Flexible transparent electric conducting film and preparation method thereof

A technology of transparent conductive film and manufacturing method, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., and can solve the problem of high resistance of flexible transparent conductive film, poor dispersion of nano-silver wire, and printing thickness of transparent ink Thickness and other issues, to achieve the effect of improving mechanical stability, high binding force, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

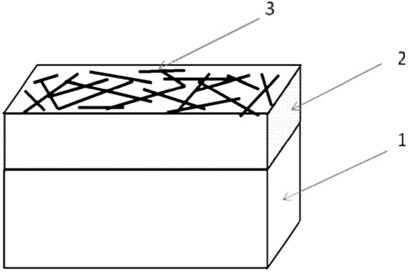

[0029] Example 1, such as figure 1 As shown, a flexible transparent conductive film is a sheet-like multilayer structure, including a flexible transparent substrate 1, which is the supporting base layer of the entire conductive film. The surface of the flexible transparent substrate 1 is coated with a transparent ink layer 2 formed by transparent ink, the surface layer of the transparent ink layer 2 is a conductive layer 3 adhered with silver nanowires, and the silver nanowires in the conductive layer 3 overlap each other connected to form a uniform two-dimensional silver nanowire network. Since nano-silver wires are distributed on the surface layer of transparent ink layer 2 by hot pressing or transfer printing, the network of nano-silver wires in conductive layer 3 can be a good seepage network thin layer, and nano-silver wires are adhesive Attached to the surface layer of the transparent ink layer 2; therefore, its two-dimensional conductive properties will not be affected...

Embodiment 2

[0040] Embodiment 2, a kind of manufacturing method of flexible transparent conductive film, comprises the following steps:

[0041] (1) Choose a flexible transparent substrate. The requirement for a flexible transparent substrate is to be thermoplastic and transparent in the visible light region. Therefore, materials that meet this condition can be used to manufacture flexible transparent substrates. Specifically preferred is a flexible transparent substrate made of polyethylene phthalate, polybutylene phthalate, polyethylene naphthalate or polycarbonate, and the size and shape of the flexible transparent substrate will be manufactured according to actual conditions. The size of the conductive film is determined. Print or coat the transparent ink evenly on the flexible transparent substrate, dry or cure the transparent ink, the drying can be natural drying or heating drying, the drying temperature is from room temperature to 180°C, so that the transparent ink can firmly adher...

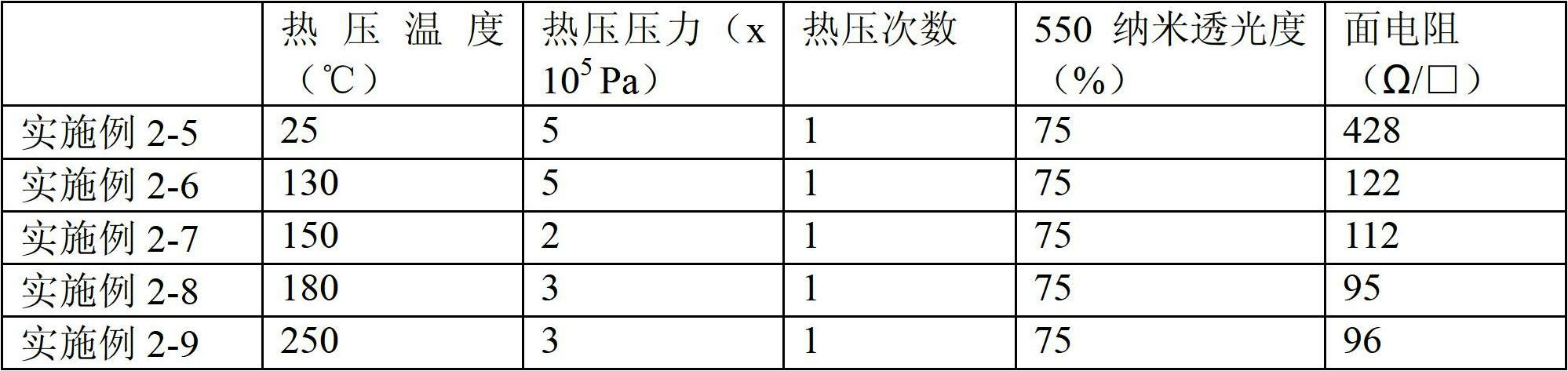

Embodiment 2-10 to Embodiment 2-15

[0058] Examples 2-10 to 2-15 were manufactured using the steps of Example 2 above, and the specific materials and experimental conditions were as follows: the material of the flexible transparent substrate was polycarbonate (purchased from DuPont Teijin Melinix, with a thickness of 80 μm), The material of the transparent ink is polyethylene glycol butyral (the number average molecular weight is 1 million, the glass transition temperature is 72 ℃), the average diameter of the nano-silver wire is 80 nanometers, and the average length is 8 μm. The concentration is 0.42wt%, and the flexible substrate coated with silver nanowires is polyethylene phthalate (thickness 12 μm). The drying condition is to dry at 80°C for 15 minutes. The hot pressing temperature is 130°C, and the hot pressing pressure is 5x10 5 Pa, the number of times of hot pressing is one time. The obtained results are listed in Table 3.

[0059] Table 3 The relationship between the thickness of transparent ink and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com