Perovskite-based nanotube array composite material and preparation method thereof

A technology of nanotube arrays and composite materials, which is applied in the field of nanotube array composite materials and its preparation, can solve the problems of low degradation rate of organic matter, achieve the effects of improved degradation rate, high-efficiency photocatalytic properties, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

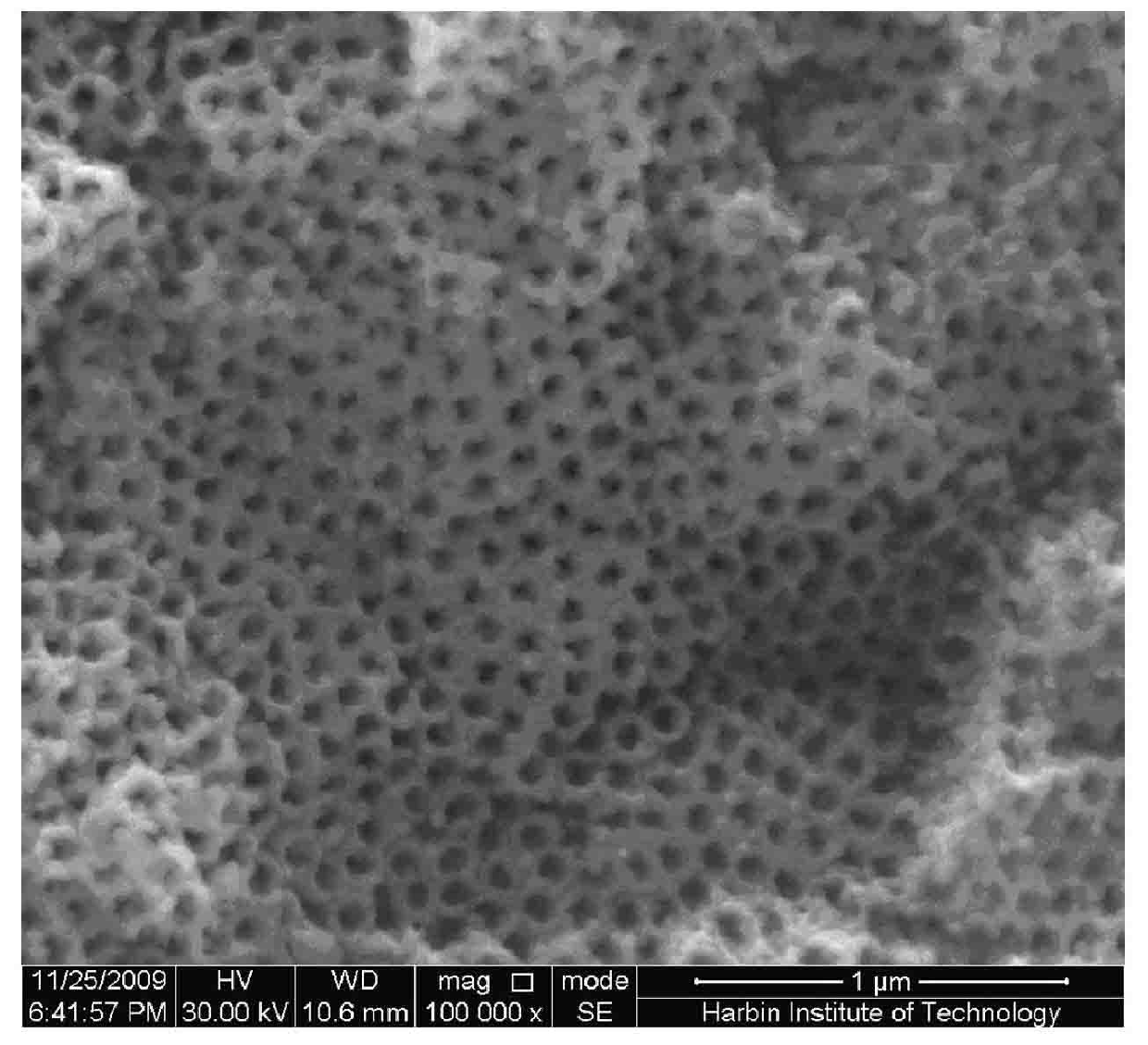

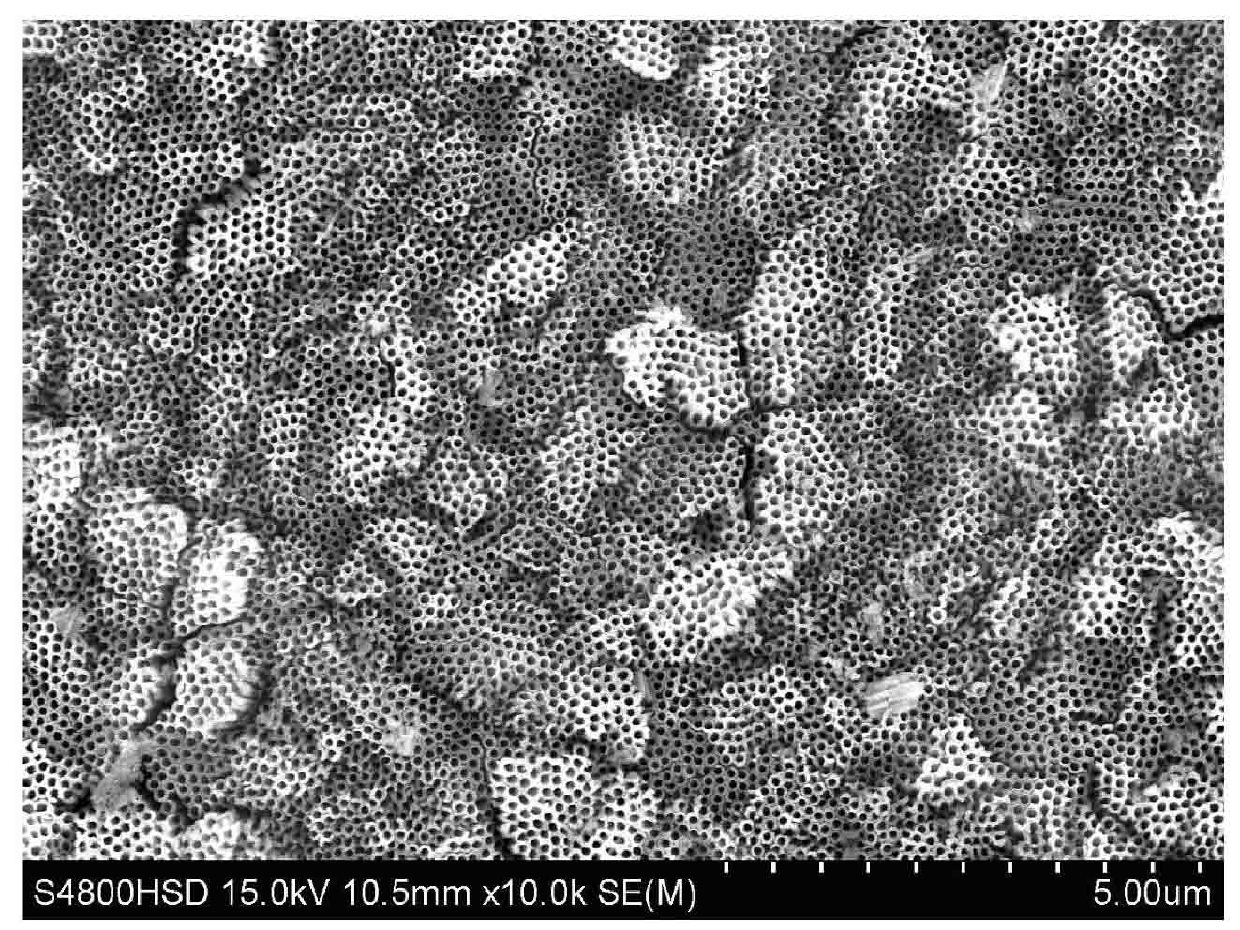

[0014] Embodiment 1: The perovskite-based nanotube array composite material of this embodiment is composed of a titanium metal material sheet, an electrolyte solution, an alkaline earth metal hydroxide aqueous solution with a concentration of 0.025 mol / L to 0.1 mol / L, and a concentration of It is made of 0.05mol / L~3mol / L metal nitrate aqueous solution; the electrolyte solution is prepared according to the ratio of 50mL~200mL ethylene glycol, 1mL~20mL water and 0.1g~2g ammonium fluoride; metal nitrate It is silver nitrate or palladium nitrate.

[0015] The perovskite-based nanotube array composite material of this embodiment has the advantage of immobilizing the catalyst, and has the characteristics of a higher quantum size effect of the nanomaterial due to the size reduction, and exhibits high-efficiency photoelectrocatalytic properties. After 15 minutes of degradation under 350W ultraviolet light, the degradation rate is 30% to 85%, which is 20% to 50% higher than that of the...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that the titanium metal material sheet is a titanium-tantalum alloy sheet, a titanium-niobium alloy sheet, a titanium-vanadium alloy sheet or a titanium sheet with a mass purity ≥ 99.0%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the alkaline earth metal hydroxide is barium hydroxide, strontium hydroxide or calcium hydroxide. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com