Preparation method of fully-inorganic cesium-lead-halogen perovskite nanocrystalline film

A cesium lead halide and perovskite technology, applied in the field of materials science, can solve the problem of single substrate selection, achieve the effect of simple operation, large selection flexibility, and favorable for large-area deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

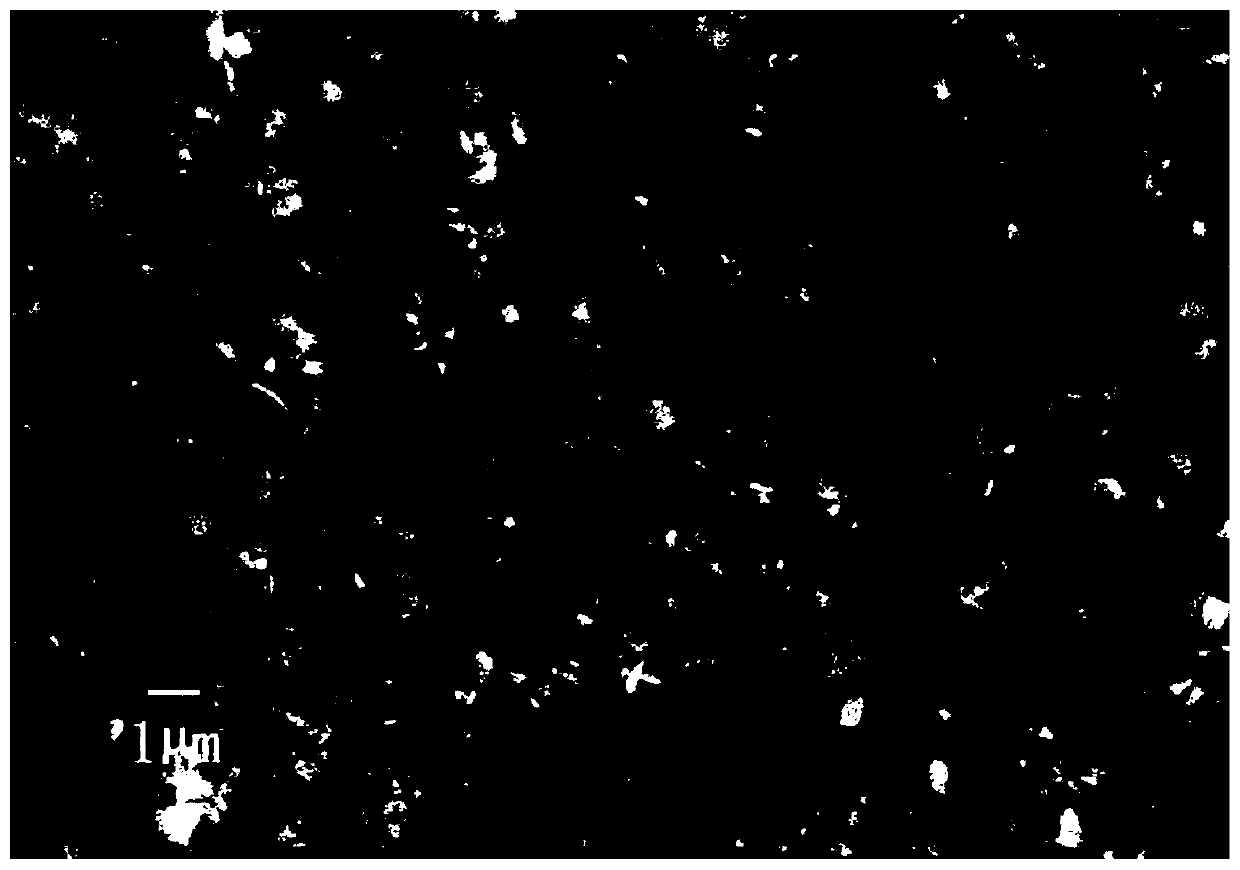

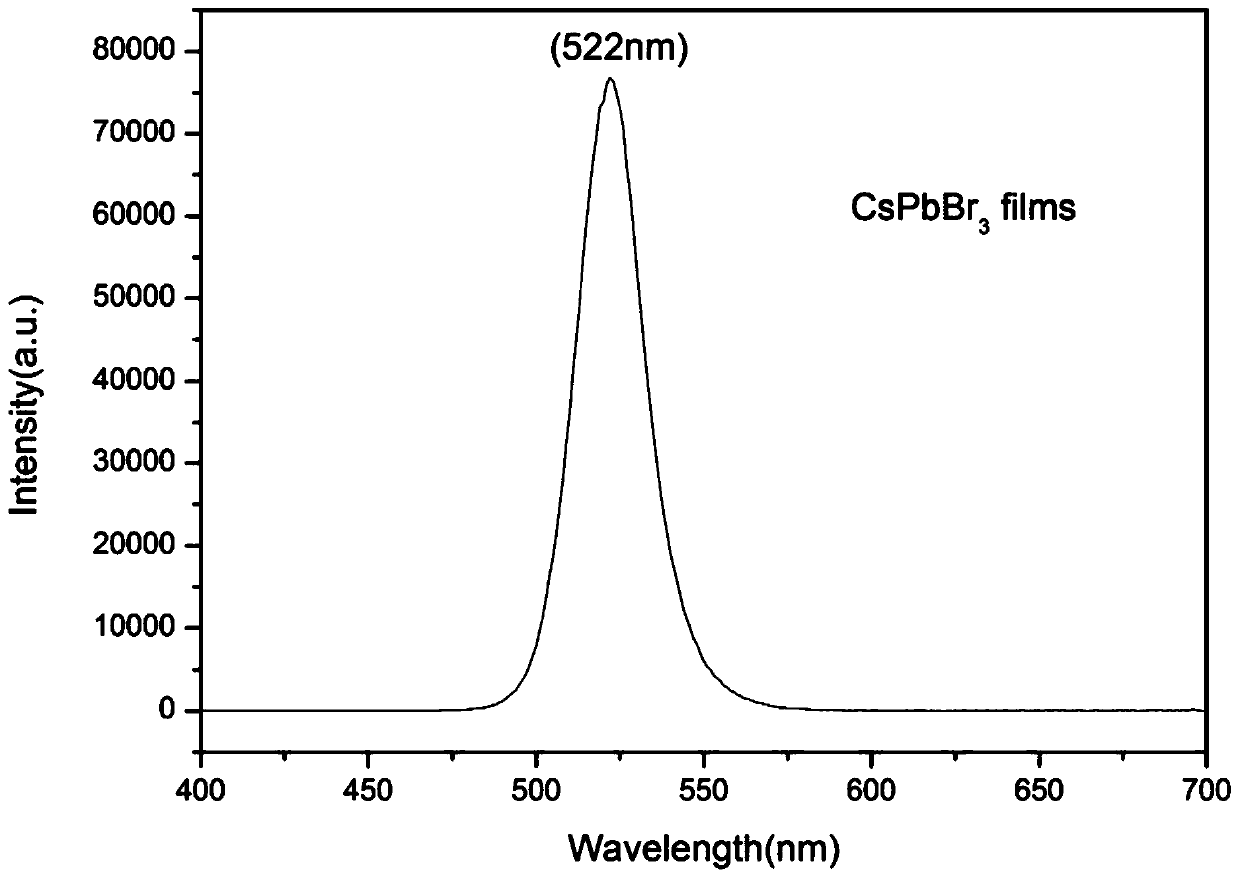

[0042] A method for preparing an all-inorganic cesium lead halide perovskite nanocrystalline film, specifically comprising the following steps:

[0043] (1) A preparation step of a precursor solution. Take 20mL N,N-dimethylformamide (DMF), 2mL oleic acid and 0.3mL oleylamine. The volume ratio of the above three reagents is 10:1:0.15. DMF, oleic acid and oleylamine are mixed at room temperature and ready to use; the purity of analytically pure CsBr and PbBr is weighed at a ratio of 1:1. 2 Add 1.6mmol of each powder into the mixed solution of DMF, oleic acid and oleylamine, the concentration of each solute is 0.08mol / L, stir for 15min, after standing still for 30min, centrifuge to get a clear solution, which is the preparation of perovskite nanocrystalline film. The required precursor solution;

[0044] (2) A preparation step of a perovskite nanocrystalline thin film, using ordinary glass as a thin film substrate, first cleaning the substrate with ethanol, then ultrasonic clean...

Embodiment 2

[0049] A method for preparing an all-inorganic cesium lead halide perovskite nanocrystalline film, specifically comprising the following steps:

[0050] (1) Preparation of precursor solution, take 20mL DMF, 2mL oleic acid and 0.3mL oleylamine, the volume ratio of the above three reagents is 10:1:0.15, mix DMF, oleic acid and oleylamine at room temperature and wait Use; according to the ratio of 1:0.1:0.9 to weigh the purity of analytically pure CsBr, PbBr 2 and PbI 2 Add 1.6mmol, 0.16mmol and 1.44mmol of the powder into the mixed solution of DMF, oleic acid and oleylamine, stir for 15min, and after standing for 30min, centrifuge to get the clear solution, which is the precursor required for the preparation of perovskite nanocrystalline film body solution;

[0051] (2) The preparation of perovskite nanocrystalline film, using ITO glass as the film substrate, the substrate is first cleaned with ethanol, then ultrasonically cleaned, and finally dried for use; the substrate is h...

Embodiment 3

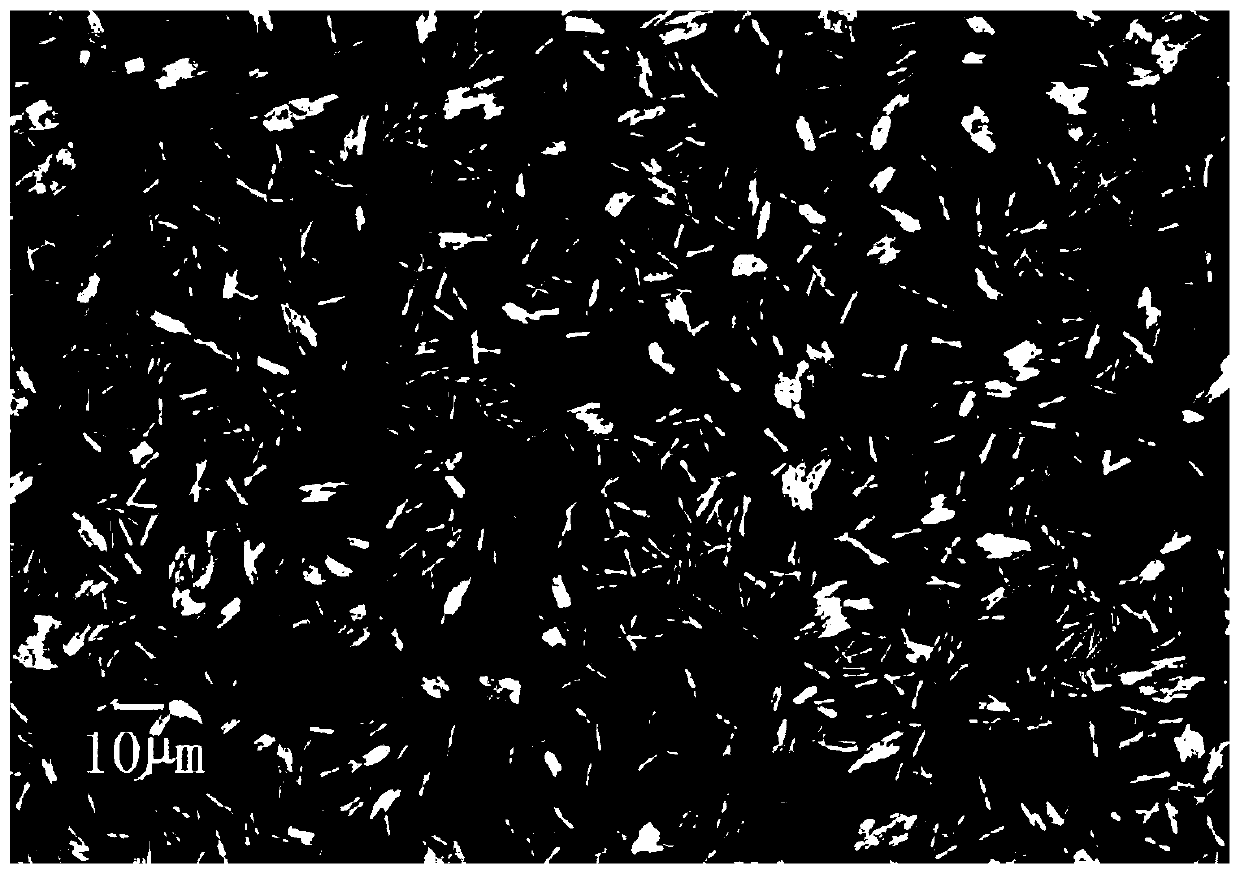

[0056] A method for preparing an all-inorganic cesium lead halide perovskite nanocrystalline film, comprising the following steps:

[0057] 1) DMF, oleic acid and oleylamine are uniformly mixed in a volume ratio of 10:0.5:0.05 to obtain a mixed solution;

[0058] 2) CsCl, CsI and PbBr 2 Add to the mixed solution in step 1) at a molar ratio of 0.5:0.5:1, and after stirring for 10 minutes, standing for 25 minutes, and centrifuging, take a clear solution to obtain a CsCl and CsI concentration of 0.005mol / L , PbBr 2 The concentration is the precursor solution of 0.01mol / L;

[0059] 3) The FTO glass is cleaned with ethanol, ultrasonically cleaned, dried, and heated to 160°C, and then the precursor solution in step 2) is sprayed on the film substrate while it is hot through a high-pressure spray gun to obtain an all-inorganic cesium lead halide Perovskite nanocrystalline film;

[0060] Wherein, during the spraying process in step 3), the distance between the spray gun and the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com