Feeding semi-pyrolysis device and method for household waste incineration boiler

A domestic waste incineration and feeding technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of large differences in combustion characteristics of waste components, chemical and physical incomplete combustion losses, and large fluctuations in excess air coefficients. , to achieve the effects of reducing the amount of dioxin produced, overcoming combustion instability, stable combustion and sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

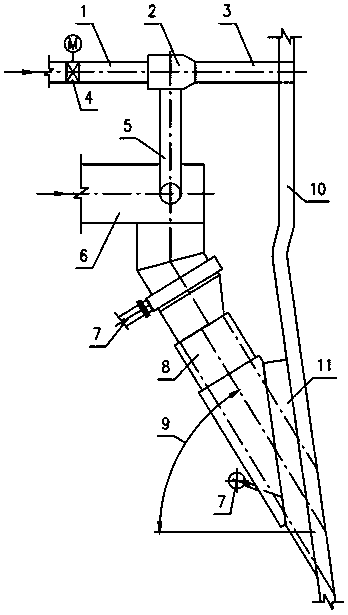

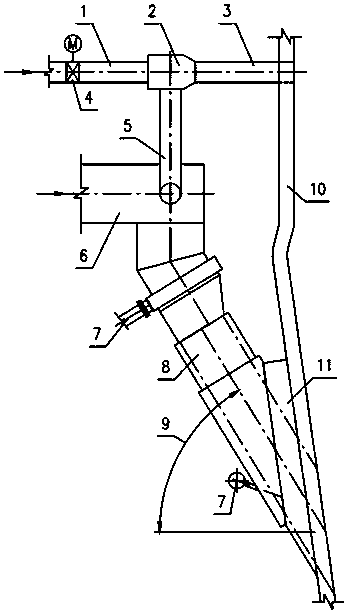

[0020] see figure 1 , a domestic waste incineration boiler feeding semi-pyrolysis device, comprising: a furnace front feeding part and a semi-pyrolysis part. The feeding parts in front of the furnace include: a screw feeder 6, a feeding chute 8, a furnace wall 10, the head of the screw feeder 6 is connected to the feeding chute 8, and the feeding chute 8 has a clamp with the horizontal plane. The angle of the angle is connected to the furnace wall 10 and enters the furnace, and the included angle is the slide pipe angle 9. The chute angle 9 can be set according to the characteristics of the material for the convenience of garbage materials falling into the furnace. The material-pulling air duct 7 on the existing feeding chute 8 needs to be canceled or blocked and out of service. The material is heated by the high-temperature flue gas extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com