Patents

Literature

154results about How to "Not easy to recycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

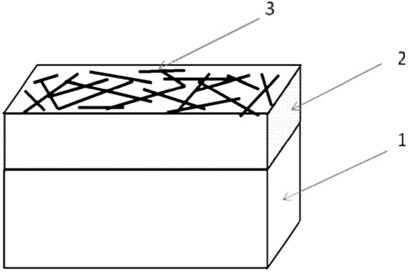

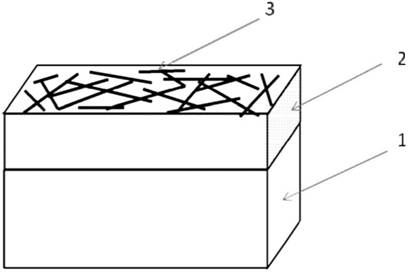

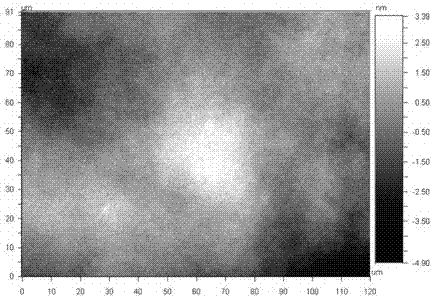

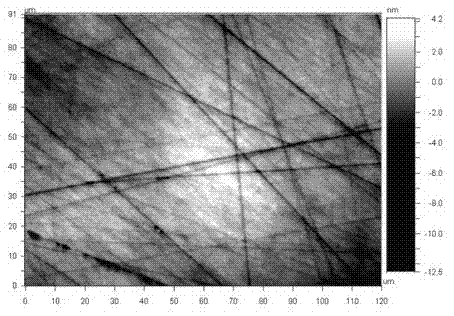

Flexible transparent electric conducting film and preparation method thereof

ActiveCN102693772AThe overall thickness is thinEvenly distributedConductive layers on insulating-supportsCable/conductor manufactureSurface layerTransparent conducting film

The invention discloses a flexible transparent electric conducting film and a manufacturing method thereof. The electric conducting film comprises a flexible transparent base plate, wherein a transparent oil ink layer is coated on the surface of the flexible transparent base plate; the surface layer of the transparent oil ink layer is an electric conducting layer pasted with nano silver wires; and the nano silver wires in the electric conducting layer are mutually overlapped so as to form a uniform two-dimensional nano silver wire network. The preparation method comprises the following steps of: printing or coating the transparent oil ink on the flexible transparent base plate; coating a nano silver wire dispersing liquid uniformly on the surface of another flexible transparent base plate so as to obtain a nano silver wire thin film; and through a hot pressing or transfer printing mode, transferring and pasting the thin film to the surface layer of the transparent oil ink so as to obtain the flexible transparent electric conducting film. The electric conducting film surface provided by the invention is lower in resistance value and is high in bonding force of each layer, has favorable contact, and has good uniformity; and the preparation method is simple in technology and is low in cost, and can prepare large-area transparent electric conducting films, and the prepared transparent electric conducting film has favorable electric conducting performance.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Chemical mechanical polishing solution for processing surface of sapphire or carborundum wafer for LED (Light Emitting Diode) substrate slice and preparation method thereof

InactiveCN102888193AAvoid damageNo subsurface damageSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesActive agentSilicon oxide

The invention discloses a chemical mechanical polishing solution for processing a surface of a sapphire or carborundum wafer for an LED (Light Emitting Diode) substrate slice. The chemical mechanical polishing solution comprises the following raw materials by weight: 2 to 30% of grinding material, 0.01 to 5% of chelating agent, 0.01 to 10% of surface active agent, 0.01 to 10% of dispersing agent, 0.1 to 20% of oxidant and the balance of deionized water. The preparation method comprises the steps as follows: preparing a grinding material-silica sol; then, sequentially adding the chelating agent, surface active agent, dispersing agent, oxidant and deionized water to the obtained silica sol along with agitating; and continuously uniformly agitating to obtain the chemical mechanical polishing solution for processing the surface of the sapphire or carborundum wafer for the LED substrate slice. The chemical mechanical polishing solution disclosed by the invention can not bring damage, scratching and corrosive pits to the surface of the LED substrate and has no pollution to the environment; the raw materials are cheap, and the cost is low; and the chemical mechanical polishing solution is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

Preparation for catalyst of Nano titanium dioxide, and method for treating ozonized water of catalysis

InactiveCN1695796AEasy reunionEasy to recycleCatalyst activation/preparationWater/sewage treatment by oxidationHYDROSOLSilica gel

A process for preparing the nano-TiO2 catalyst includes slowly dissolving tetrabutyl titanate in absolute alcohol, immersing the granular activated carbon or active Al2O3 or white silica gel or molecular sieve or zeolite in it, oscillating for 5-48 hrs, filtering, and drying or ageing. It can be used to treat water by making it, ozone and water to be treated in contact for 1-50 min.

Owner:HARBIN INST OF TECH

Flocculating agent for treating sewage in Chinese patent medicine production enterprises and preparation method thereof

ActiveCN102887581ANot easy to recycleBiodegradableOther chemical processesWater/sewage treatment by flocculation/precipitationMedicinePhytic acid

The invention discloses a flocculating agent for treating sewage in Chinese patent medicine production enterprises, wherein the flocculating agent comprises the following compositions: 30-45% of carapace crushed materials, 3-12% of modified chitosan, 0.05-0.5% of nanometer titanium dioxide, 0.1-0.5% of phytic acid, and 45-55% of zeolite; in order to optimize the effect, the flocculating agent is also added with 1-5% of white mica and 1-5% of active carbon. The flocculating agent provided by the invention is utilized to treat the sewage; the flocculating agent provided by the invention has very high efficiencies of removing COD (chemical oxygen demand) and BOD (biochemical oxygen demand); and the flocculating agent provided by the invention is efficient and economical.

Owner:JIANGSU SHANGDA WATER AFFAIR

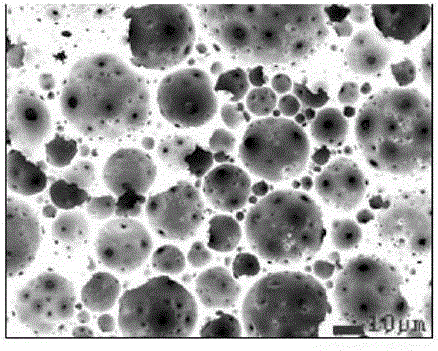

Magnetic adsorbent for removing heavy metal in water and method for preparing magnetic adsorbent

InactiveCN105664884AHigh mechanical strengthImprove physical and chemical propertiesOther chemical processesWater contaminantsPolyvinyl alcoholSorbent

The invention relates to the technical field of water treatment, and specifically discloses a magnetic adsorbent for removing heavy metals in water and a preparation method thereof. The adsorbent is prepared by sequentially modifying magnetic chitosan-polyvinyl alcohol microspheres through glutaraldehyde cross-linking modification and carbon disulfide modification; wherein the magnetic chitosan-polyvinyl alcohol microspheres are made of chitosan, polyvinyl alcohol Vinyl alcohol and nano-magnetic iron are prepared as raw materials; the mass ratio of chitosan, polyvinyl alcohol and nano-magnetic iron is 1:1:1. The present invention makes the adsorbent magnetic by adding nano-magnetic iron, and uses glutaraldehyde and carbon disulfide to modify the magnetic chitosan-polyvinyl alcohol microspheres to enhance the mechanical strength of the adsorbent and the adsorption effect on heavy metal ions, so that The prepared adsorbent has the characteristics of large adsorption capacity, high removal rate of various heavy metal ions, magnetic separation under an external magnetic field, and renewable recycling, and can be used to remove heavy metals in domestic sewage, industrial wastewater and natural water.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Precious metal nanoparticle-modified porous carrier catalytic material and preparation method thereof

InactiveCN104815693AEasy to recycleReduce method stepsCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsOil phaseMaterials science

The invention relates to a precious metal nanoparticle-modified porous carrier catalytic material and a preparation method thereof. The precious metal nanoparticle-modified porous carrier catalytic material comprises dendritic amphiphilic PEI@PS and precious metal M carried by the dendritic amphiphilic PEI@PS. The dendritic amphiphilic PEI@PS comprises a hydrophilic core PEI and an oleophylic shell PS chemically coating the hydrophilic core, and the precious metal M is one of Au, Pt, Ag and Pd. The preparation method comprises that the dendritic amphiphilic M@PEI@PS as a stabilizer, a vinyl monomer, a diene cross-linking agent, an initiator and a pore-foaming agent are mixed into an oil phase, the oil phase and water as a dispersant undergo thick water-in-oil emulsion polymerization reaction under the action of the initiator and the product is washed and dried, or comprises that the precious metal M is added into a water phase of a thick emulsion system adjusted by the dendritic amphiphilic PEI@PS, the mixture undergoes a polymerization reaction to produce a porous material and the porous material is reduced by a reducer. Compared with the existing catalytic material, the precious metal nanoparticle-modified porous carrier catalytic material has protruding stability and catalytic performances, has macroscopic dimension and can be easily separated from the reaction system and recycled.

Owner:TONGJI UNIV

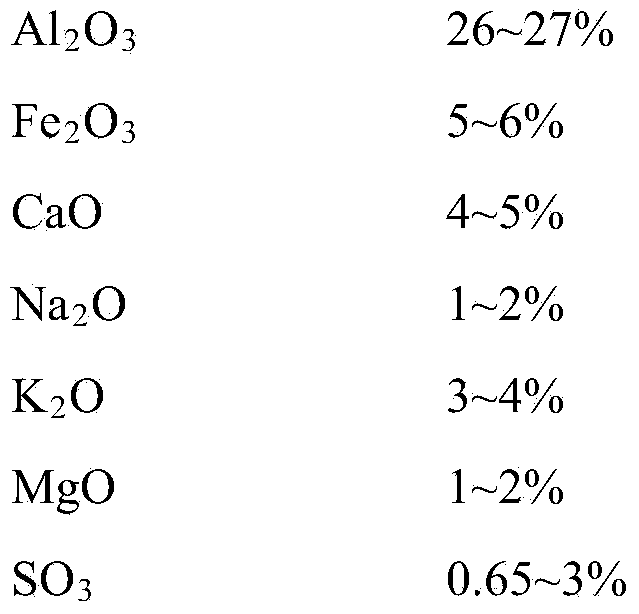

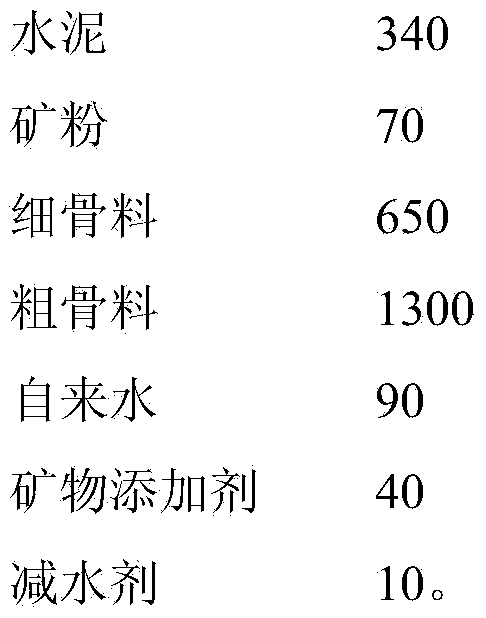

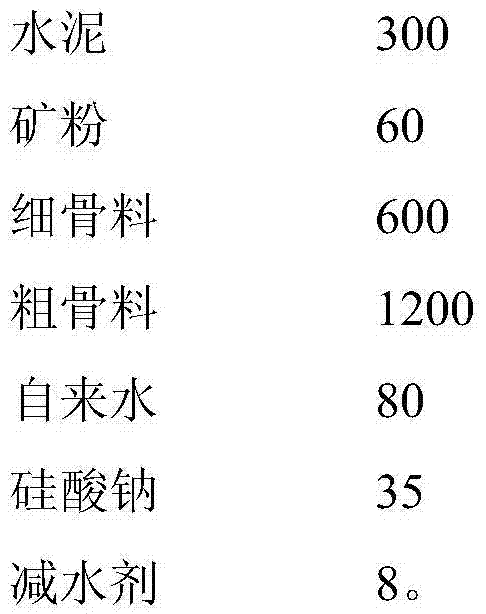

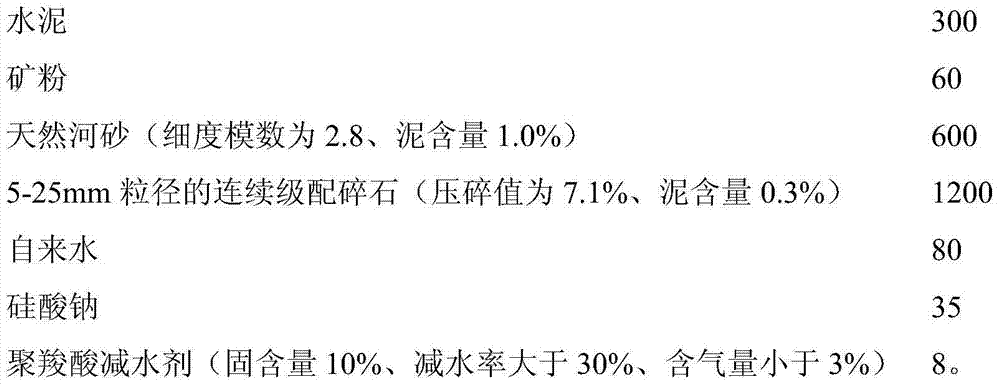

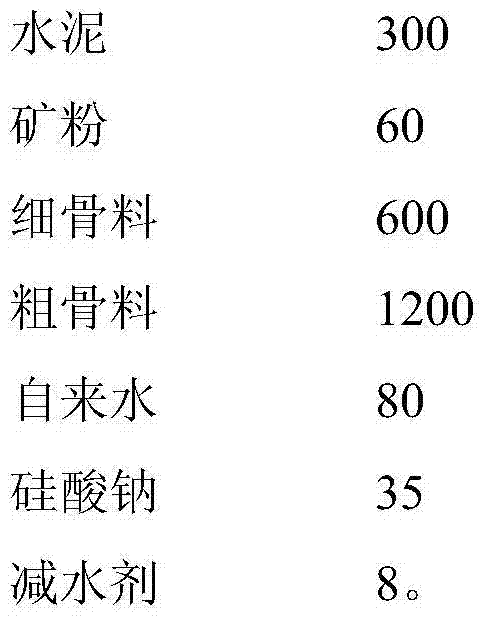

Production method of non-residual slurry non-autoclaved prestressed concrete pipe pile

ActiveCN103434020AReduce pollutionReduce energy consumptionShaping reinforcementsLow speedPre stress

The invention relates to a production method of a non-residual slurry non-autoclaved prestressed concrete pipe pile. The production method comprises the following steps: (1) sequentially adding fine aggregate, coarse aggregate, cement, mineral powder, a mineral additive, water and a water reducing agent into a reaction kettle, and evenly stirring to obtain a concrete mixture; (2) prestressed tensioning the concrete mixture after material distribution and die assembling; (3) centrifuging the concrete mixture after prestressed tensioning, and sequentially carrying out low speed, low medium speed, medium speed and high speed centrifugation steps in centrifugation without producing residual slurry in the centrifugation process; (4) placing the centrifuged concrete mixture into a steam maintenance pool for steam maintenance. According to the production method, after multiple experiments, through contrastive analysis, the nanoscale mineral additive is added, and by matching with the compound high-performance water reducing agent and adjusting existing pipe pile centrifugation and steam maintenance steps, the non-residual slurry centrifugation and one-time demoulding strength of C80 are realized, so that the working procedures of pouring residual slurry and steam maintenance are eliminated, and the environmental pollution and energy consumption of enterprises are greatly reduced.

Owner:TIANJIN YONGSHENG XINHE PILE

Polishing solution for silicon carbide substrate

InactiveCN102533124AAvoid damageLow subsurface damageSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSURFACTANT BLENDCorrosion

The invention relates to a chemically mechanical polishing solution for a silicon carbide substrate. The chemically mechanism polishing solution comprises the following components in percentage by weight: 1-50 percent of grinding material, 0.01-8 percent of chelant, 0.01-10 percent of surfactant, 0.01-10 percent of dispersing agent, 0.1-20 percent of oxidant and the balance of deionized water. The polishing solution has little damage to the surface of the silicon carbide substrate; the silicon carbide substrate has low roughness degree value and can reach the roughness Ra of being less than 0.5nm; no scratch and corrosion pit defect exists on the surface of the silicon carbide substrate; and the chemically mechanical polishing solution has high removing speed of scratch and corrosion pit, is easy to clean, does not corrode processing equipment and pollute the environment, and is low is price of raw materials, low in cost and easy to store. The chemically mechanical polishing solution is mainly used for chemically mechanical polishing of a silicon carbide wafer for the substrate.

Owner:上海上硅中试基地科技有限公司 +1

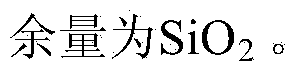

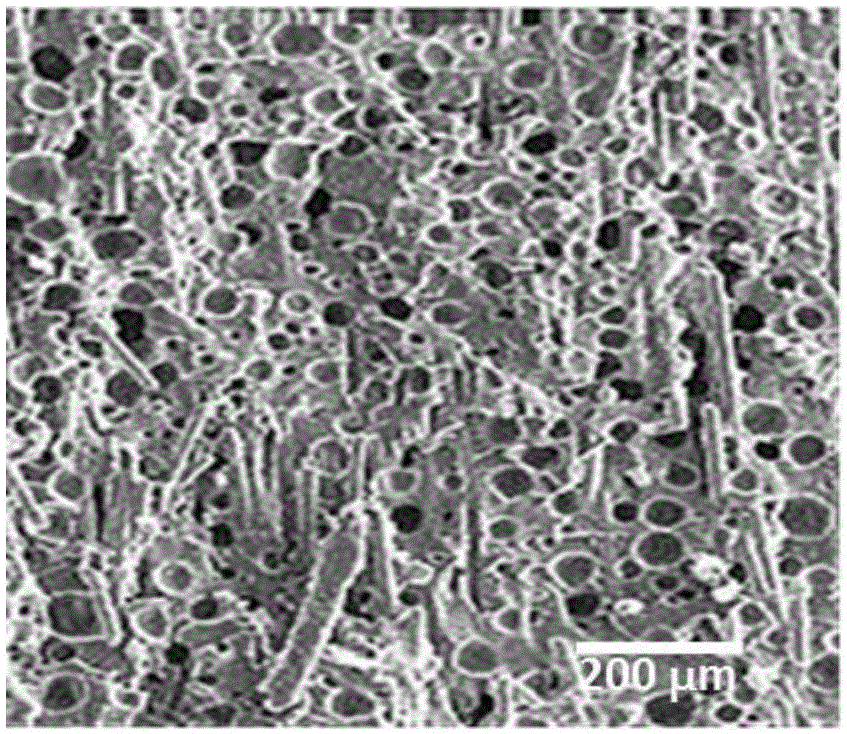

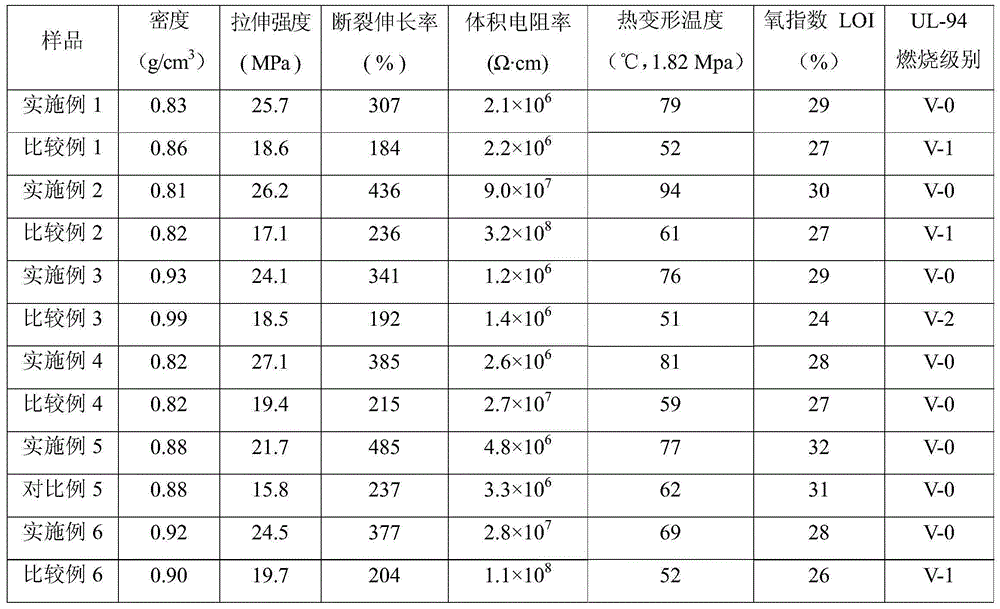

Polyolefin-kind high-molecular obstruction explosion-proof material and preparation method thereof

The invention belongs to the technical field of high-molecular materials, and especially relates to a preparation method for a polyolefin-kind high-molecular obstruction explosion-proof material. The method comprises fully drying polyolefin, a fire retardant, an antistatic agent, a flexibilizer and various auxiliary agents, uniformly mixing in a high-speed mixer, then adding into a screw-combined co-rotating conical twin-screw extruder with an appropriate length-diameter ratio, setting the extruder temperature to be 160-280 DEG C, performing cooling and heating processing, then sending into a slitting system, and cutting into an obstruction explosion-proof polyethylene material pellet with a fixed length, so as to prepare the obstruction explosion-proof material which is cheap in price, easy to process and excellent in performances.

Owner:JIANGSU AMPUTE EXPLOSION PREVENTION TECH

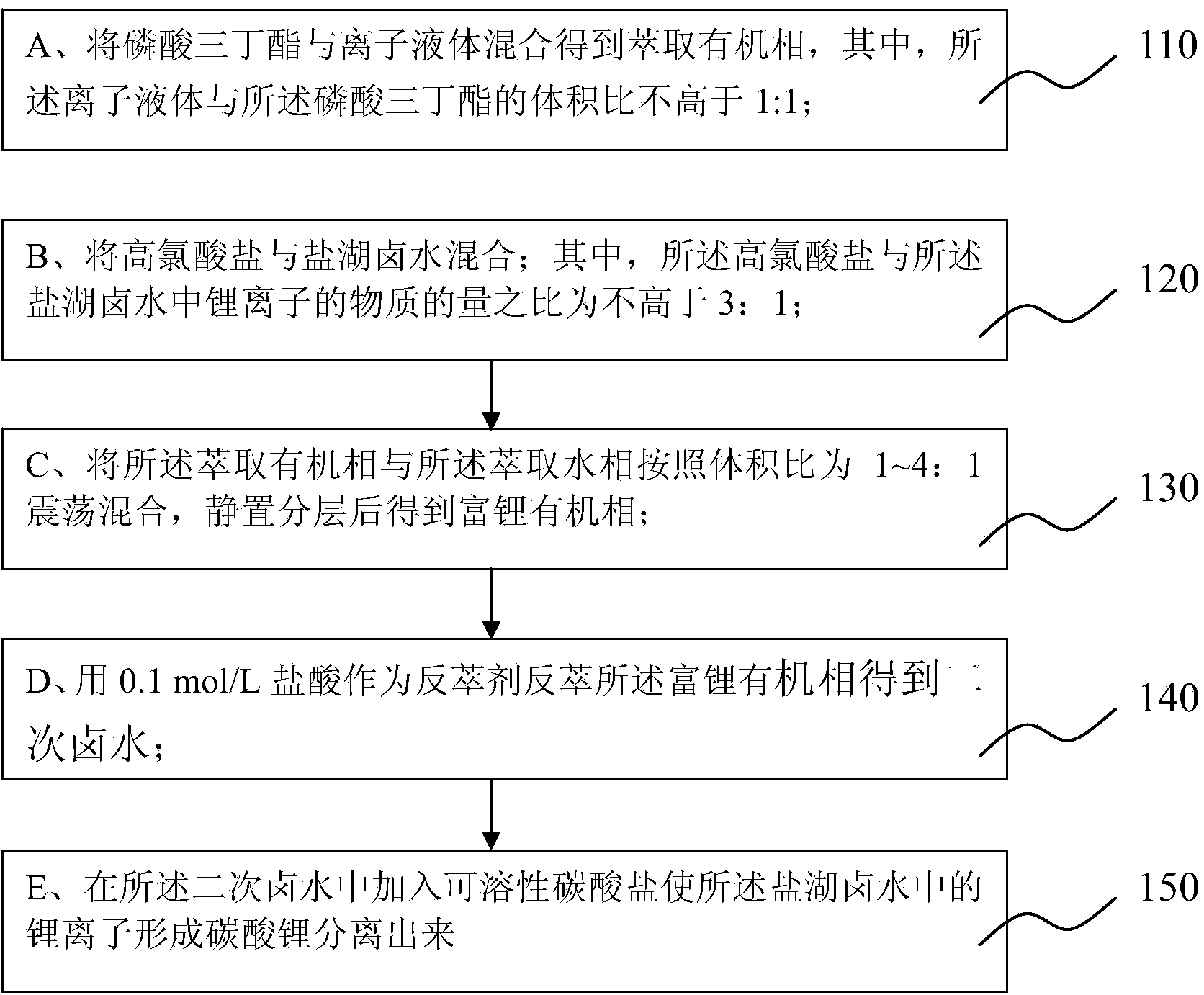

Method for separating lithium from salt lake brine

InactiveCN104232896ANo pollution in the processAvoid pollutionProcess efficiency improvementPhase splittingSalt lake

The invention discloses a method for separating lithium from salt lake brine. The method comprises the steps as follows: tributyl phosphate and an ionic liquid are mixed to obtain an extracted organic phase, wherein the volume ratio of the ionic liquid to tributyl phosphate is not higher than 1:1; perchlorate and the salt lake brine are mixed, wherein the ratio of lithium ions in the perchlorate to those in the salt lake brine is (0.5-3):1, and the extracted organic phase and an aqueous phase are oscillated and mixed for 8-12 min at room temperature at the volume ratio of (1-4):1 and is left to stand for 20 min to obtain a lithium-rich organic phase. According to the method for separating lithium from the salt lake brine, lithium is separated from the salt lake brine with high ratio of magnesium to lithium, the separating efficiency is high, and the problems of pollution caused by solvent volatilization and phase-splitting difficulty due to system emulsification are solved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Manufacturing method of oil absorbing fiber felt

ActiveCN103437067AImprove performanceSimple processNon-woven fabricsCross-linkManufacturing technology

The invention discloses a manufacturing method of oil absorbing fiber felt, belonging to the technical field of manufacturing of fiber felts. By simultaneously adopting a semi-interpenetrating polymer network technique and an electrostatic spinning technique, the manufacturing method comprises the following steps: firstly, synthesizing monomers, which are unlikely to form cross-linked structures, to linear non-crosslinking methacrylate polymers by suspension polymerization; dissolving the polymers in a solvent suitable for electrostatic spinning to prepare liquor, and adding monomers, which are likely to form cross-linked structures and contain an initiator, into the liquor; preparing polymer liquor containing the semi-interpenetrating network structure by liquor polymerization; after insulating and defoaming, spraying the liquor to a receiving roller by an electrostatic spinning method; and along with volatilization of the solvent, after fibers are cured, fixing the semi-interpenetrating network structure inside the fibers so as to form the fiber felt with an intrinsic oil absorbing function. Compared with existing polypropylene fiber felt, the fiber felt disclosed by the invention has the advantages of higher adsorption rate, stronger oil keeping capacity and the like, and satisfies the industrial practical demands.

Owner:TIANJIN POLYTECHNIC UNIV

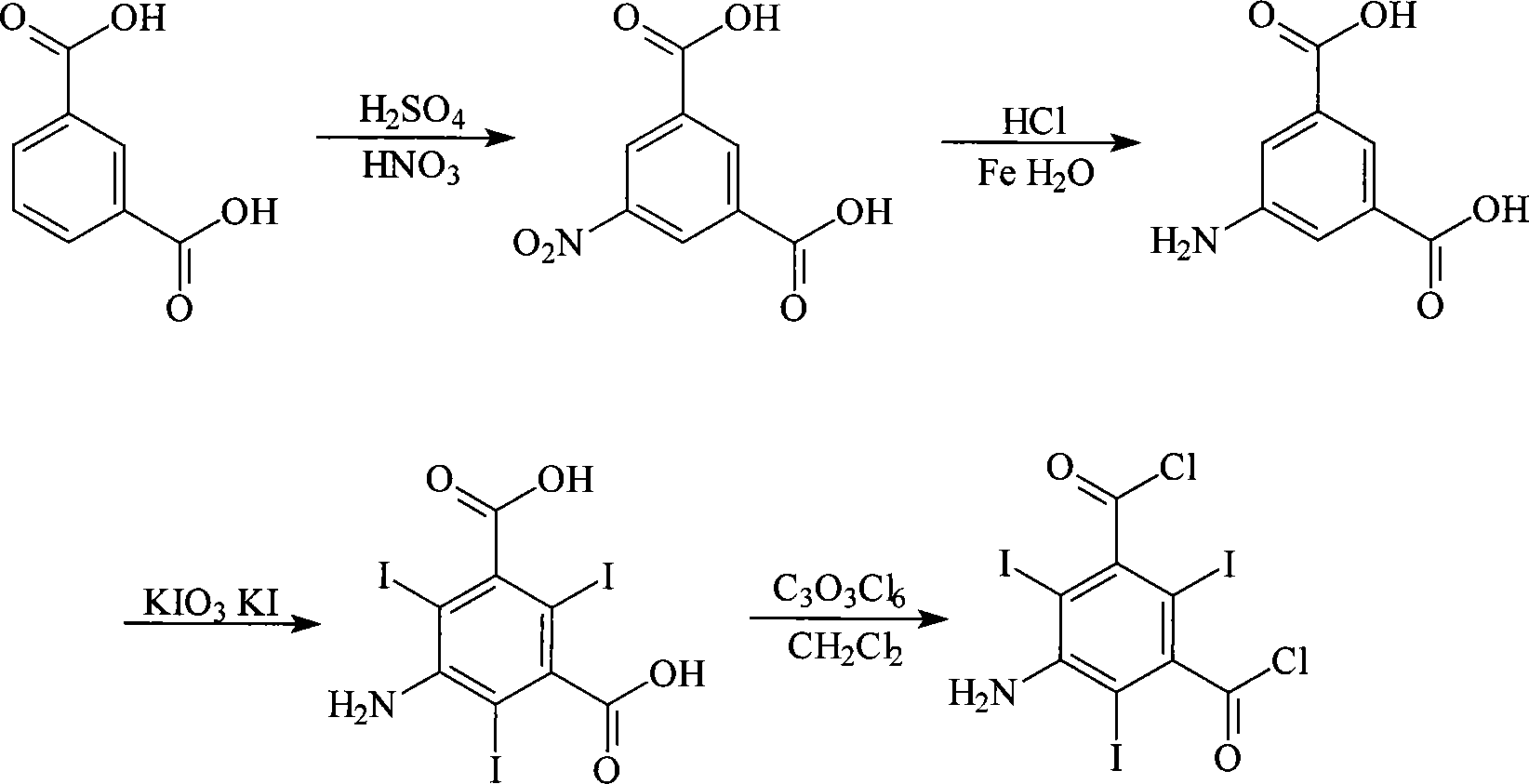

Method for synthesizing 5-amino-2,4,6-triiodoisophthaloyl dichloride

ActiveCN101215244AEasy to operateNot easy to recycleOrganic compound preparationAmino-carboxyl compound preparationCarbonyl chlorideNitration

A synthesis process of 5-amino-2, 4, 6-triiodoisophthalic acid acyl chloride, which comprises using m-phthalic acid as starting material, preparing 5-amino isophthalic acid through nitration and reduction, preparing 5-amino-2, 4, 6-triiodoisophthalic acid through iodobenzene reaction, using solid carbonyl chloride as acyl chloride agent and addling initiating agent, conducting acyl chloride reaction towards 5-amino-2, 4, 6-triiodoisophthalic acid to prepare 5-amino-2, 4, 6-triiodoisophthalic acid acyl chloride. The 5-amino-2, 4, 6-triiodoisophthalic acid acyl chloride which is prepared by the invention is mainly used to synthesize intermediate compound of ionic contrast agent.

Owner:山西新天源药业有限公司

Palladium/alkali metal compound supported catalyst and preparation method and application thereof

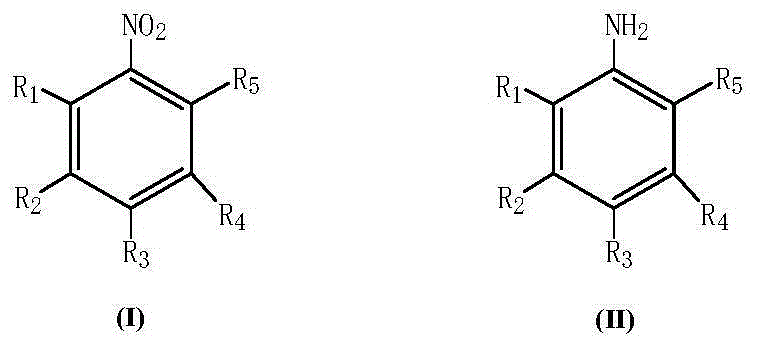

ActiveCN105195140ASmall particle sizeHigh catalytic activityOrganic compound preparationAmino compound preparationNitro compoundActive component

The invention provides a palladium / alkali metal compound supported catalyst and a preparation method and application thereof. The catalyst is composed of a supporter and an active component supported on the supporter. The supporter is active carbon. The active component comprises elemental palladium and an alkali metal compound. Based on the mass of the supporter active carbon, the supporting amount of the elemental palladium is 0.25-15.0wt%, and the theoretical supporting amount of alkali metal elements in the alkali metal compound is 0.01-5.0wt%. The catalyst can be applied to a catalytic hydrogenation reaction of a haloaromatic nitrocompound and / or an aromatic nitro compound. The catalyst is high in catalytic activity and easy to recycle and use indiscriminately, no dehalogenation inhibitor needs to be added when the catalyst is applied to the catalytic hydrogenation reaction of the haloaromatic nitrocompound, and the reaction conversion rate and the product selectivity are still excellent on the premise of keeping the high reaction speed.

Owner:ZHEJIANG UNIV OF TECH

Cooling device for wind power generating unit and wind power generating unit

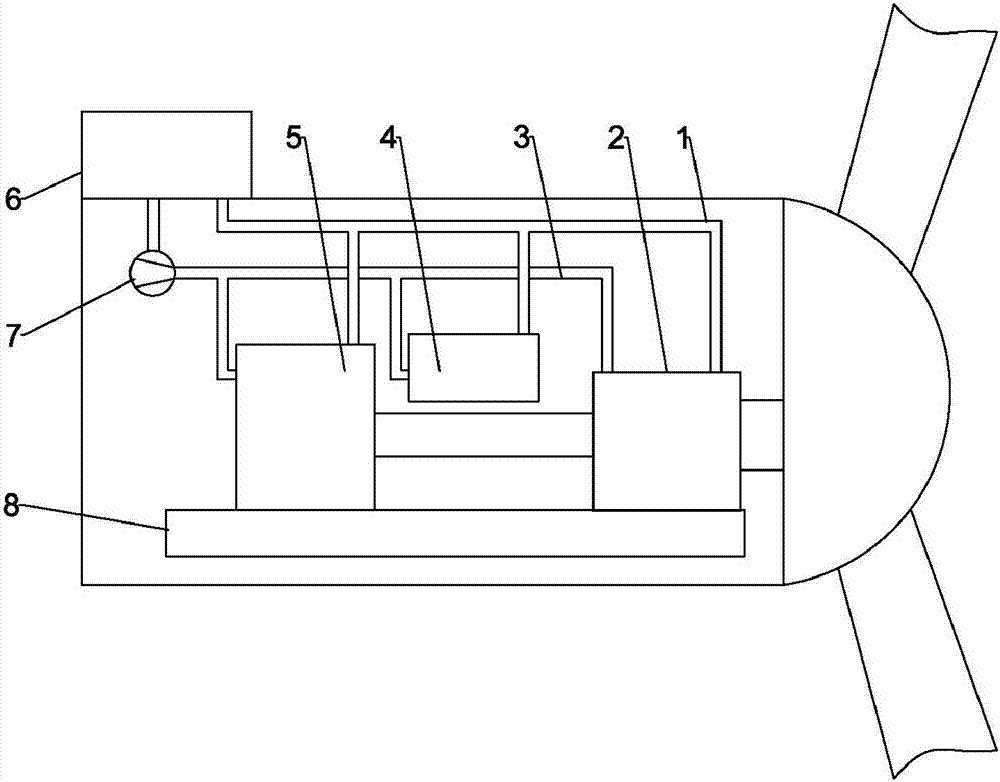

InactiveCN107542629AGuaranteed uptimeGuaranteed safe operationFinal product manufactureMachines/enginesEngineeringLiquid metal

The invention relates to the technical field of wind power generator cooling equipment, in particular to a cooling device for a wind power generating unit and the wind power generating unit. The cooling device for the wind power generating unit is provided and comprises an outer radiator, a drive mechanism and at least one heat exchange element, the heat exchange element and the outer radiator arein communication through a pipeline to form a cooling loop, the cooling loop is internally provided with liquid metal, and the drive mechanism drives the liquid metal to circularly move in the cooling loop. According to the cooling device for the wind power generating unit and the wind power generating unit, the liquid metal is introduced for the first time to serve as a cooling medium of the wind power generating unit, and due to the fact that the liquid metal combines high heat conductivity of the metal medium and fluidity of fluid, efficient heat transportation and extreme heat dissipationcapability is achieved, and the cooling efficiency is improved. Meanwhile, the liquid metal is stable in physical and chemical property and easy to recycle, and safe and efficient running of the cooling device can be guaranteed. In addition, the provided cooling device is simple in structure, low in manufacturing cost and high in practicability.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

Waterproof recycled paper and production method thereof

InactiveCN103397559AExtended use timeWith waterproof functionWater-repelling agents additionInorganic compound additionSulfite saltPlant fibre

Owner:区锦泉

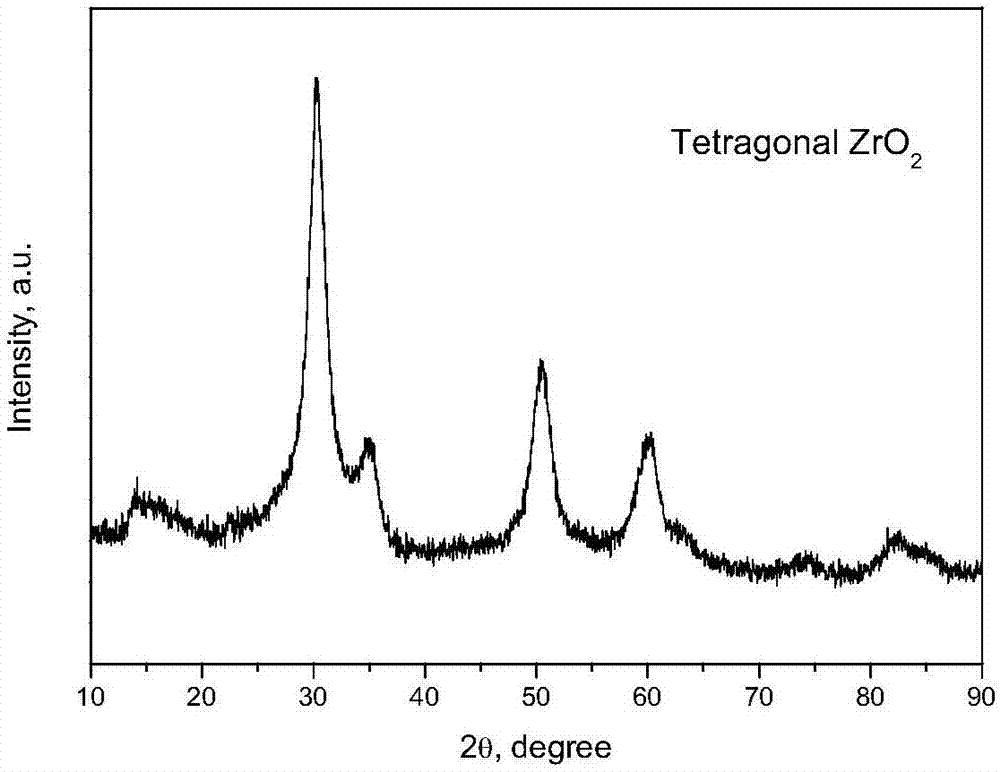

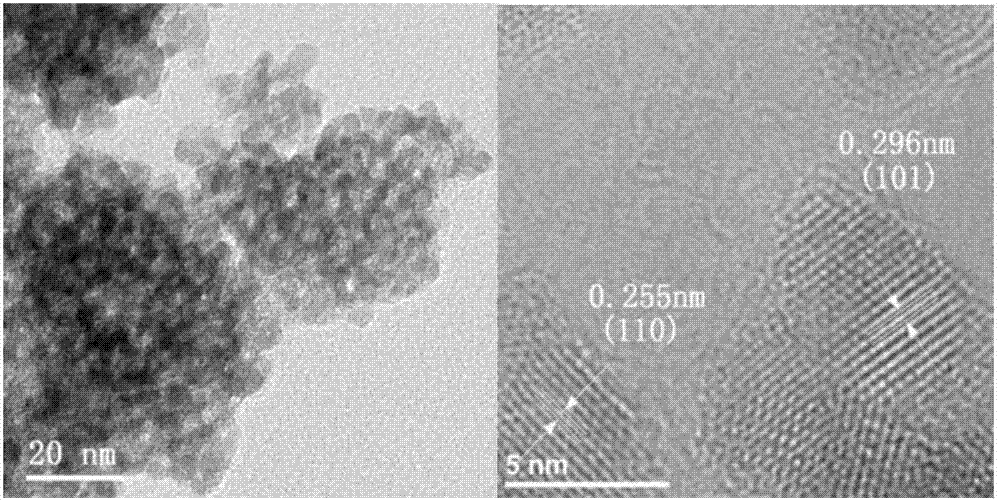

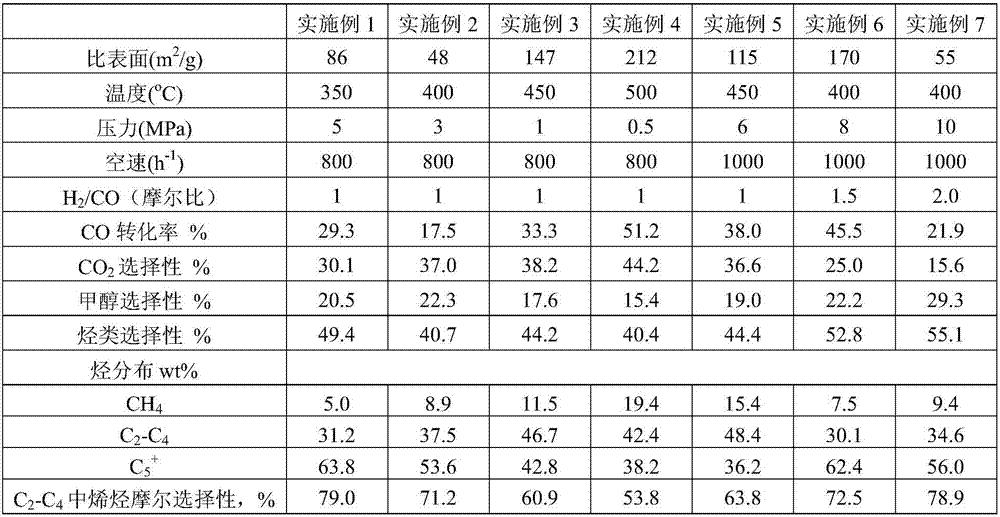

Tetragonal nano zirconia with high specific surface and high purity, preparation method of nano zirconia as well as application in catalytic conversion of catalytic synthesis gas

ActiveCN107032397ALow boiling pointEasy to recycleMaterial nanotechnologyPhysical/chemical process catalystsAir atmosphereOrganic solvent

The invention discloses tetragonal nano zirconia with high specific surface and high purity, a preparation method of nano zirconia as well as an application in catalytic conversion of catalytic synthesis gas. The preparation method of the tetragonal nano zirconia comprises the steps as follows: (1) water-soluble zirconium salt or an aqueous solution of other hydrates is prepared, and a zirconium salt aqueous solution is obtained; (2) the zirconium salt aqueous solution is mixed with an organic solvent, and a mixed solution is obtained; (3) sodium oleate is added to the mixed solution, and the solution is heated until reflux is produced; (4) the system obtained in step (3) is left to stand for layering, an supernatant liquid is taken and dried, and zirconia oleate or zirconium oleate is obtained; (5) zirconia oleate or zirconium oleate is roasted in an oxygen atmosphere. The used solvent is low in boiling point, low in cost and easy to recycle; equipment is operated under the normal pressure, raw materials are roasted at the low temperature in an air atmosphere, energy consumption is lower, the equipment investment and operation cost are low, and industrial production is facilitated.

Owner:SYNFUELS CHINA TECH CO LTD

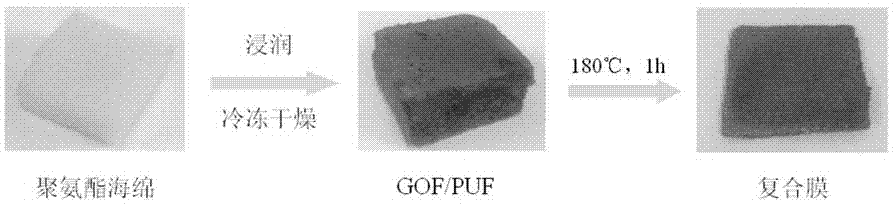

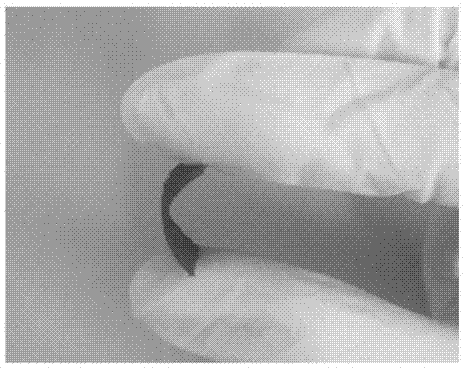

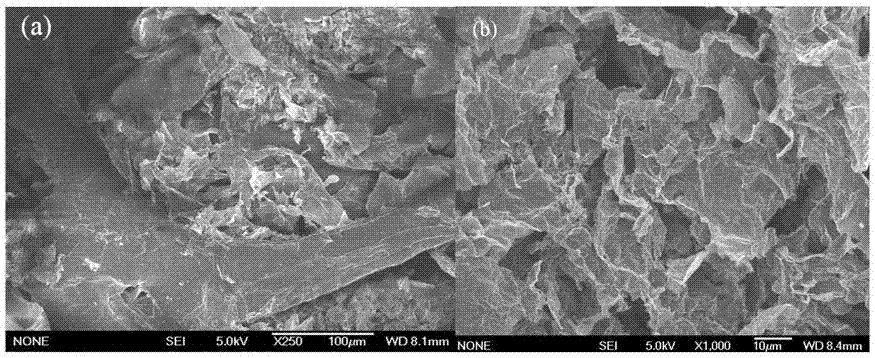

Reduced graphene oxide-polyurethane dual-sponge adsorption film, preparation method therefor and application of reduced graphene oxide-polyurethane dual-sponge adsorption film

ActiveCN106861657AImprove adsorption capacityNot easy to flowOther chemical processesWater contaminantsFreeze-dryingLarge size

The invention discloses a reduced graphene oxide-polyurethane dual-sponge adsorption film, a preparation method therefor and an application of the reduced graphene oxide-polyurethane dual-sponge adsorption film. The reduced graphene oxide-polyurethane dual-sponge adsorption film comprises reduced graphene oxide sponge and a polyurethane hot-pressed sponge film, wherein the reduced graphene oxide sponge is uniformly filled in pores of the polyurethane hot-pressed sponge film and is physically bonded with the polyurethane hot-pressed sponge film. The preparation method comprises the following steps: (1) preparing a graphene oxide-polyurethane sponge dispersion solution; (2) carrying out freeze drying; and (3) carrying out hot-pressing film forming. The reduced graphene oxide-polyurethane dual-sponge adsorption film has the advantages that the adsorption performance is good, the efficiency of removing contaminants from water is high, large-size preparation can be achieved, the adsorption film is easy to recover and can be repeatedly used, and the like; and the preparation method is simple in process and low in cost and advantageously achieves industrial production.

Owner:HUNAN UNIV

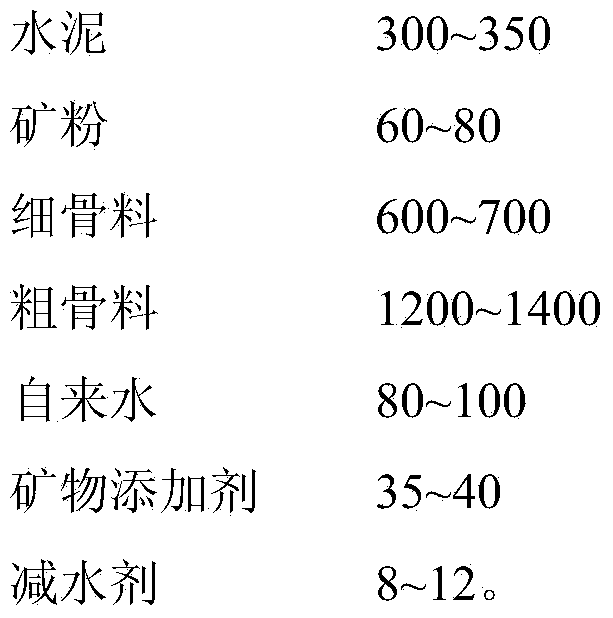

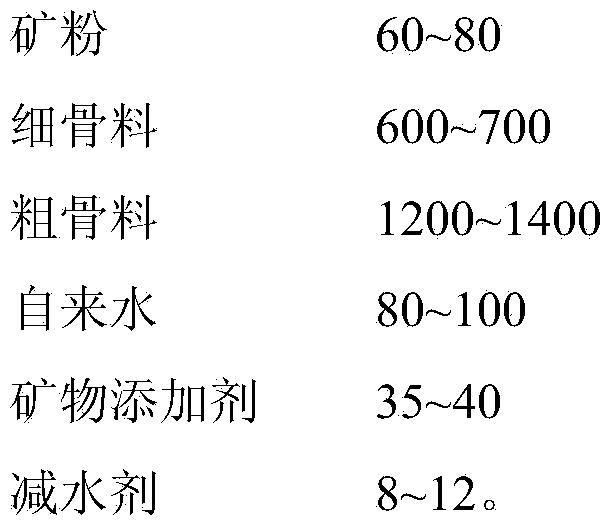

Remained slurry-free and non-autoclaved prestressed concrete pipe pile

The invention relates to a remained slurry-free and non-autoclaved prestressed concrete pipe pile, comprising the following raw components in parts by weight: 300-350 parts of cement, 60-80 parts of mineral powder, 600-700 parts of fine aggregate, 1200-1400 parts of coarse aggregate, 80-100 parts of running water, 35-40 parts of mineral additive, and 8-12 parts of water reducer. After a lot of experiments and contrastive analysis of the remained slurry-free and non-autoclaved prestressed concrete pipe pile, remained slurry-free centrifugation is achieved and one-time demoulding strength achieves C80 by adding a nano-sized mineral additive, matching with complexed high-performance water-reducer, and adjusting the centrifuging and steaming steps of the existing pipe pile. The procedures of removing the remained slurry and steaming are removed; the environmental pollution and energy consumption of enterprises are greatly reduced; the endurance quality of concrete is greatly improved.

Owner:TIANJIN YONGSHENG XINHE PILE

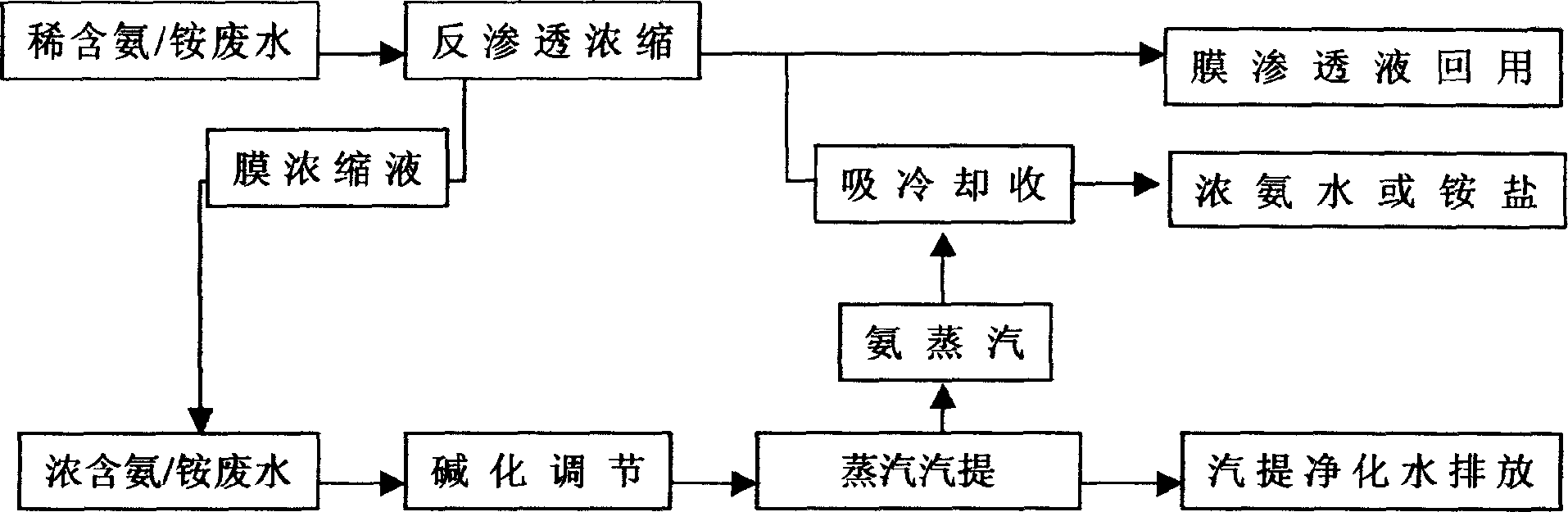

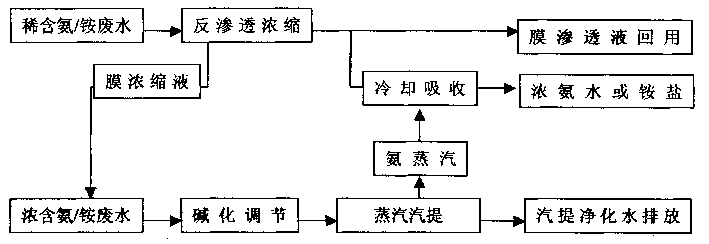

Process for reclaiming ammonia-contained sewage

InactiveCN1123543CHigh salt contentReduce dosageMultistage water/sewage treatmentHigh concentrationWastewater

A process for treating and recovering the ammonia / ammonium contained waste water generated in preparing catalyst includes reverse-osmosis concentration of the said waste with low ammonia content, direct use of the resultant liquid or partial use of it as the ammonia vapour absorbing liquid in stripping tower, mixing the concentrated liquid with the high-concentration the said waste water, adding alkali to regulate pH value, loading in stripping tower to recover ammonia from tower top and discharging the clean water. Its advantages include low energy and chemical consumption, and high recovery rate.

Owner:CHINA PETROCHEMICAL CORP +1

Production process of pyrolysis cyanuric acid

InactiveCN105906577ASave heatReduce energy consumptionOrganic chemistryThermal energySuperheated steam

The invention discloses a production process of pyrolysis cyanuric acid, comprising: pumping liquid urea at 132-140 DEG C continuously at a flow speed of 5-6 m / s under 5-10 m<3> / h into a roller barrel into which superheated steam at a temperature of 50-500 DEG C under a pressure of 3-4 Mpa under 500-1000 m<3> / h is introduced, polymerizing urea at 250-280 DEG C to generate crude cyanuric acid, refining the crude cyanuric acid from the roller kiln, and then preparing cyanuric acid 98.5-99% in purity. Heat required for melting urea can be saved, energy consumption can be effectively reduced, high-temperature steam produced in byproduct acid production from sulfur is used to provide heat, the defects such as low heat utilization rate of hot air, high coal firing consumption and high post-treatment cost of pollutants are overcome, zero environmental pollution is caused, heat loss is low, material consumption is low, product quality is stable, and product yield is high; operating is facilitated, safety is high, an operating environment is good, labor intensity is low, carbon emission is reduced, environmental pollution is reduced, heat utilization is increased, and product quality is improved.

Owner:王建伍 +1

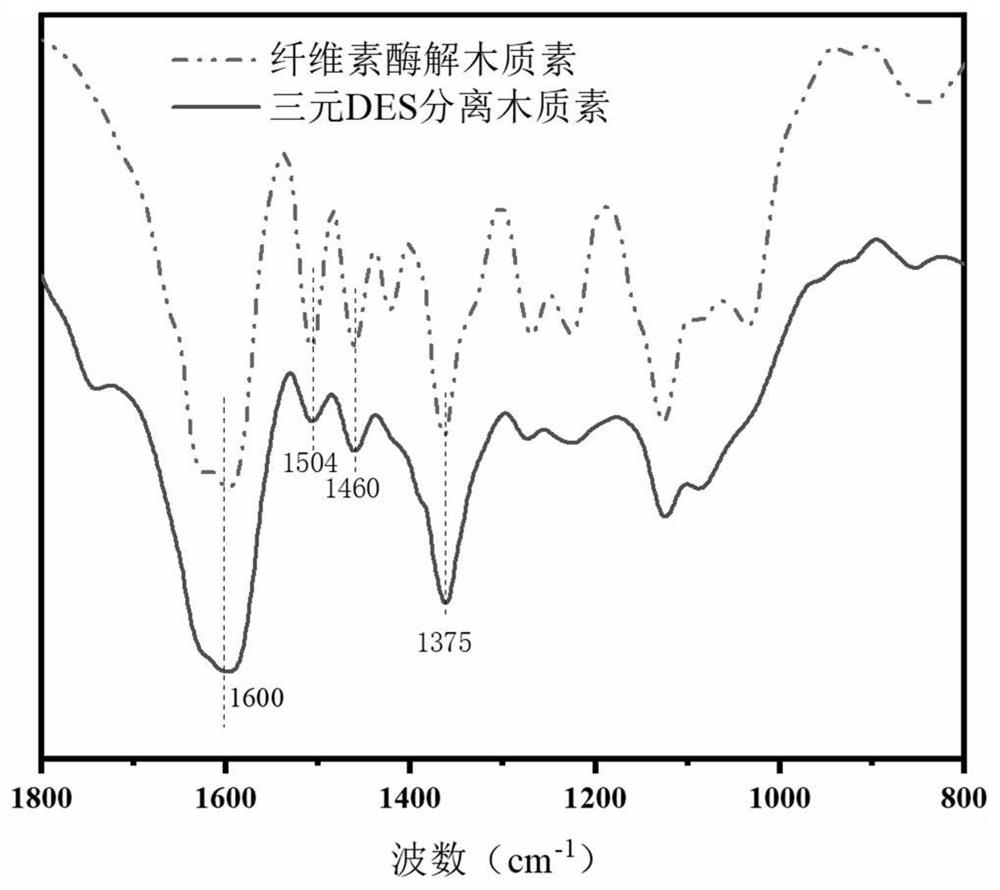

Method for rapidly separating lignin with high yield by using green solvent

The invention provides a method for rapidly separating lignin with high yield by using a green solvent. The method comprises the following steps: (1) mixing and heating a first hydrogen bond donor, a second hydrogen bond donor and a hydrogen bond acceptor to obtain a homogeneous transparent ternary eutectic solvent; (2) adding a lignocellulose raw material into the ternary eutectic solvent obtained in the step (1), and carrying out heating treatment to obtain a slurry; (3) adding an acetone aqueous solution into the slurry obtained in the step (2), stirring, then filtering to obtain a filtrate, washing filter residues with an acetone aqueous solution until a washing solution is colorless, and combining the filtrate and the washing solution; and (4) performing evaporation concentration, then performing extraction, adding saturated salt water for regeneration, and finally obtaining the lignin. The process is simple and convenient to operate, low in cost and environment-friendly.

Owner:BEIJING FORESTRY UNIVERSITY

Active carbon fiber-loaded NaBiO3-based composite oxide and preparation method thereof, and method for degrading organic dye waste water by using composite oxide

InactiveCN103623805ASimple equipment requirementsSimple requirementsWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsEpoxyFiber

The invention discloses an active carbon fiber-loaded NaBiO3-based composite oxide and a preparation method thereof and a method for degrading organic dye waste water by using the composite oxide. The preparation method comprises the following steps: successively cleaning an active carbon fiber with ammonia water, nitric acid, acetone and deionized water and drying the active carbon fiber for subsequent usage; synthesizing BSO from NaBiO3 and AgNO3 in a liquid phase and preparing a composite function material according to a mass ratio of BSO to NaBiO3 of 1: 1-3; and placing an epoxy resin and the composite function material according to a weight ratio of 1.5-2.5: 1 into a container containing acetone, carrying out high speed stirring, dipping the active carbon fiber 5 to 10 times of the mass of the composite oxide function material into an acetone solution for 2 h and successively subjecting the active carbon fiber to vacuum drying and then to heat treatment under the protection of N2 so as to obtain the composite oxide. The degradation method comprises the following steps: adding 2 to 5 g / L of the composite oxide into the organic dye waste water under irradiation by visible light; carrying out stirring at room temperature and normal pressure; and discharging waste water through centrifugation after basic decolouring of the waste water. The degradation method provided by the invention has the advantages of simple requirements on equipment, low energy consumption, convenient operation and capacity of achieving the purposes of decolouring, degradation and mineralization of the dye waste water in a short period of time.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

Production method of concrete pipe pile

InactiveCN104742249AReduce pollutionReduce energy consumptionSolid waste managementShaping reinforcementsPre stressSlurry

The invention relates to a production method of a concrete pipe pile. The production method comprises the following steps: (1) a fine aggregate, a coarse aggregate, cement, mineral powder, sodium silicate, water and a water reducing agent are added into a reaction kettle in sequence, and are evenly mixed to obtain a concrete mixture; (2) the prestress tension is performed for the concrete mixture after the material distribution and the mold assembly; (3) the concrete mixture is centrifuged after the prestress tension; and (4) the centrifuged concrete mixture is put in a steaming pool for steaming. The sodium silicate is added by multiple experiments through the contrastive analysis, and fits the compounded high-performance water reducing agent, and traditional pipe pile centrifuging and steaming steps are adjusted, so that no residual slurry is generated in centrifuging, the once demolding strength reaches C80, the procedures of residual slurry pouring and steaming are omitted, and the environmental pollution of enterprises and the energy consumption are greatly reduced.

Owner:TIANJIN ZEYUAN CONCRETE CO LTD

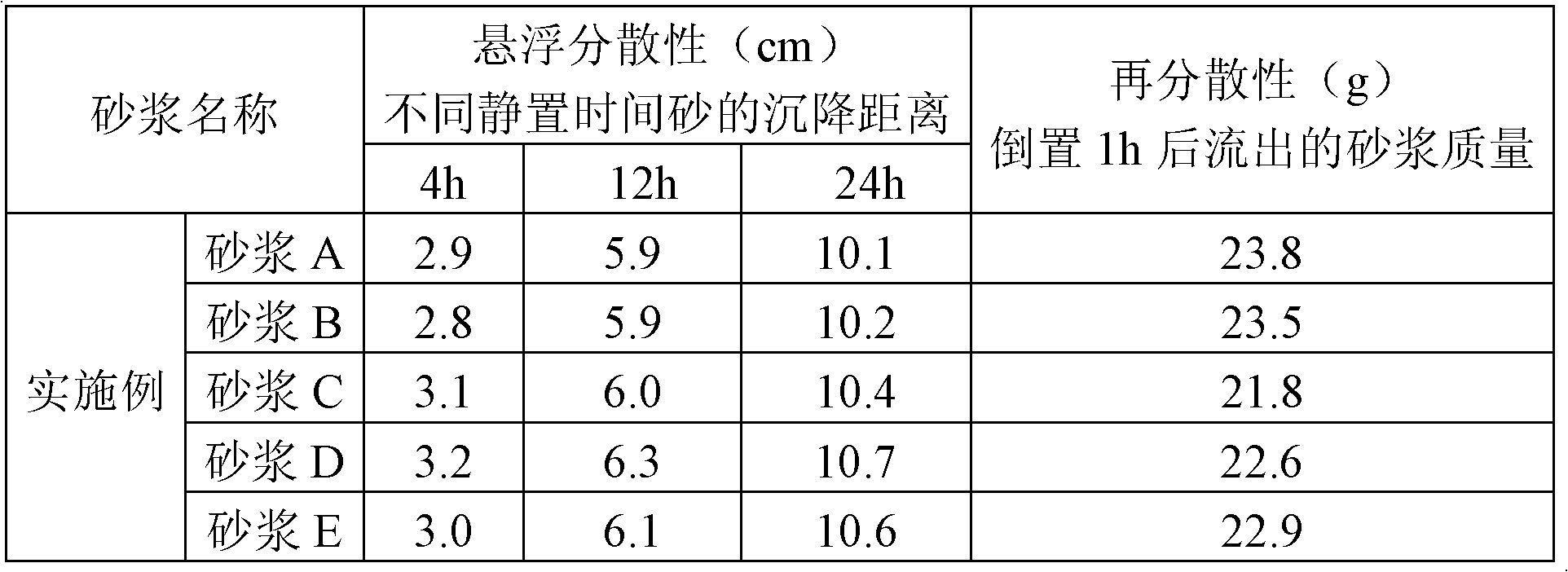

Method for improving dispersibility of silicon carbide mortar

ActiveCN101979483ASave configuration timeImprove quality and efficiencyAdditivesSingle crystalAqueous solution

The invention provides a method for improving the dispersibility of silicon carbide mortar. The method comprises the following steps of: adding a dispersant which is in the mass of 0.001 to 10 percent of that of silicon carbide into 20 to 80 weight percent of a silicon carbide aqueous solution system at the temperature of between 20 and 70 DEG C; stirring for 30 to 120 minutes; after washing withwater, controlling the pH of the silicon carbide aqueous solution to be between 3 and 8; and drying to obtain high-dispersibility and high-redispersibility silicon carbide micro powder. The silicon carbide powder processed by the method of the invention is used for cutting monocrystalline silicon and polycrystalline silicon, can effectively shorten the preparation time of cutting fluid mortar, and solves the problem that the silicon carbide micro powder is difficult to redisperse in a cutting or recovering process.

Owner:LIAONING OXIRANCHEM INC

Compound immobilization method for fructosyl transferase

InactiveCN104560936ANovel cracking methodNovel methodMicroorganism based processesOn/in organic carrierCalcium alginateBatch reaction

The invention discloses a compound immobilization method for fructosyl transferase, and belongs to the field of biotechnologies. The technology has the advantages that fructosyl transferase extraction technological equipment is simple; the fructosyl transferase is embedded by calcium alginate after chitosan covalence immobilization; the problems of forming and integer of chitosan covalence immobilized enzyme can be solved; the immobilization efficiency of the enzyme is high (enzyme activity recovery rate reaches above 70%); the enzyme can be used repeatedly for more than 85 times during batch reaction.

Owner:BAOLINGBAO BIOLOGY

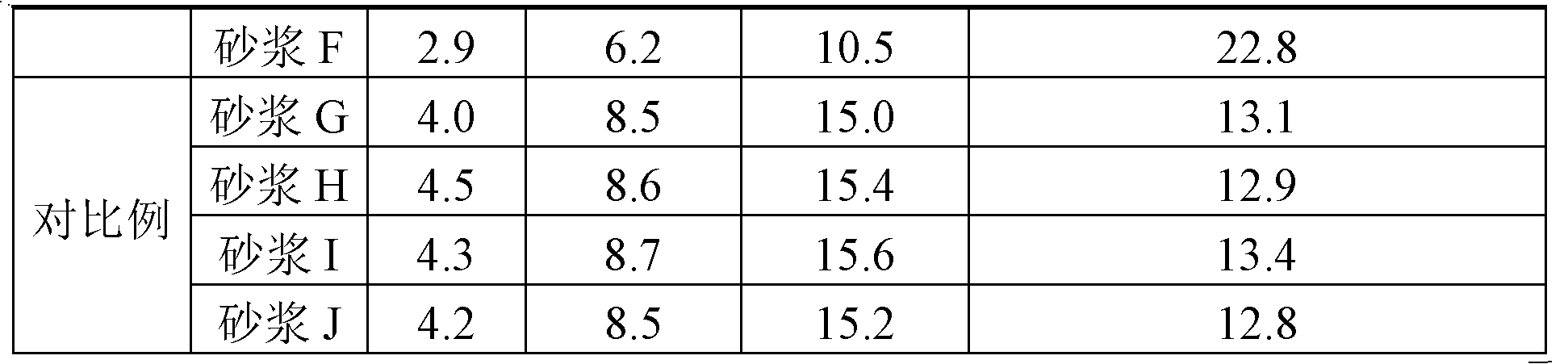

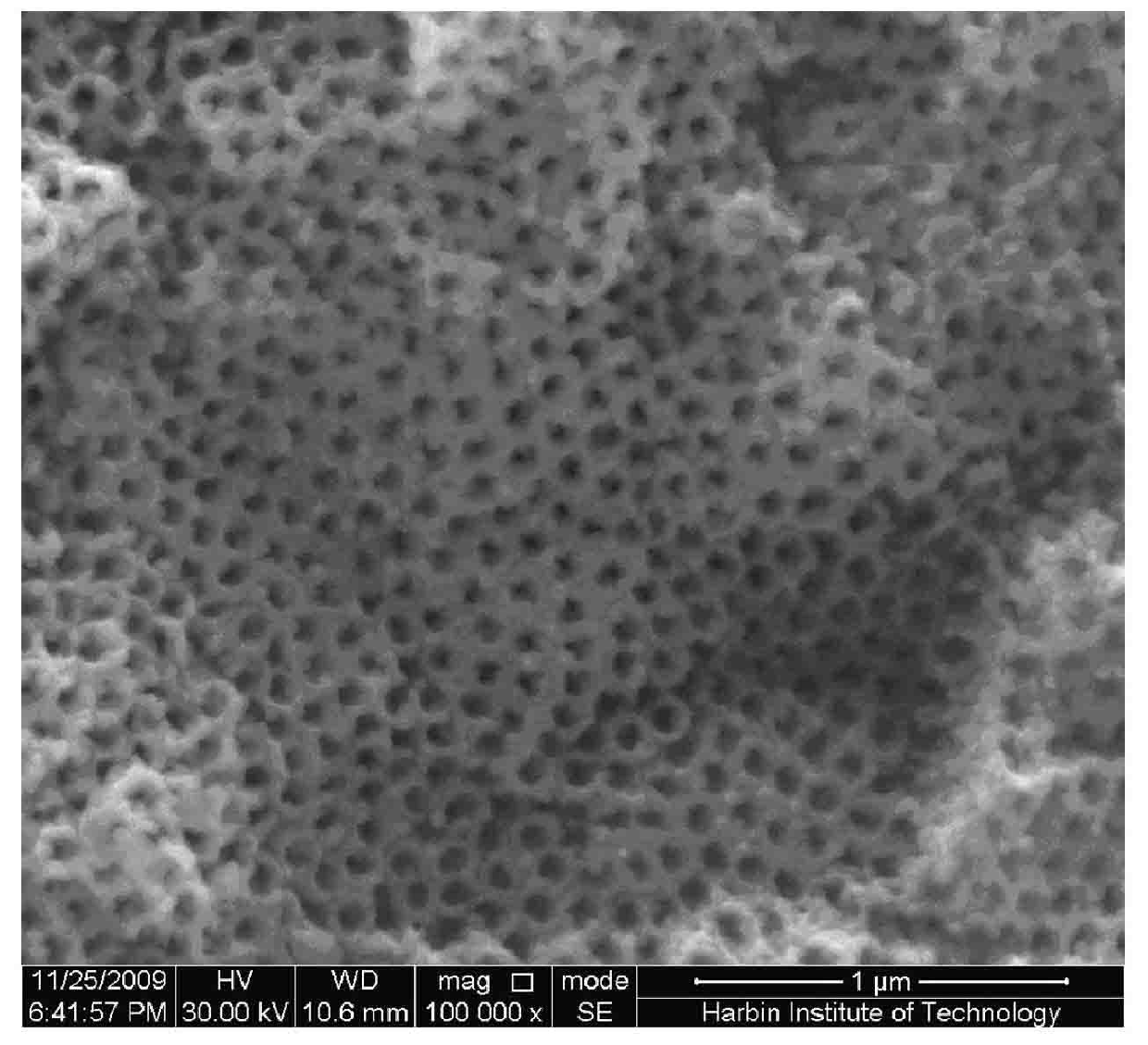

Perovskite-based nanotube array composite material and preparation method thereof

InactiveCN101767768AEnhancing the Quantum Size EffectHigh quantum size effectIndividual molecule manipulationSurface reaction electrolytic coatingAlkaline earth metalUltraviolet lights

The invention discloses a perovskite-based nanotube array composite material and a preparation method thereof, relating to a nanotube array composite material and a preparation method thereof. The invention solves the problems that the conventional perovskite-based nano-film photocatalyst has low degradation ratio on organic matters, and the perovskite-based nanotube array composite material photocatalyst is not reported. The perovskite-based nanotube array composite material is prepared from titanium material sheets, an electrolyte solution, an alkaline-earth metal hydroxide water solution and a metal nitrate water solution. The preparation method comprises the following steps of: polishing and washing the titanium material sheets, then anodizing in the electrolyte solution, putting intothe alkaline-earth metal hydroxide water solution for carrying out hydrothermal reaction, soaking in the metal nitrate solution and then carrying out reductive treatment by ultraviolet lights to obtain the perovskite-based nanotube array composite material. The perovskite-based nanotube array composite material has the degradation ratio on methyl orange is 30 to 85 percent and can be reused and used for carrying out photocatalytic degradation on pollutants in atmosphere and water; and the preparation method can carry out large-area film formation.

Owner:HARBIN NORMAL UNIVERSITY

Recovery process of waste materials generated in industrial manufacture process of poly-p-phenylene terephthamide aramid fiber II

InactiveCN102560748ANot easy to recycleNot easy to useArtificial filament recoveryArtificial filament washing/dryingEngineeringHot melt

The invention relates to a recovery process of waste materials generated in an industrial manufacture process of poly-p-phenylene terephthamide aramid fiber II, belonging to the field of synthetic fibres. The recovery process of waste materials generated in the industrial manufacture process of the poly-p-phenylene terephthamide (PPTA) aramid fiber II is characterized in that the waste materials of aramid fiber II can be manufactured into valuable products, and the environmental safety is not harmed. According to the recovery process, the solubility of the poly-p-phenylene terephthamide in concentrated sulfuric acid is utilized, and the hot melt of poly-p-phenylene terephthamide / sulfuric acid solution is utilized for recovery processing. Different processing and recovering processes and parameters are designed according to different waste materials, the waste materials are recovered together to be made into the aramid fiber II staple, and therefore cost is saved.

Owner:王锡璐

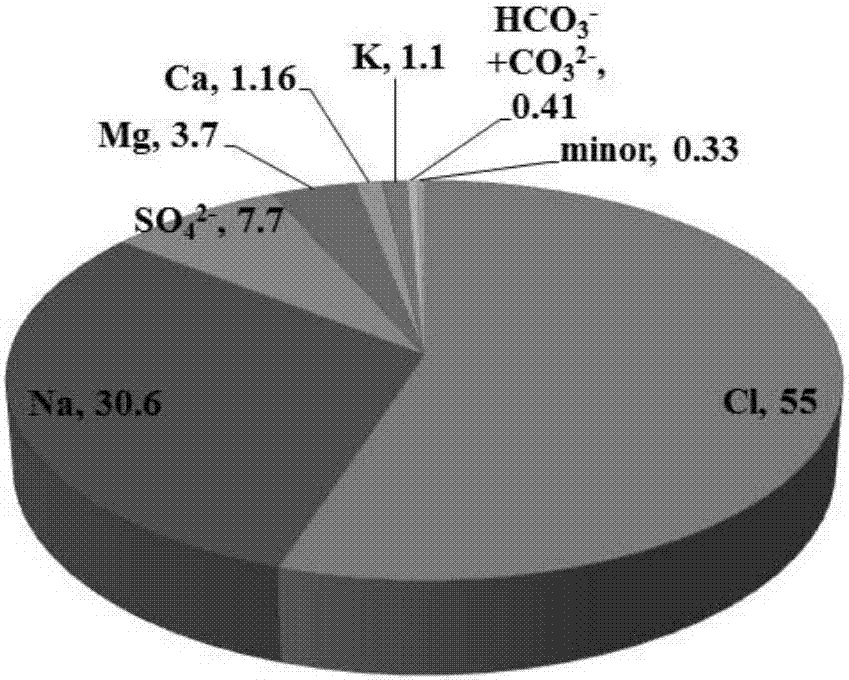

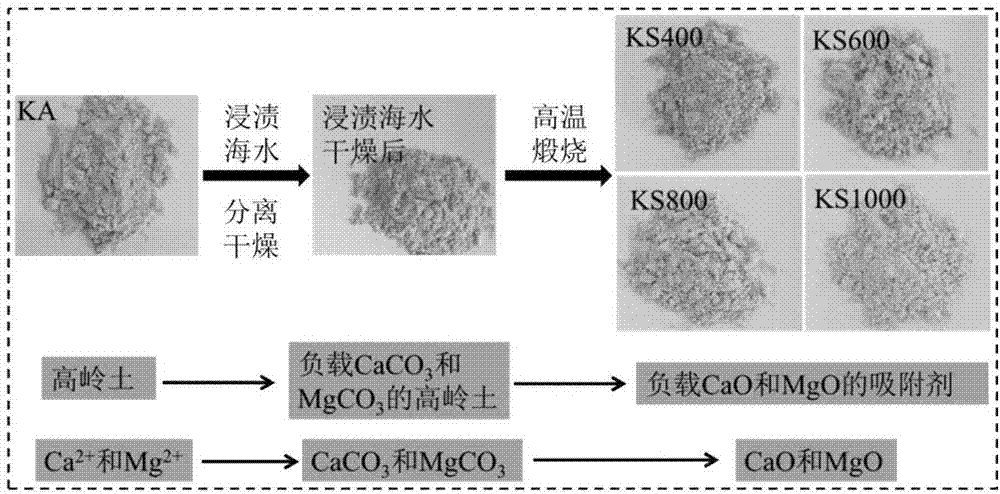

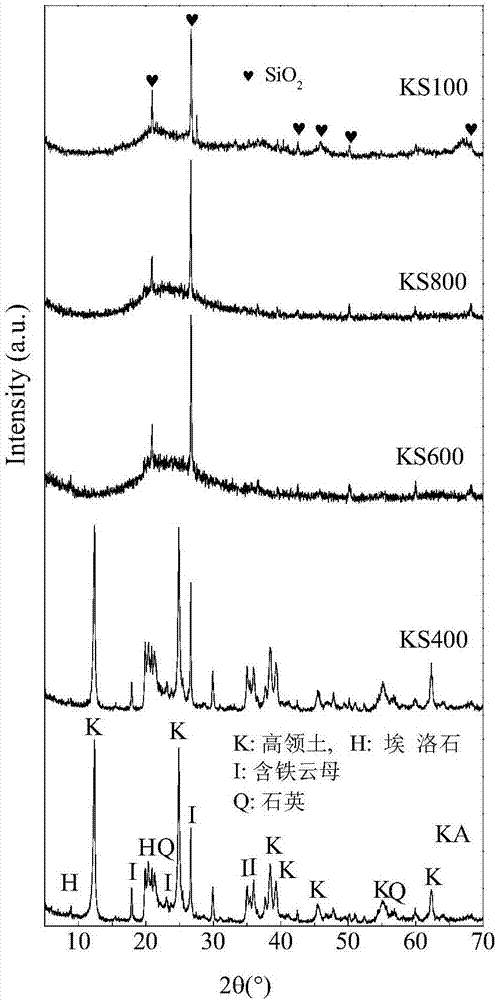

Preparation method for adsorbent for removing phosphorus in water

InactiveCN107185479AHigh phosphorus removal rateNot easy to recycleOther chemical processesWater contaminantsSorbentRoom temperature

The invention relates to a preparation method of an adsorbent, in particular to a preparation method of an adsorbent for removing phosphorus in water, and belongs to the field of environmental engineering. A method for preparing an adsorbent for removing phosphorus in water, the method comprising the following steps: adding seawater to kaolin, mechanically stirring and mixing at room temperature, removing the clarified liquid after natural precipitation, and washing with water to obtain kaolin mud; Drying, crushing, and calcining to obtain an adsorbent for phosphorus removal in water. Compared with the prior art, the invention adopts a simple method to prepare an adsorbent for phosphorus removal in water, and the phosphorus removal rate of the adsorbent is extremely high, greater than 97%, even up to 99%.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

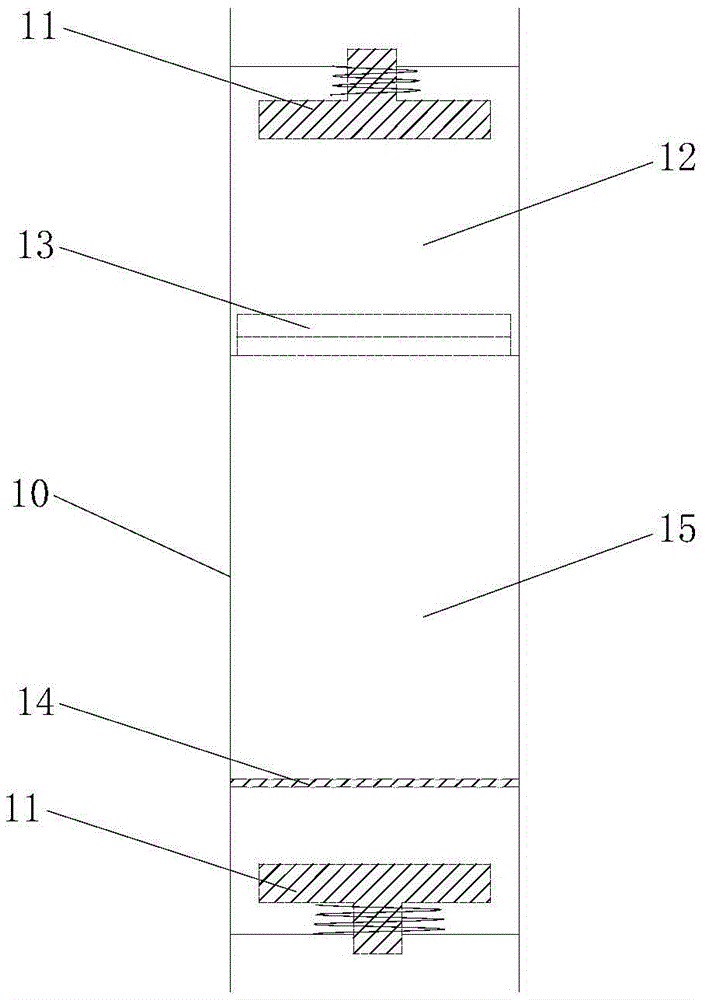

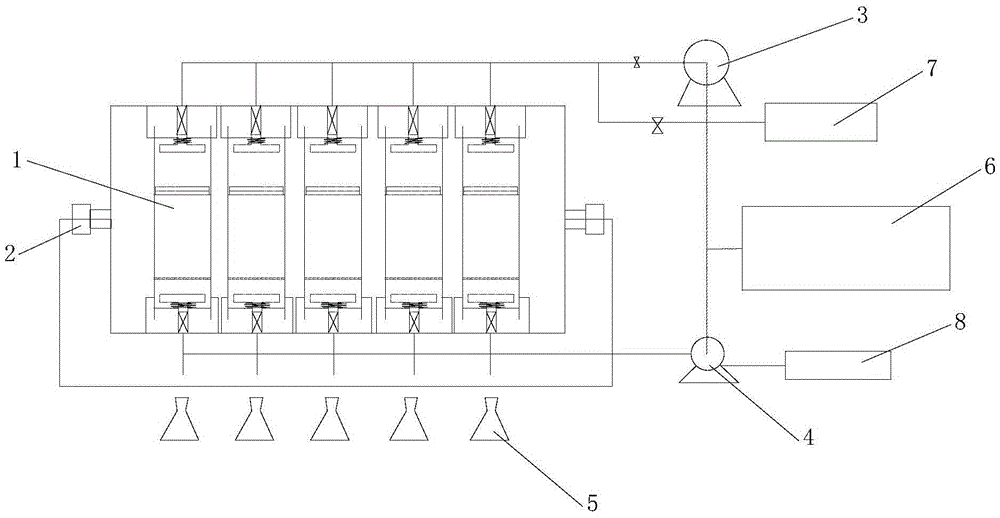

Soil fumigation capsule, fumigation and digestion device and fumigation and digestion process

InactiveCN105638626AImprove the efficiency of fumigation and extractionReduce health risksInsect catchers and killersSoil-working methodsHealth riskEngineering

The invention discloses a soil fumigation and digestion device. The device comprises multiple soil fumigation capsules, a rotary frame, an air-blowing and fluid injection system, a vacuum system and vibration fluid collection vessels, the air-blowing and fluid injection system conducts air blowing and fluid injection on a sealed piston at the top of each soil fumigation capsule, the vacuum system conducts vacuumization on a sealed piston at the bottom of each soil fumigation capsule, the soil fumigation capsules are installed on the rotary frame side by side and connected through pipes, each pipe is provided with an independent valve, and each capsule can be assembled and disassembled without influencing running of the whole system. By means of the technical scheme of the soil fumigation and digestion device, soil fumigation and digestion efficiency is improved, potential environmental risks and operator health risks caused by fumigant are decreased, working load of performing conventional soil fermentation and digestion is greatly lowered, the fumigant can be recycled, and part of fumigant can be reutilized through extraction and purification. Meanwhile, the invention provides a soil fumigation and digestion device and a soil fumigation and digestion process.

Owner:NORTH CHINA INST OF AEROSPACE ENG

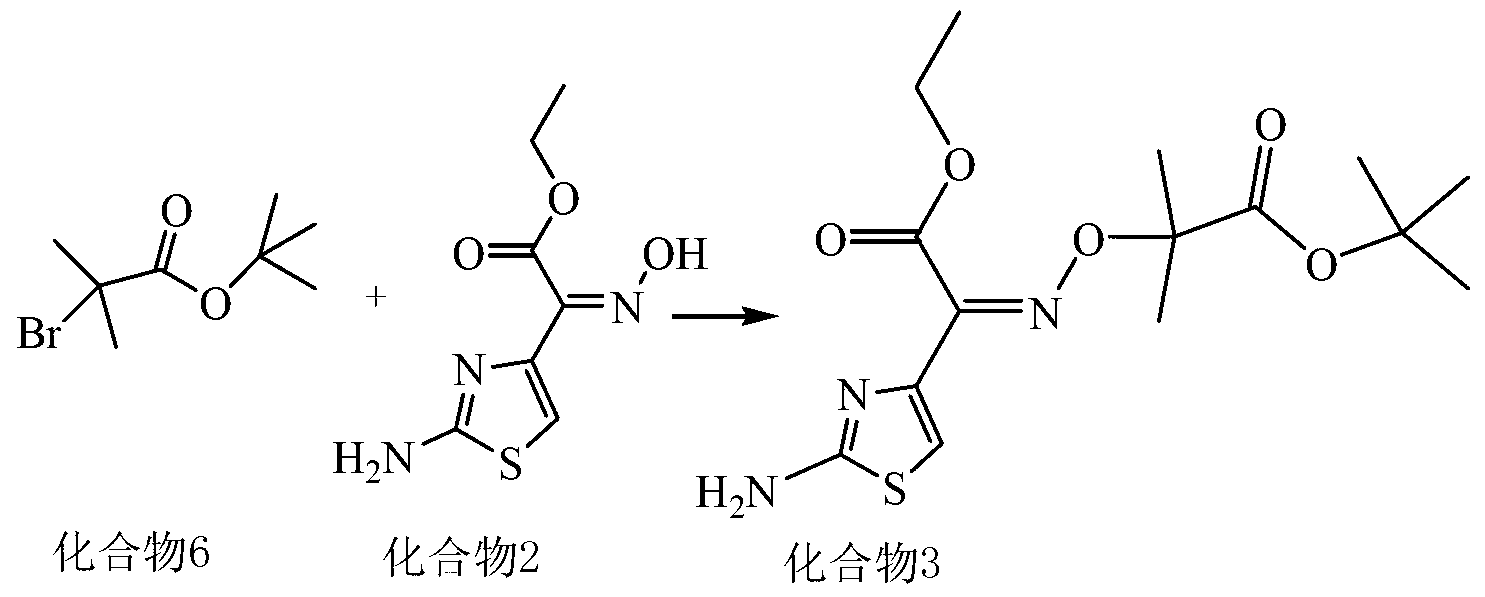

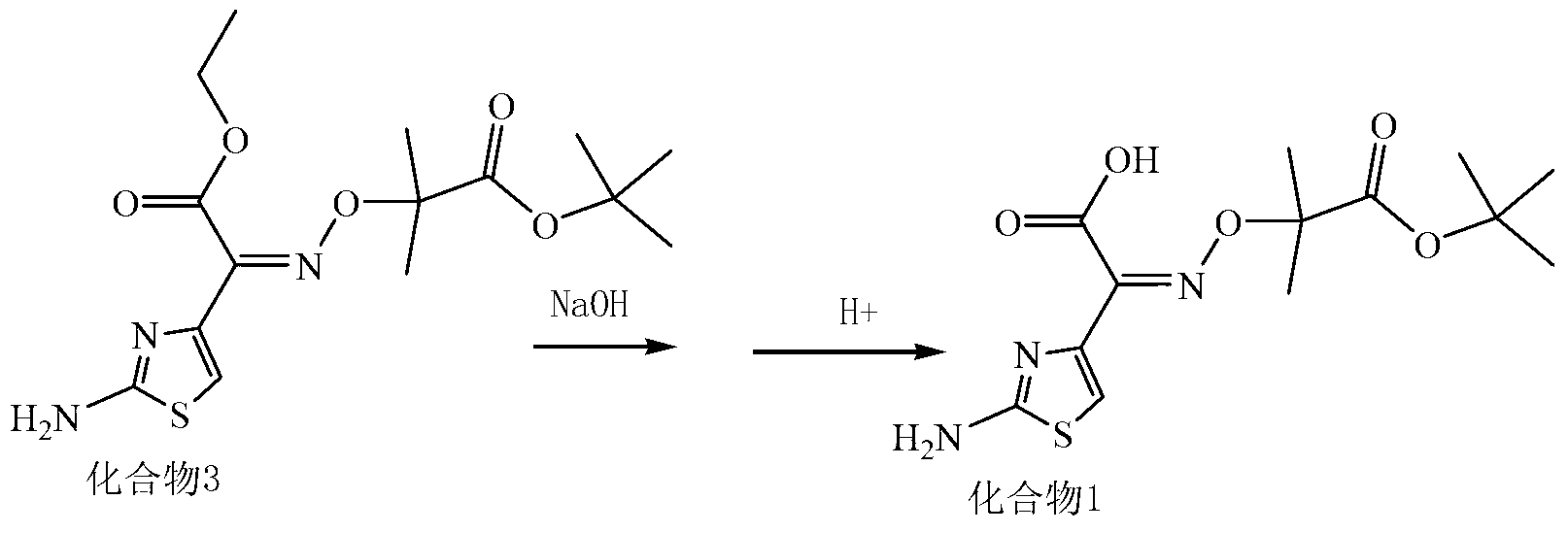

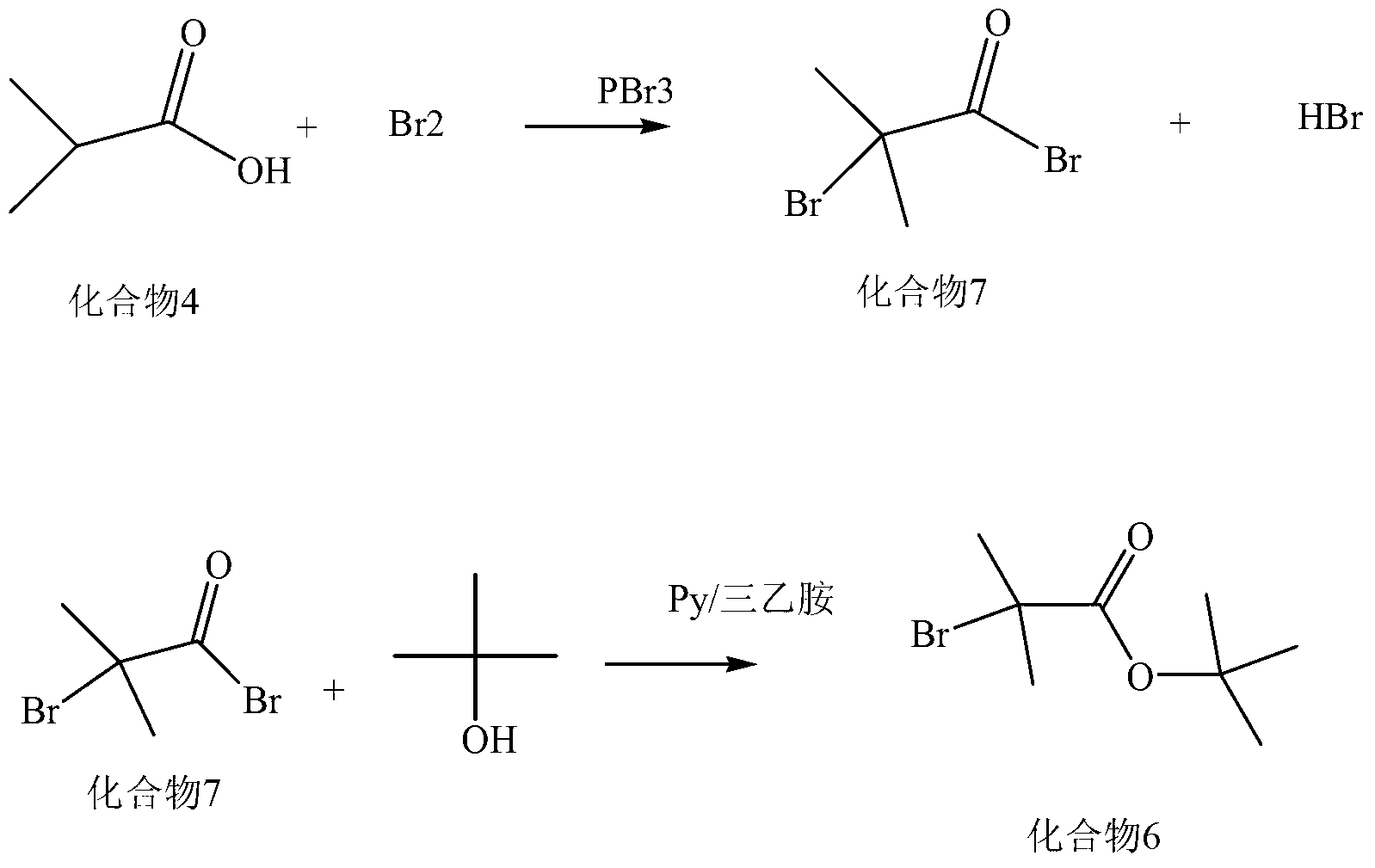

Synthesis method of new cephalosporin side-chain intermediate compound

ActiveCN103232405AIncrease profitImprove conversion rateOrganic compound preparationCarboxylic acid esters preparationSide chainDistillation

The invention discloses a synthesis method of a new cephalosporin side-chain intermediate compound, which comprises the following steps: by taking isobutyric acid and element bromine as raw materials, dropwisely adding the element bromine more than once, reacting to obtain alpha-bromoisobutyric acid, wherein after the element bromine is dropwisely added each time, chlorine gas is introduced to further react, so that the HBr byproduct is converted into element bromine which can be used for reaction with the isobutyric acid; reacting the obtained alpha-bromoisobutyric acid and isobutylene under the action of a protonic acid strong catalyst, and performing direct distillation to obtain tert-butyl alpha-bromoisobutyrate; performing alkylation reaction on the tert-butyl alpha-bromoisobutyrate and ethyl 2-(2-aminothiazol-4-yl)-2-hydroxyiminoacetate under the catalytic action of a phase-transfer catalyst by taking acetone as solvent; and hydrolyzing to obtain (Z)-2-amino-alpha-[[2-(tert-butoxy)-1,1-demethyl-2-oxoethoxy]imino]-4-thiazol acetic acid. The production process disclosed by the invention has the advantages of simple process, high raw material conversion rate and yield, environment friendliness and low cost.

Owner:APELOA PHARM CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com