Special corrosion and scale inhibitor for high concentration index recycling water and preparation method of special corrosion and scale inhibitor

A corrosion and scale inhibitor, circulating water technology, applied in chemical instruments and methods, descaling and water softening, complex/solubilizing agent treatment, etc. Precipitate chlorine ions and other problems to achieve the effect of reducing chemical and biological corrosion, increasing the concentration multiple, reducing pitting corrosion and under-deposit corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

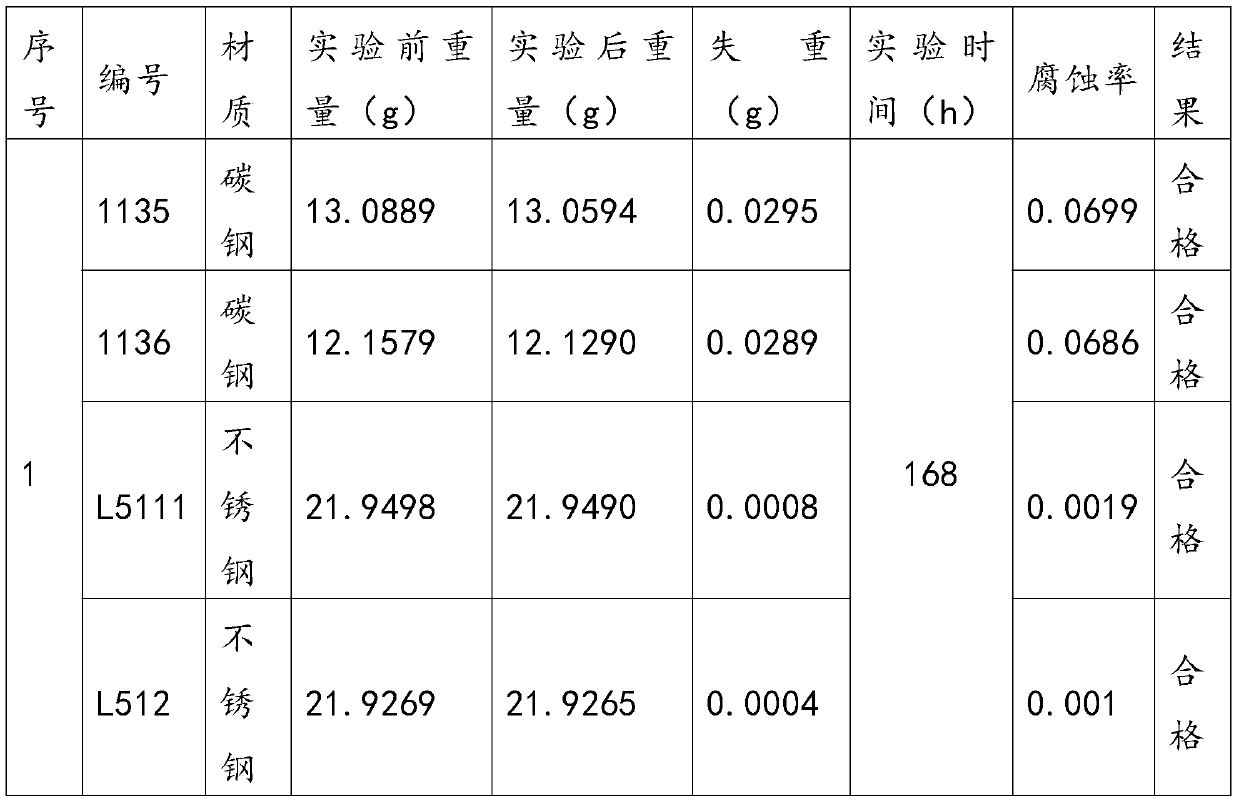

Examples

Embodiment 1

[0032] Add 20% of acrylic acid-acrylate-phosphonic acid-sulfonate tetrapolymer, 22% of carboxylic acid-sulfonic acid-acrylate terpolymer, 15% of 2-hydroxyphosphonoacetic acid, 15% of phosphine carboxylic acid, 26% of deionized water, after stirring evenly, add 2% of zinc sulfate heptahydrate, and stir again to get the finished product.

Embodiment 2

[0034] Add 18% of acrylic acid-acrylate-phosphonic acid-sulfonate tetrapolymer, 20% of carboxylic acid-sulfonic acid-acrylate terpolymer, 13% of 2-hydroxyphosphonoacetic acid, 15% of phosphine carboxylic acid, 32% of deionized water, after stirring evenly, add 2% of zinc sulfate heptahydrate, and stir again to obtain the finished product.

Embodiment 3

[0036] Add 16% of acrylic acid-acrylate-phosphonic acid-sulfonate tetrapolymer, 18% of carboxylic acid-sulfonic acid-acrylate terpolymer, 11% of 2-hydroxyphosphonoacetic acid, 15% of phosphine carboxylic acid, 38% of deionized water, after stirring evenly, add 2% of zinc sulfate heptahydrate, and stir again to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com