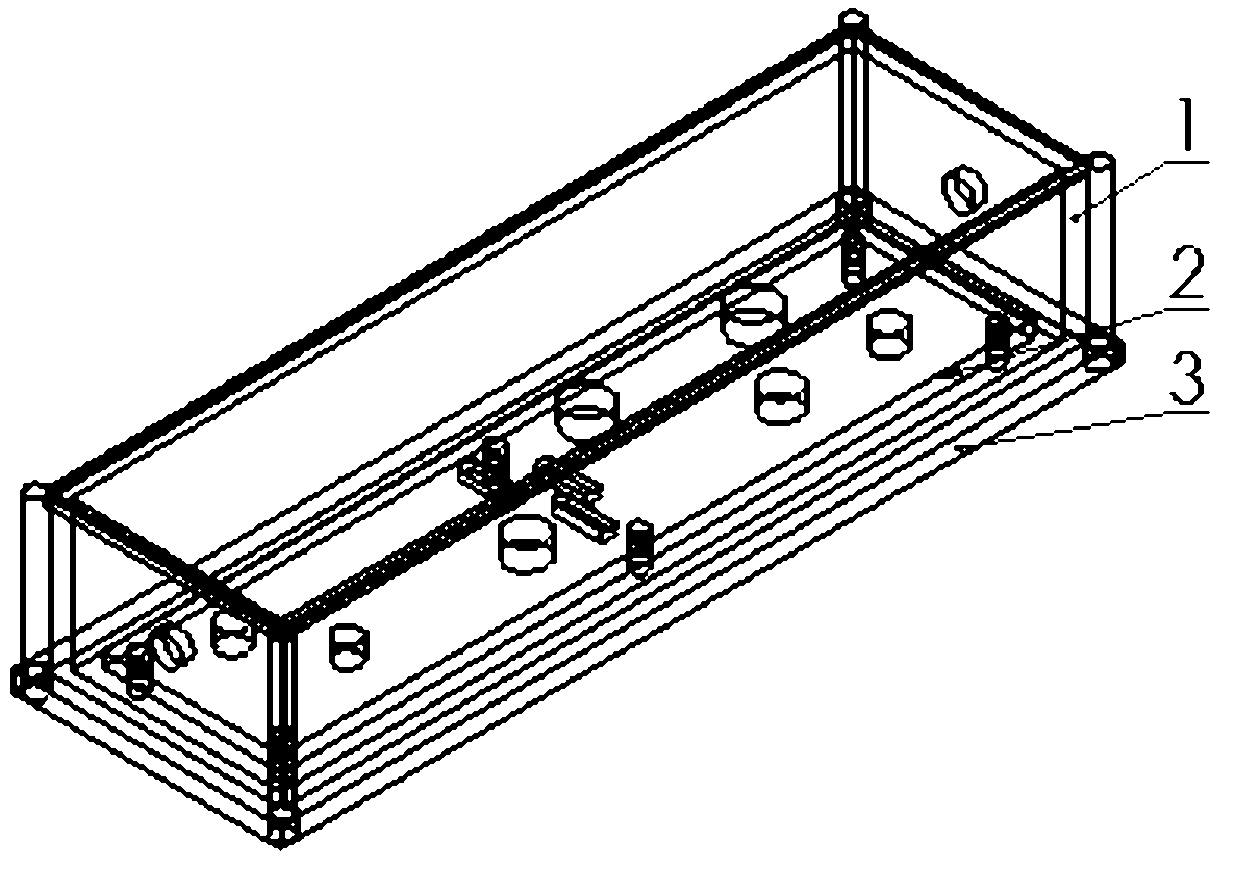

Novel PCR (polymerase chain reaction) tube and preparation method thereof

The invention discloses a novel PCR (polymerase chain react) tube. A formula comprises the following components in parts by weight: 20-30 parts of PP (polypropylene) materials, 0.01-0.1 part of a transparent agent, 0.01-0.1 part of diffusion oil, wherein the PP materials consist of homopolymerization injection-molding-level and transparent-level PP materials. The invention further discloses a preparation method of the novel PCR tube. According to the novel PCB tube and the preparation method, transparency of the finished product is increased, so that reactants and reaction degree in the tube can be conveniently observed, and experiment progress is controlled; moreover, the novel PCR tube is strengthened in flexibility and is not easy to break, so that requirements of PCR are satisfied, and an experimental success rate is improved.

Owner:海南科晶生物技术有限公司

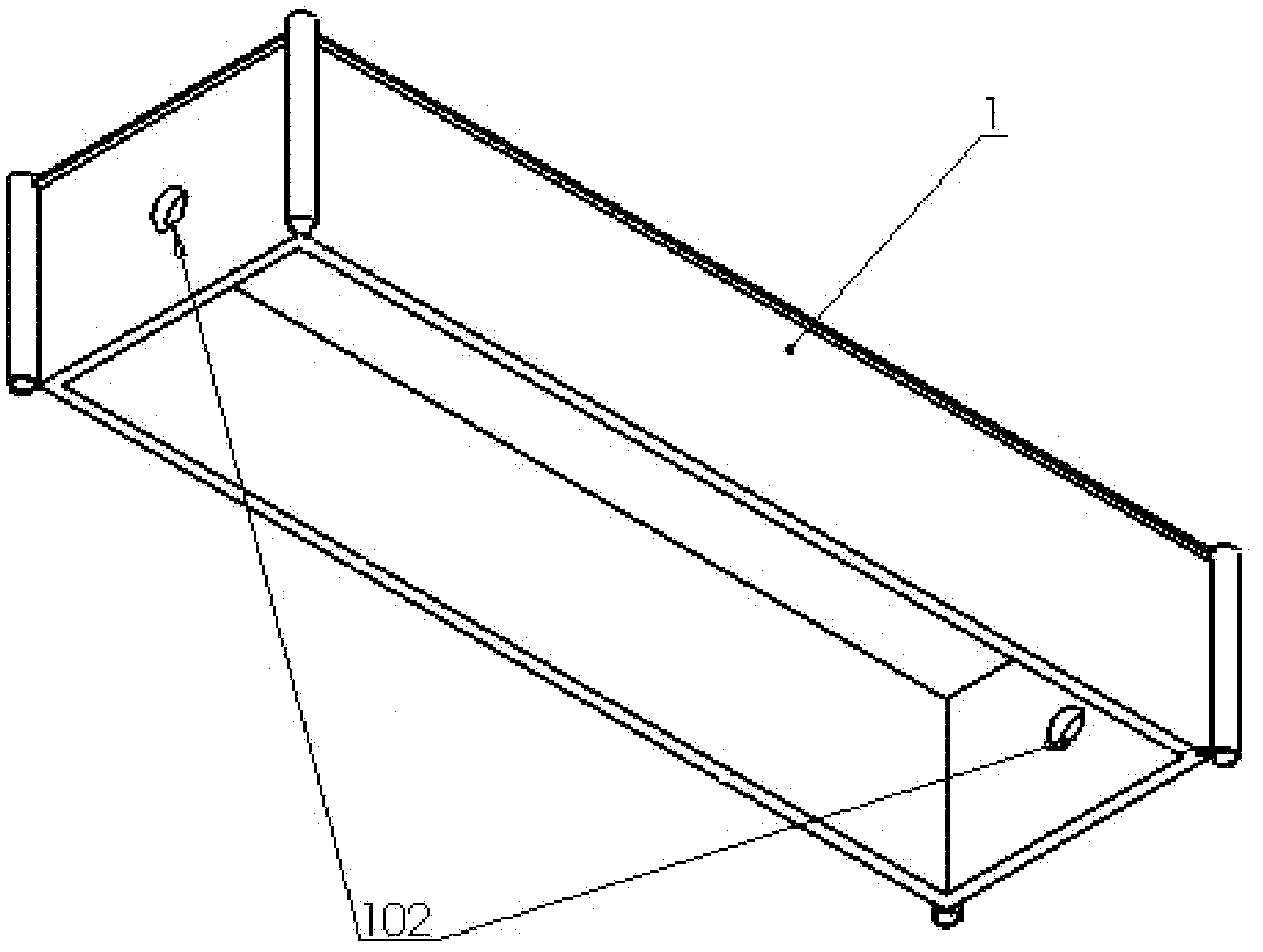

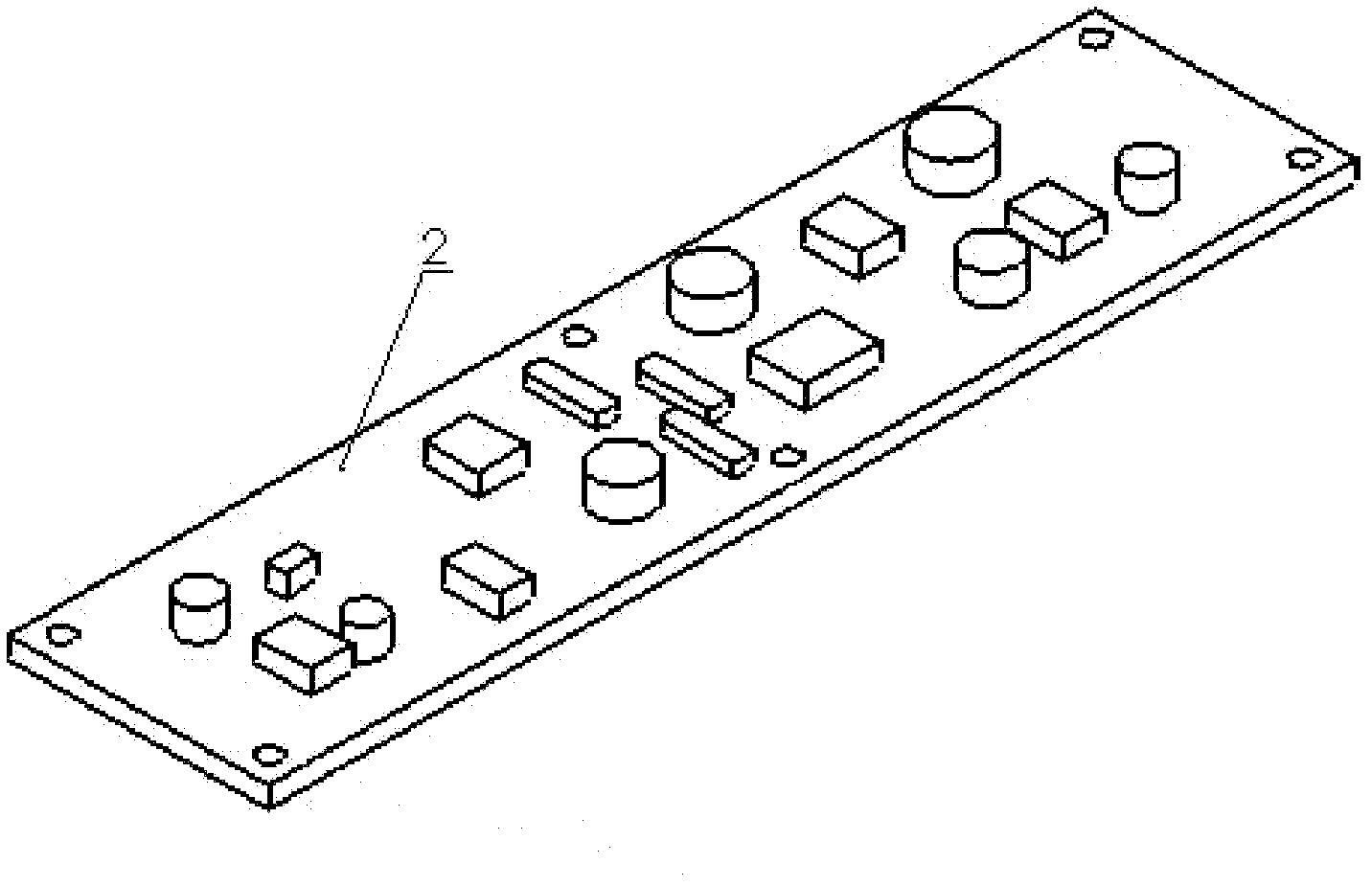

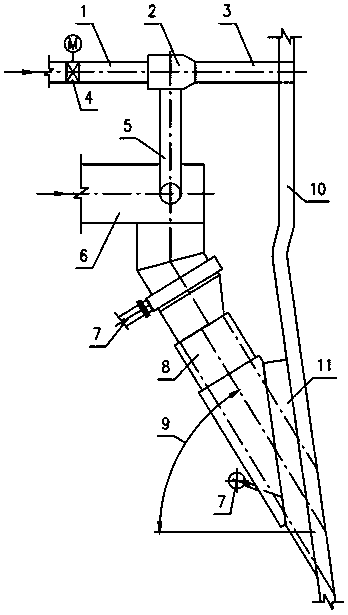

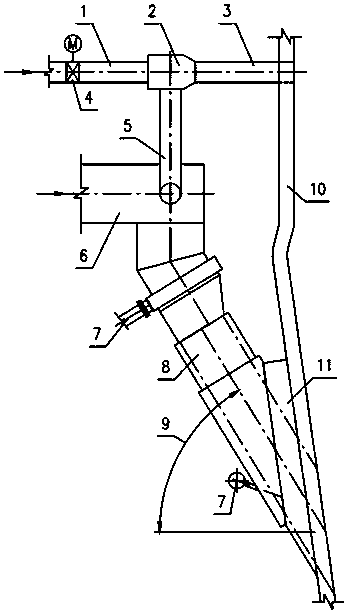

Feeding semi-pyrolysis device and method for household waste incineration boiler

PendingCN109959015AImprove energy efficiencyReduce generationIncinerator apparatusBoiler furnaceIncineration

The invention relates to a feeding semi-pyrolysis device and method for a household waste incineration circulating fluidized bedboiler. The feeding semi-pyrolysis device for the household waste incineration boiler comprises a boiler front feeding part and a semi-pyrolysis part. The head of a screw feeder (6) of the boiler front feeding part is connected with a feeding chute (8), and the feeding chute is connected into a boiler wall (10) to enter a boiler furnace in the mode of forming an included angle between the feeding chute and the horizontal plane. The included angle refers to a chute angle (9). The semi-pyrolysis part comprises a hot air duct (1), an air evacuating device (2), a boiler-in pipeline (3) and an air evacuating pipeline (5). The air evacuating device is installed betweenthe hot air duct and the boiler-in pipeline. Boiler hot air is connected into the hot air duct. The boiler-in pipeline enters a boiler furnace lean-phase zone through a boiler wall opened hole. One end of the air evacuating pipeline is connected with the air evacuating device, and the other end of the air evacuating pipeline is connected with the head of the screw feeder. A ventilation door (4) isinstalled on the hot air duct in front of the air evacuating device. According to the feeding semi-pyrolysis device for the household waste incineration boiler, materials can be burnt more stably andsufficiently in the waste circulating fluidized bedboiler and exhausting standards are met.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

Lightweight composite cartridges for low to medium chamber pressures

InactiveCN104567560BHigh strengthStable chemical propertiesSynthetic resin layered productsCartridge ammunitionFiberEpoxy

In view of the problems existing in the existing cartridges, the present invention provides a lightweight composite material cartridge suitable for medium and low chamber pressures, which includes a base layer, a reinforcement layer and a surface coating. The base layer uses epoxy resin as the base material and adopts It is made of air mold casting, in which 2% SiO2 nanoparticles and a small amount of curing agent are evenly infiltrated. The reinforcement layer is carbon fiber. The carbon fiber is wound around the outside of the base layer at a winding angle of 60O-63O. The surface coating is polytetrafluoroethylene and sprayed Outside the reinforcement layer; the invention enables the cartridge to have the characteristics of high strength, light weight, stable chemical properties, etc., improves work efficiency and high radio frequency firing rate, and reduces the consumption of metal resources.

Owner:ZHONGBEI UNIV

A process method for chemical mechanical planarization of devices with a size below 40nm

ActiveCN104979277BReduce metal lossImprove performanceSemiconductor/solid-state device manufacturingAtomic layer depositionTungsten

The invention provides a chemical machinery planarization process method. The method comprises the following steps: filling metallic tungsten by use of an atomic layer deposition method; carrying out a first removal process and a second removal process so as to realize chemical machinery planarization of the metallic tungsten, wherein the pressure and the rotating speed in the second removal process are respectively smaller than the pressure and the rotating speed in the first removal process. According to the invention, the chemical machinery planarization of the metallic tungsten is realized by use of a two-step removal process, and the pressure and the rotating speed in the later removal process are reduced, such that the mechanical effect in a grinding process is reduced in the second removal process, metal loss at the top of a metal gate can be reduced, and the performance and the yield of a device are improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Preparation method and application of a carbon fiber/three-dimensional network graphene composite material

ActiveCN107833756BIncrease the areaImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureFiberCapacitance

Owner:上海格素电子科技有限公司

Method for Inhibiting Both Glycolysis and Glutamine Metabolism in Cells and Use Thereof

InactiveUS20200121716A1Improve stabilityNot easily oxidizedAntibacterial agentsBiocideOXALIC ACID DIHYDRATEFacultative anaerobic organism

A method for inhibiting a cellular glycolysis process and an application thereof. The method is using reductive selenium dioxide, selenite or formic acid, formate, oxalic acid, oxalate, sulfur-containing reducing agent, and the like to inhibit a hydrogen cyclic process required in a redox reaction in the cellular glycolysis process. The application comprises: tumor prevention and treatment by applying different reducing agents by means of injection, oral administration, external application, spraying, or fumigation; prevention and treatment of digestive tract inflammation and tumors by means of oral administration; inhibition of a metabolic process of anaerobes and facultative anaerobes, where the reductive selenium dioxide, selenite, formic acid, formate, and the like are used as one of the active ingredients or ingredients of a fungicide; and disease prevention and antioxidation of fresh goods, food, fish and meat, vegetables and fruits, natural perfume, natural cosmetics, detergents, skin care products, and daily sanitary products, maintaining of human redox equilibrium, preservation and fresh-keeping, or related health care field. Problem caused by acidity of the body fluid can be solved by using alkaline sodium carbonate, which is the product of sodium formate and sodium oxalate after metabolism.

Owner:QIN CAIDONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com