Chemical mechanical polishing solution for processing surface of sapphire or carborundum wafer for LED (Light Emitting Diode) substrate slice and preparation method thereof

A surface treatment and chemical-mechanical technology, applied in the field of chemical-mechanical polishing liquid and its preparation, can solve the problems of low efficiency of ordinary polishing liquid and damage of wafer surface, etc., and achieve the effect of low production cost, simple preparation process and no pollution to the environment

Inactive Publication Date: 2013-01-23

SHANGHAI INST OF TECH

View PDF5 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] One of the purposes of the present invention is to provide a chemical mechanical polishing liquid for surface treatment of sapphire or silicon carbide wafers used for LED substrates in order to solve the low efficiency of common polishing liquids and the technical problems of a large amount of damage on the wafer surface

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0154] The present invention is further illustrated below by the examples, but the present invention is not limited.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a chemical mechanical polishing solution for processing a surface of a sapphire or carborundum wafer for an LED (Light Emitting Diode) substrate slice. The chemical mechanical polishing solution comprises the following raw materials by weight: 2 to 30% of grinding material, 0.01 to 5% of chelating agent, 0.01 to 10% of surface active agent, 0.01 to 10% of dispersing agent, 0.1 to 20% of oxidant and the balance of deionized water. The preparation method comprises the steps as follows: preparing a grinding material-silica sol; then, sequentially adding the chelating agent, surface active agent, dispersing agent, oxidant and deionized water to the obtained silica sol along with agitating; and continuously uniformly agitating to obtain the chemical mechanical polishing solution for processing the surface of the sapphire or carborundum wafer for the LED substrate slice. The chemical mechanical polishing solution disclosed by the invention can not bring damage, scratching and corrosive pits to the surface of the LED substrate and has no pollution to the environment; the raw materials are cheap, and the cost is low; and the chemical mechanical polishing solution is suitable for industrial production.

Description

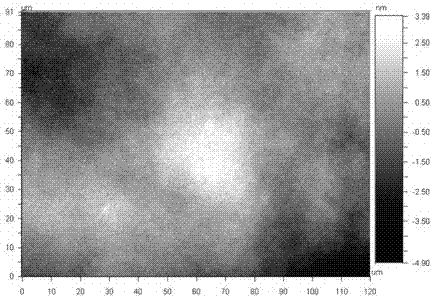

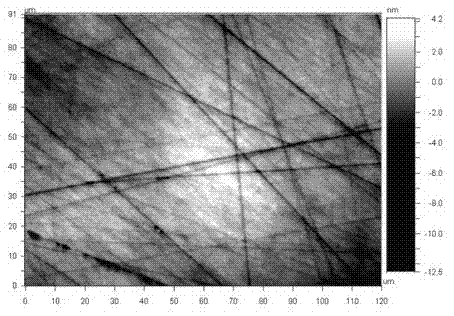

technical field [0001] The invention relates to a chemical mechanical polishing liquid, in particular to a chemical mechanical polishing liquid for surface treatment of sapphire or silicon carbide wafers used for LED substrates and a preparation method thereof. Background technique [0002] LED substrates require the surface of the substrate wafer to be ultra-smooth, free of defects and damage, and the surface quality of sapphire and SiC crystal processing will directly affect the performance of the device. However, due to the extremely high hardness of sapphire and SiC crystals, the Mohs hardness is 9 and 9.2 respectively, second only to diamond, making surface processing extremely difficult, and it is difficult to obtain high-quality surfaces with low roughness, which greatly limits their wide application. To prepare high-quality epitaxial wafers, the requirements for the substrate are not only low warpage, low curvature, and small total thickness deviation, but also speci...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09G1/02H01L21/304H01L33/00

Inventor 储耀卿徐家跃

Owner SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com