Patents

Literature

35results about How to "Suppression of contact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

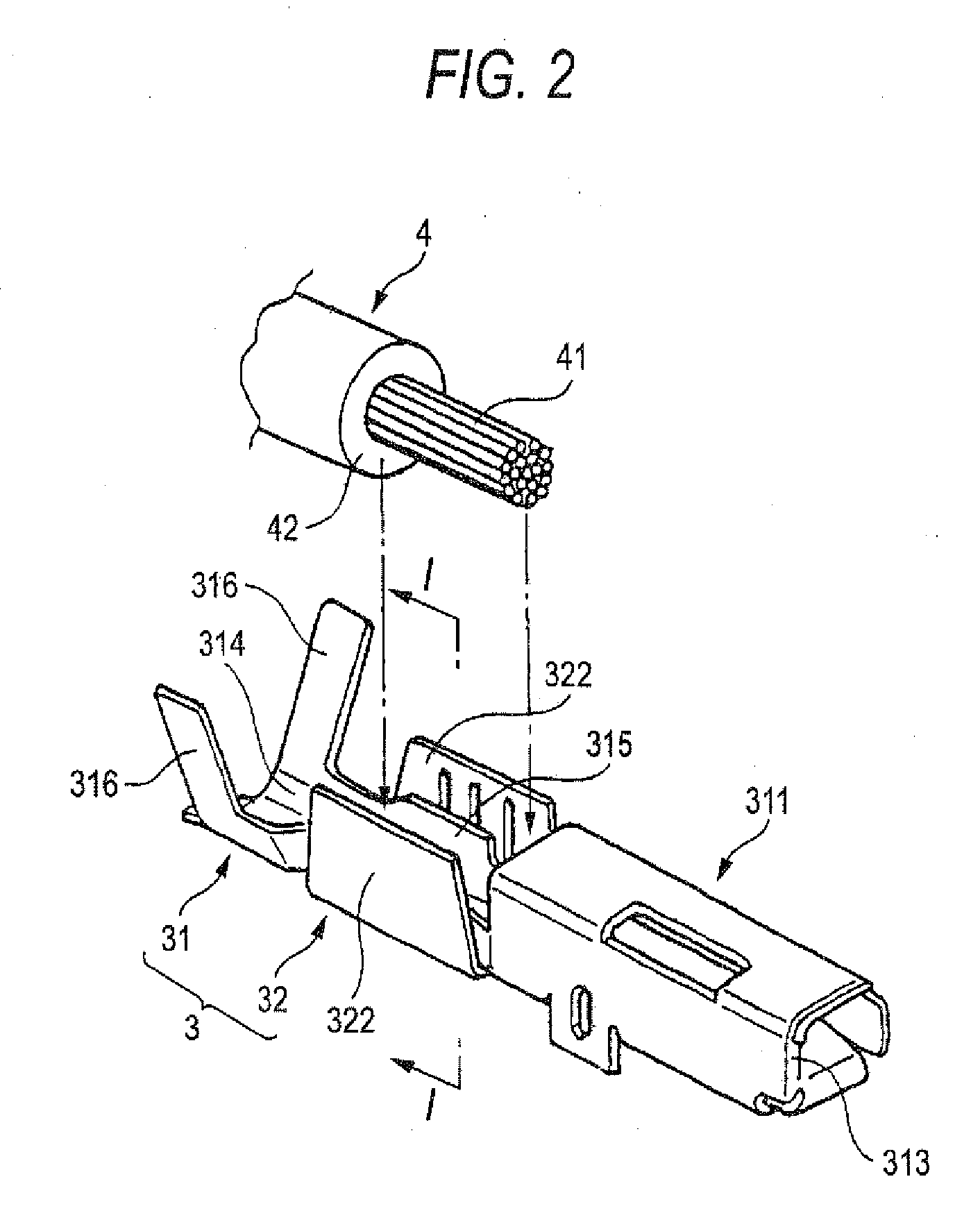

Terminal fitting having bi-metallic caulking pieces

ActiveUS7494388B2Suppression of contact resistanceEasy to installCoupling contact membersConnections effected by permanent deformationEngineeringMetal

Owner:YAZAKI CORP

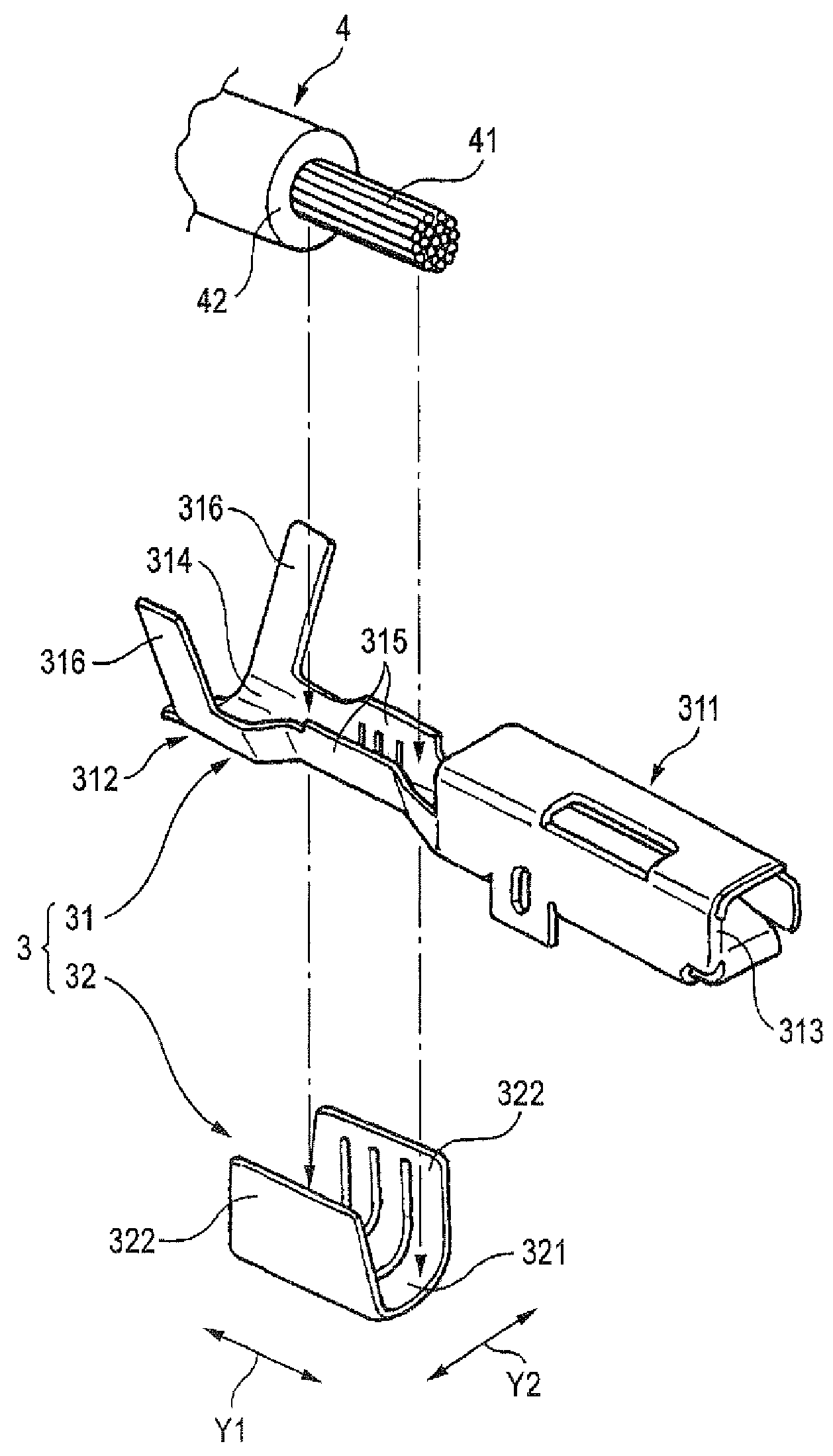

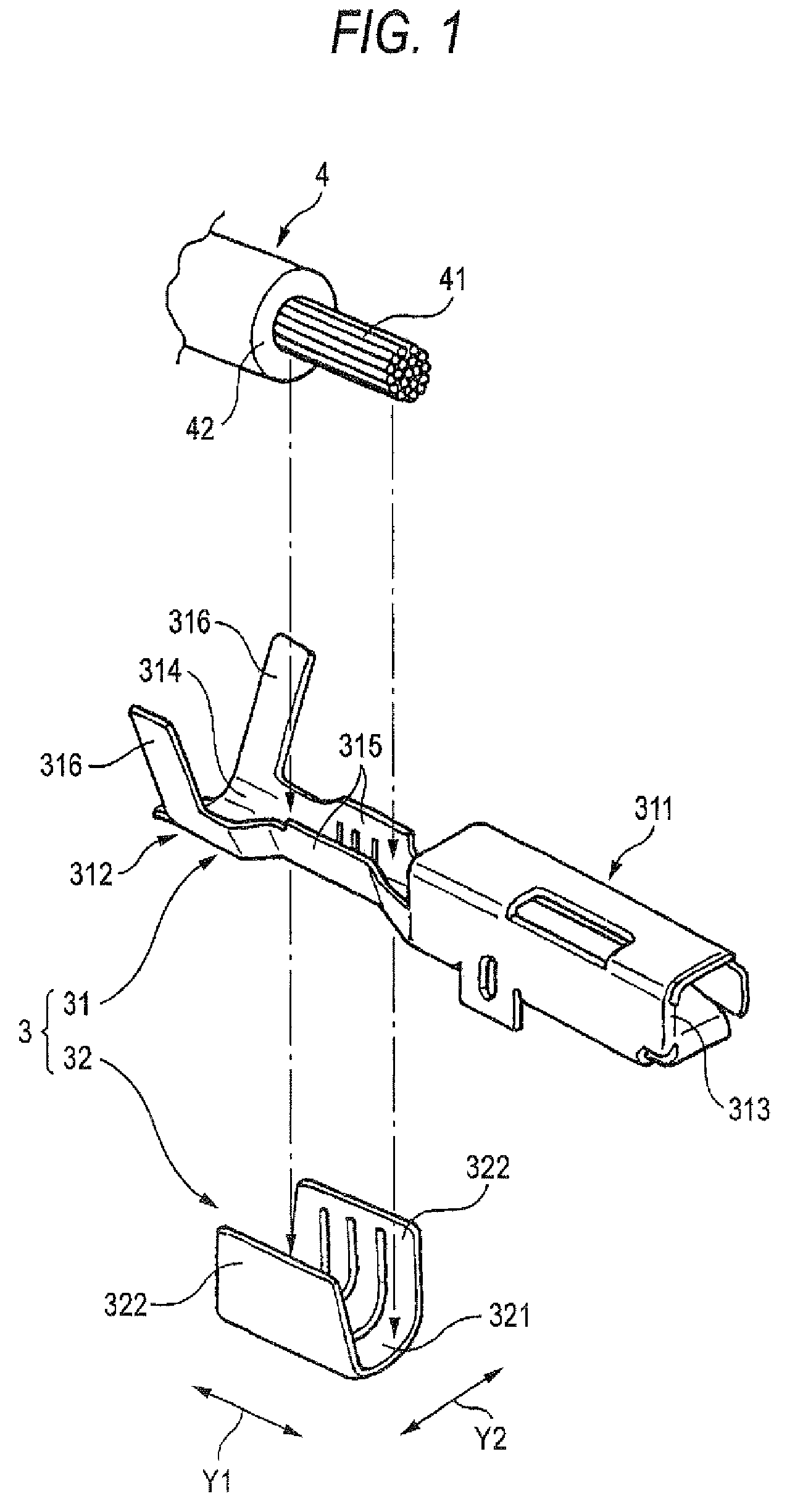

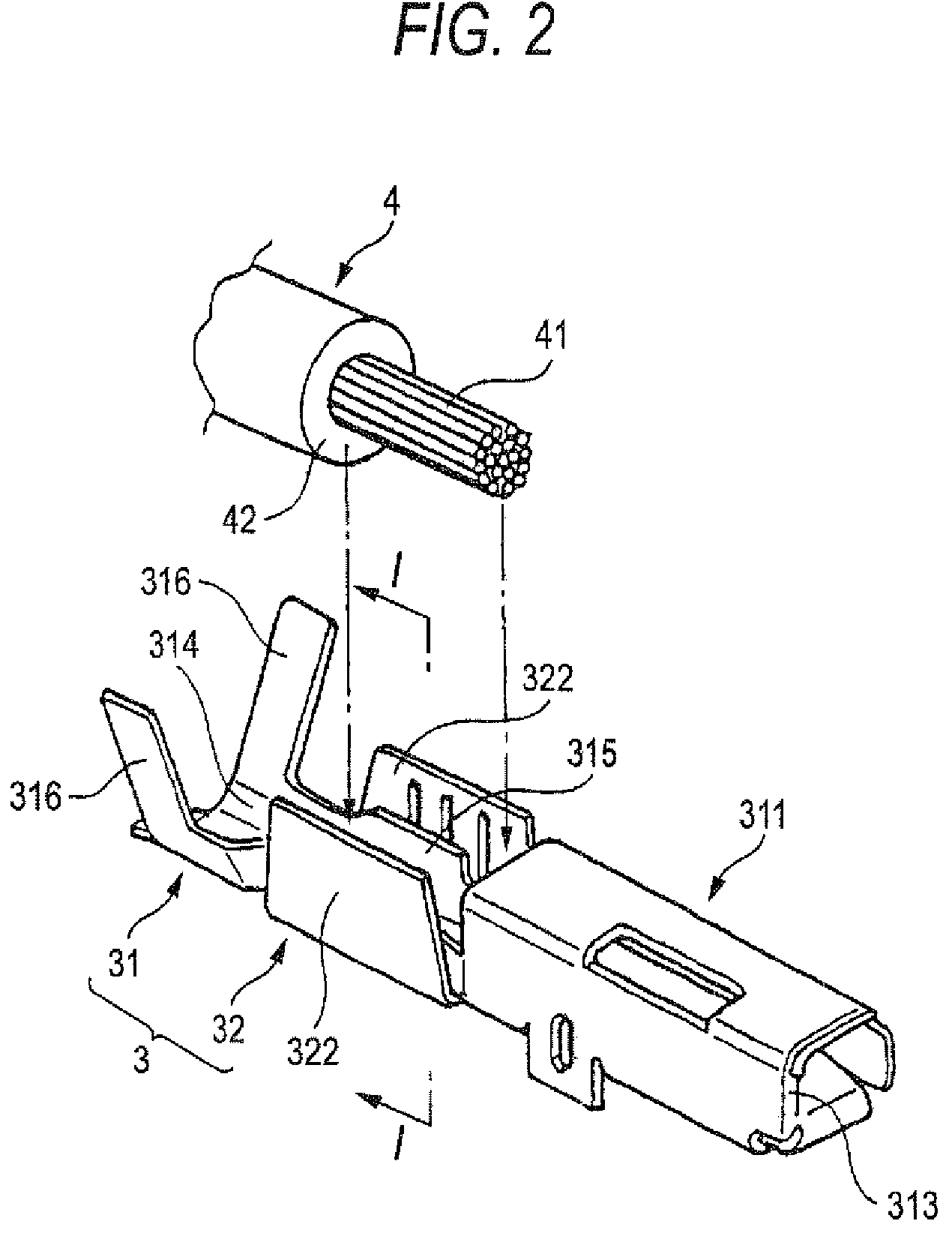

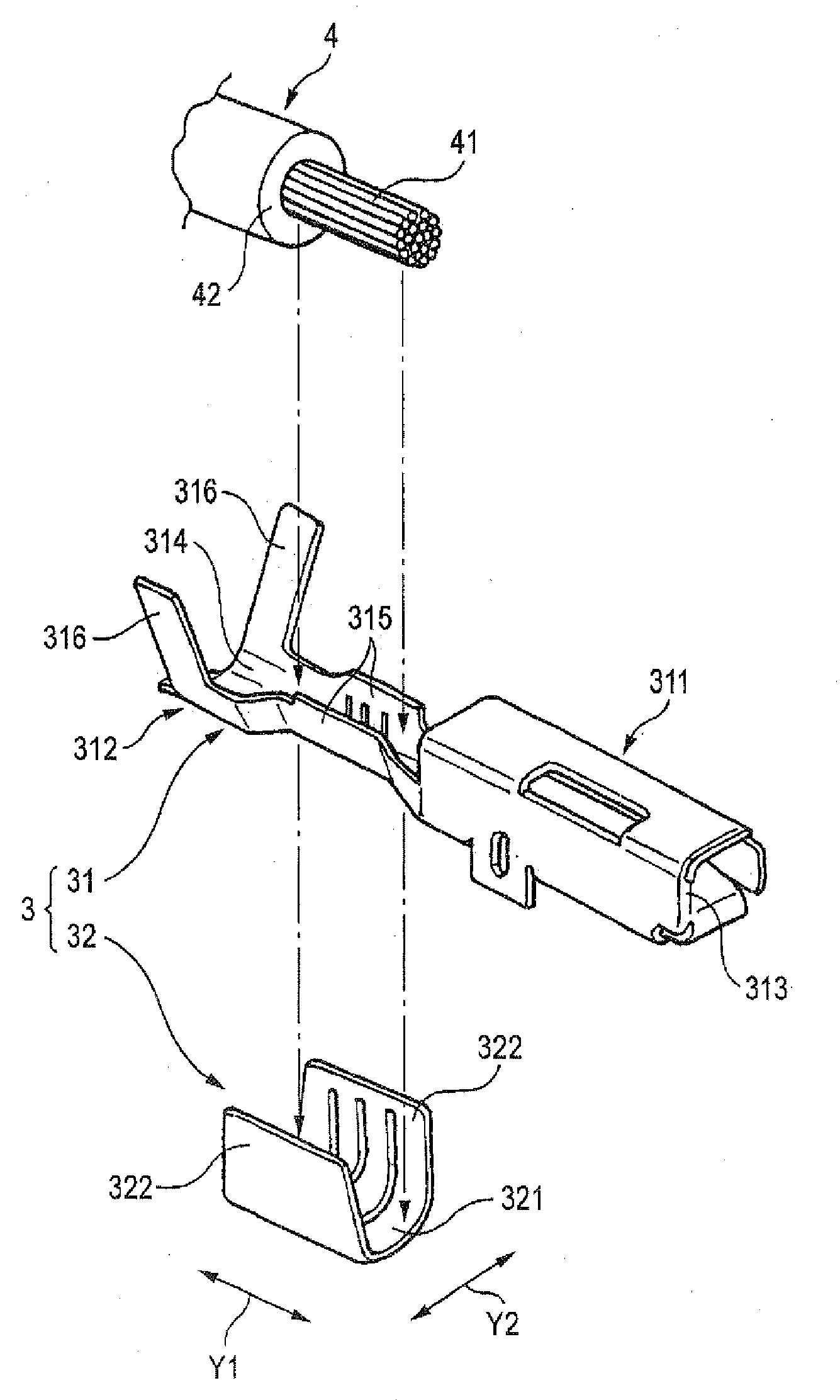

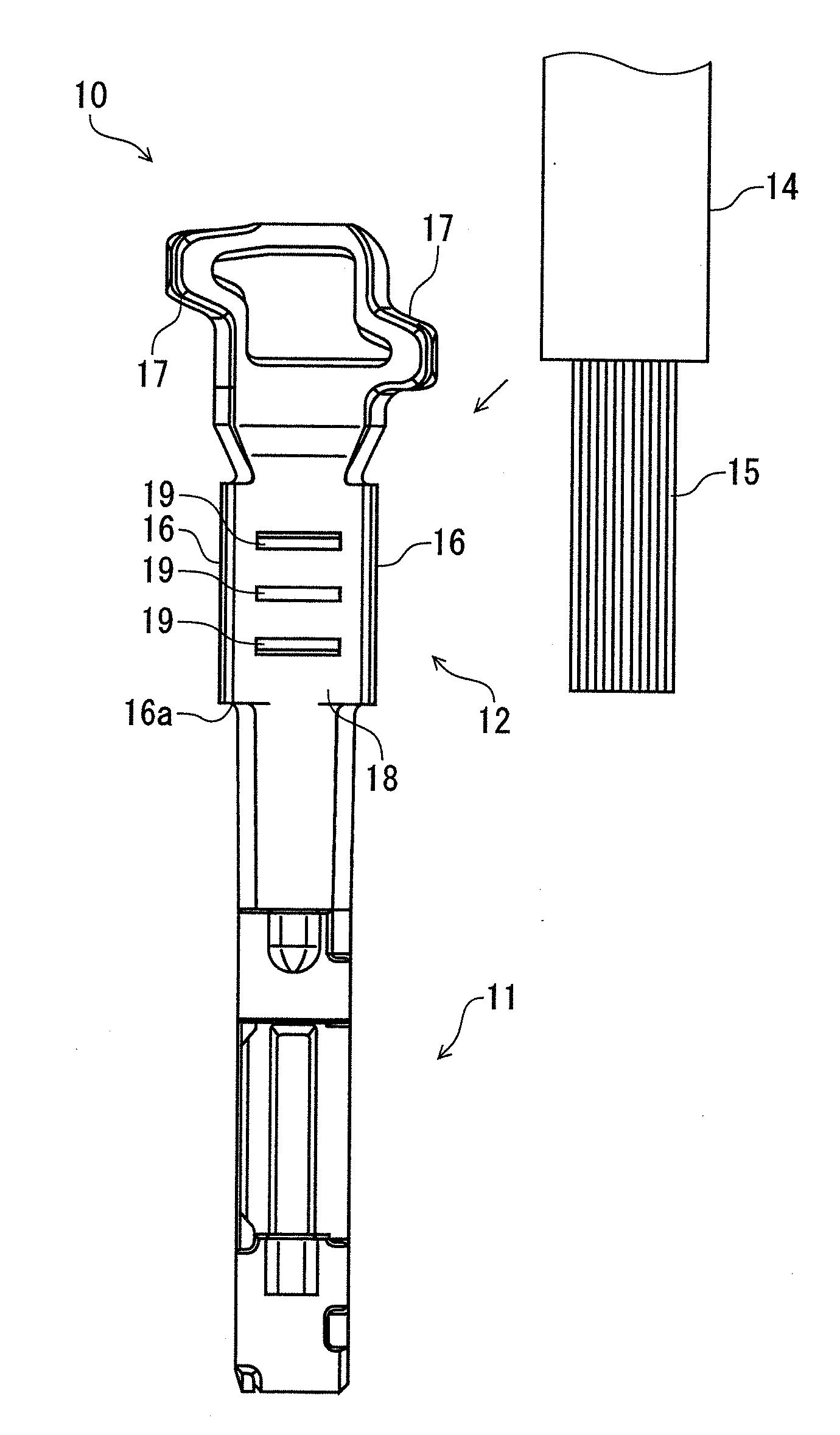

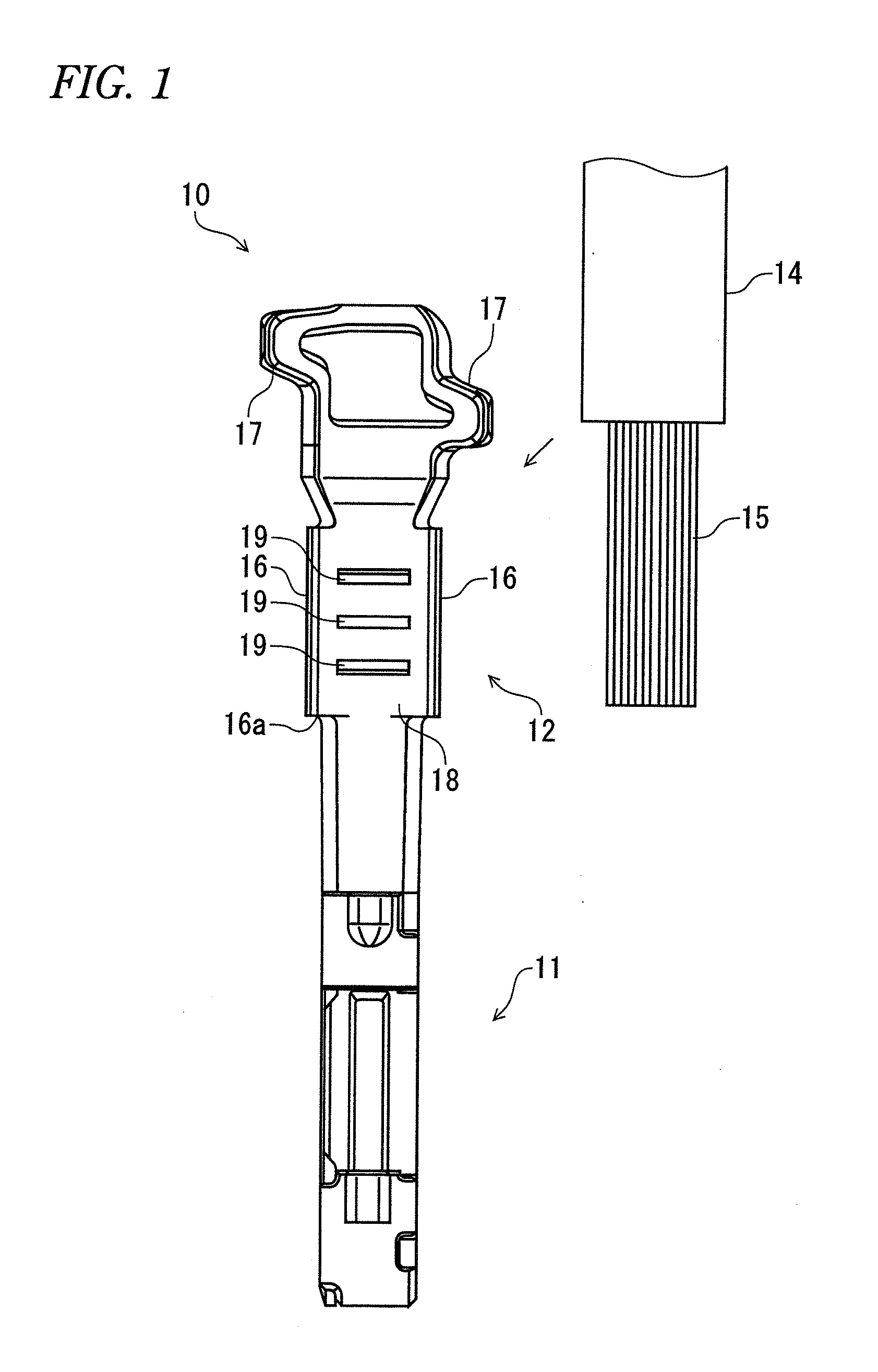

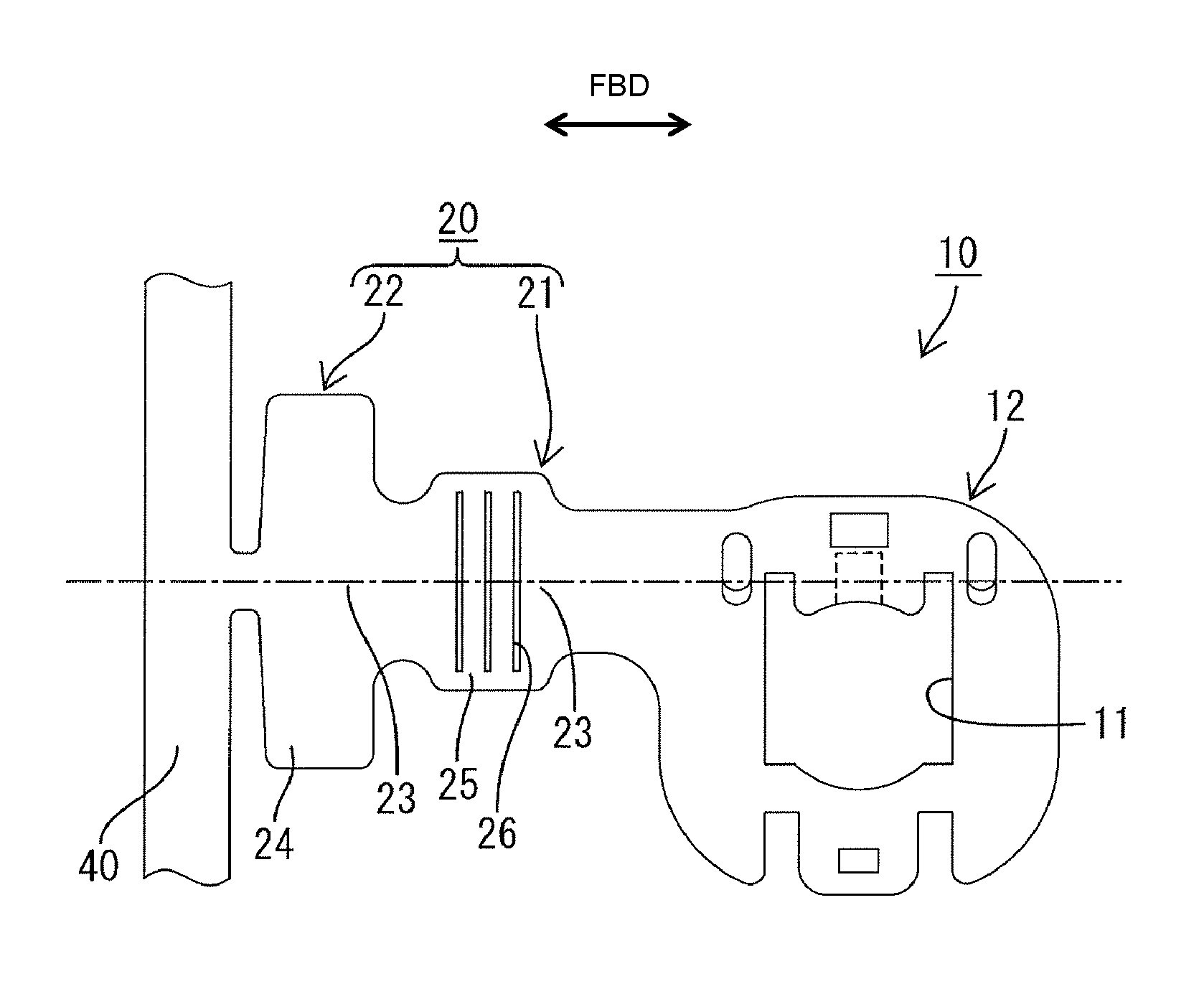

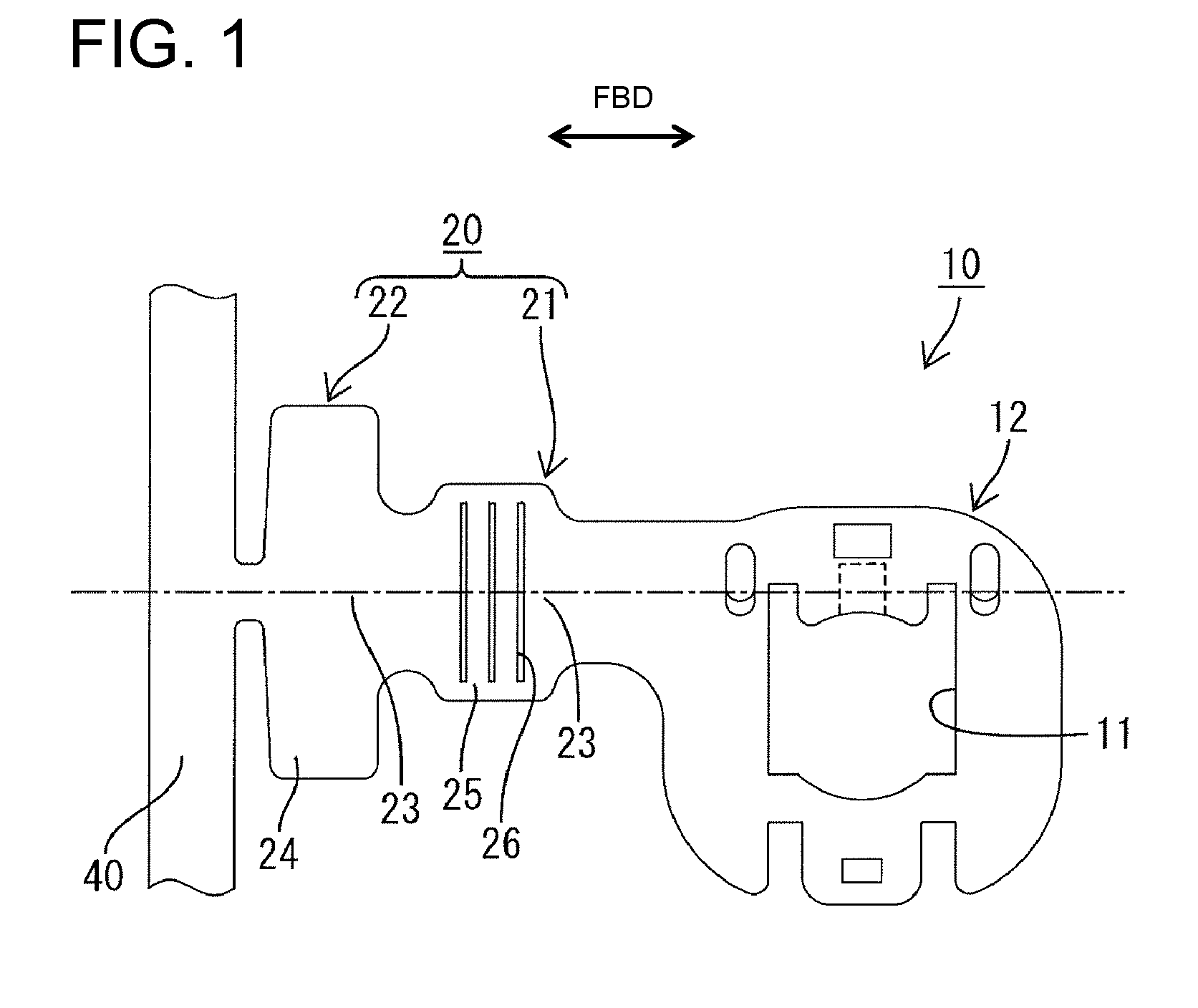

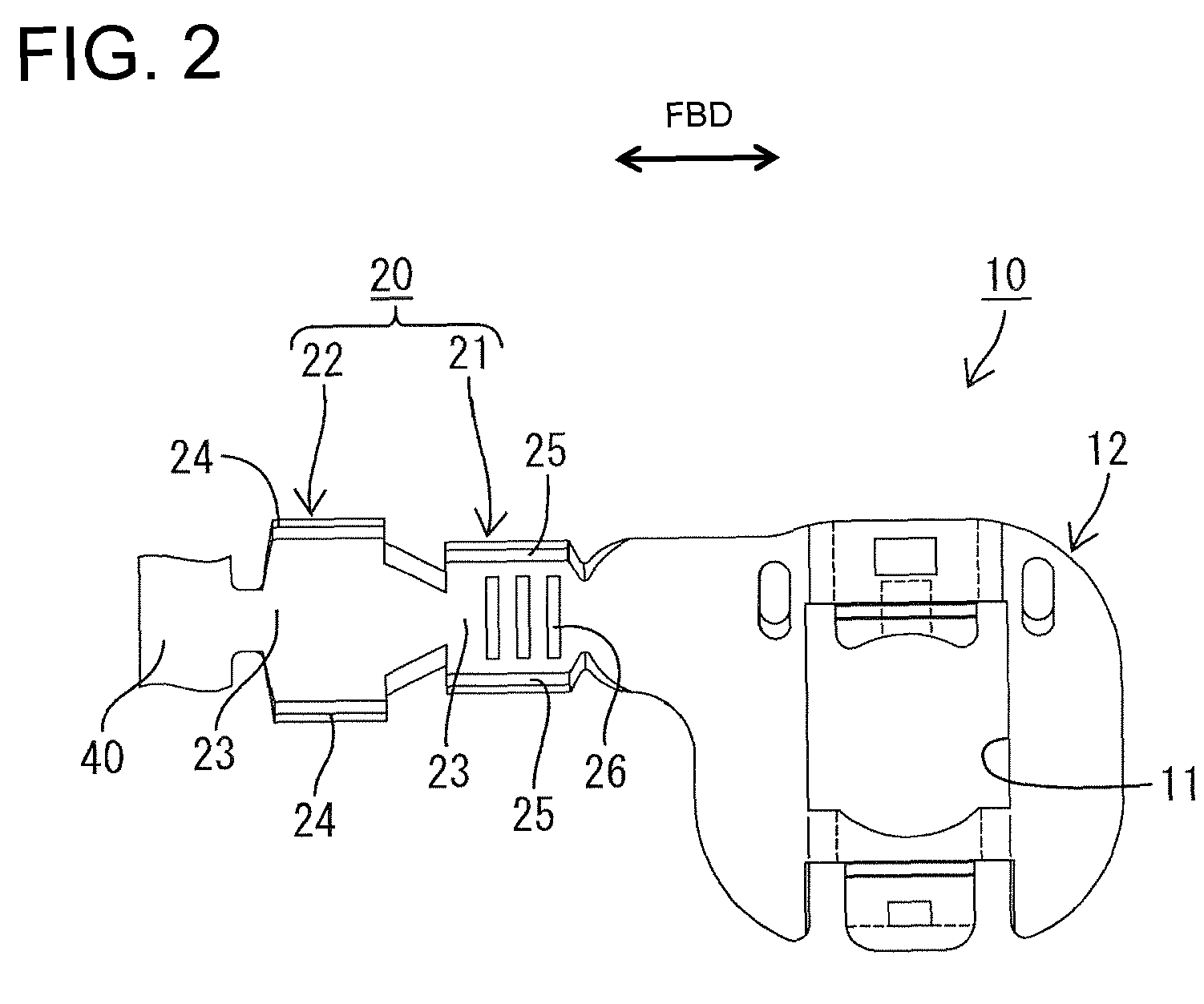

Terminal fitting and mounting method

ActiveUS20070264873A1Smooth connectionIncrease contact pressureCoupling contact membersConnections effected by permanent deformationEngineeringCopper alloy

An Al terminal has a first bottom wall, and a pair of caulking pieces that are stood from the first bottom wall and caulked in a state where the first bottom wall covers a wire connection portion with the core wires arranged on the upper side from the underside. Thereby, the Al terminal made of Al or Al alloy can be crimped from outside the terminal fitting main body made of copper or copper alloy, and the spring back of the terminal fitting main body made of copper or copper alloy can be suppressed by the Al terminal.

Owner:YAZAKI CORP

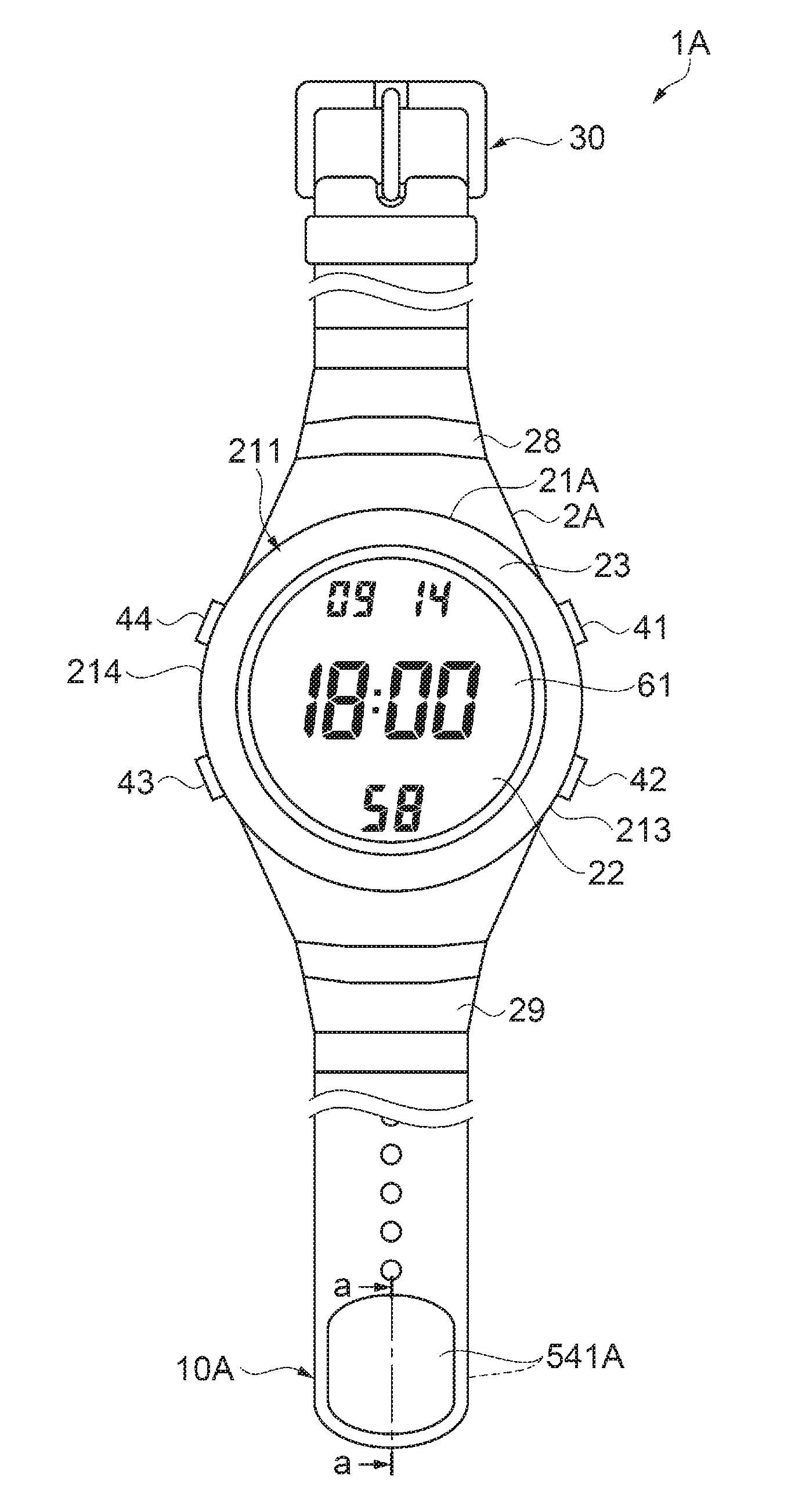

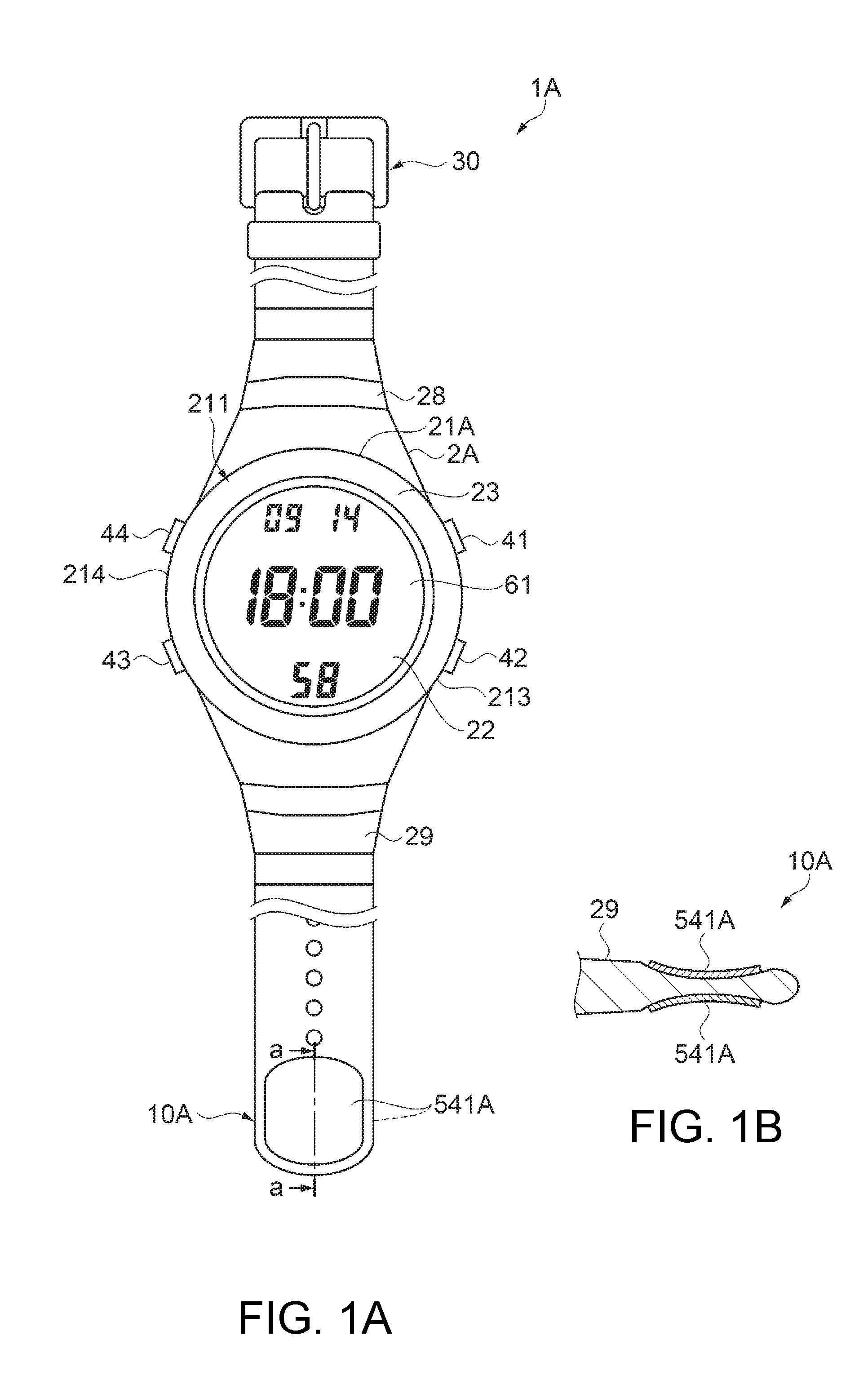

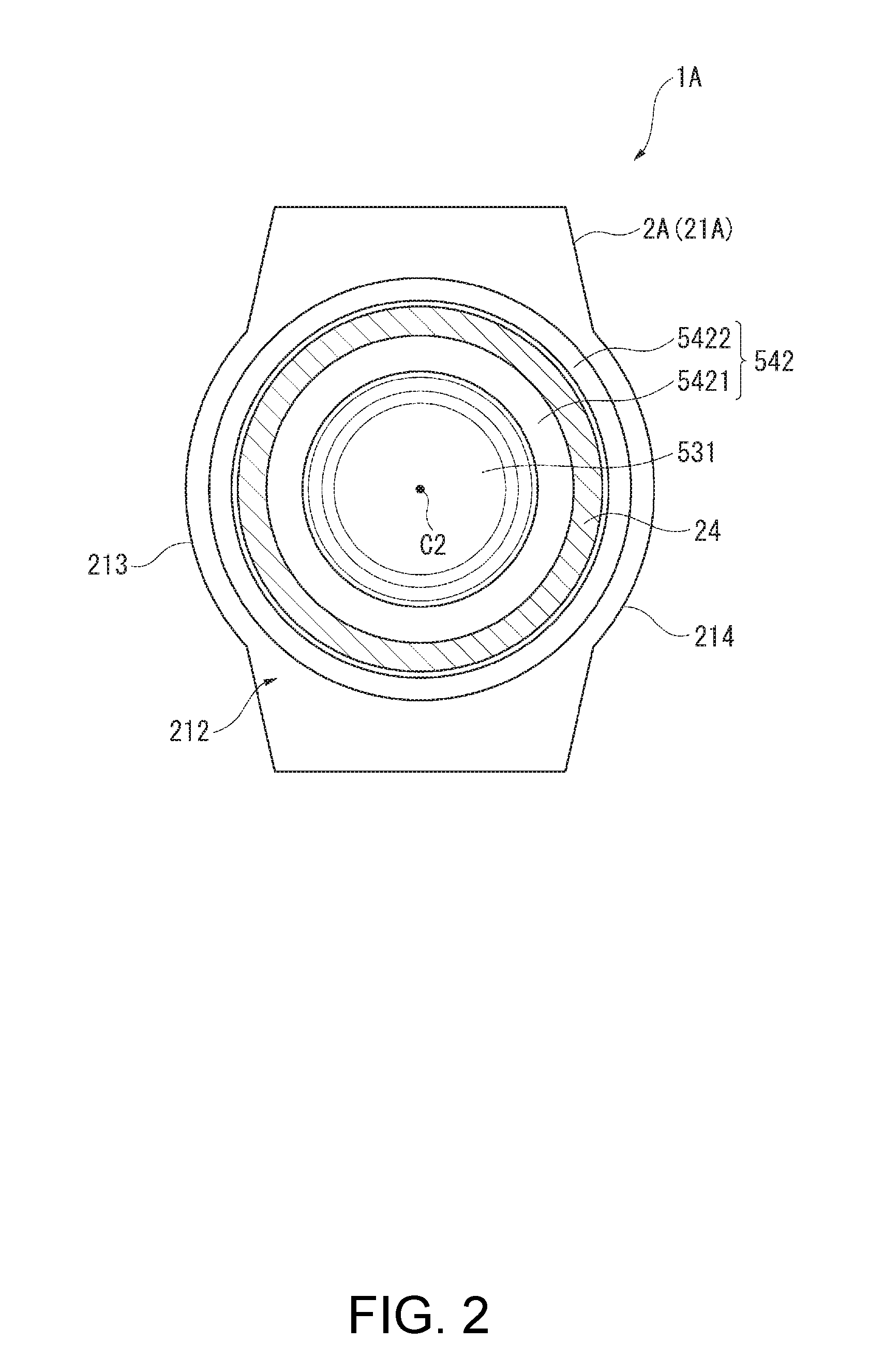

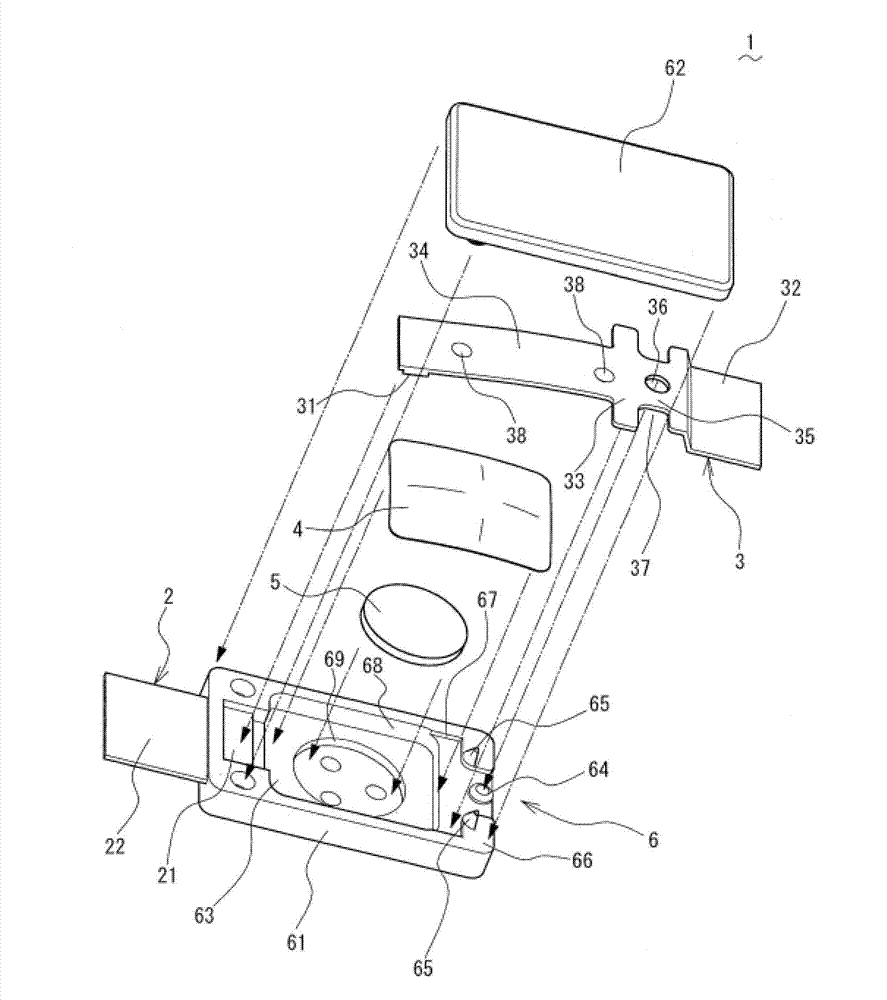

Biological information measurement apparatus

InactiveUS20160338598A1Improve precisionSuppression amountElectrocardiographySensorsMeasurement deviceBiomedical engineering

A biological information measurement apparatus including a case section including a biological information detector that detects biological information on a user, a band that attaches the case section to the user, a first electrode provided on a contact surface of the case section or the band that comes into contact with the user's body, a pinched section provided as part of the band and pinched by the user with fingers, a second electrode provided on the pinched section, and an electrocardiogram detector that uses the first electrode and the second electrode to detect the user's electrocardiogram.

Owner:SEIKO EPSON CORP

Crimped electric wire with terminal and method for producing the same

InactiveUS8628363B2Suppression of contact resistanceSuppress elongationConnections effected by permanent deformationConnection formation by deformationEngineeringElectric wire

A crimped electric wire with a terminal, includes: an electric wire having a core wire made of aluminum or aluminum alloy; and a terminal fitting having an electric wire crimping section for crimping the core wire partly exposed from the electric wire, wherein: a value obtained by dividing the height of the electric wire crimping section by the width of the electric wire crimping section after the crimping of the electric wire crimping section is set to 0.5 or more and 0.6 or less; and the value obtained by dividing the gross cross-sectional area of the core wire after the crimping of the electric wire crimping section by the gross cross-sectional area of the core wire before the crimping of the electric wire crimping section is set to 55% or more and 65% or less.

Owner:AUTONETWORKS TECH LTD +2

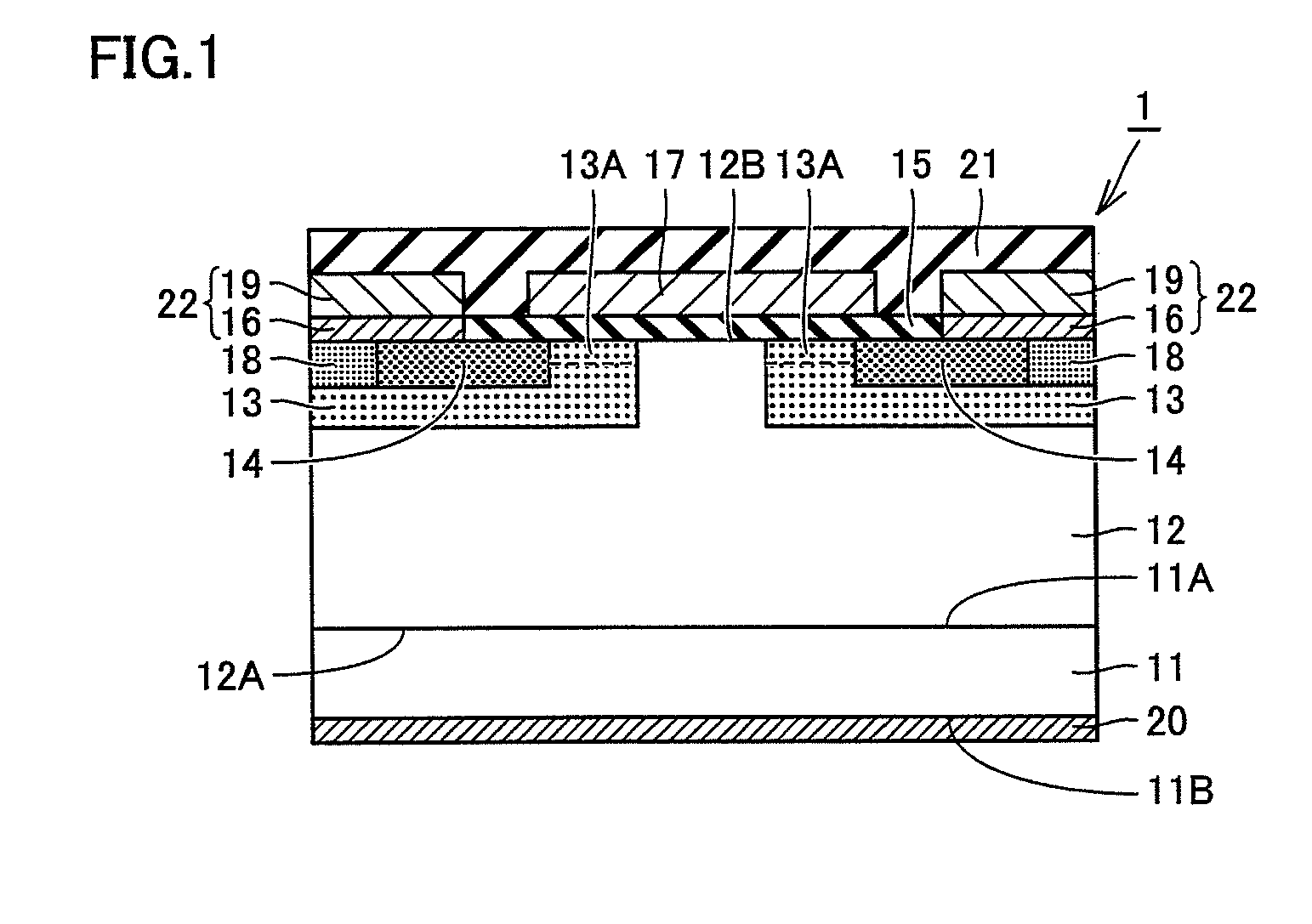

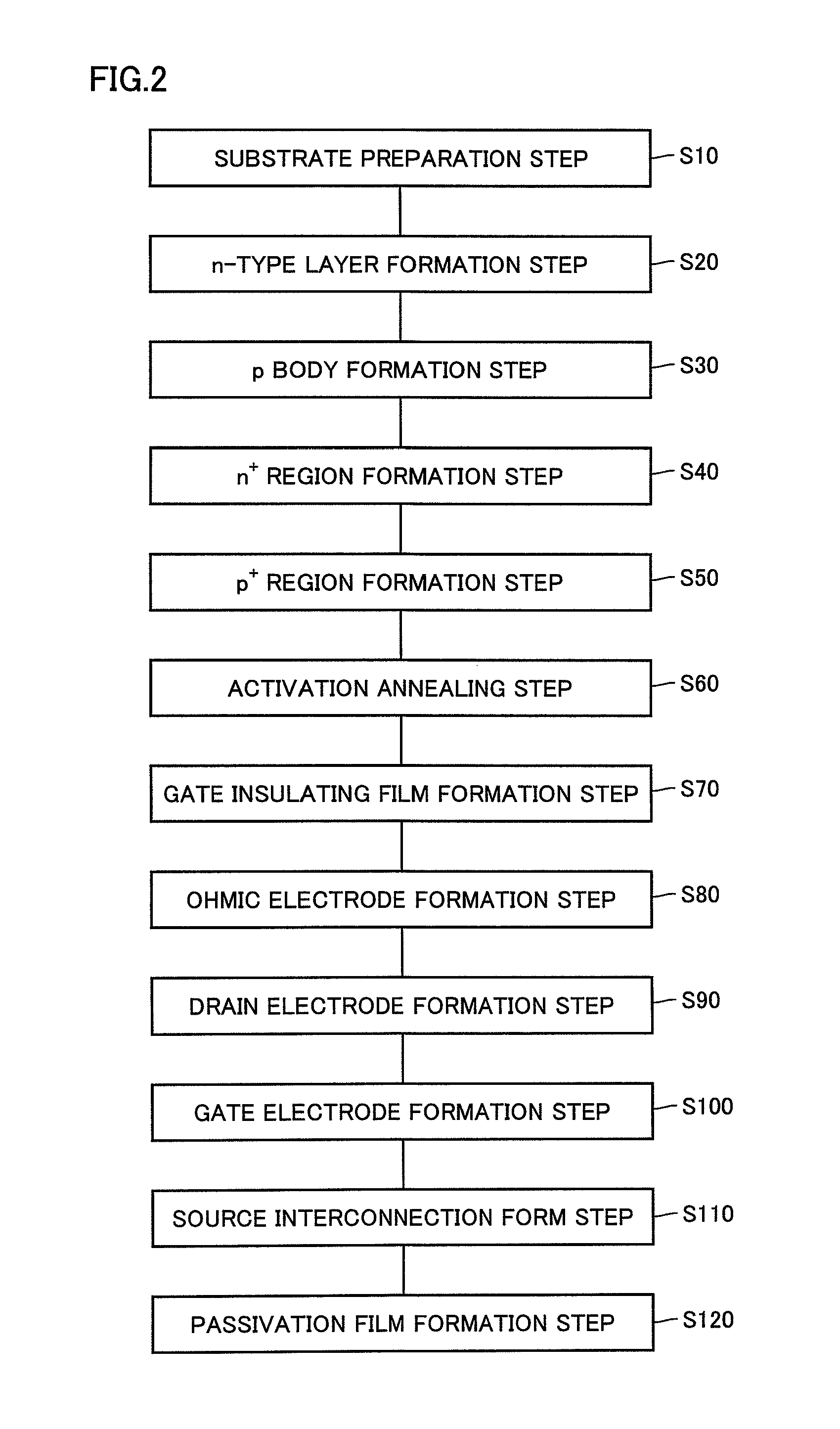

Semiconductor device and method of manufacturing the same

ActiveUS8373176B2Reduce the number of stepsHighly integratedSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETPower semiconductor device

Owner:SUMITOMO ELECTRIC IND LTD

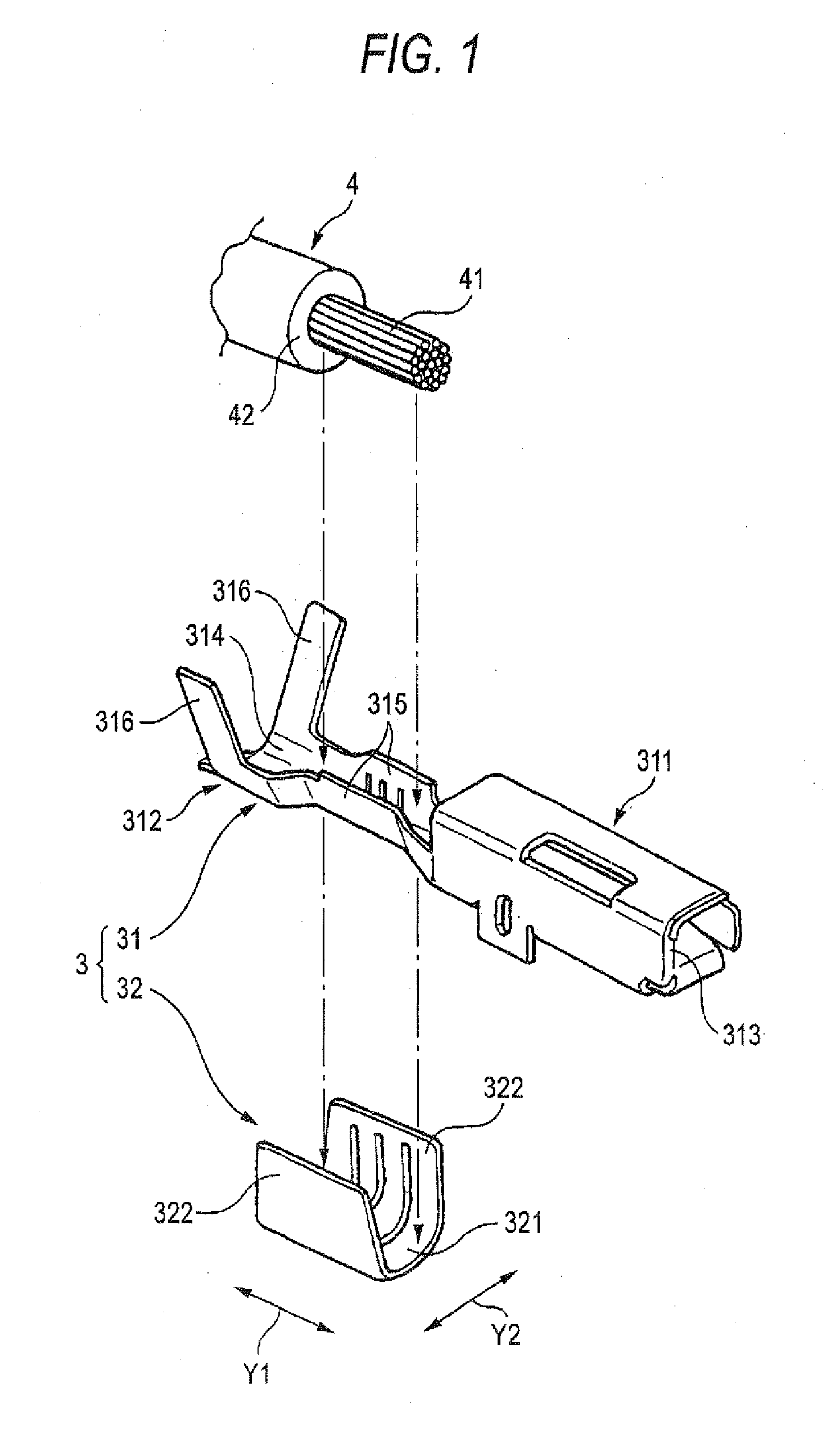

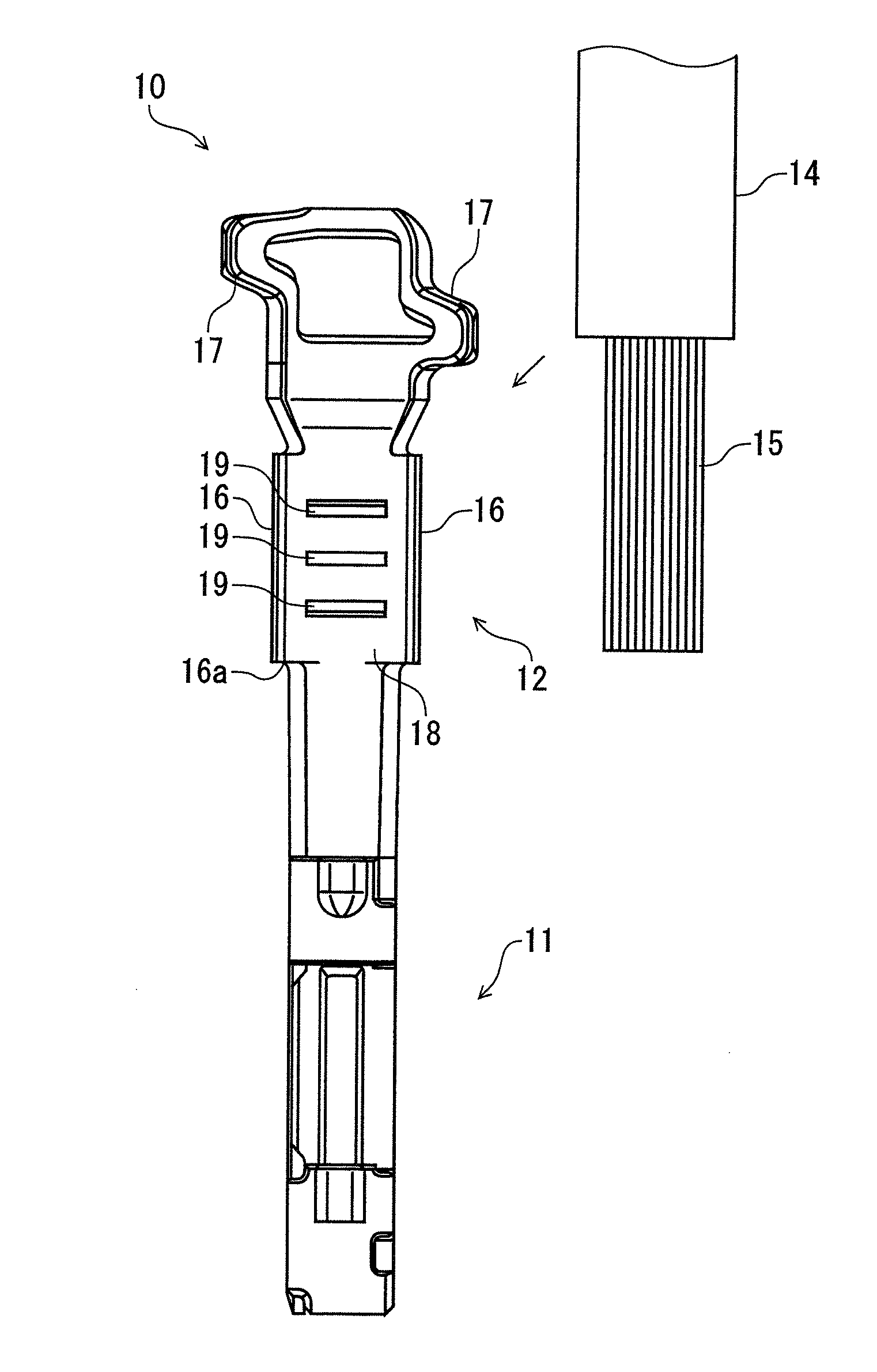

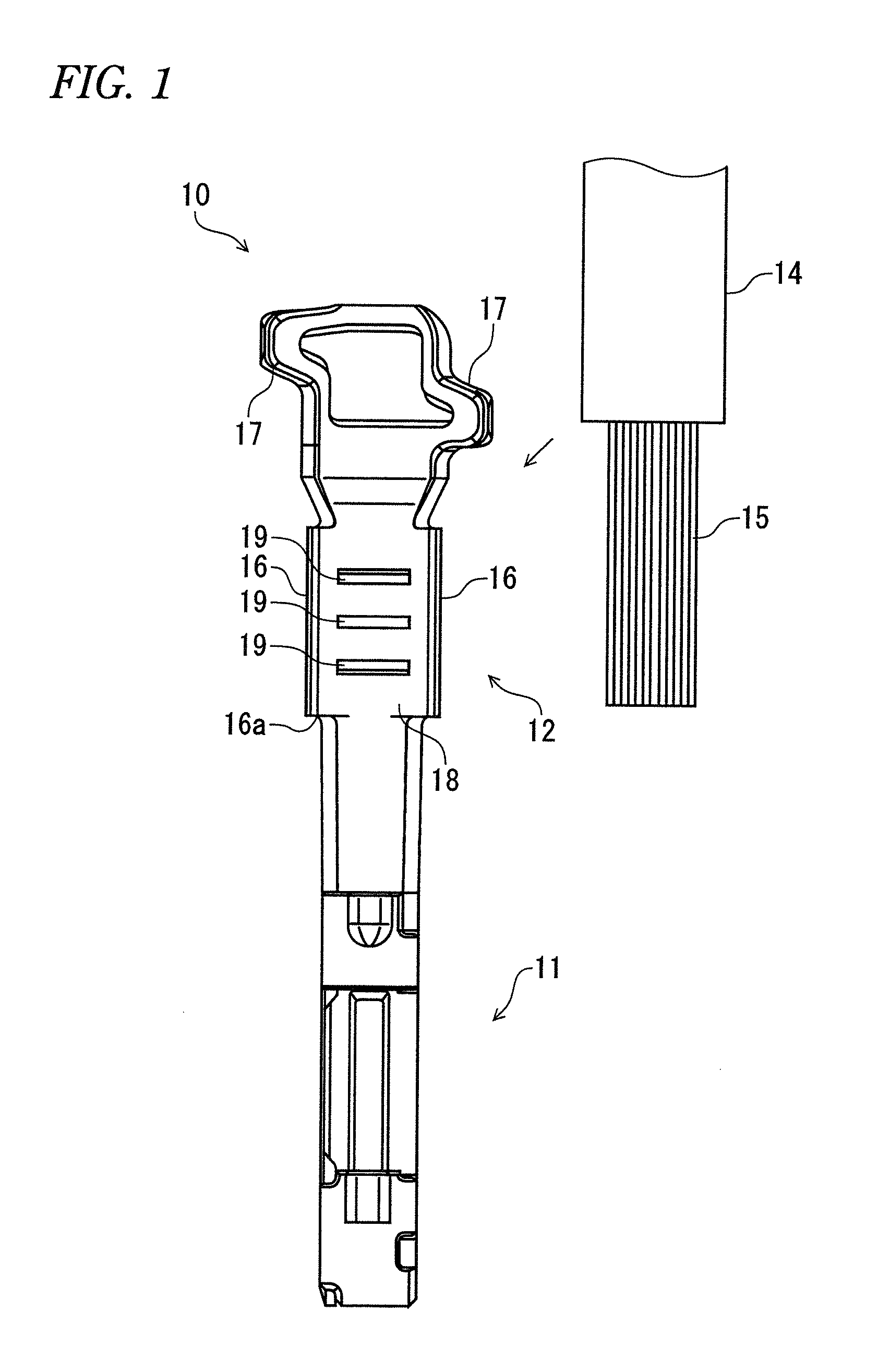

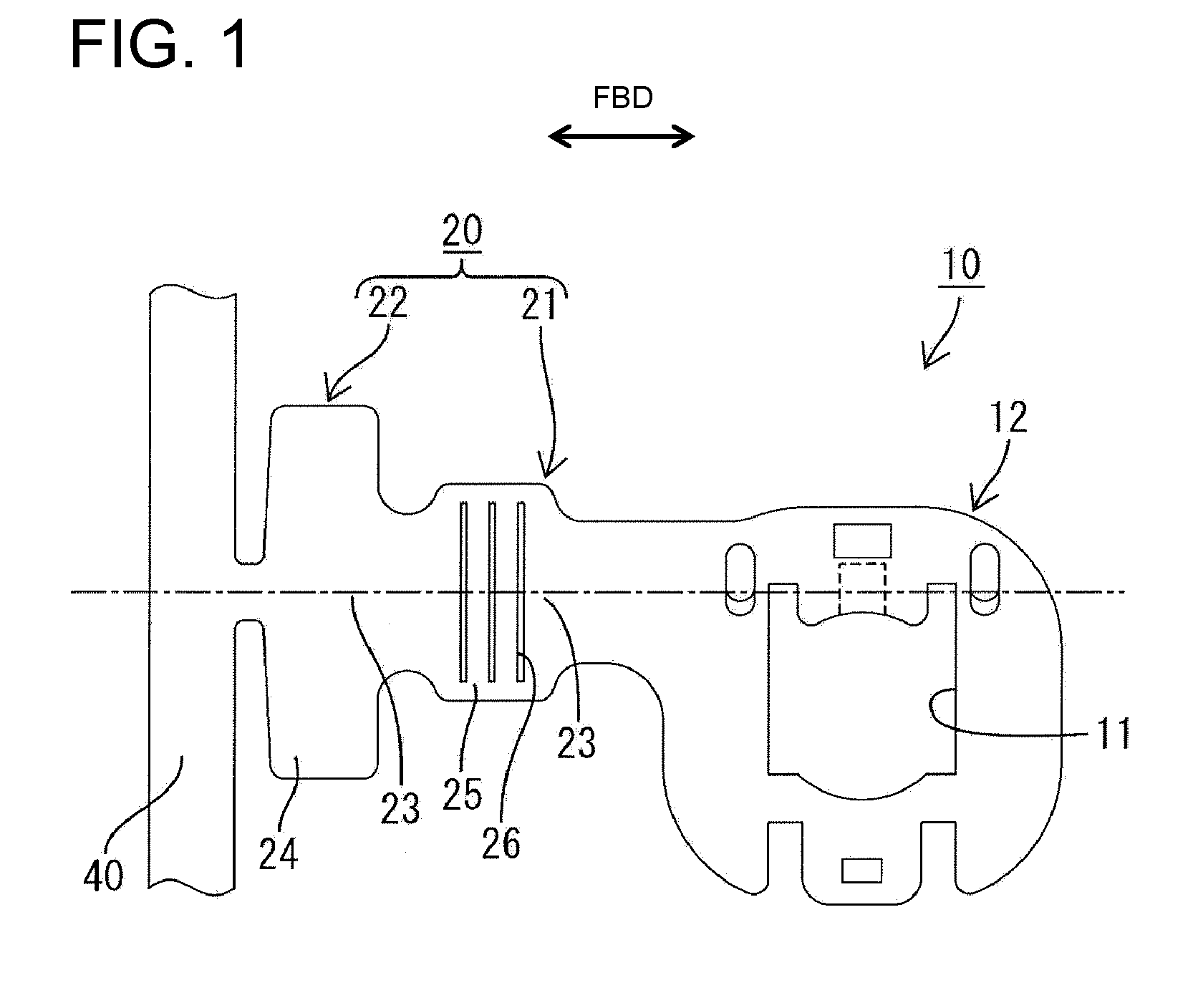

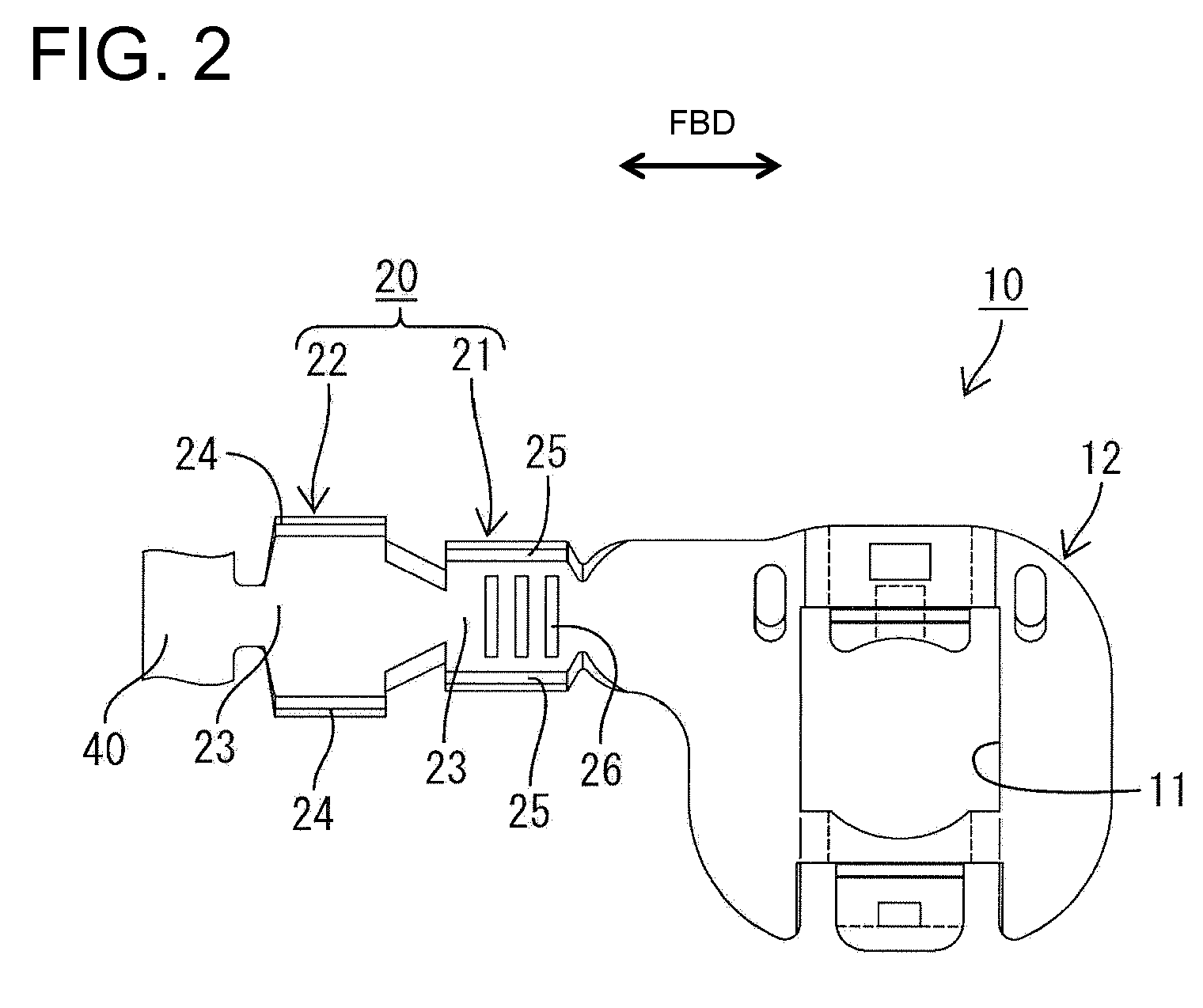

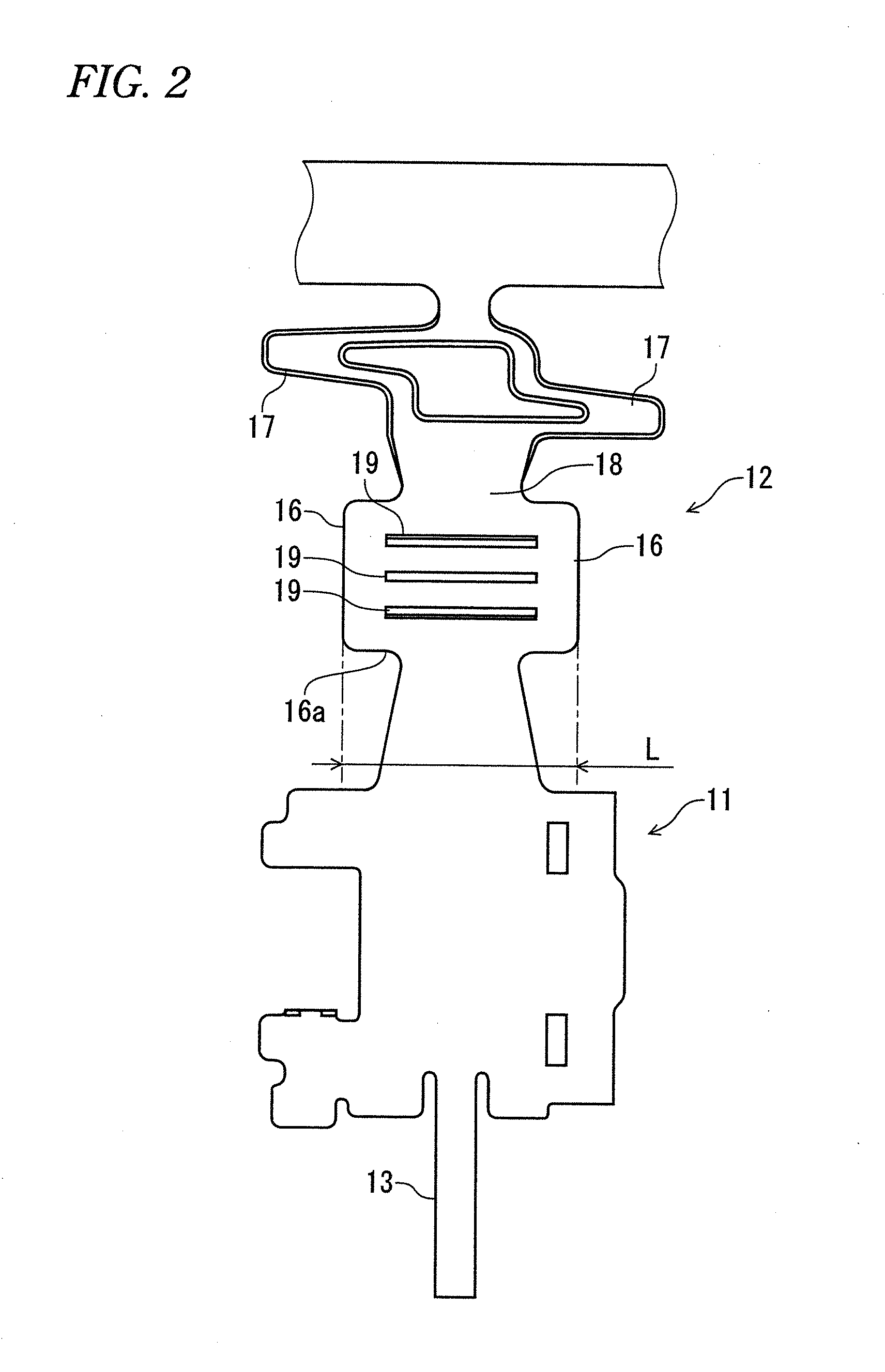

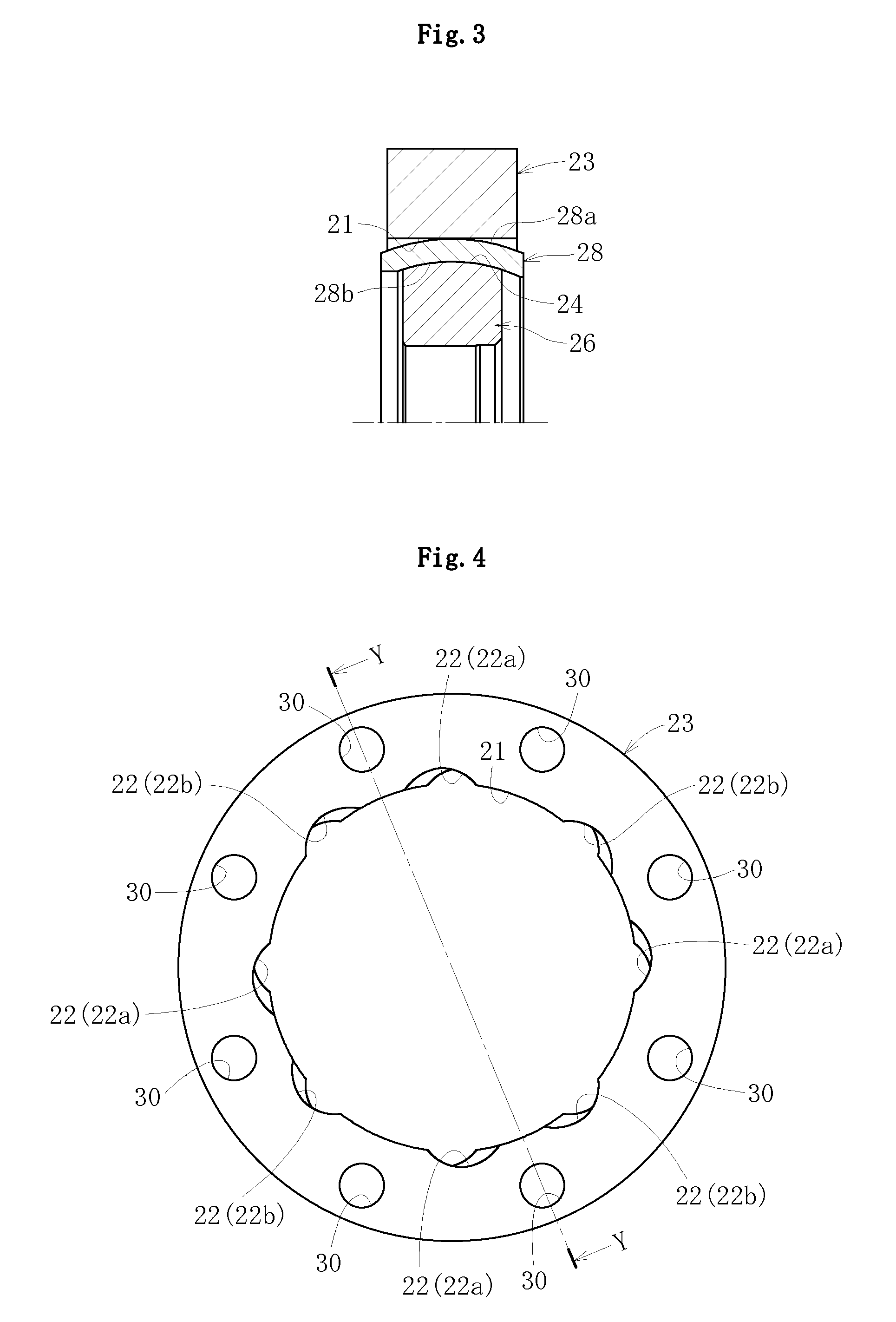

Crimping terminal fitting, method of forming it and wire with terminal fitting

InactiveUS20110021092A1Ensure mechanical strengthImprove retentionContact member manufacturingConnections effected by permanent deformationEngineeringMechanical engineering

A crimping terminal fitting has a wire barrel (21) to be crimped and connected to core strands (31) of a wire (30). The wire barrel (21) has a base plate (23) continuously extending from a ground terminal (11) in a longitudinal direction. Two core crimping pieces (25) extend from the opposite sides of the base plate (23). A thinned portion (27) is formed at least at a leading end of each core crimping piece (25) and is thinner than the base plate (23).

Owner:SUMITOMO WIRING SYST LTD

Crimped electric wire with terminal and method for producing the same

InactiveUS20110034091A1Hard be roundIncrease rigidityConnections effected by permanent deformationConnection formation by deformationEngineeringAluminium alloy

A crimped electric wire with a terminal, includes: an electric wire having a core wire made of aluminum or aluminum alloy; and a terminal fitting having an electric wire crimping section for crimping the core wire partly exposed from the electric wire, wherein: a value obtained by dividing the height of the electric wire crimping section by the width of the electric wire crimping section after the crimping of the electric wire crimping section is set to 0.5 or more and 0.6 or less; and the value obtained by dividing the gross cross-sectional area of the core wire after the crimping of the electric wire crimping section by the gross cross-sectional area of the core wire before the crimping of the electric wire crimping section is set to 55% or more and 65% or less.

Owner:AUTONETWORKS TECH LTD +2

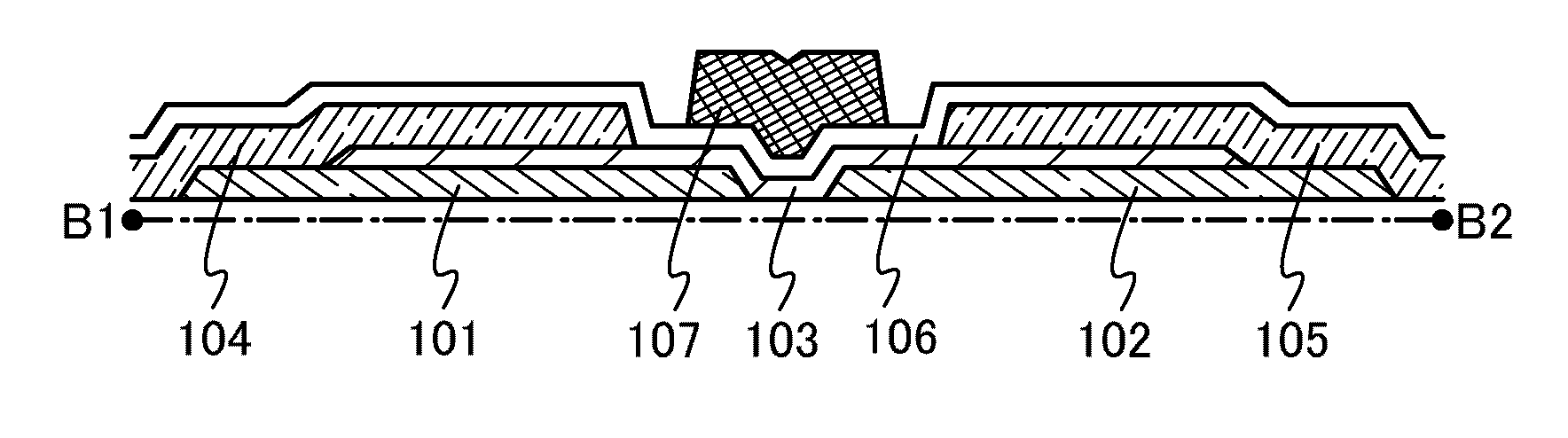

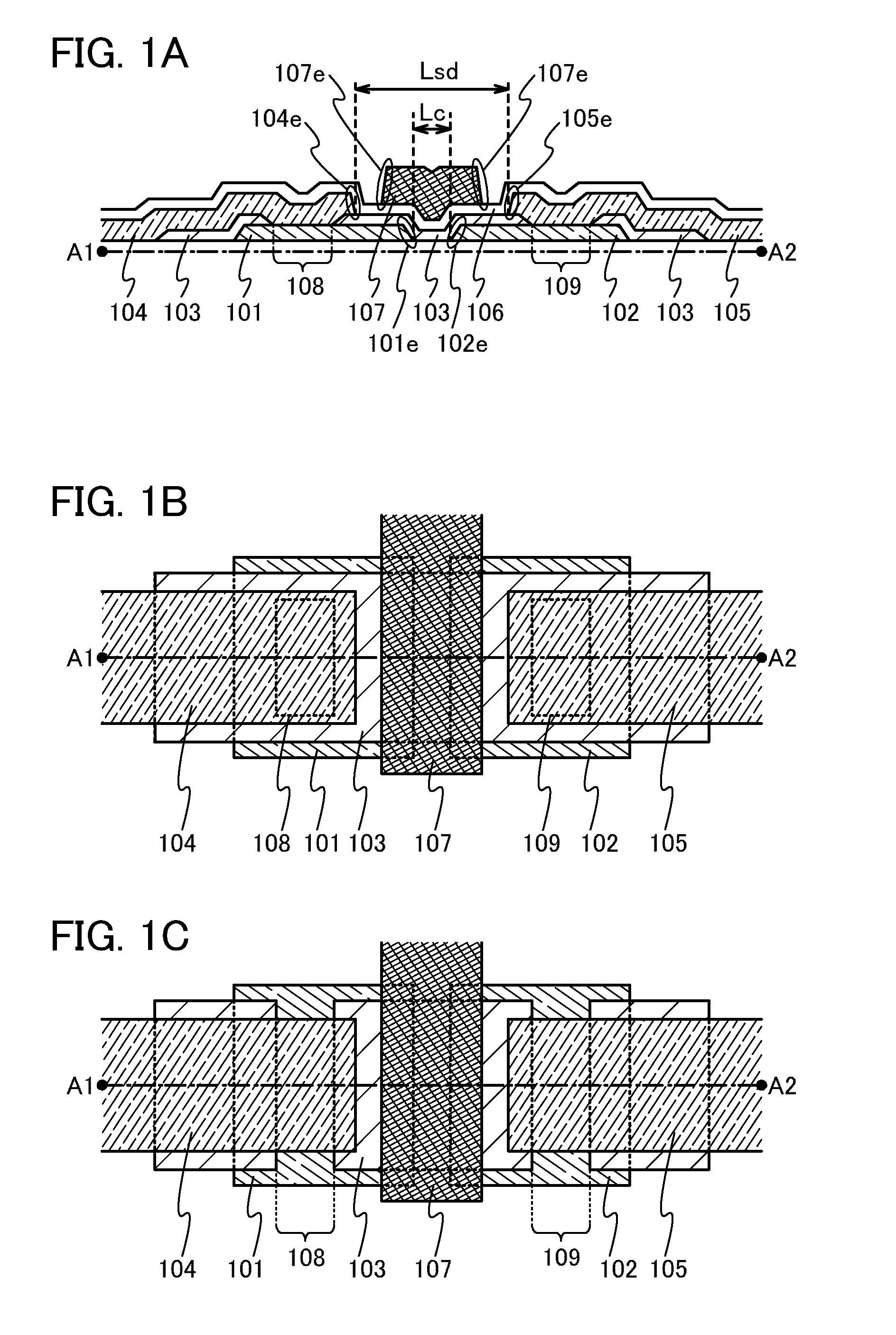

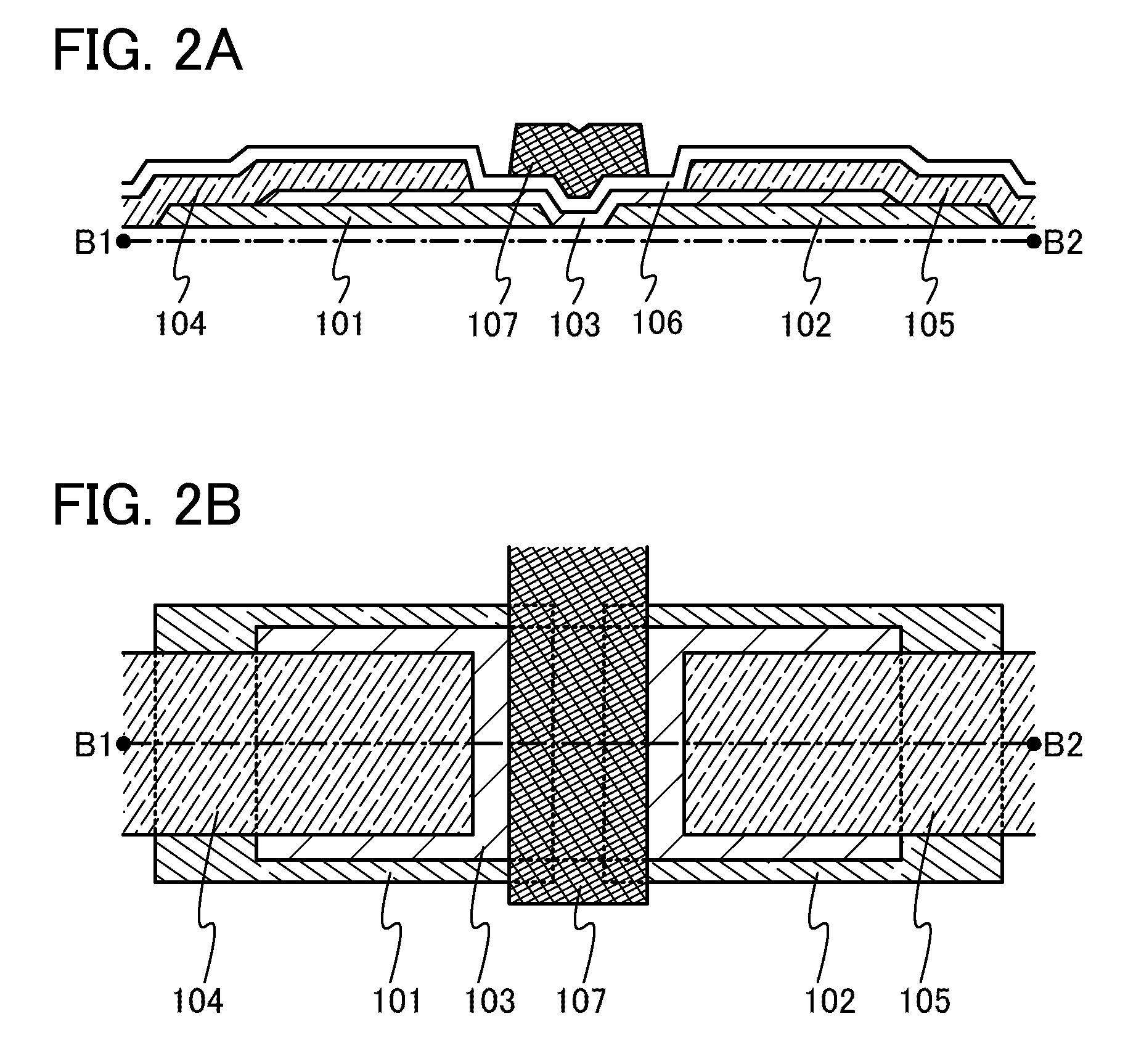

Semiconductor device

InactiveUS20130075721A1Increase the on-currentHigh currentSolid-state devicesSemiconductor devicesEngineeringSemiconductor

Provided is a semiconductor device including a transistor with large on-state current even when it is miniaturized. The transistor includes a pair of first conductive films over an insulating surface; a semiconductor film over the pair of first conductive films; a pair of second conductive films, with one of the pair of second conductive films and the other of the pair of second conductive films being connected to one of the pair of first conductive films and the other of the pair of first conductive films, respectively; an insulating film over the semiconductor film; and a third conductive film provided in a position overlapping with the semiconductor film over the insulating film. Further, over the semiconductor film, the third conductive film is interposed between the pair of second conductive films and away from the pair of second conductive films.

Owner:SEMICON ENERGY LAB CO LTD

Electrochemical battery and manufacture method thereof

ActiveCN102842699AContact resistance (connection resistance) is smallInhibition of dissolutionElectrolytic capacitorsCell component detailsElectricityPower flow

The invention relates to an electrochemical battery and a manufacture method thereof. The electrochemical battery using a small-size exterior package container discharges on high current. The electrochemical battery is composed of the exterior container, a battery core (7) and electrolyte, wherein the exterior container is composed of a seat (1) and a cover (6), the battery core (7) is mounted in the seat (1), the electrochemical battery comprises at least one lining membrane (2) and a connection terminal (4), the lining membrane (2) is formed on the inner side surface of the seat (1) and composed of an electronic pipe metal, the connection terminal (4) is arranged on the outer side surface of the seat (1) and electrically connected with the lining membrane (2), and a battery core lead (8) being an extension part of the battery core is welded with the lining membrane (2).

Owner:SEIKO INSTR INC

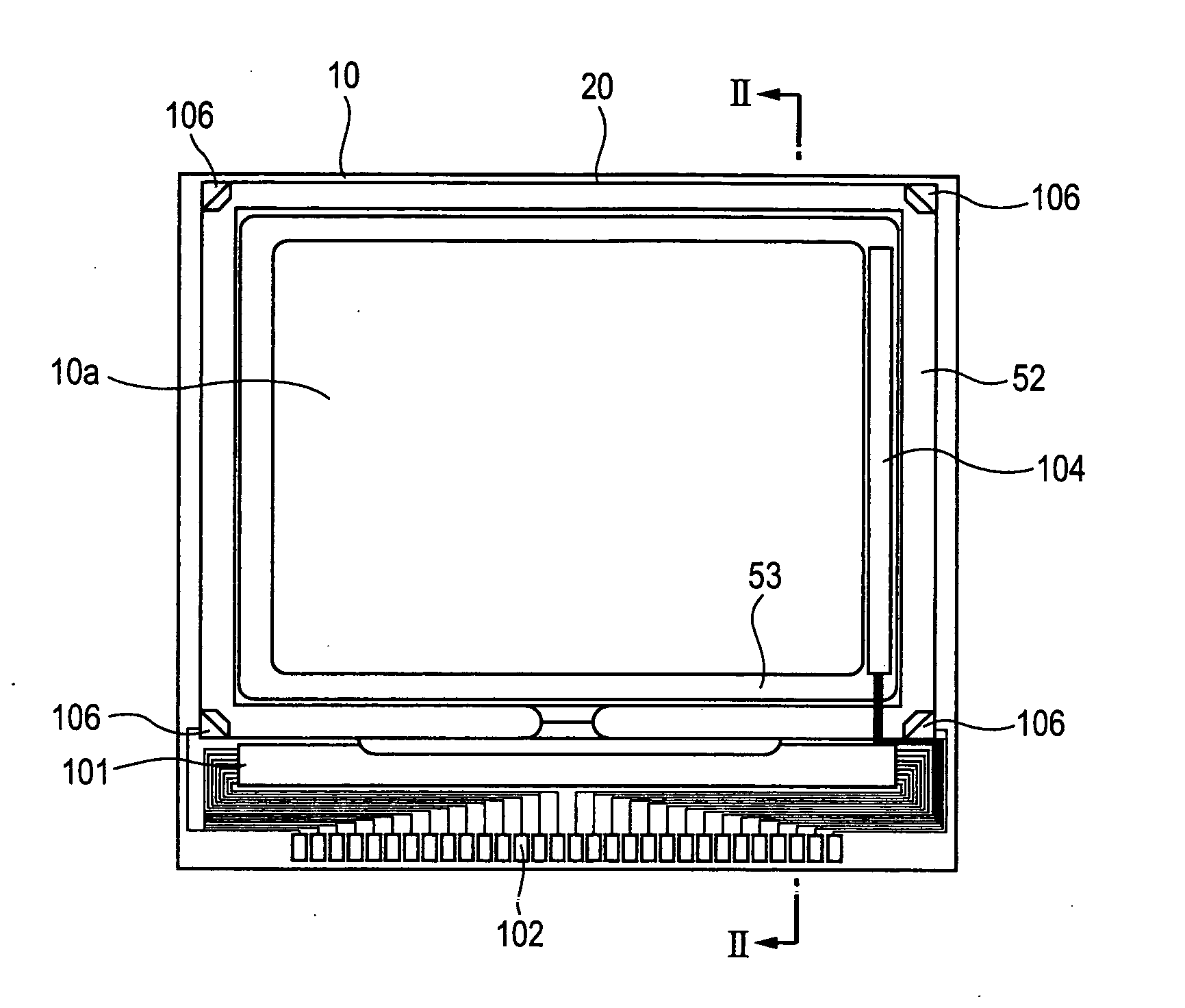

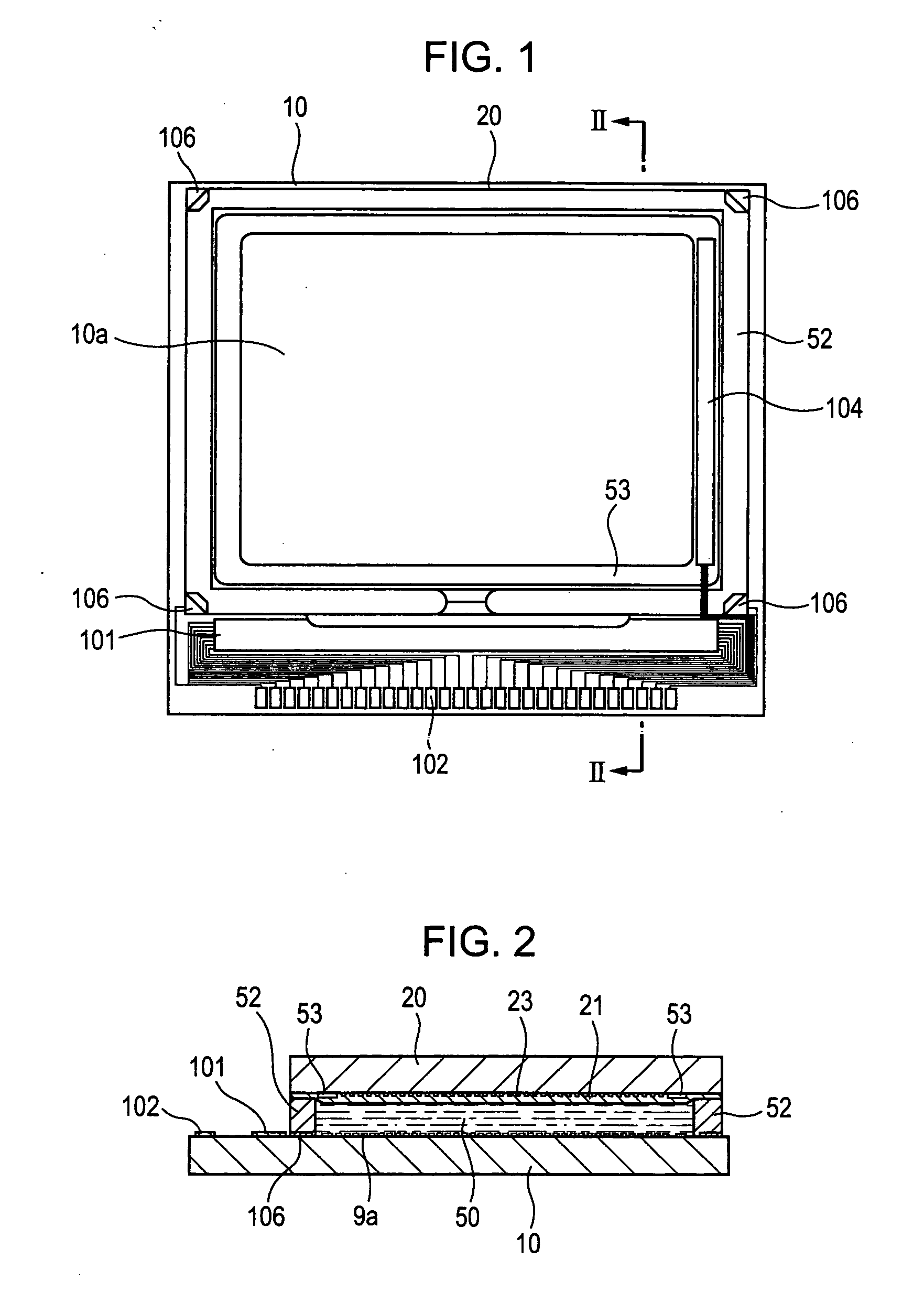

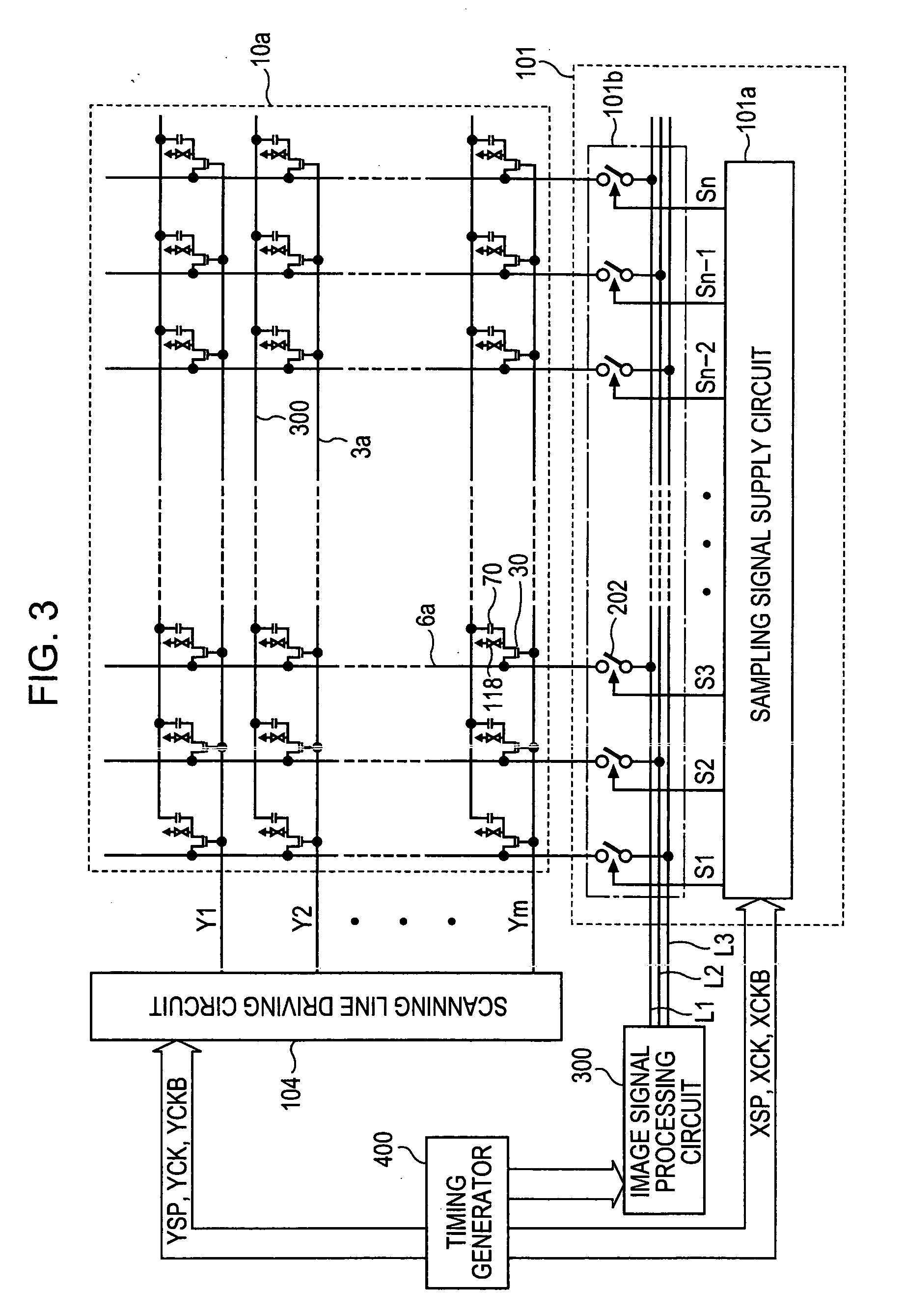

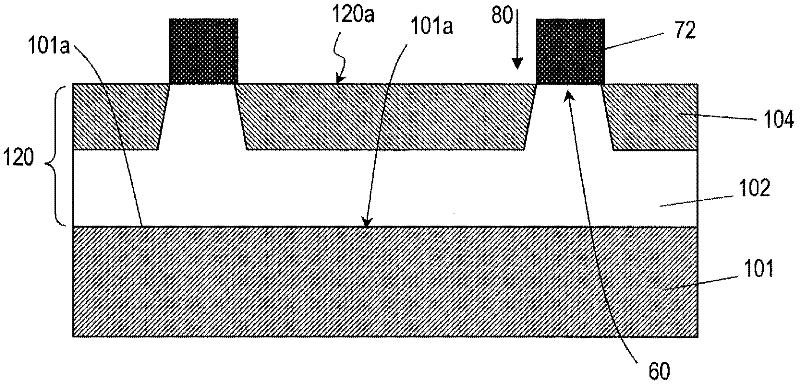

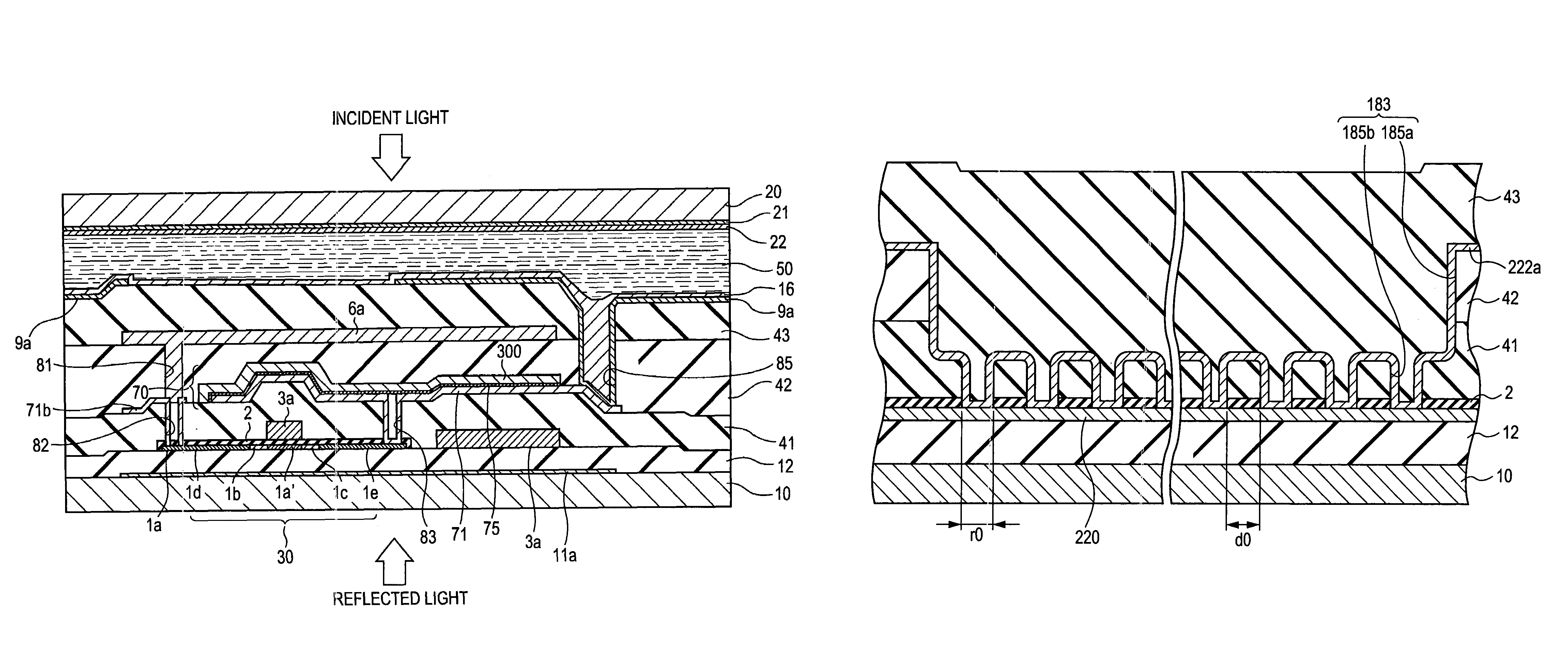

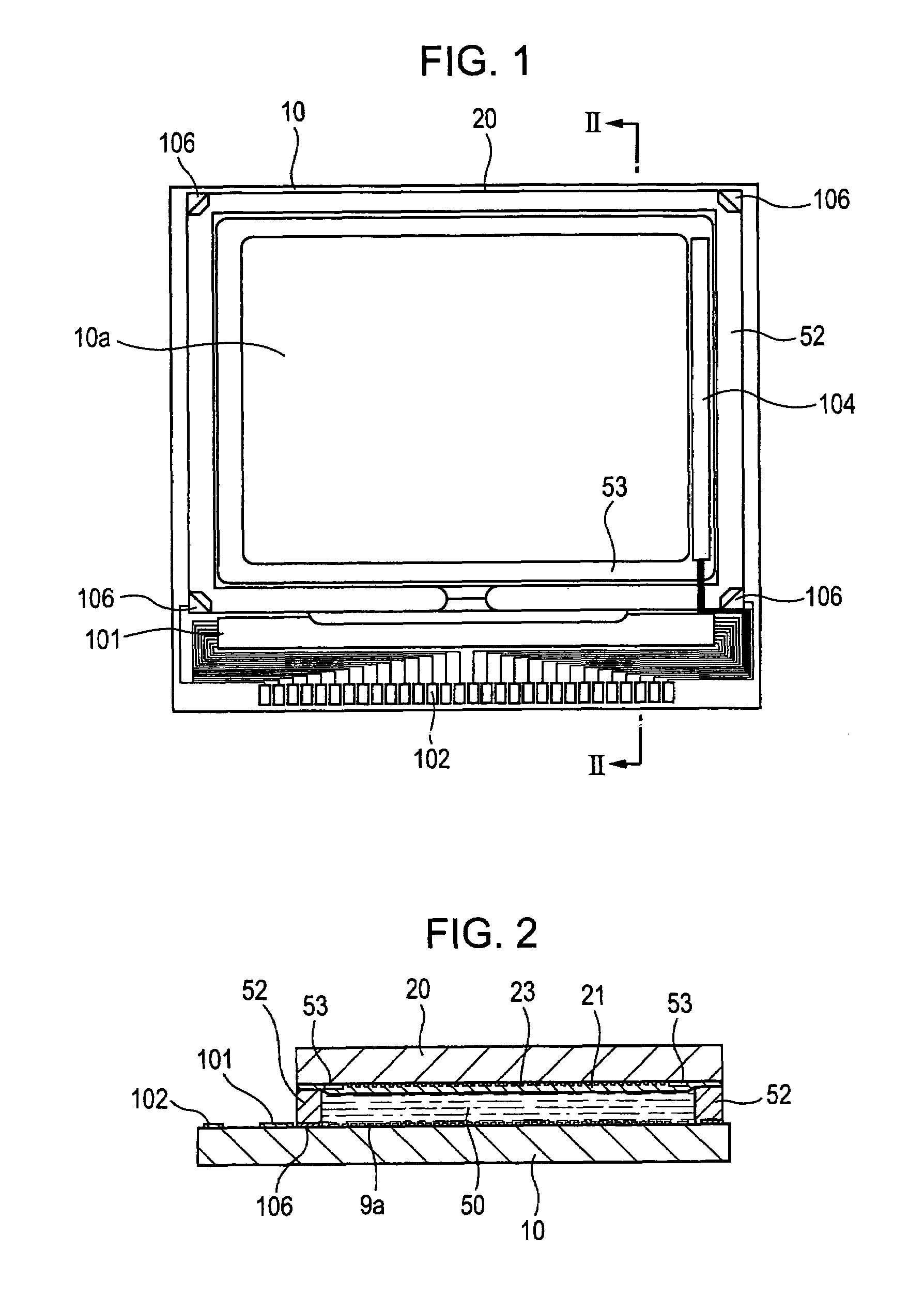

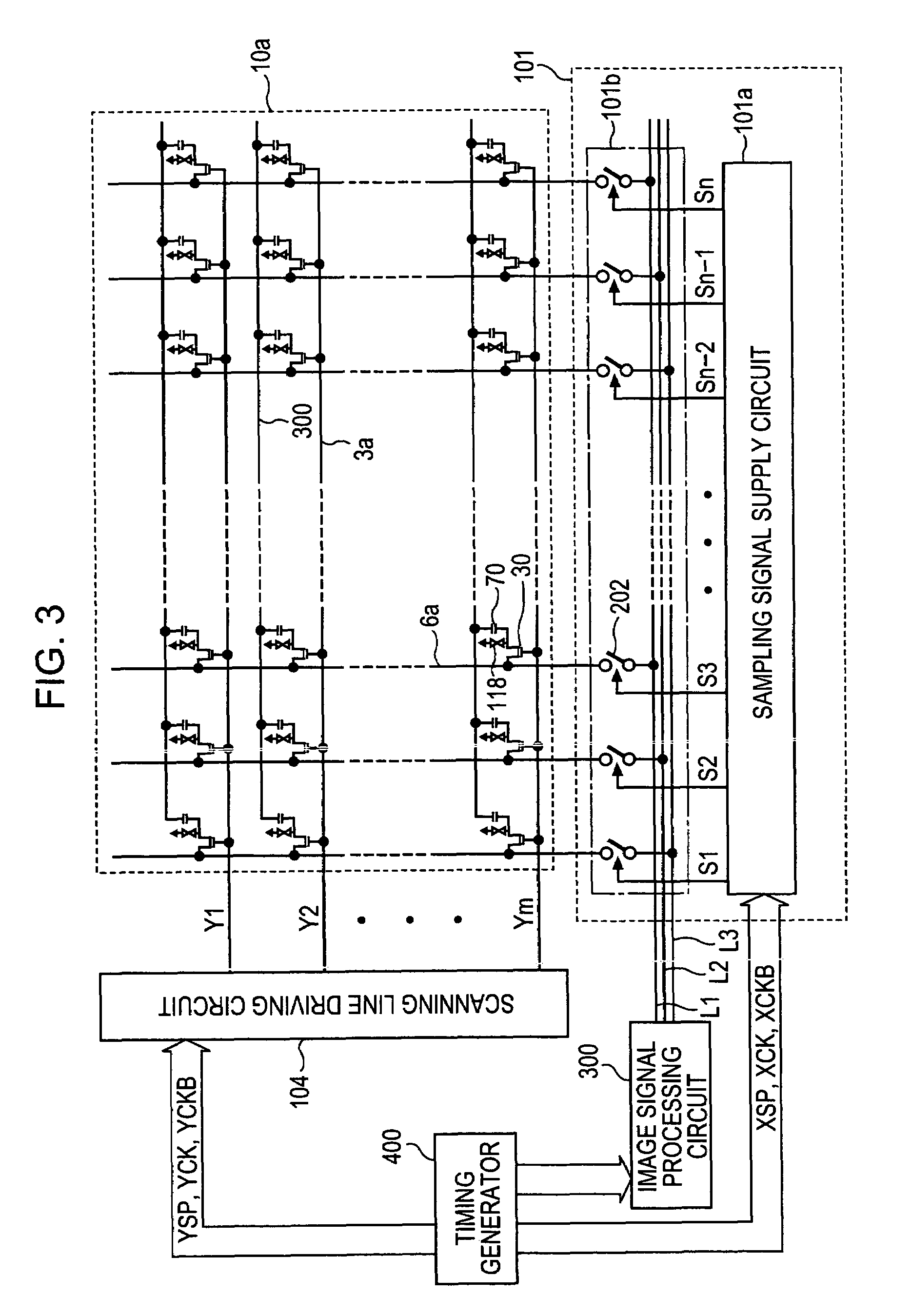

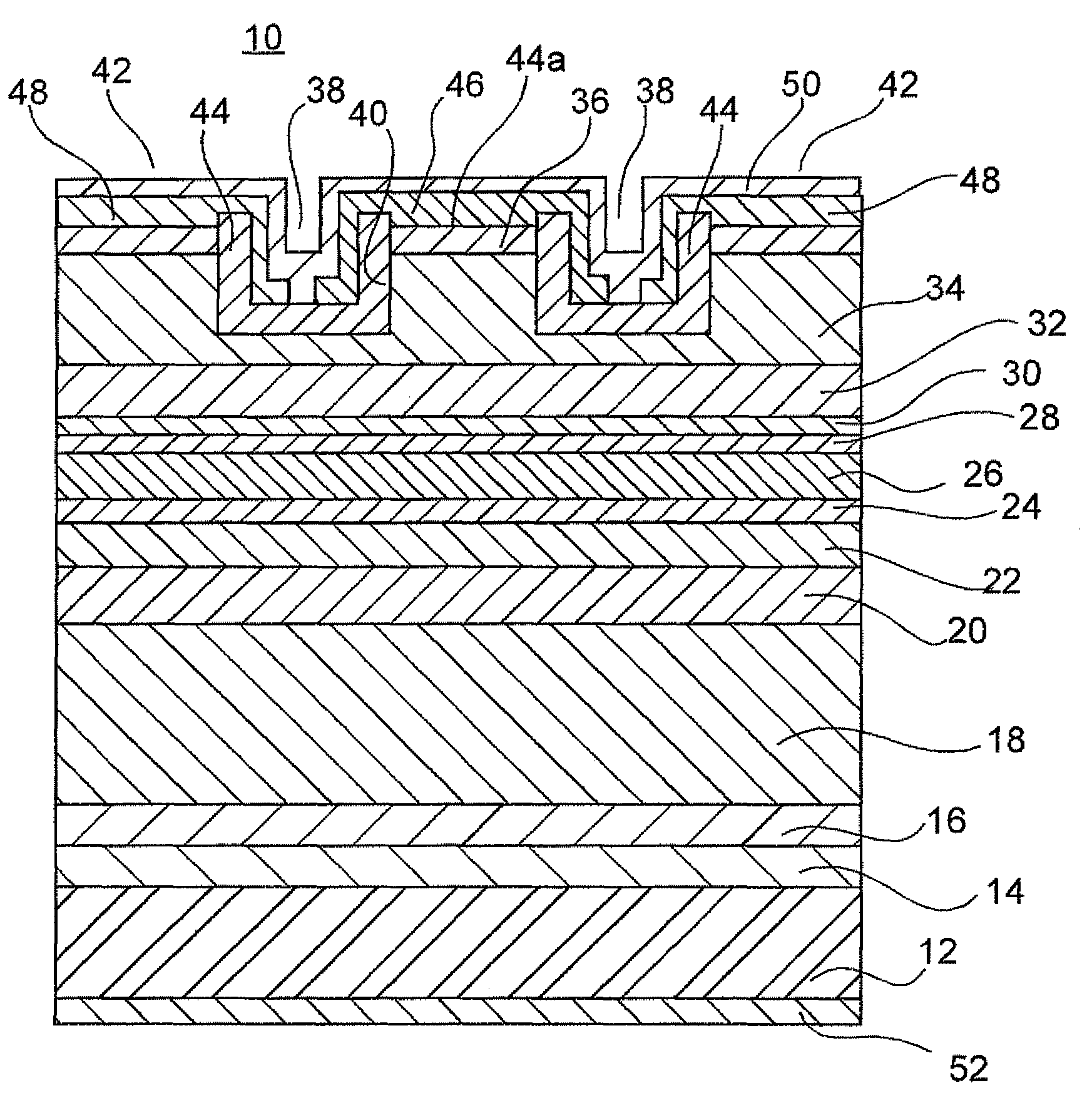

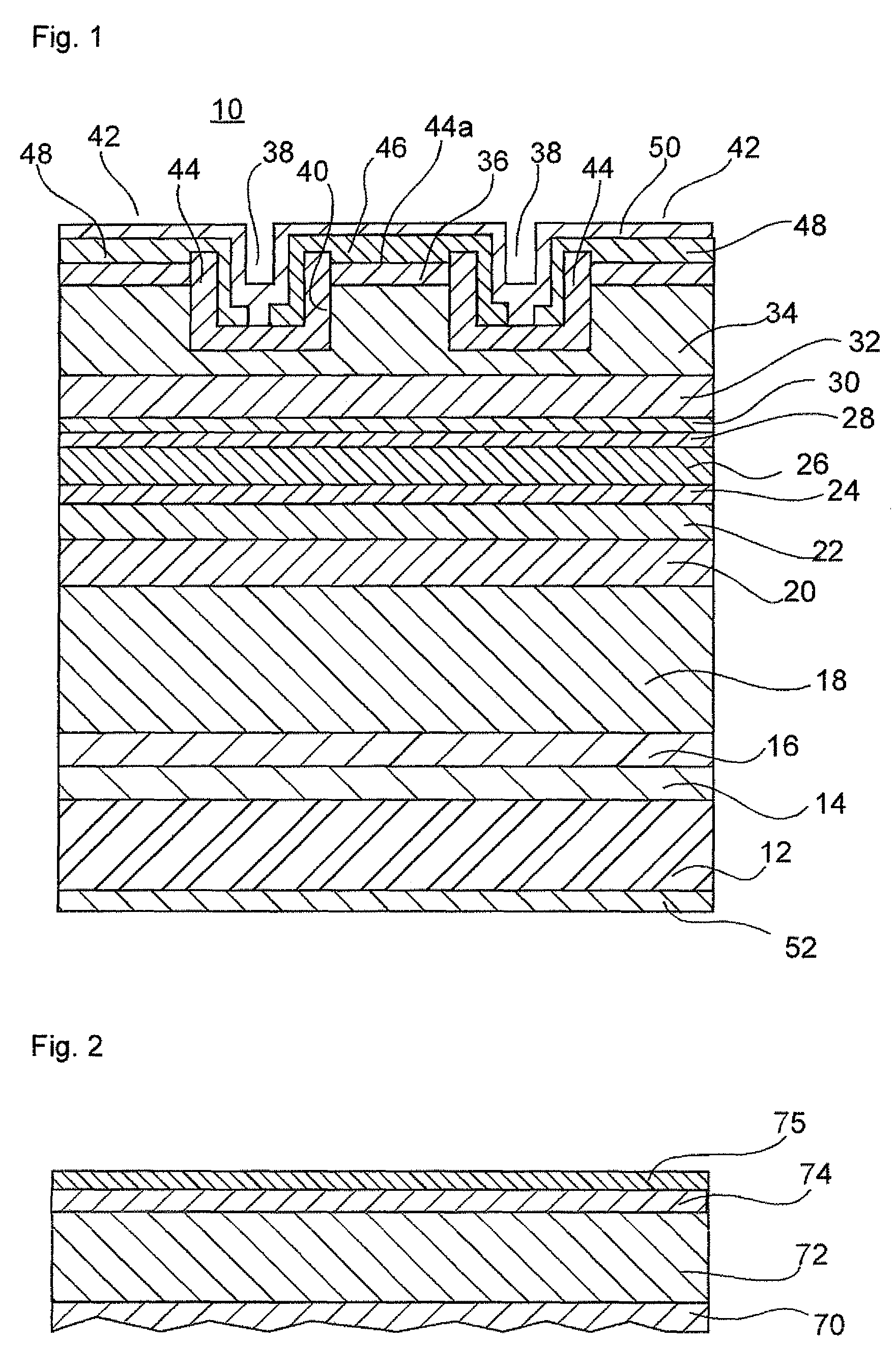

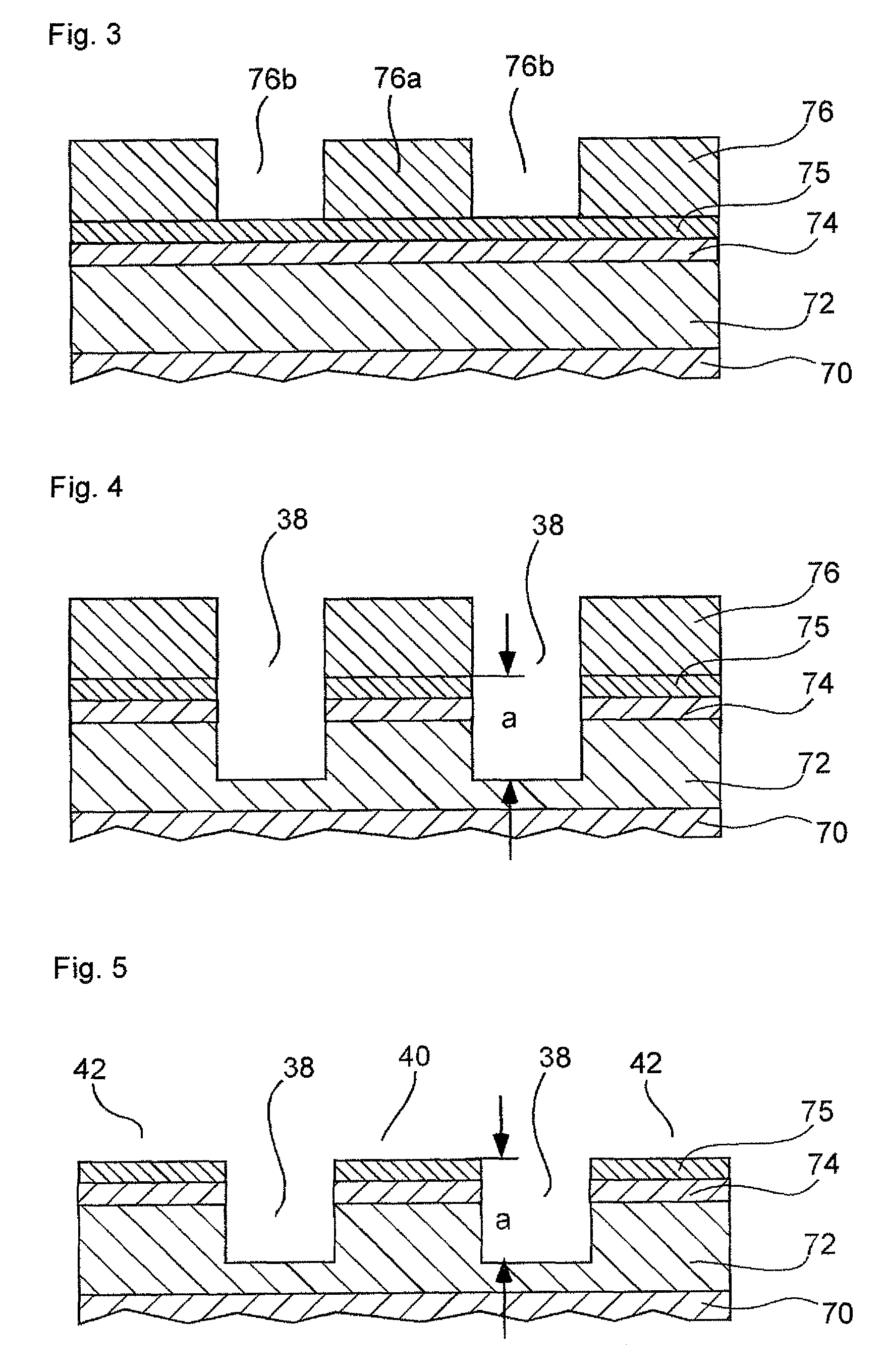

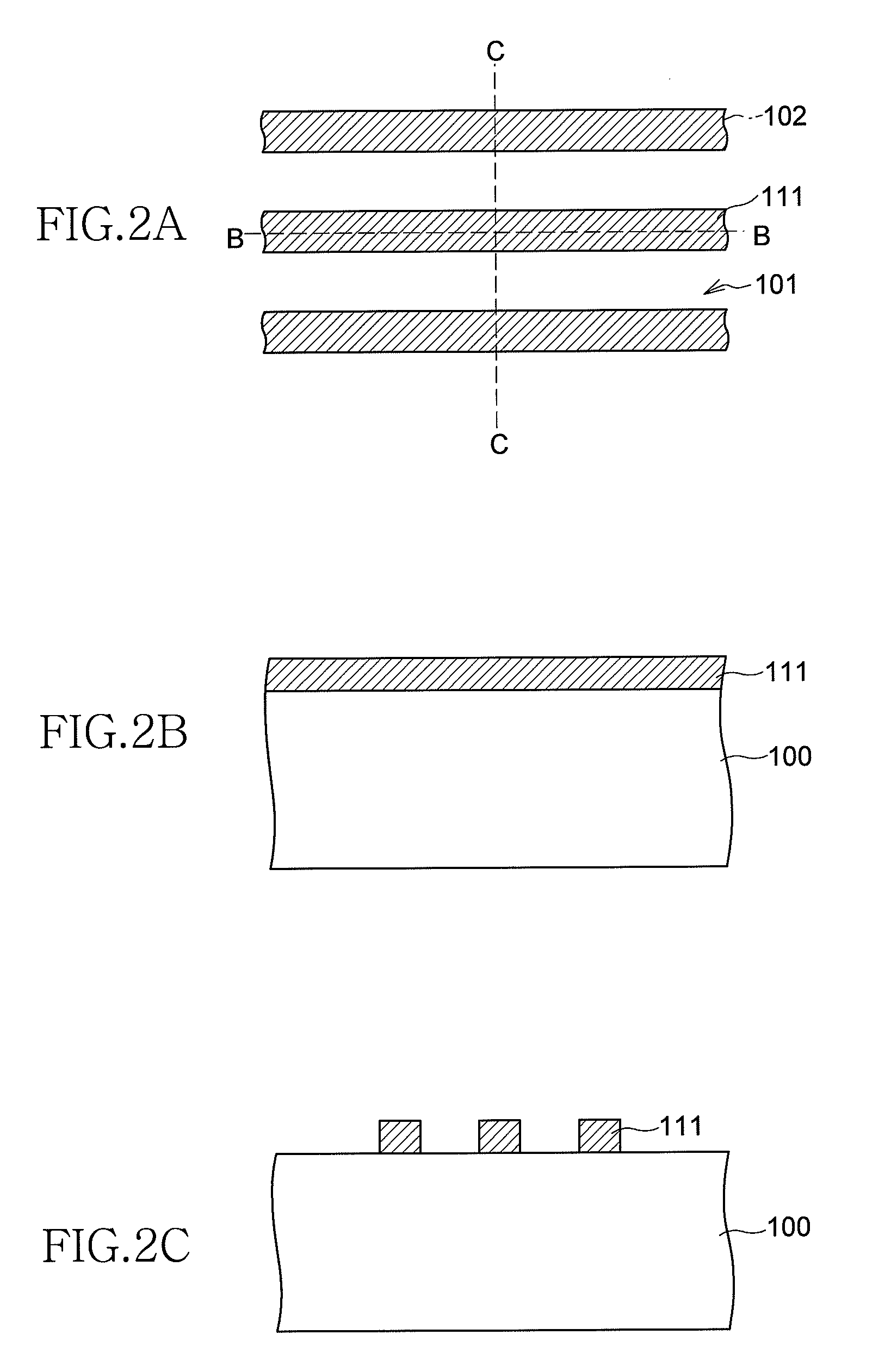

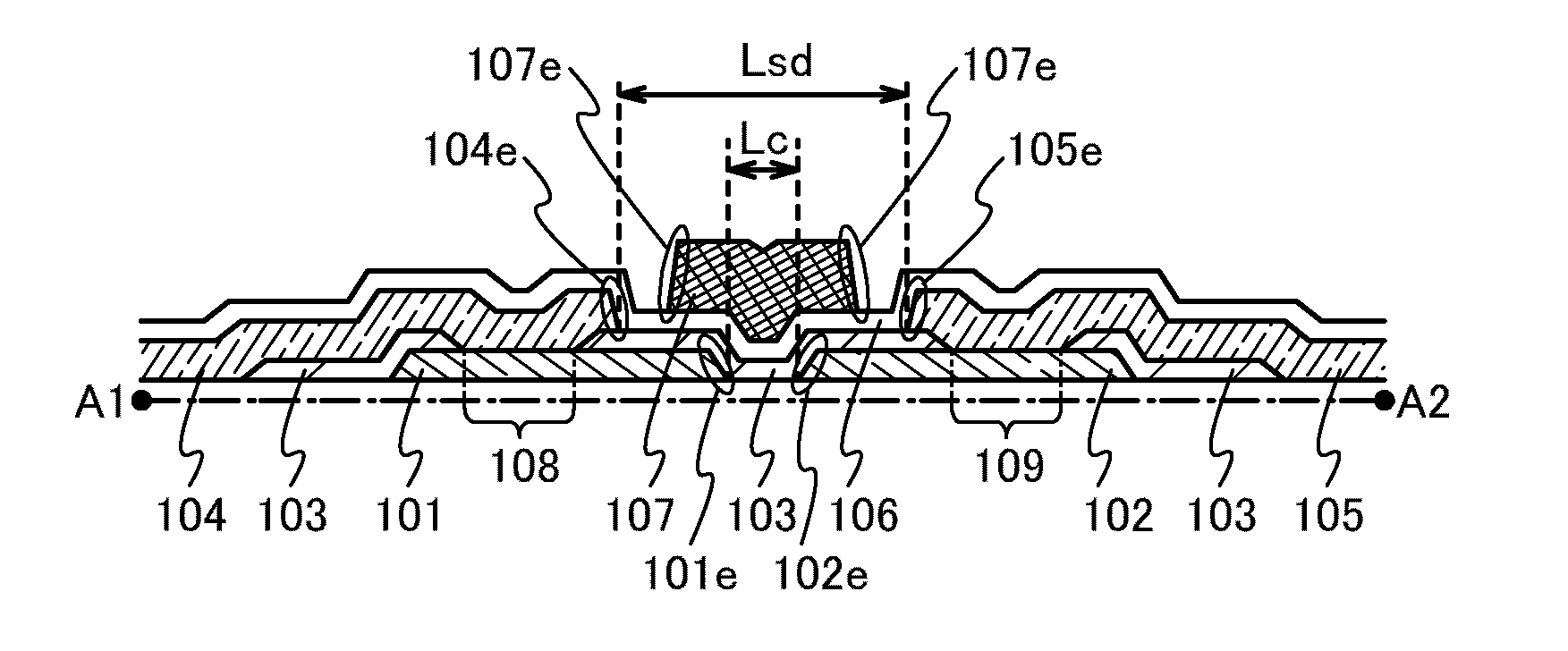

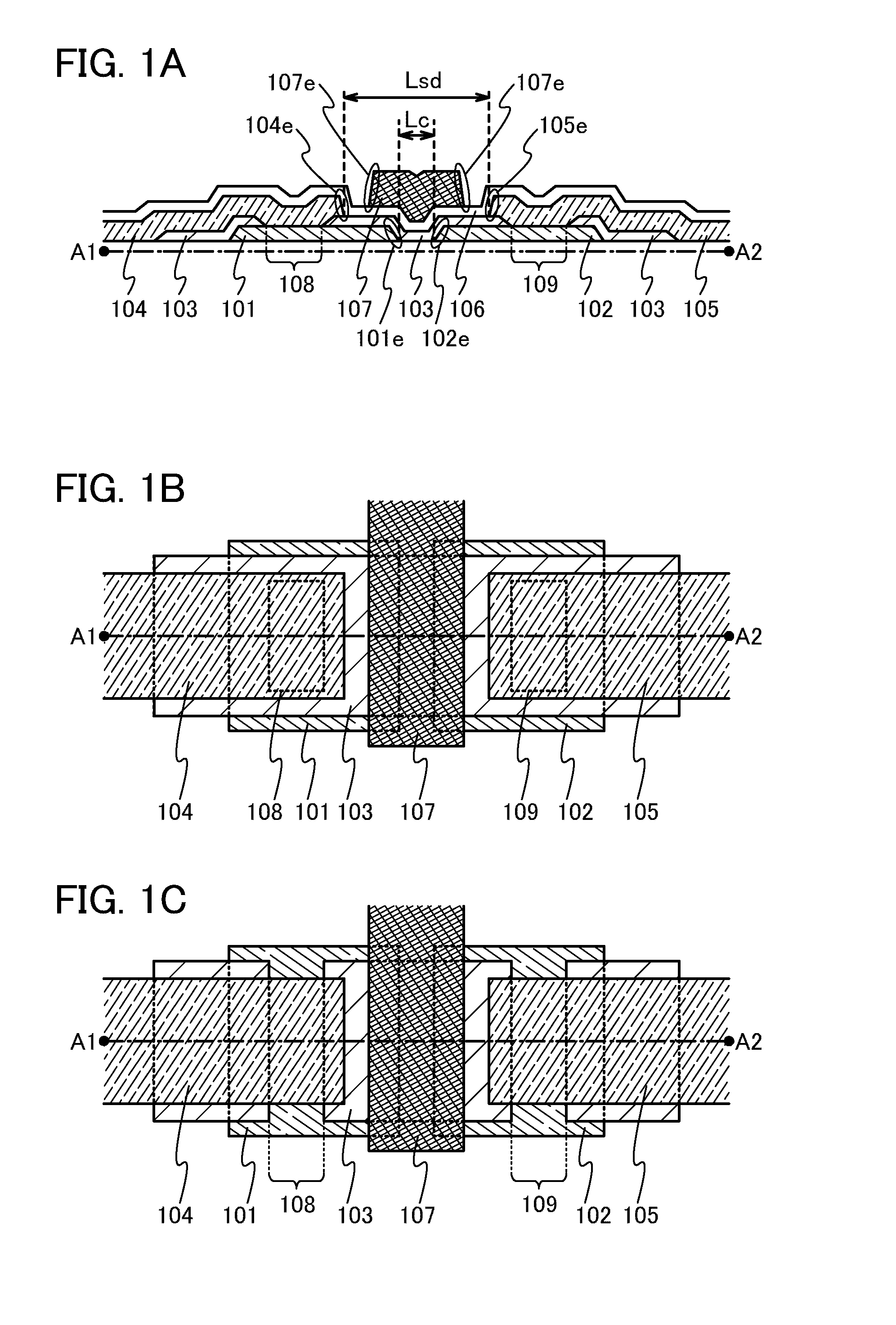

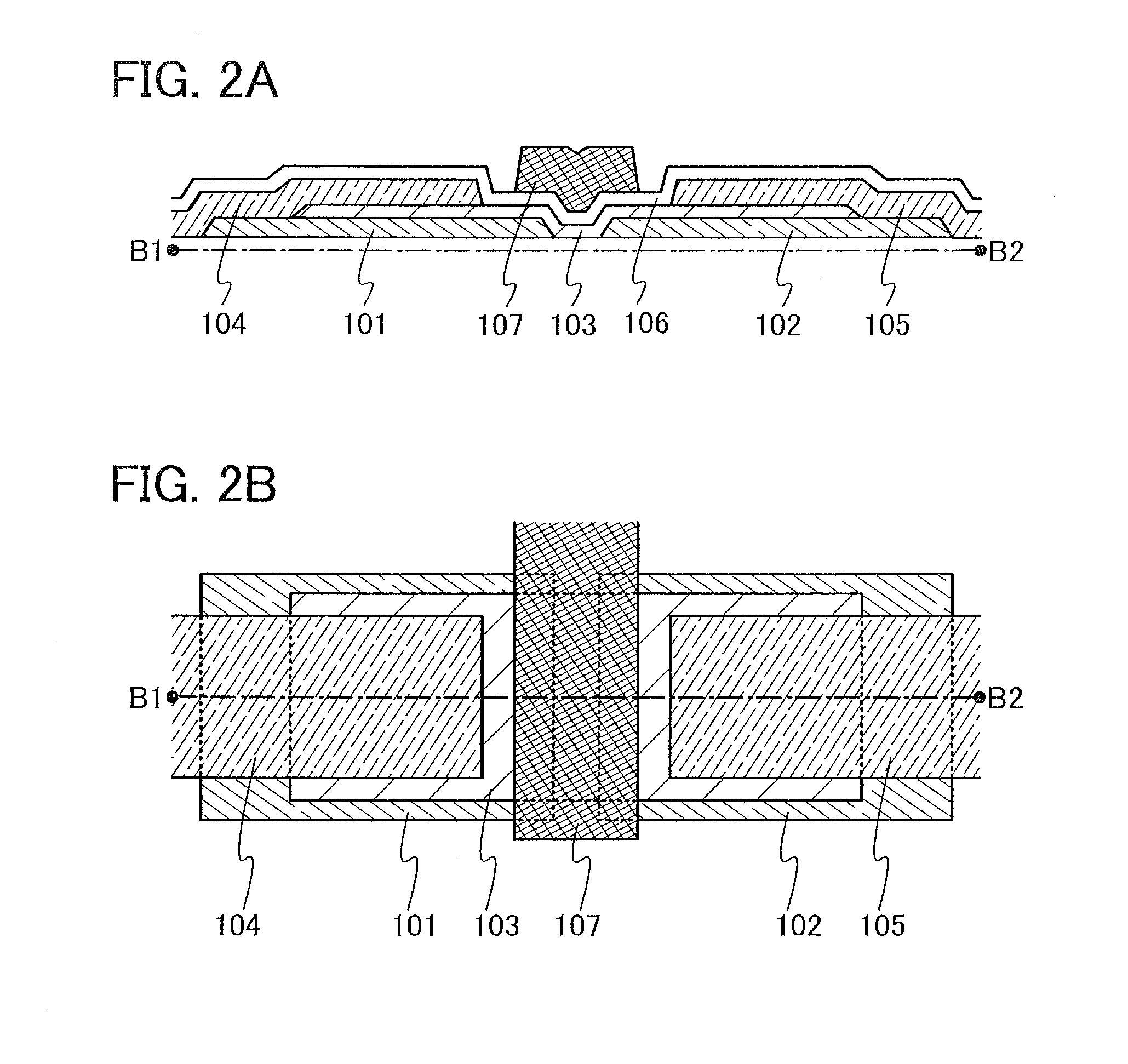

Substrate for semiconductor device, method of manufacturing substrate for semiconductor device, substrate for electro-optical device, electro-optical device, and electronic apparatus

InactiveUS20060011979A1Suppression of contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

A substrate for a semiconductor device includes a substrate, a thin film transistor that is provided on the substrate, a wiring line that is provided above the thin film transistor, an interlayer insulating film that electrically isolates the wiring line from at least a semiconductor layer of the thin film transistor, and a contact hole that has a first hole being cut in the interlayer insulating film and extending in a longitudinal direction in plan view on a substrate surface and a plurality of second holes passing through the interlayer insulating film from a bottom of the first hole to reach a surface of the semiconductor layer and being arranged in the longitudinal direction of the first hole. The connect hole connects the wiring line to the semiconductor layer via the interlayer insulating film.

Owner:SEIKO EPSON CORP

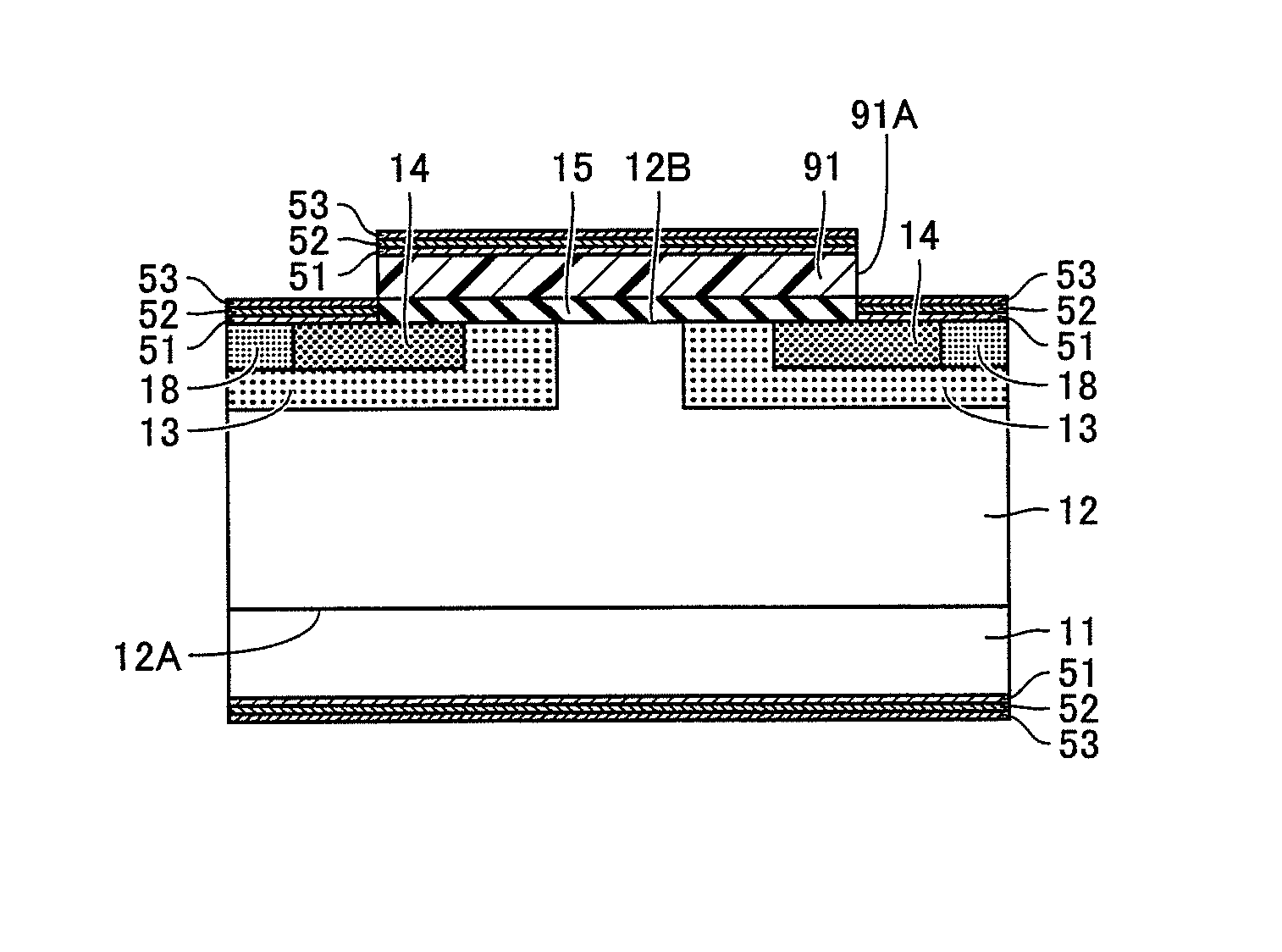

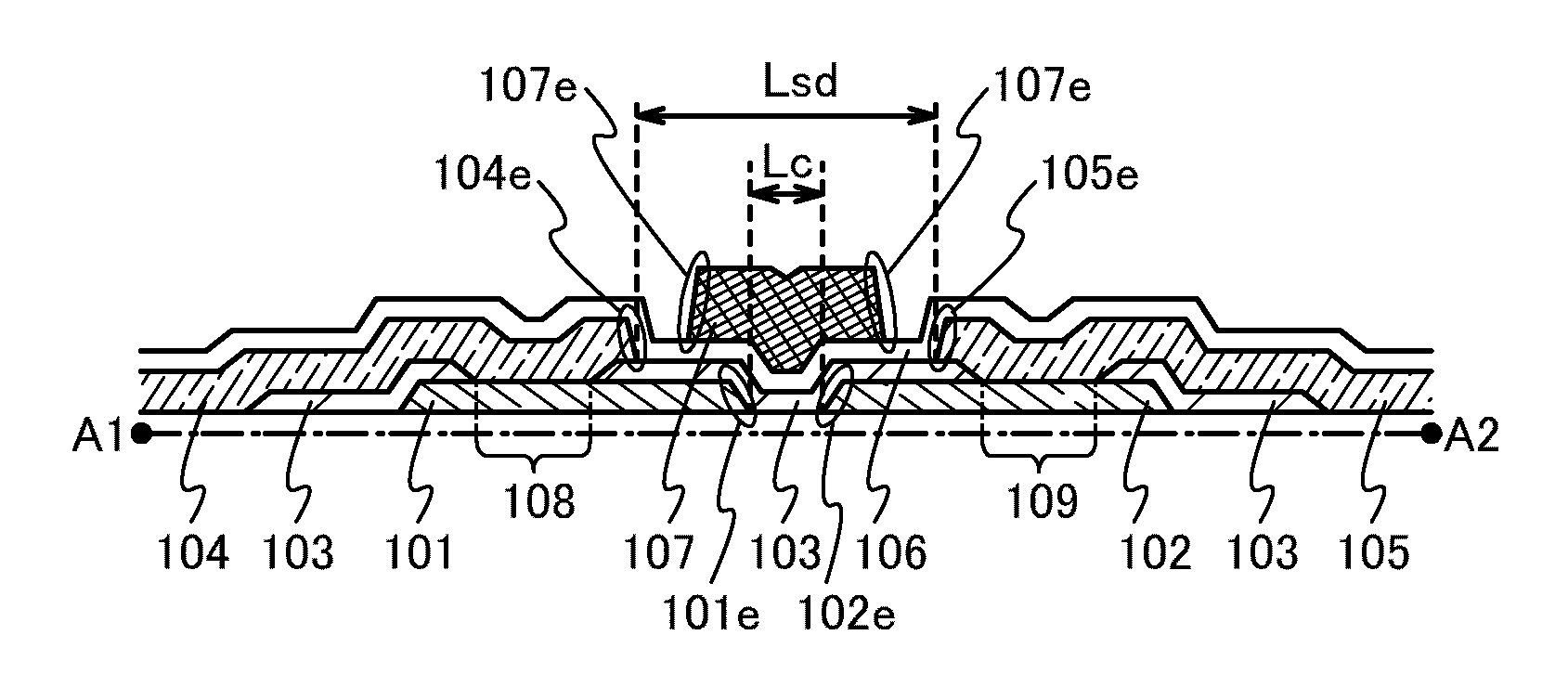

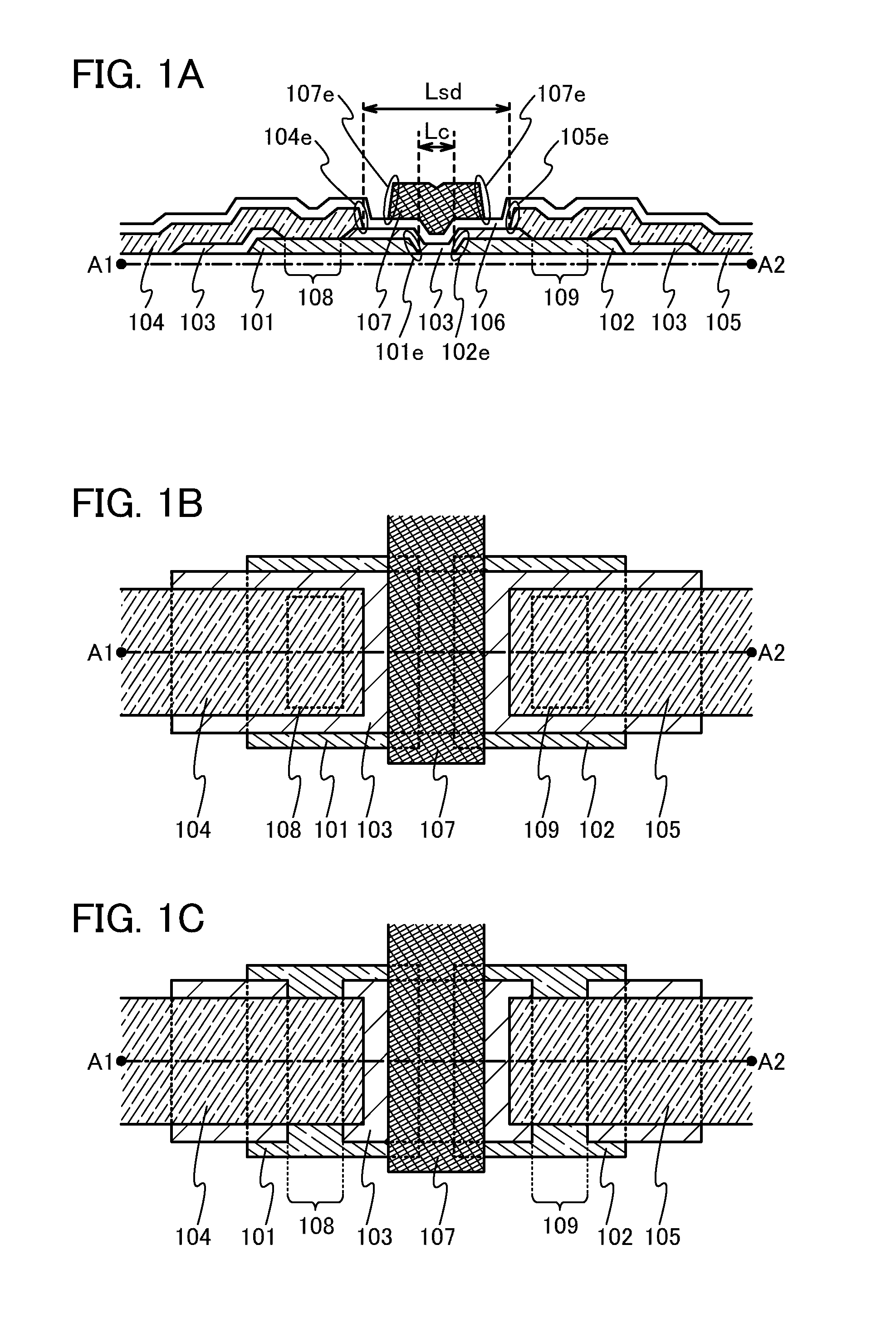

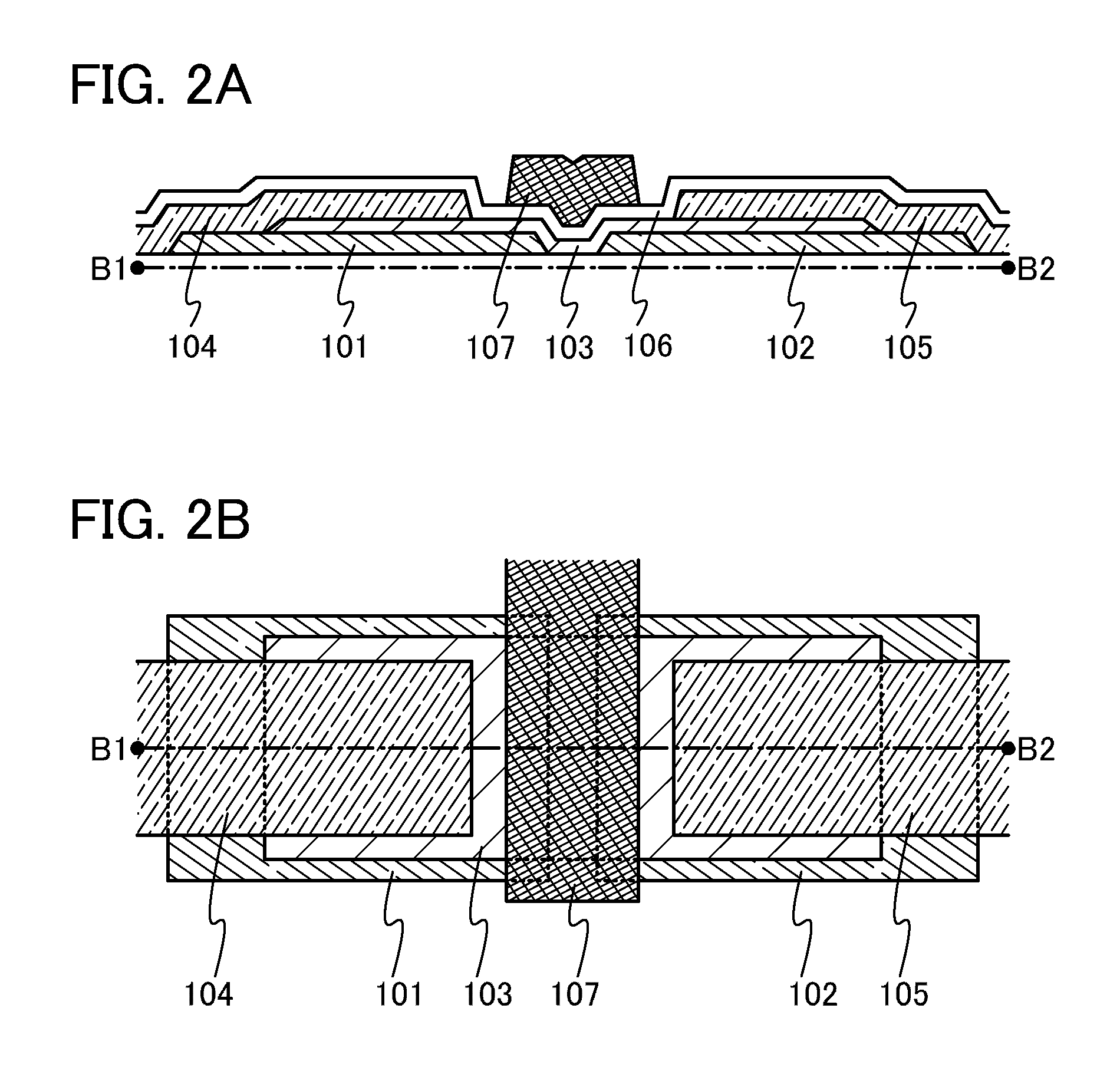

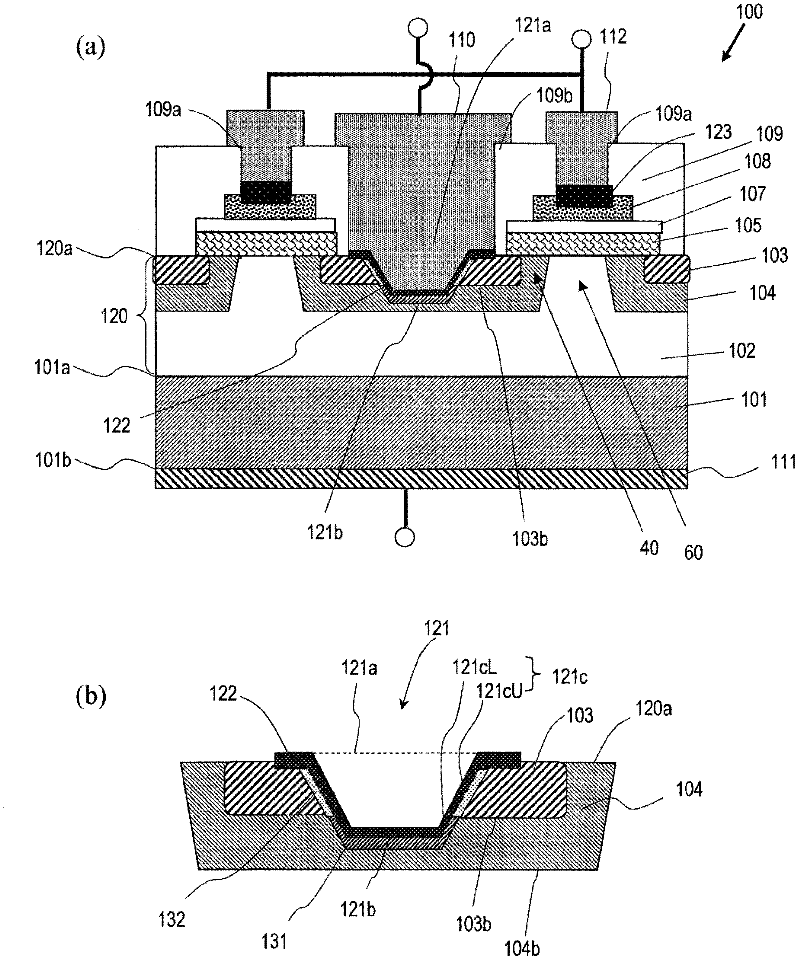

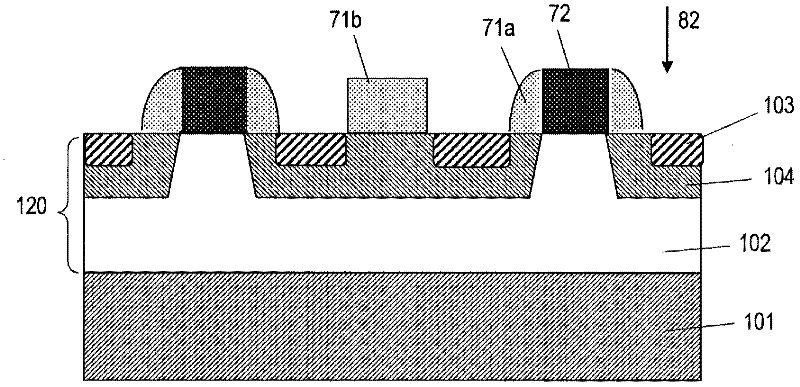

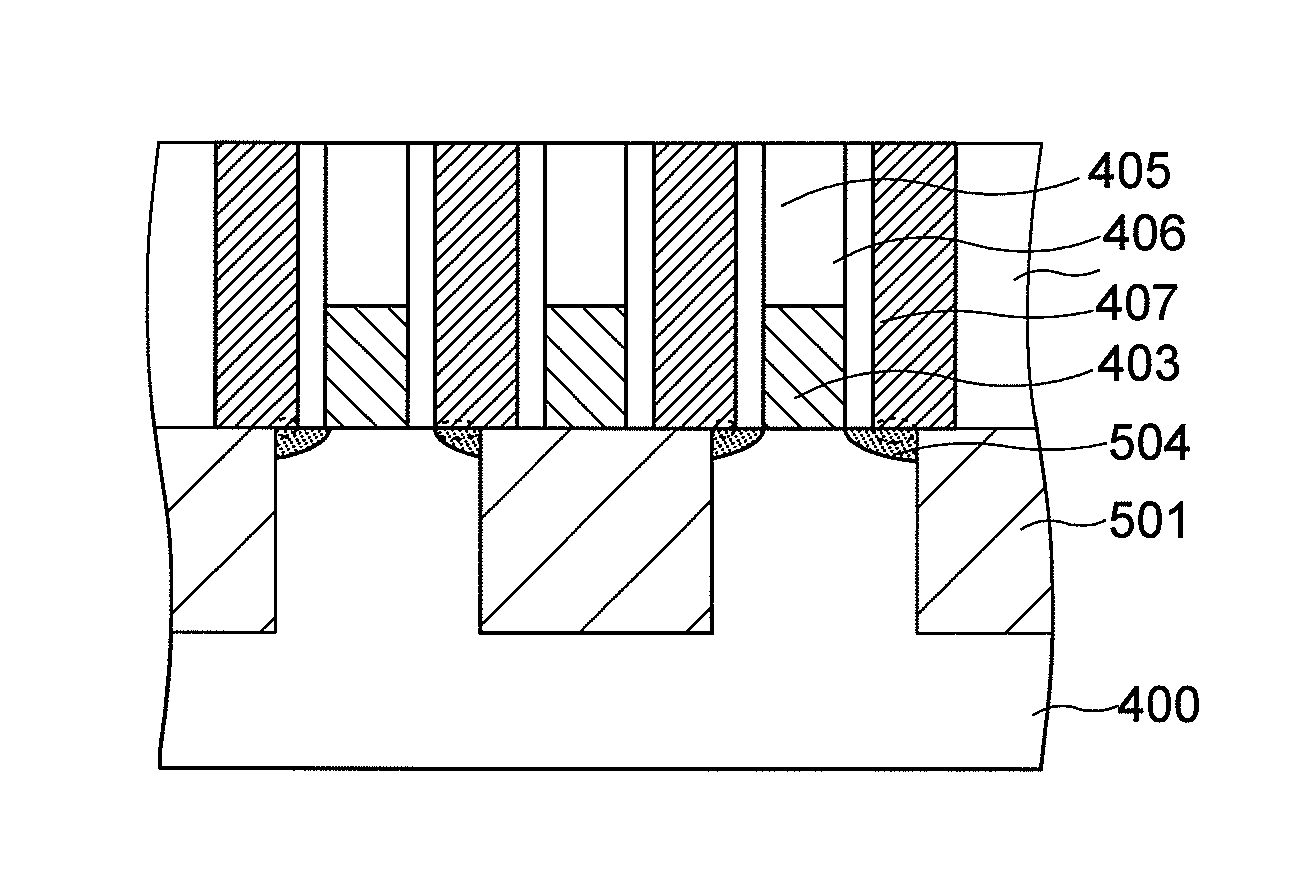

Semiconductor device and process for production thereof

InactiveCN102576723AGuaranteed contact areaIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesHigh concentrationBody region

Disclosed is a semiconductor device (100) comprising: a semiconductor substrate (101); a first silicon carbide layer (120) which is arranged on the main surface of the semiconductor substrate (101); a first first-conductivity-type impurity region (103), a second-conductivity-type body region (104), and a second-conductivity-type contact region (131) formed in a deeper place than the first impurity region (103) in the body region and containing a second-conductivity-type impurity at a higher concentration than that in the body region, all of which are arranged in the first silicon carbide layer; a first-conductivity-type drift region (102); and a first ohmic electrode (122) which is in ohmically contact with the first impurity region (103) and the contact region (131). In the first silicon carbide layer (120), a contact trench (121) that penetrates the first impurity region (103) is provided. The first ohmic electrode (122) is arranged in the contact trench (121) so as to contact with the contact region (131) at at least a part of a lower part (121cL) of the side wall or the bottom surface (121b) of the contact trench.

Owner:PANASONIC CORP

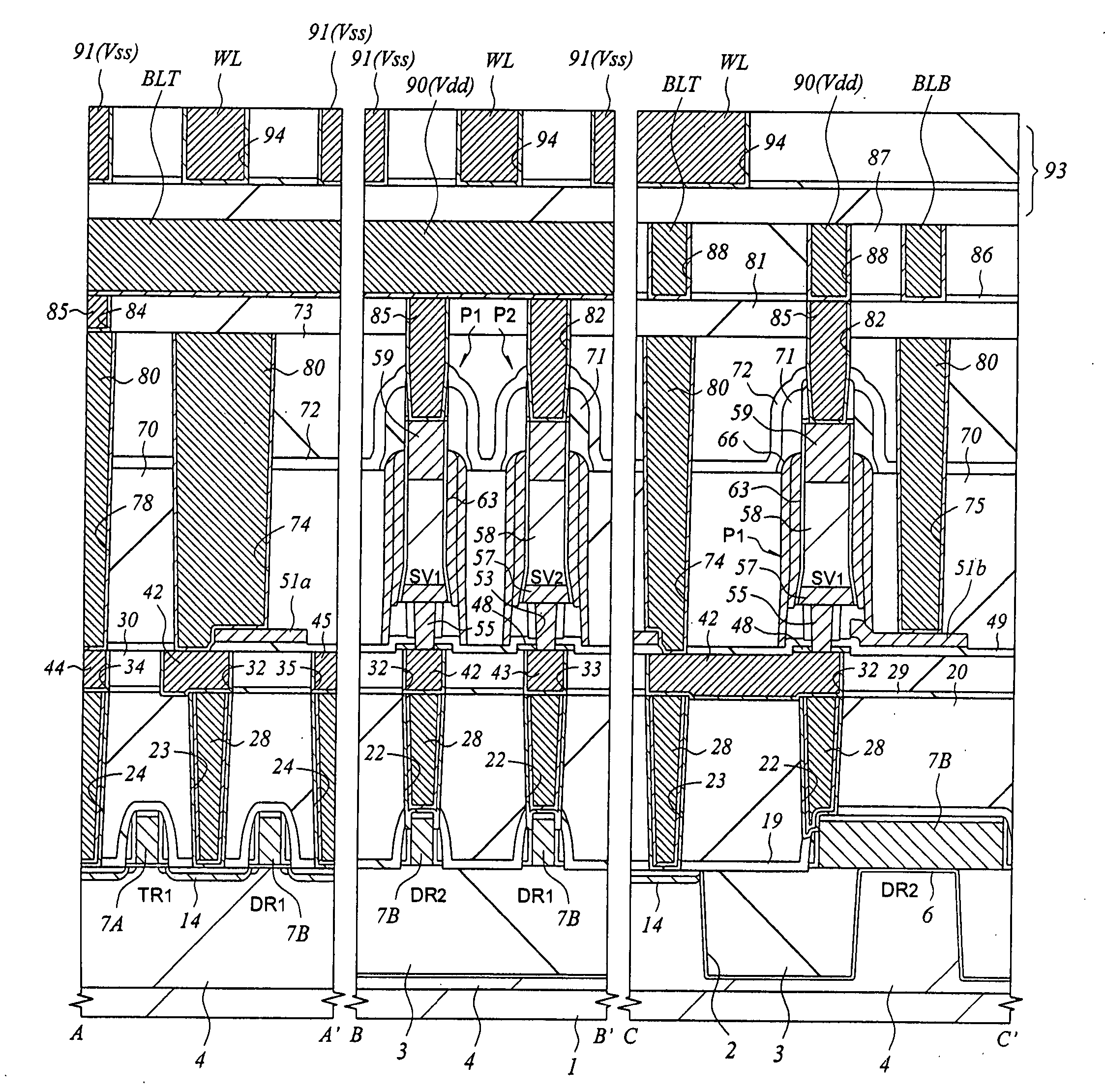

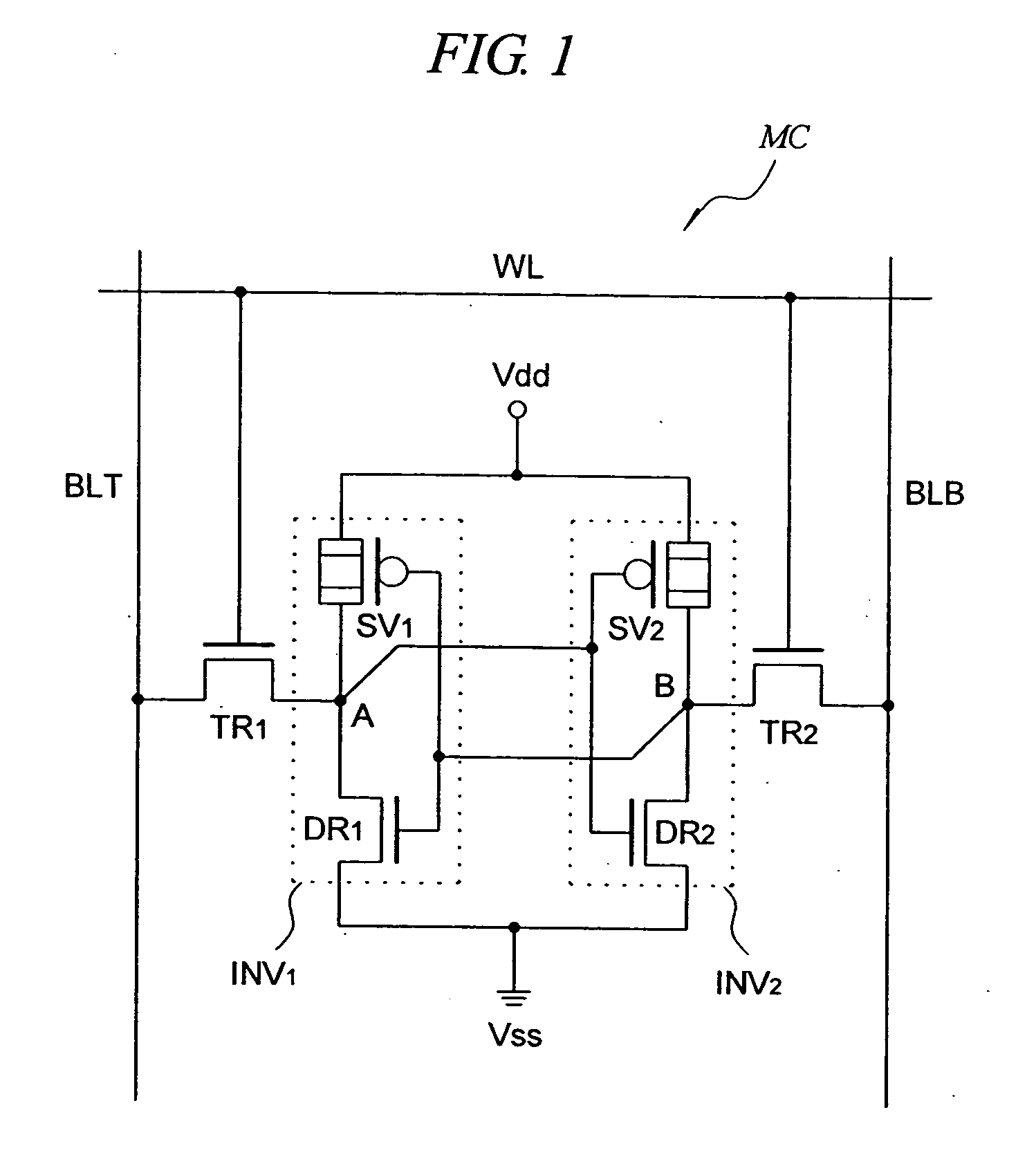

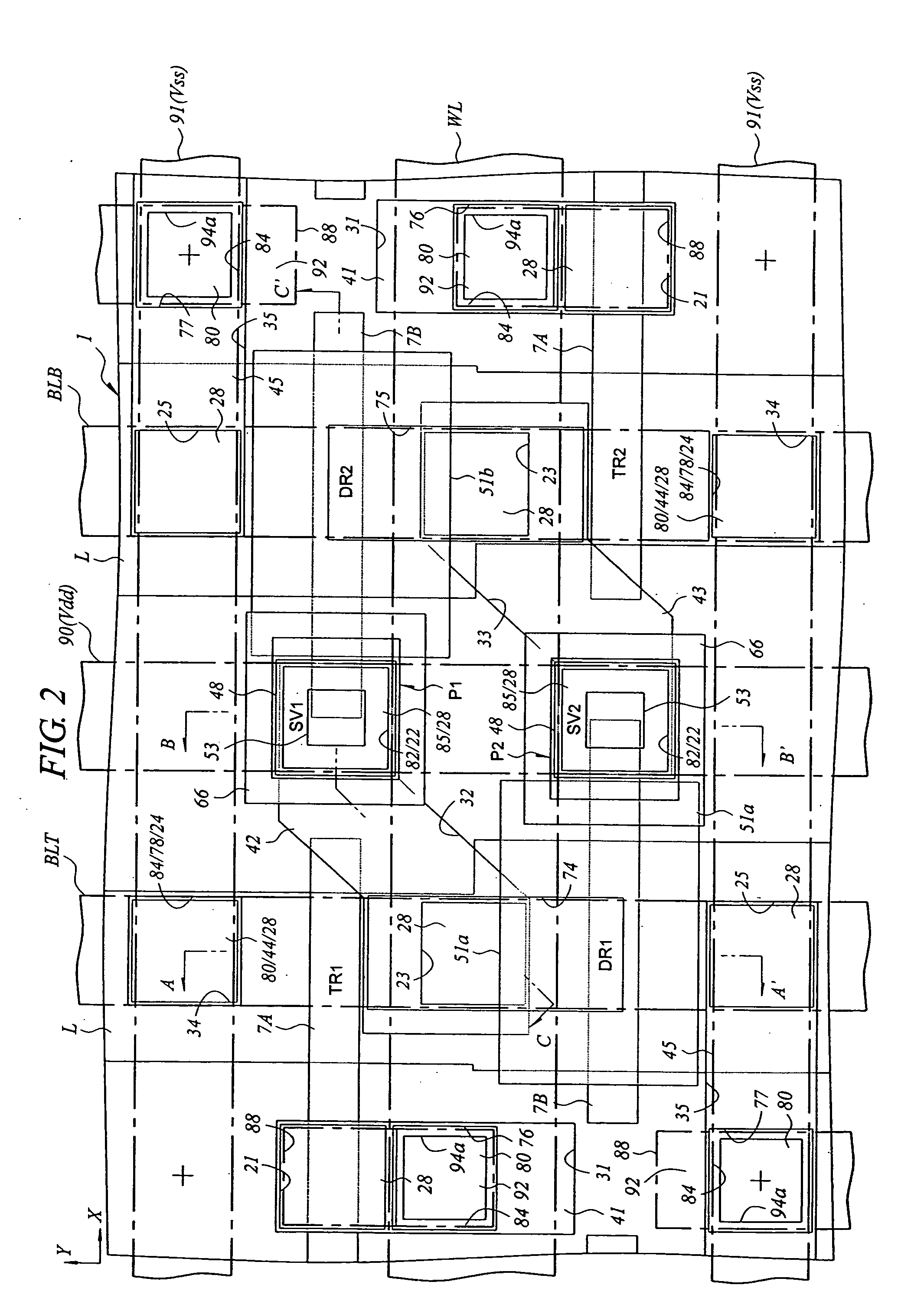

Semiconductor integrated circuit equipment and its manufacture method

InactiveUS20050230716A1Reduce contact resistanceIncrease contactTransistorSemiconductor/solid-state device detailsHigh resistanceSemiconductor

The object of the present invention is to suppress the increase of the contact resistance at the interface between the metal layer and the silicon plug in the wiring structure in which a metal layer is formed on and connected to a silicon plug. For its achievement, a lower semiconductor layer (drain) of a vertical-type MISFET is connected to an intermediate metal layer via an underlying plug composed of a polycrystalline silicon film, and a trap layer composed of a silicon nitride (TiN) film is formed on a part of the surface of the intermediate metal layer so as to surround the plug. The trap layer is formed in order to prevent an undesired high-resistance oxide layer from being formed at the interface between the plug and the intermediate metal layer.

Owner:RENESAS TECH CORP

Semiconductor device

InactiveUS8822989B2Increase the on-currentHigh currentTransistorSolid-state devicesPower semiconductor deviceEngineering

Owner:SEMICON ENERGY LAB CO LTD

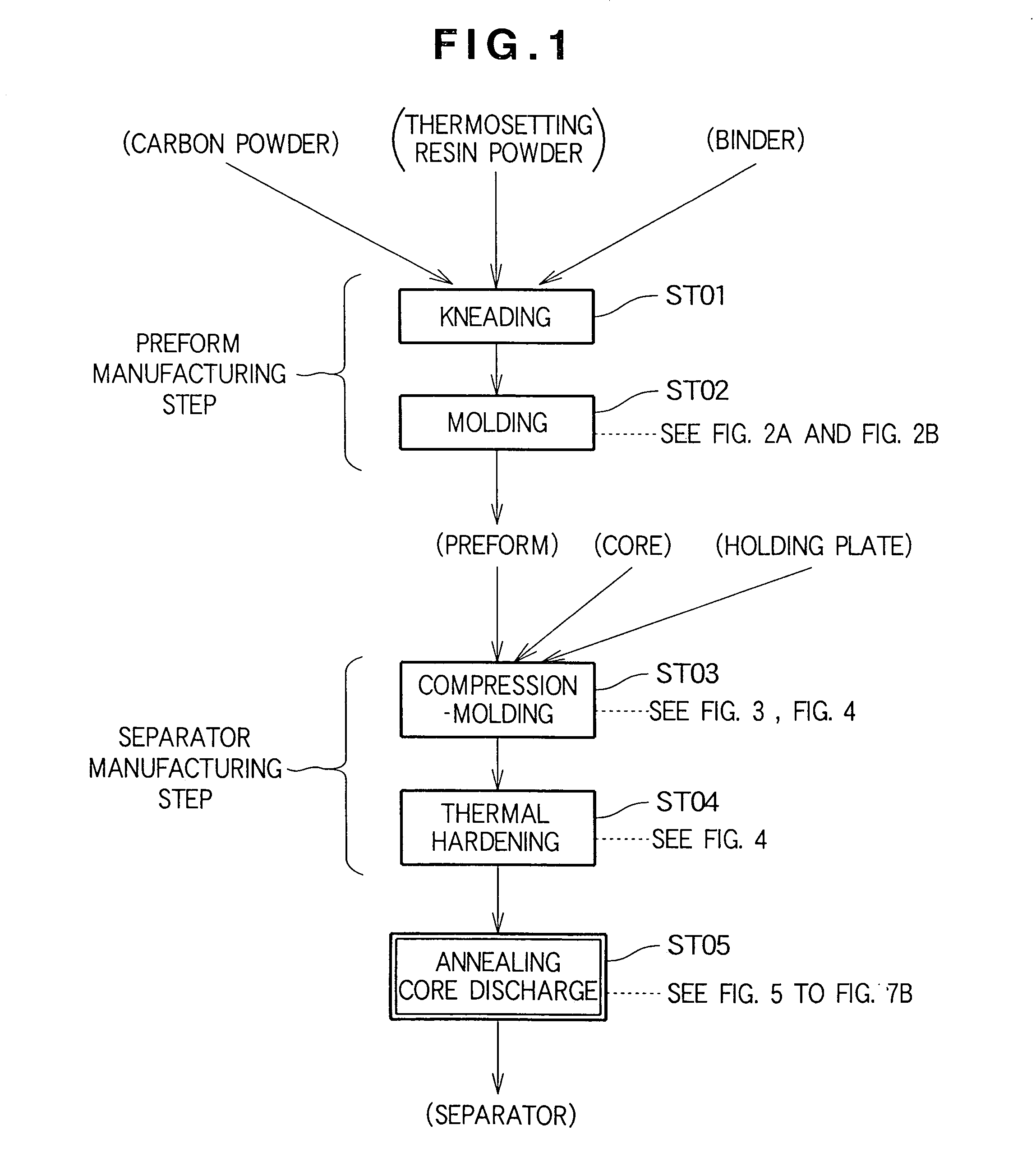

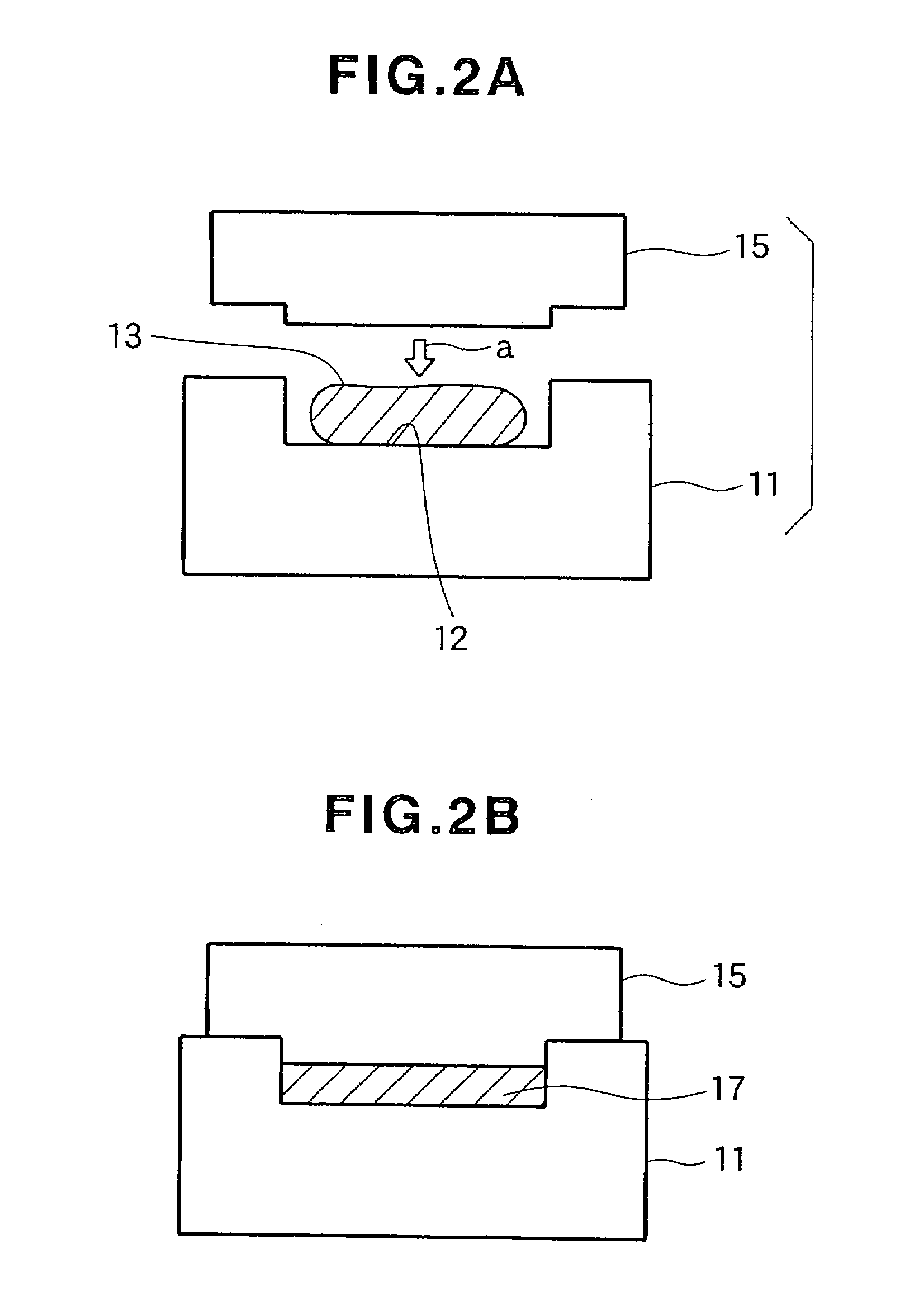

Method of manufacturing separator for fuel cell

InactiveUS7138206B2Eliminate contact resistanceDischargingFinal product manufactureFuel cell auxillariesFuel cellsNuclear engineering

In manufacturing a separator for use in a fuel cell, first, a core (31, 94) is interposed between two preforms (17, 90, 101) and a with-core separator (41, 95, 107) is formed. After this, the core is melted by heating and discharged to form multiple cooling water passages (54). Because consequently there is no need to bring separators together to form the cooling water passages, a seal becomes unnecessary. Also, since there is no need to bring separators together the electrical contact resistance also falls.

Owner:HONDA MOTOR CO LTD

Substrate for semiconductor device, method of manufacturing substrate for semiconductor device, substrate for electro-optical device, electro-optical device, and electronic apparatus

InactiveUS7339189B2Suppression of contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Owner:SEIKO EPSON CORP

Crimping terminal fitting, method of forming it and wire with terminal fitting

InactiveUS8123575B2High strengthMaintain strengthContact member manufacturingConnections effected by permanent deformationEngineeringMechanical engineering

A crimping terminal fitting has a wire barrel (21) to be crimped and connected to core strands (31) of a wire (30). The wire barrel (21) has a base plate (23) continuously extending from a ground terminal (11) in a longitudinal direction. Two core crimping pieces (25) extend from the opposite sides of the base plate (23). A thinned portion (27) is formed at least at a leading end of each core crimping piece (25) and is thinner than the base plate (23).

Owner:SUMITOMO WIRING SYST LTD

Method for manufacturing semiconductor optical device

InactiveUS7981704B2Prevent decrease in contact areaSimple stepsOptical wave guidanceLaser detailsResistSemiconductor

After a metal cap layer is laminated on a semiconductor laminated structure, a waveguide ridge is formed, the waveguide ridge is coated with an SiO2 film, and a resist is applied; then, a resist pattern is formed, the resist pattern exposing the surface of the SiO2 film on the top of the waveguide ridge, and burying the SiO2 film in channels with a resist film having a surface higher than the surface of the metal cap layer of the waveguide ridge and lower than the surface of the SiO2 film of the waveguide ridge; the SiO2 film is removed by dry etching, using the resist pattern as a mask. The metal cap layer is removed by wet etching, and a p-GaN layer of the waveguide ridge is exposed to form the electrode layer.

Owner:MITSUBISHI ELECTRIC CORP

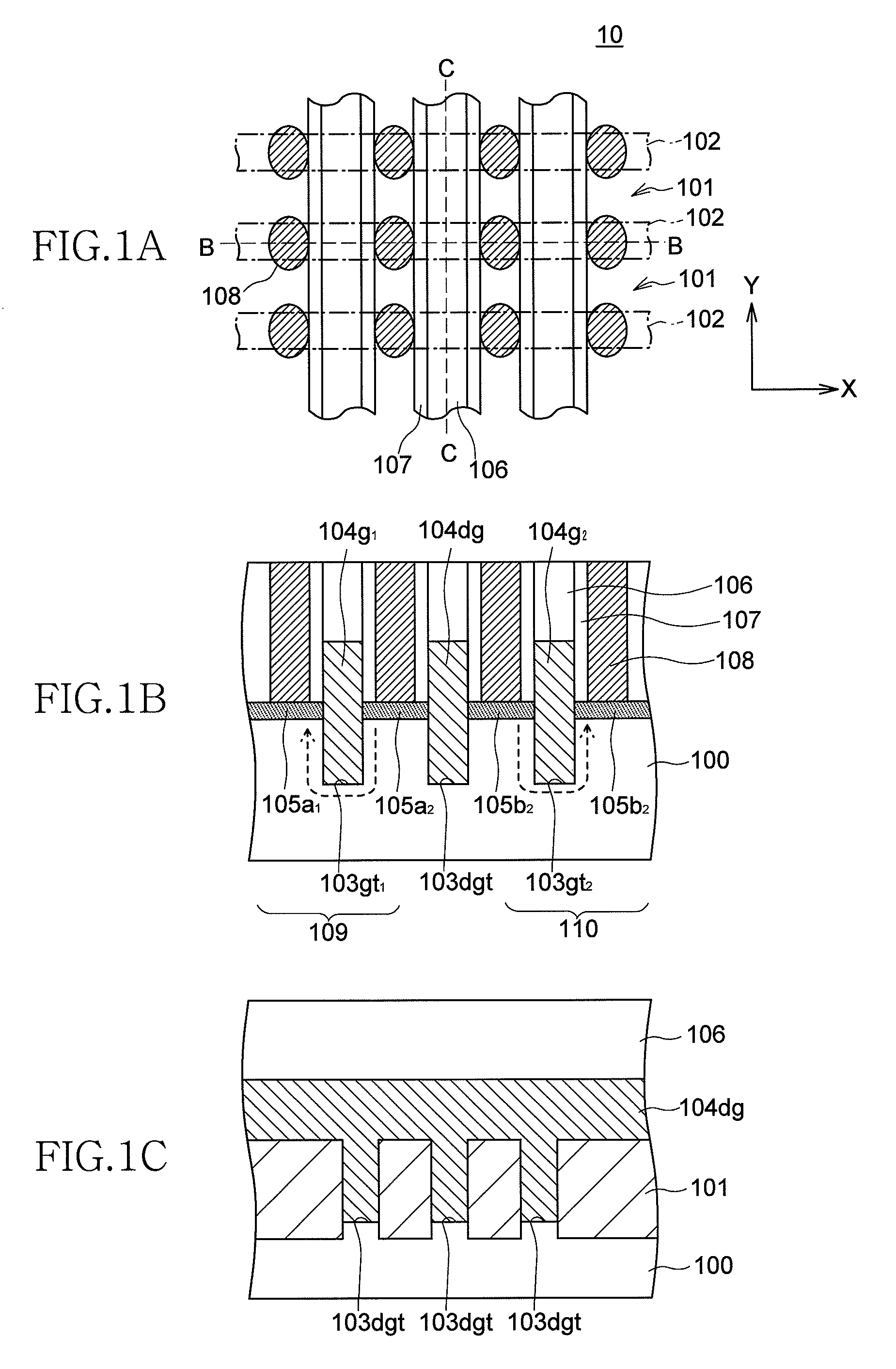

Semiconductor device having gate trenches and manufacturing method thereof

ActiveUS8390064B2Easy to resolvePrevent reduction in active region patternSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceEngineering

A semiconductor device includes a first gate trench, a second gate trench, and a dummy gate trench provided in an active region extending in an X direction; and a first gate electrode, a second gate electrode, and a dummy gate electrode extending in a Y direction crossing the active region, at least a part of which are buried in the first gate trench, the second gate trench, and the dummy gate trench, respectively. The dummy gate electrode arranged between second and third diffusion layers isolates and separates a transistor constituted by the first gate electrode and first and second diffusion layers provided on both sides of the first gate electrode, respectively, from a transistor constituted by the second gate electrode and third and fourth diffusion layers provided on both sides of the second gate electrode, respectively.

Owner:LONGITUDE LICENSING LTD

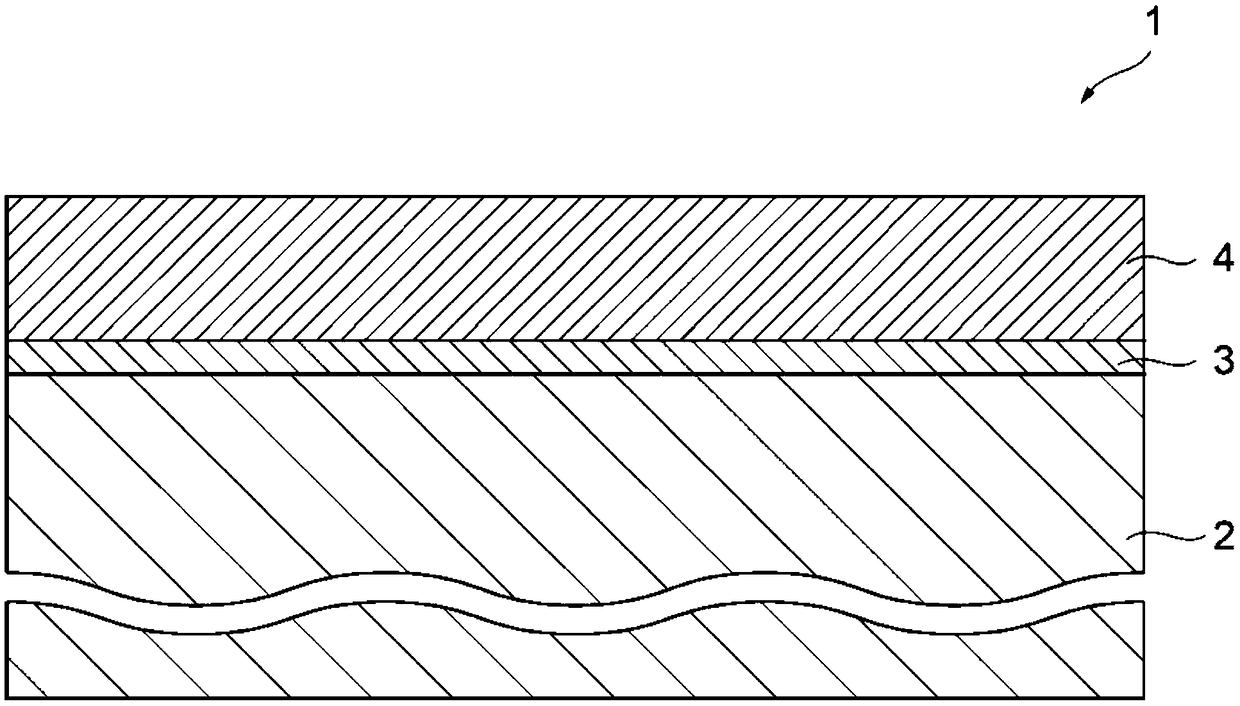

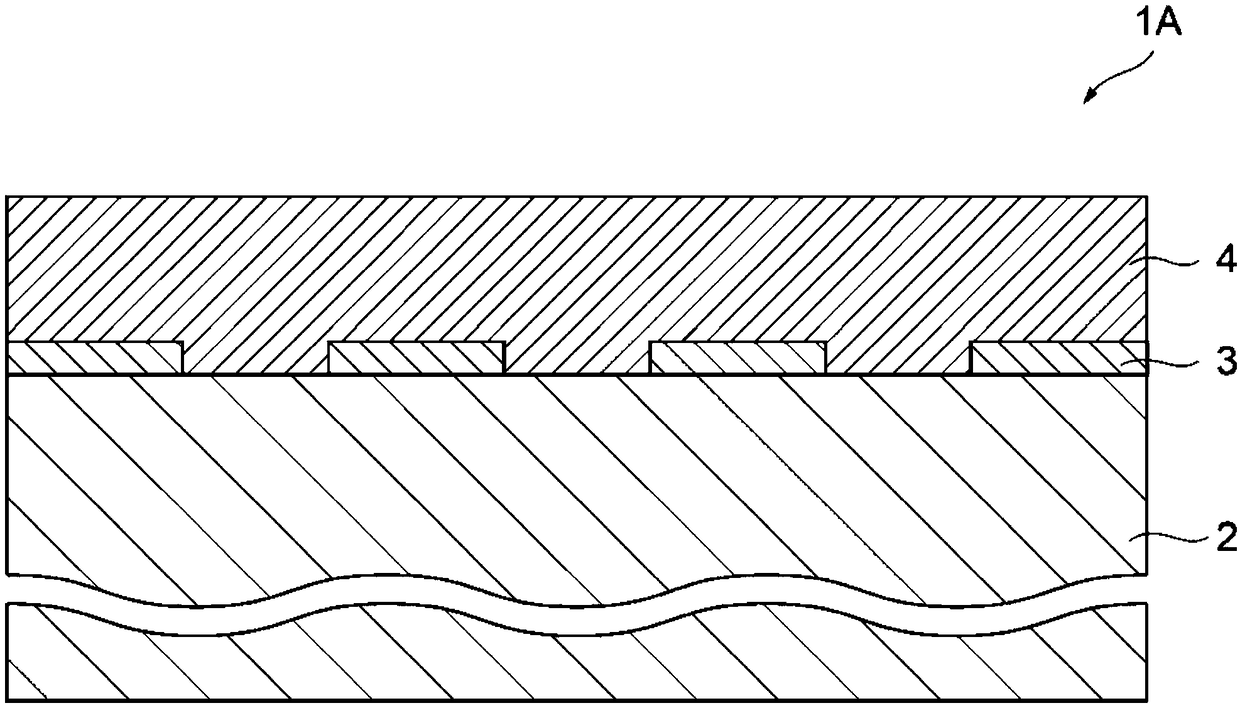

Surface treatment material, production method thereof, and component formed using surface treatment material

InactiveCN109072470AMaintain propertiesNo deterioration of bending workabilityCoupling contact membersLiquid/solution decomposition chemical coatingElectrical resistance and conductanceOptoelectronics

The present invention provides a surface treatment material or the like that exhibits suppressed deterioration of the characteristics of the surface of a surface treatment coating, particularly the characteristics of contact resistance and solder wettability when used in a high temperature (200 DEG C, for example) environment, without adversely affecting bending workability. The surface treatmentmaterial (1) according to the present invention has a conductive substrate (2) and a surface treatment coating (4) comprising at least one metal layer formed on the conductive substrate (2). The surface treatment coating (4) is a plating coating, is formed on the entire surface of the conductive substrate (2) or a portion thereof via a zinc-containing layer (3) having a thickness of 50 nm or lessand having zinc as a main component, or is formed on the conductive substrate (2) without using the zinc-containing layer (3), and has a bonding area percentage of 85% or more where the bonding area is the test area as measured using the tape test method stipulated by JIS H8504:1999.

Owner:FURUKAWA ELECTRIC CO LTD

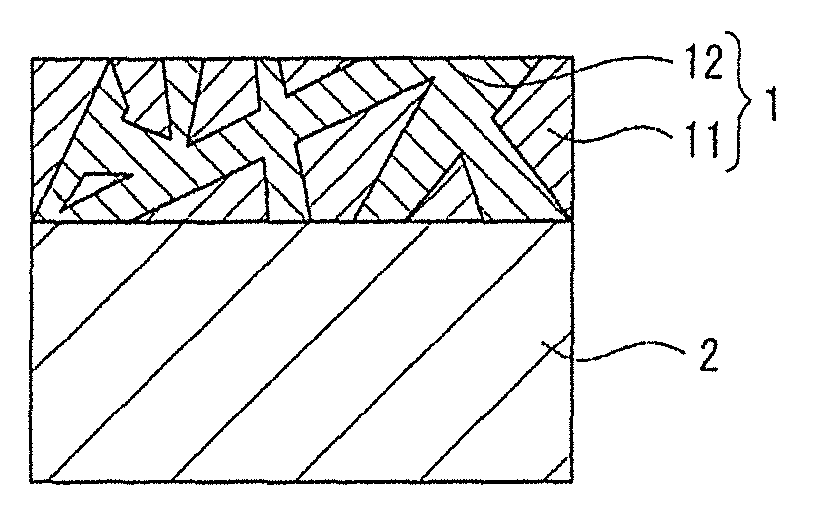

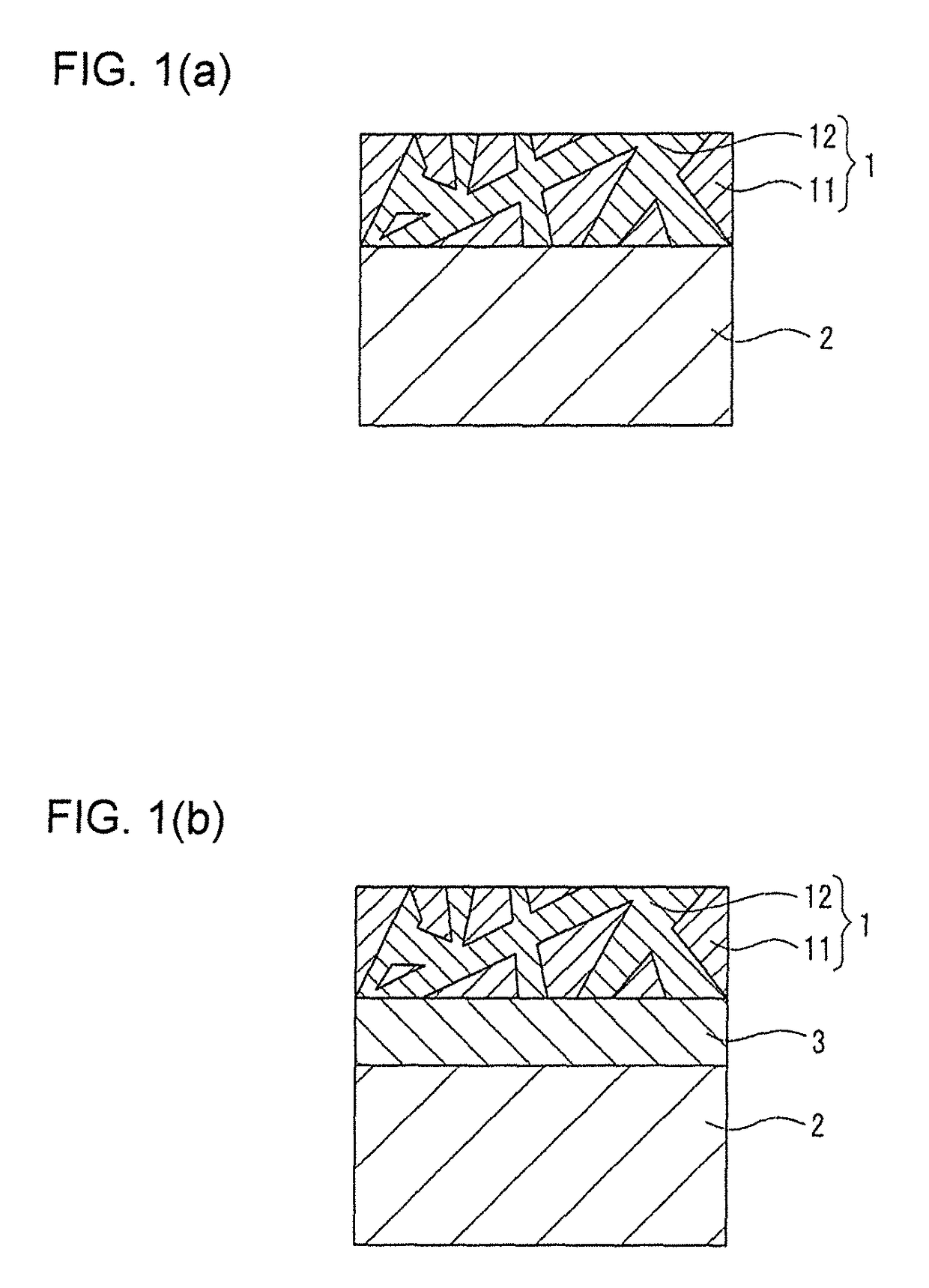

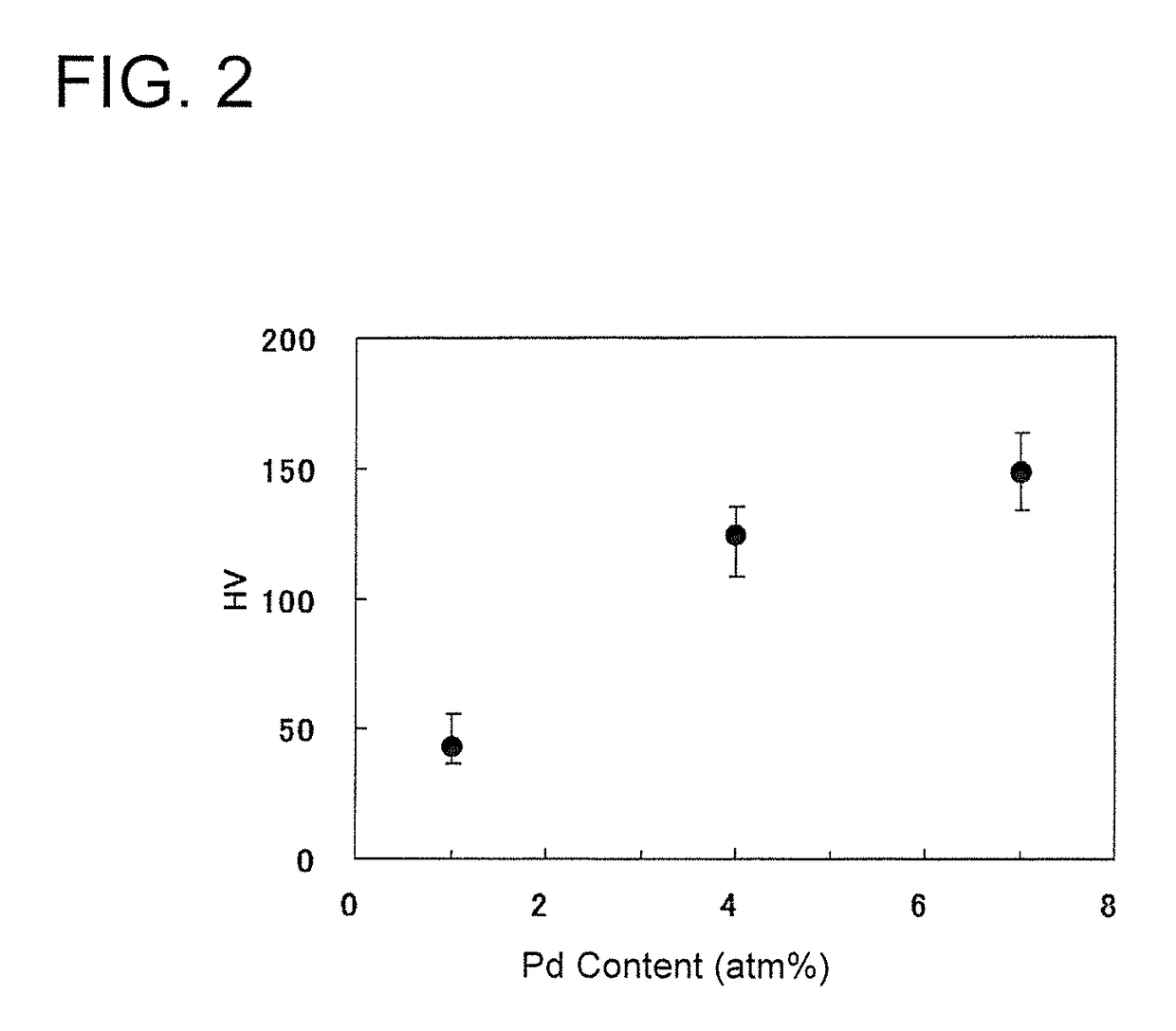

Plated terminal for connector and terminal pair

ActiveUS9673547B2Reduce coefficient of frictionHigh hardnessCoupling contact membersElectroplatingMetal

The present invention aims to provide a plated terminal for connector which requires a smaller insertion force by reducing a friction coefficient and a terminal pair formed using such a plated terminal for connector. An alloy containing layer (1) made of tin and palladium and containing a tin-palladium alloy is formed on a surface of a terminal base material (2) made of copper or copper alloy. Here, the alloy containing layer (1) is preferably such that domain structures of a first metal phase (11) made of an alloy of tin and palladium are formed in a second metal phase (12) made of pure tin or an alloy having a higher ratio of tin to palladium than in the first metal phase (11).

Owner:AUTONETWORKS TECH LTD +2

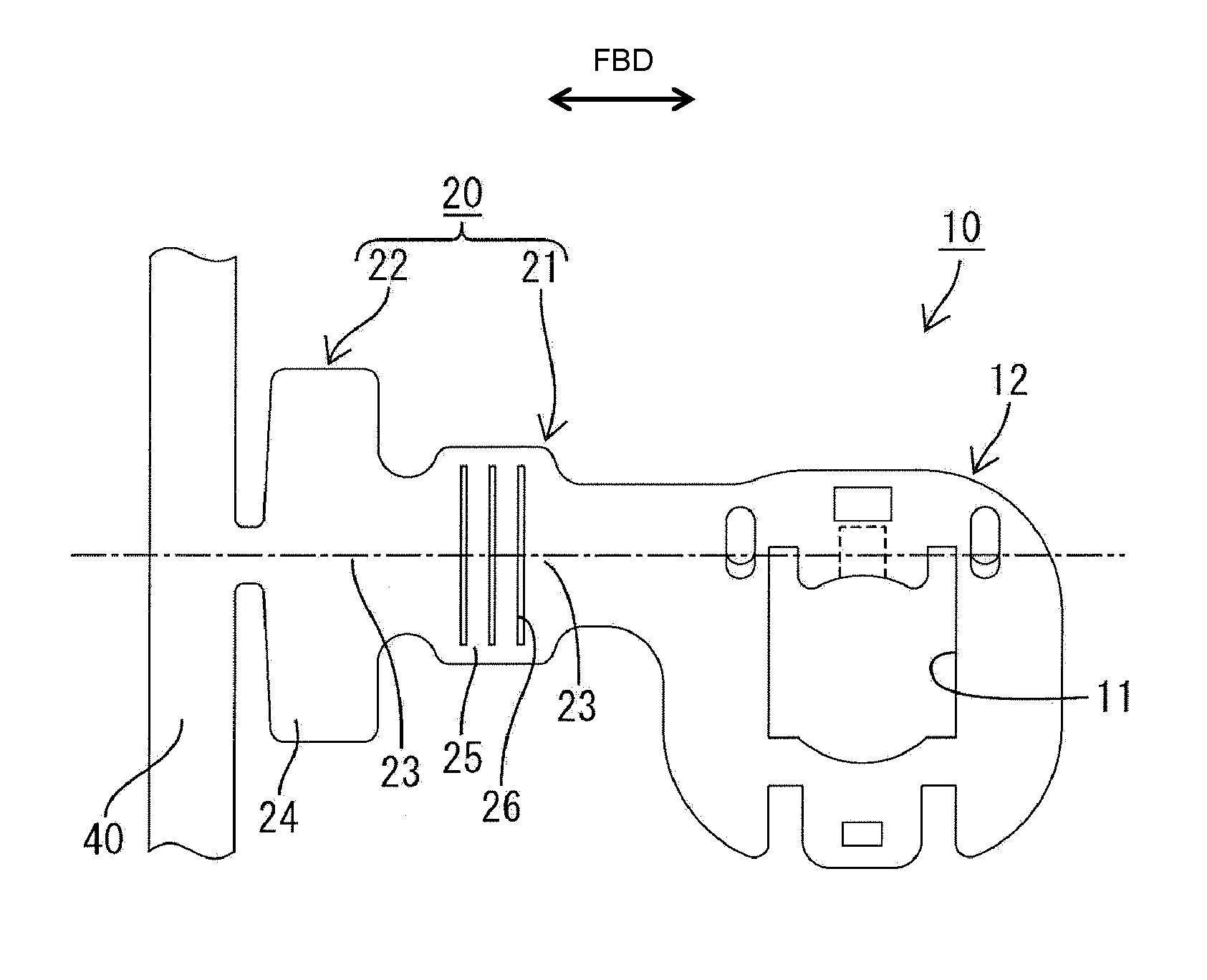

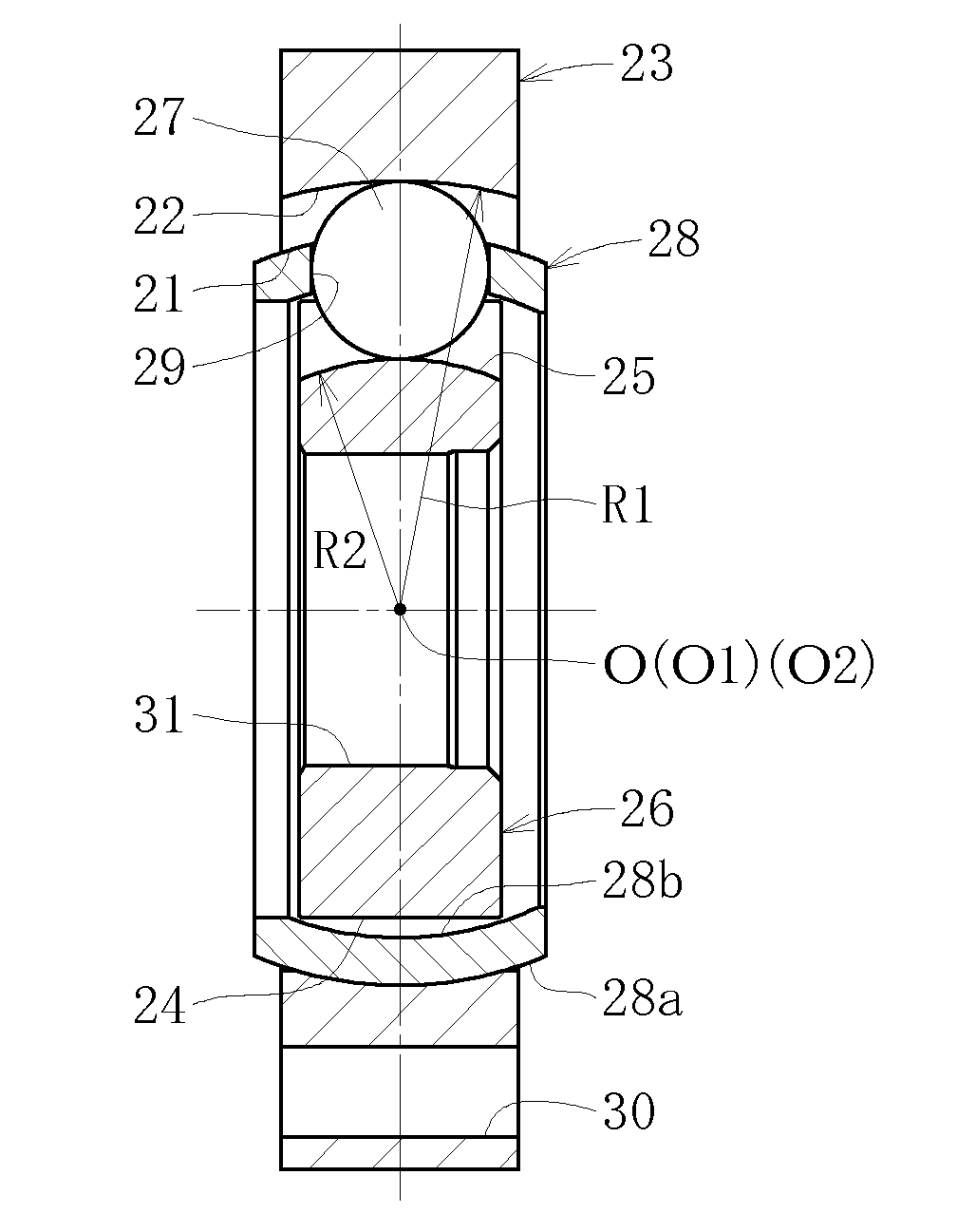

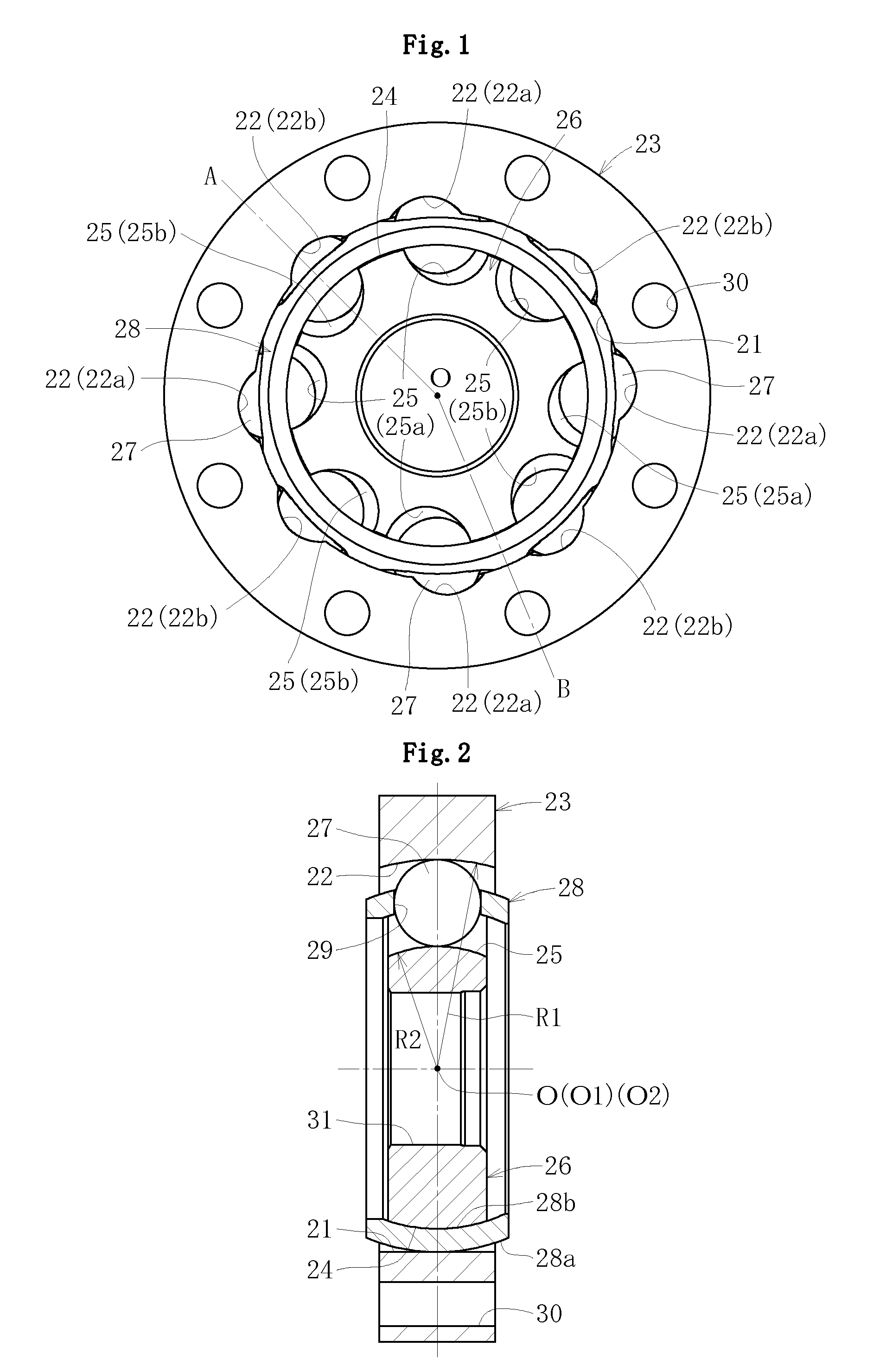

Fixed type constant velocity universal joint

ActiveUS8808097B2Improve accuracyLow costYielding couplingRotary machine partsUniversal jointEngineering

A fixed type constant velocity universal joint prevents heat generation when a high load is applied or during high-speed rotation to improve durability, and suppresses a contact resistance between a cage and inner and outer races to improve constant velocity performance. Curvature centers of track grooves of outer and inner joint members have an offset of 0 in an axial direction. Track grooves of the outer and inner joint members, which are tilted in opposite directions from each other with respect to an axis line, are alternately formed in a circumferential direction. An outer surface of the inner joint member is a spherical surface to be brought into sliding contact with an inner spherical surface of the cage. An inner surface of the outer joint member is a cylindrical surface.

Owner:NTN CORP

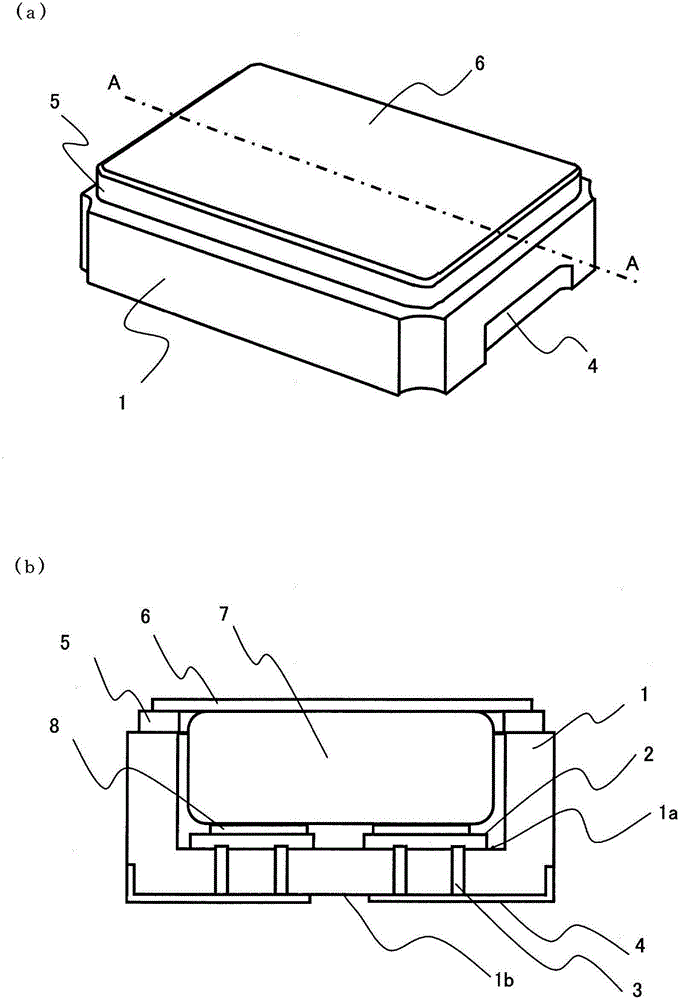

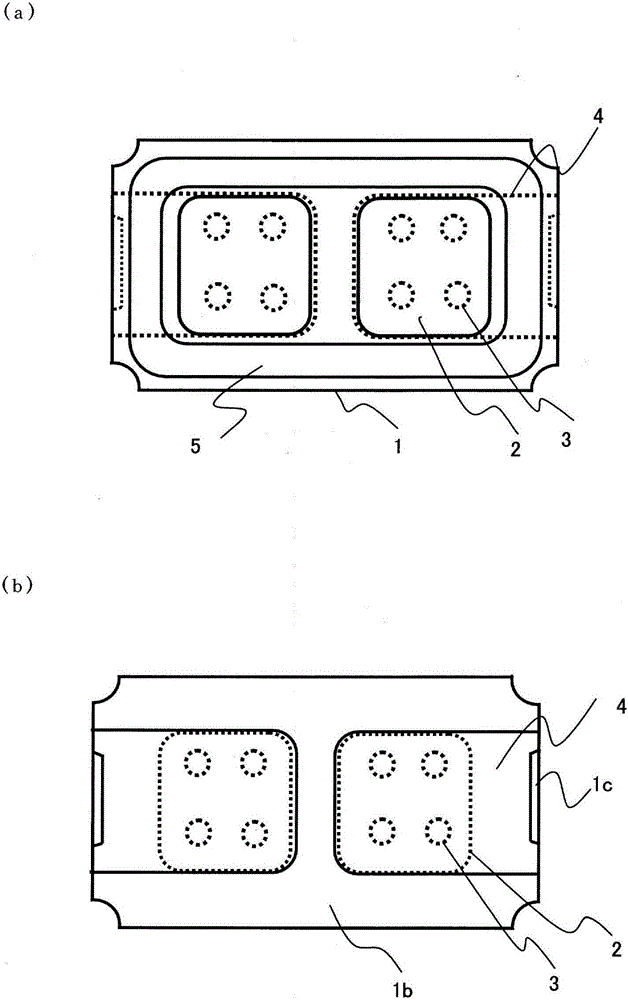

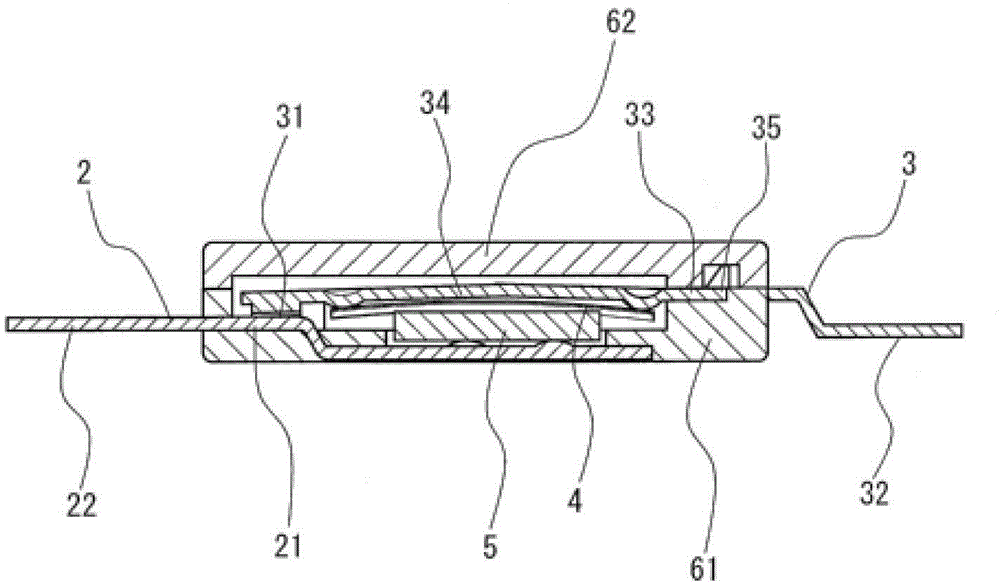

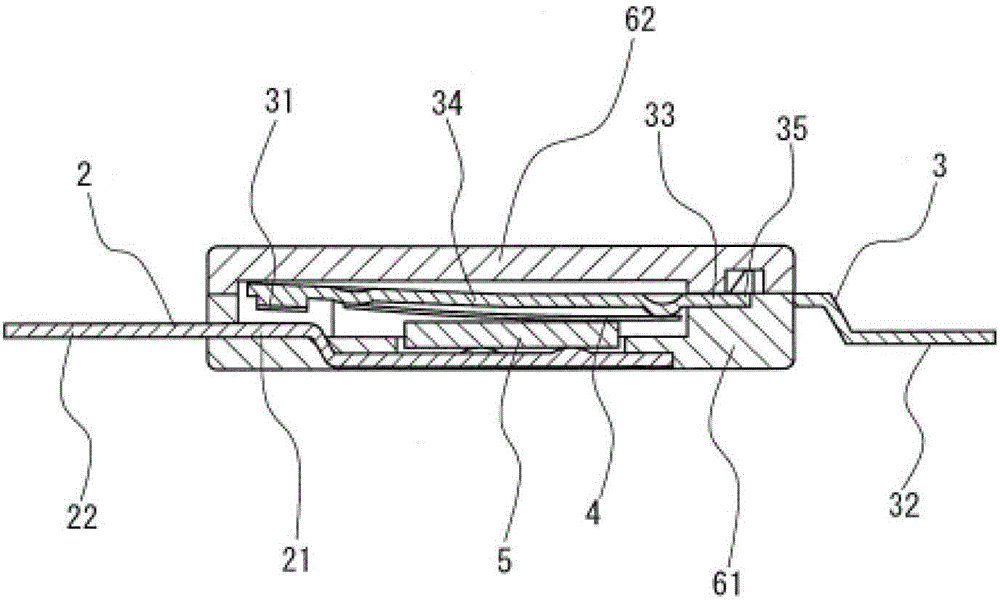

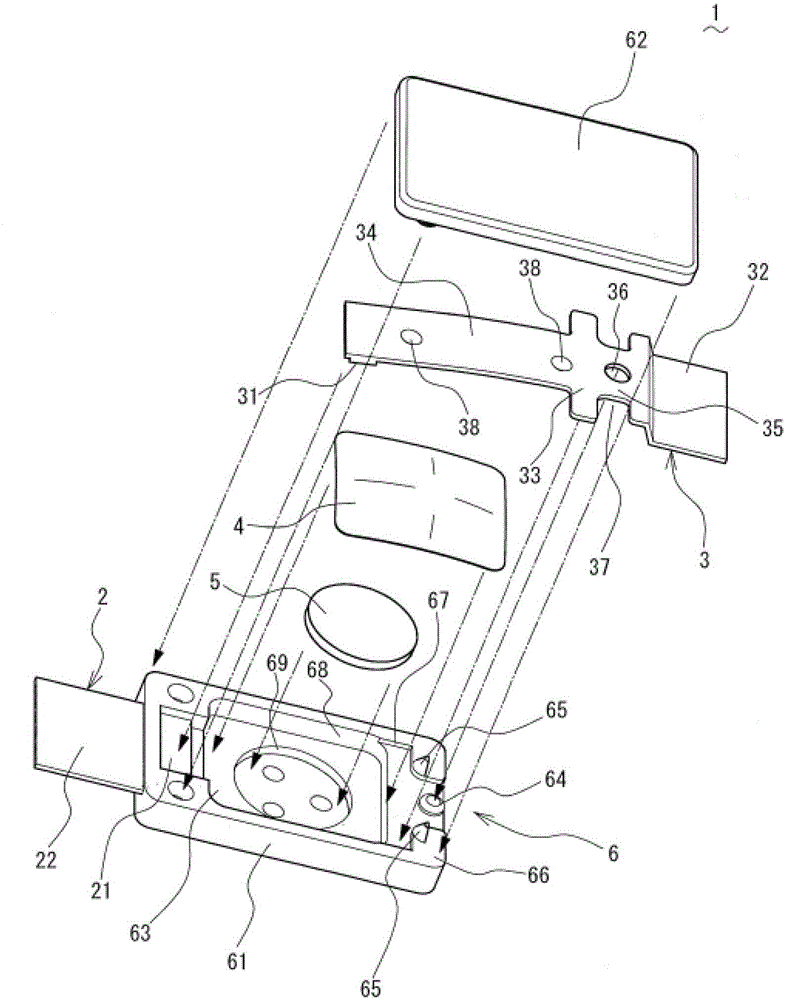

Breaker

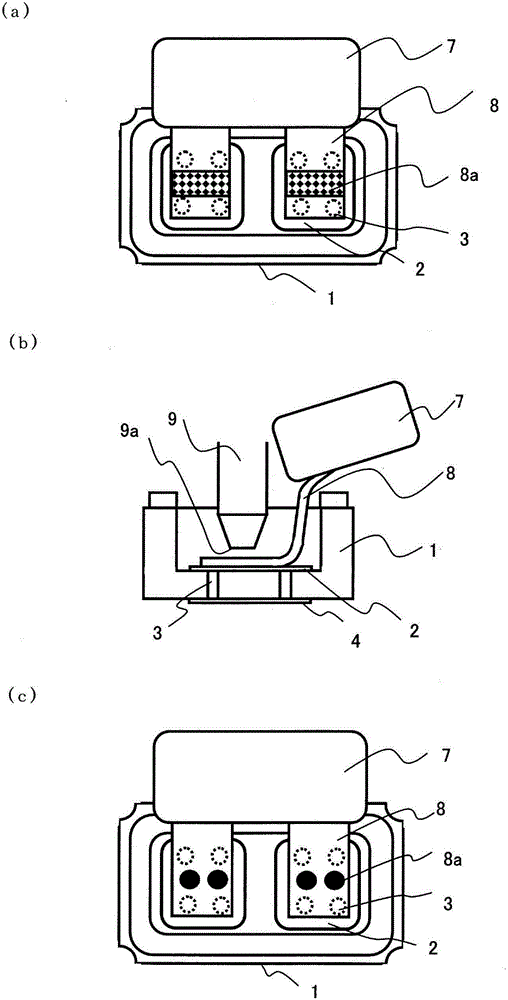

InactiveCN102782793AMiniaturizationSuppression of contact resistanceThermal switch detailsContact electric connectionElectrical resistance and conductanceContact resistance

Disclosed is a miniature breaker which progressively reduces contact resistance and permits further miniaturisation by appropriately maintaining the contact locations of a fixed contact point and moveable contact point. The breaker is equipped with a fixed contact point (2), a moveable contact point (3), a bimetal (4) and a case (6), where the moveable contact point (3) is equipped with a second elastic member (35) possessing a lower elastic coefficient than a first elastic member (34), and a fixing member (33) disposed between the first elastic member (34) and second elastic member (35) which is fixed by the case (6).

Owner:KOMATSULITE MFG

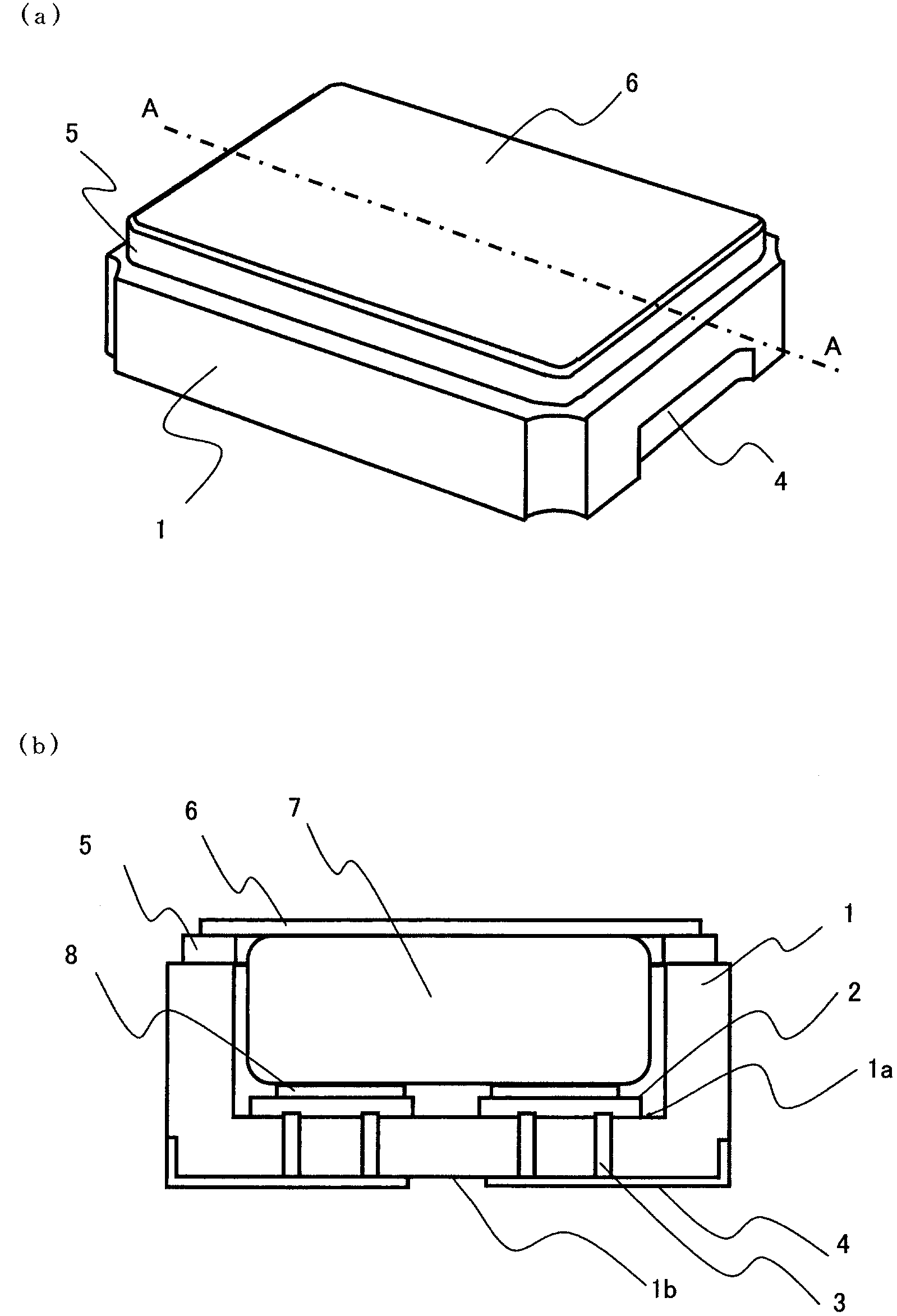

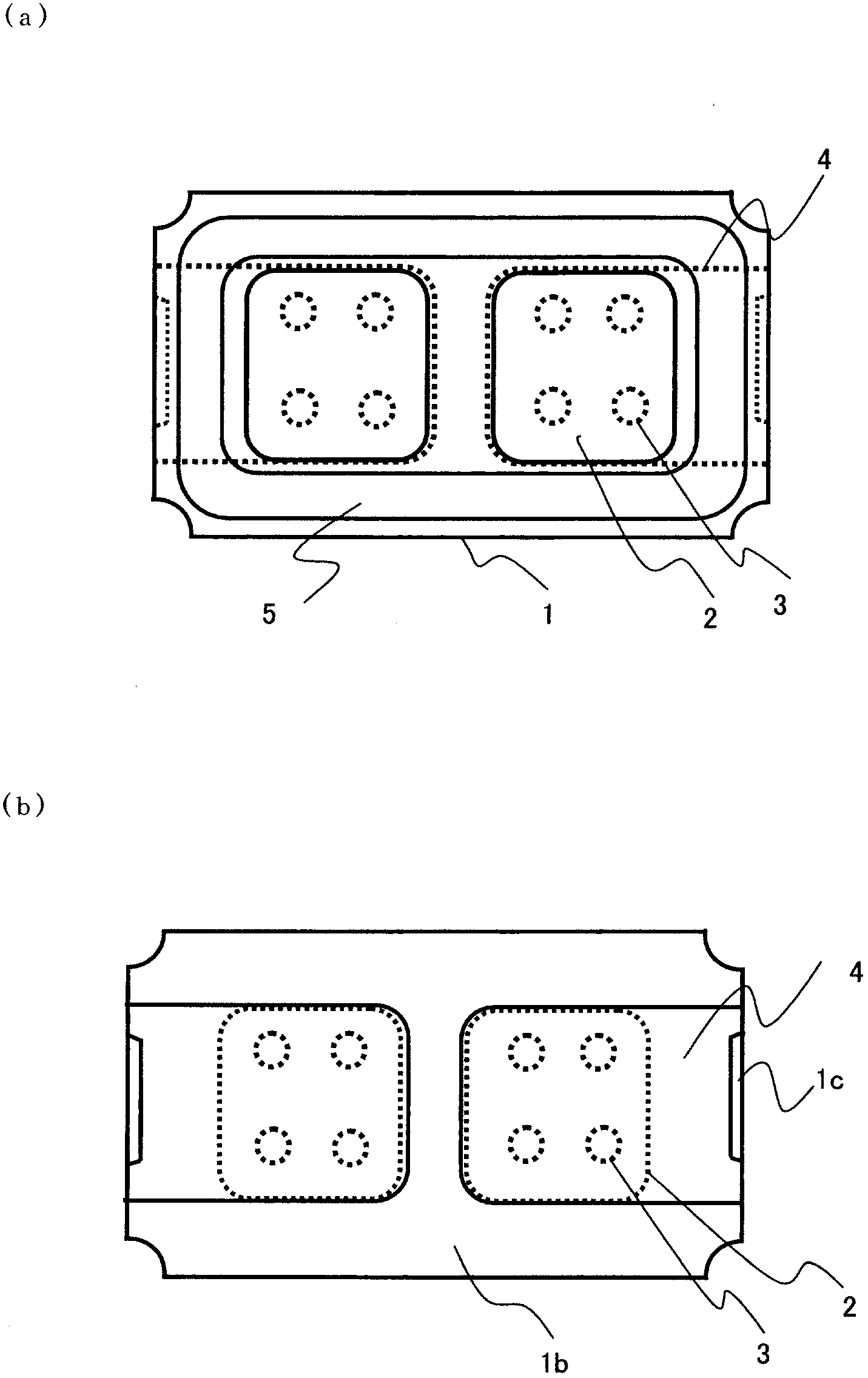

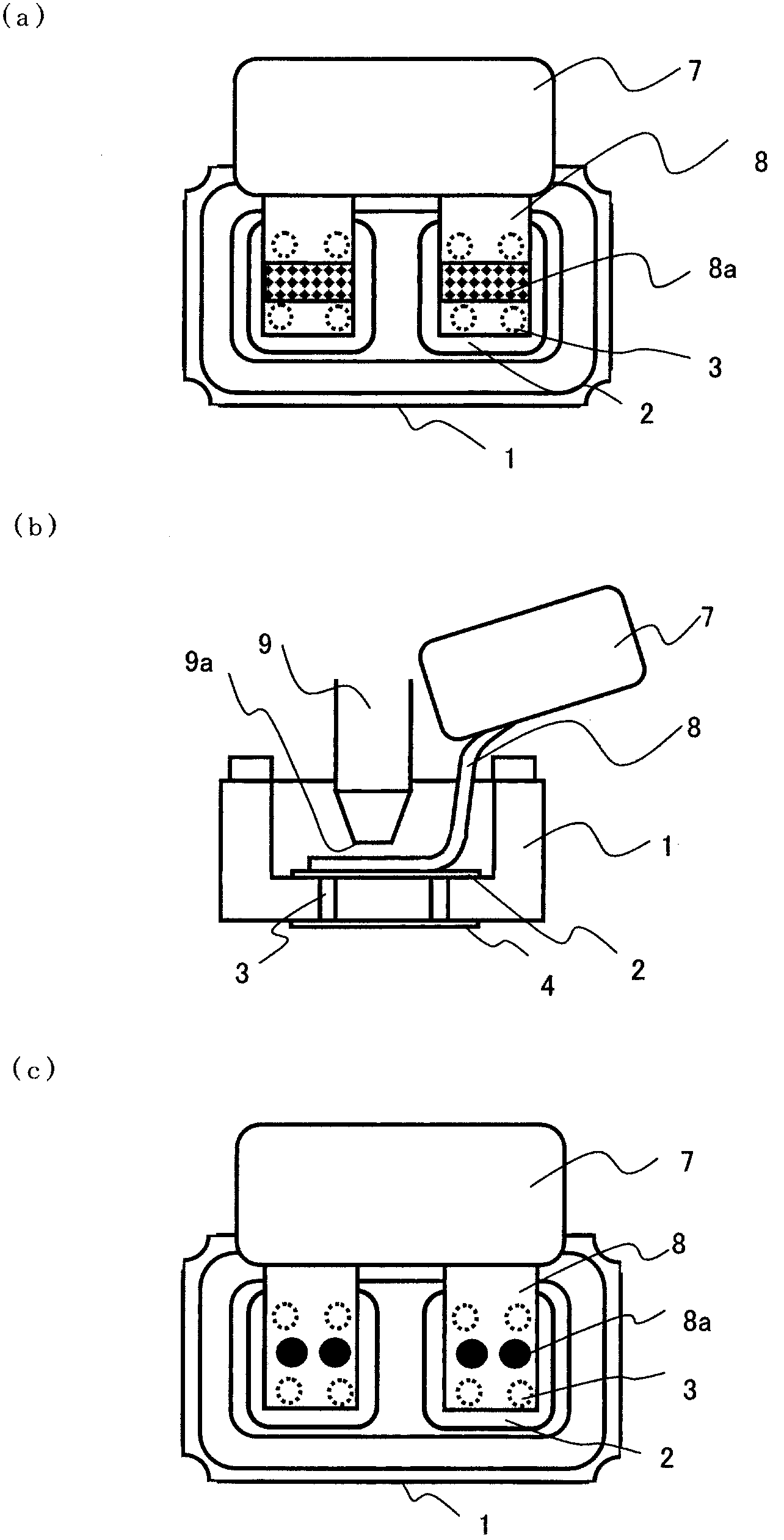

Electrochemical cell and method of manufacturing the same

ActiveCN102842699BOmit the sealing processReduce the amount of electrolytesCell component detailsHybrid/EDL manufactureEngineeringElectrochemical cell

The invention relates to an electrochemical battery and a manufacture method thereof. The electrochemical battery using a small-size exterior package container discharges on high current. The electrochemical battery is composed of the exterior container, a battery core (7) and electrolyte, wherein the exterior container is composed of a seat (1) and a cover (6), the battery core (7) is mounted in the seat (1), the electrochemical battery comprises at least one lining membrane (2) and a connection terminal (4), the lining membrane (2) is formed on the inner side surface of the seat (1) and composed of an electronic pipe metal, the connection terminal (4) is arranged on the outer side surface of the seat (1) and electrically connected with the lining membrane (2), and a battery core lead (8) being an extension part of the battery core is welded with the lining membrane (2).

Owner:SEIKO INSTR INC

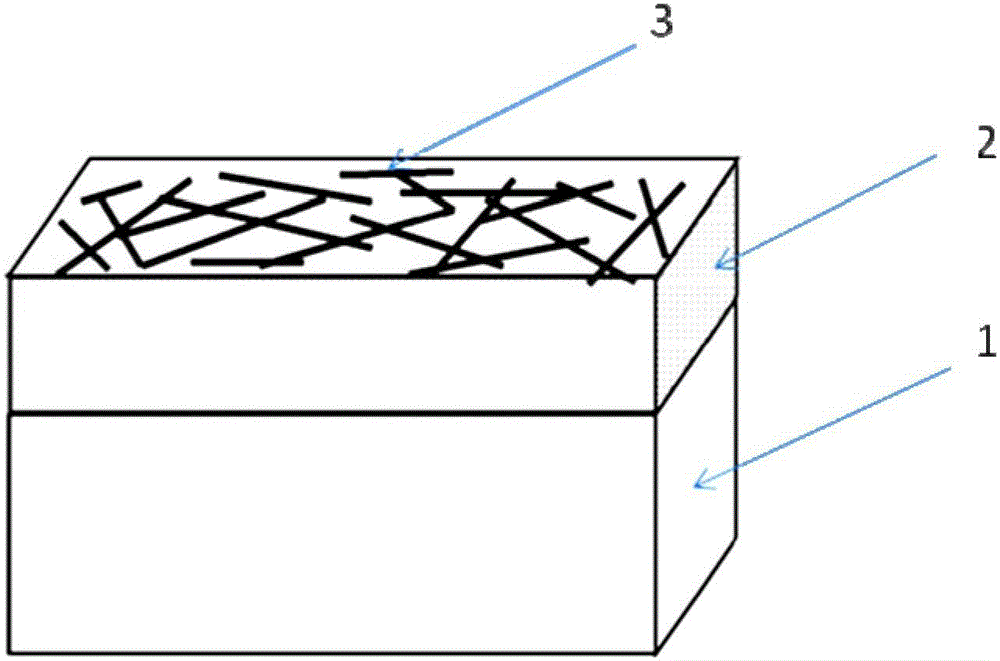

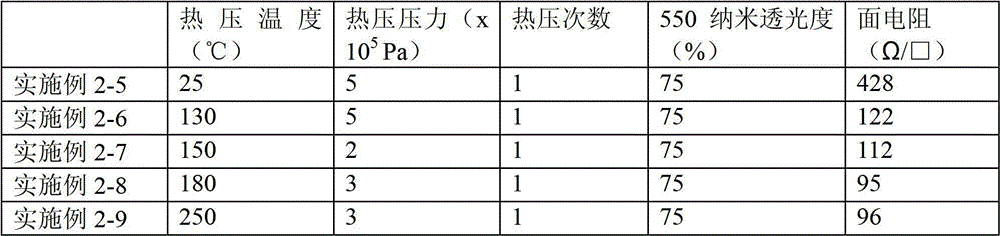

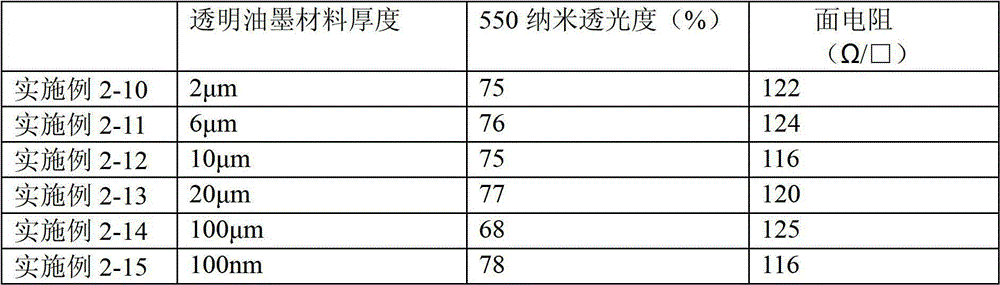

Flexible transparent conductive film and manufacturing method thereof

ActiveCN102693772BThe overall thickness is thinEvenly distributedConductive layers on insulating-supportsCable/conductor manufactureSurface layerEngineering

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

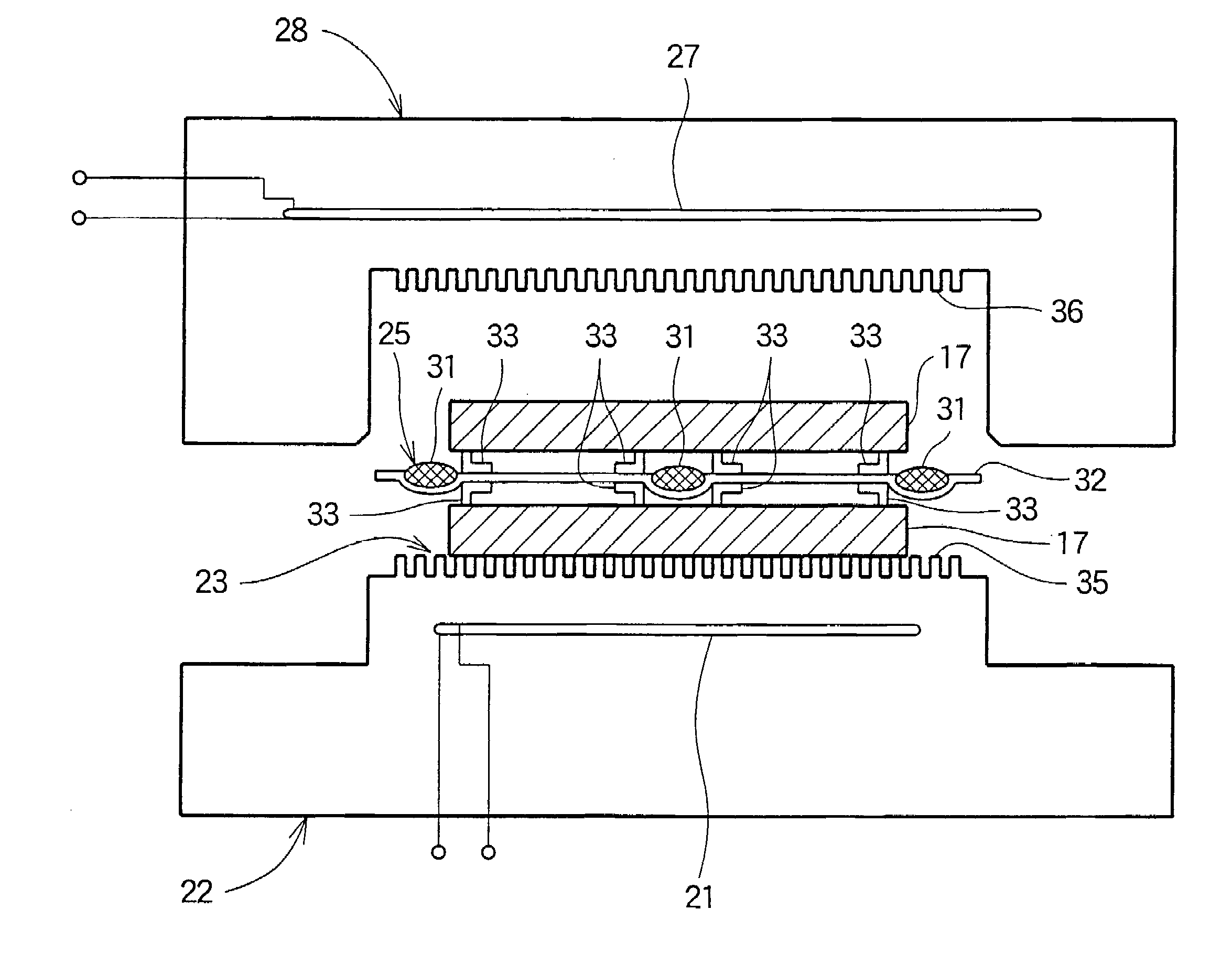

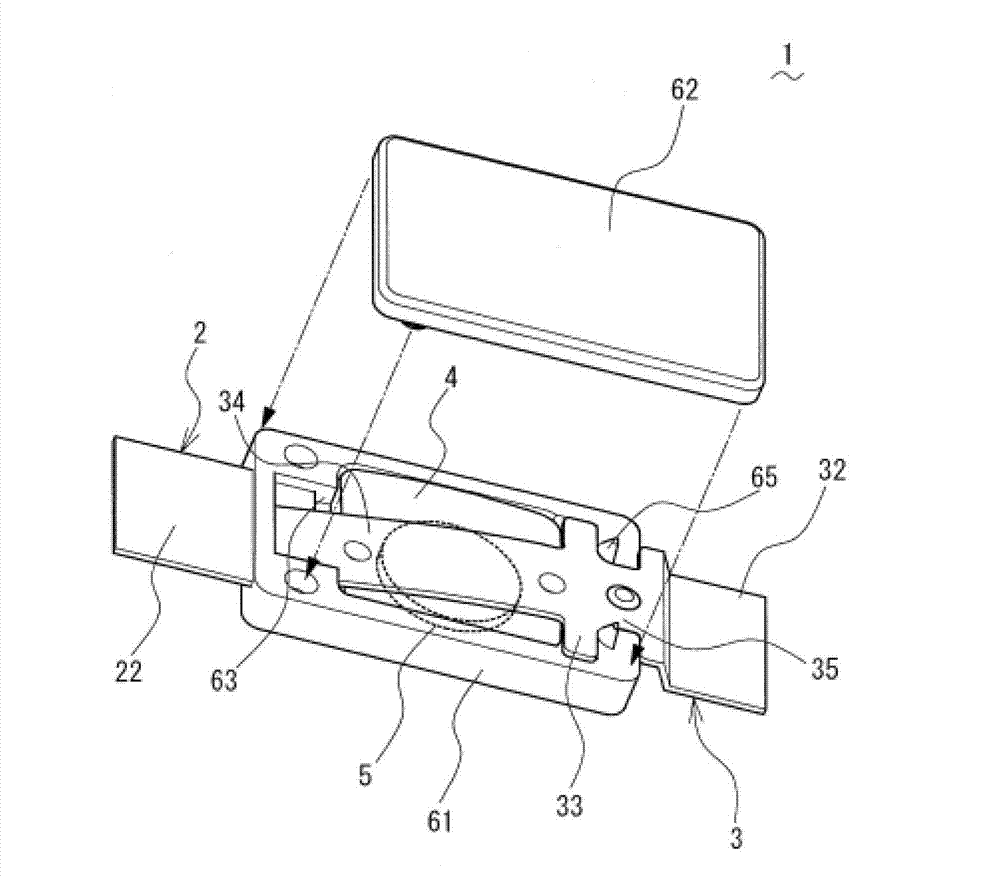

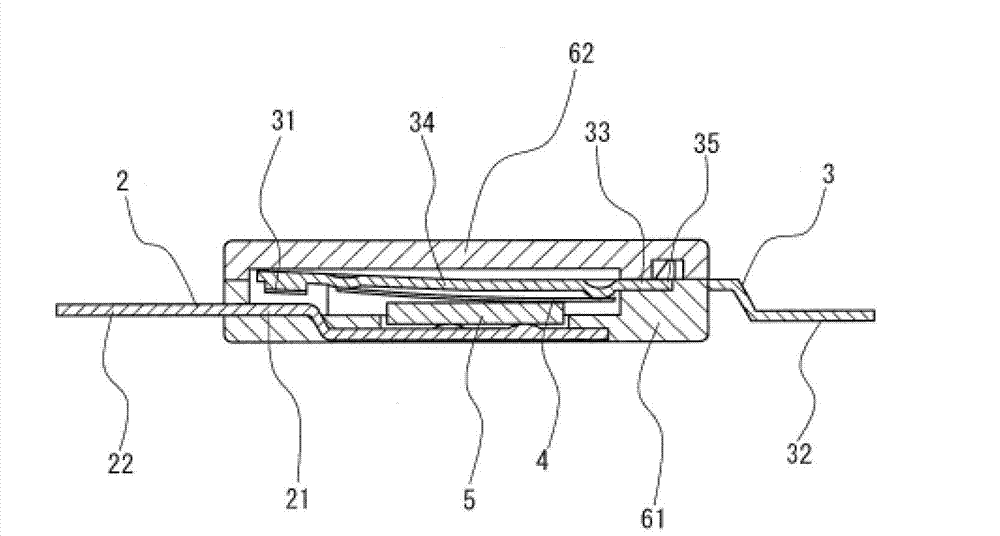

Electrical connecting apparatus

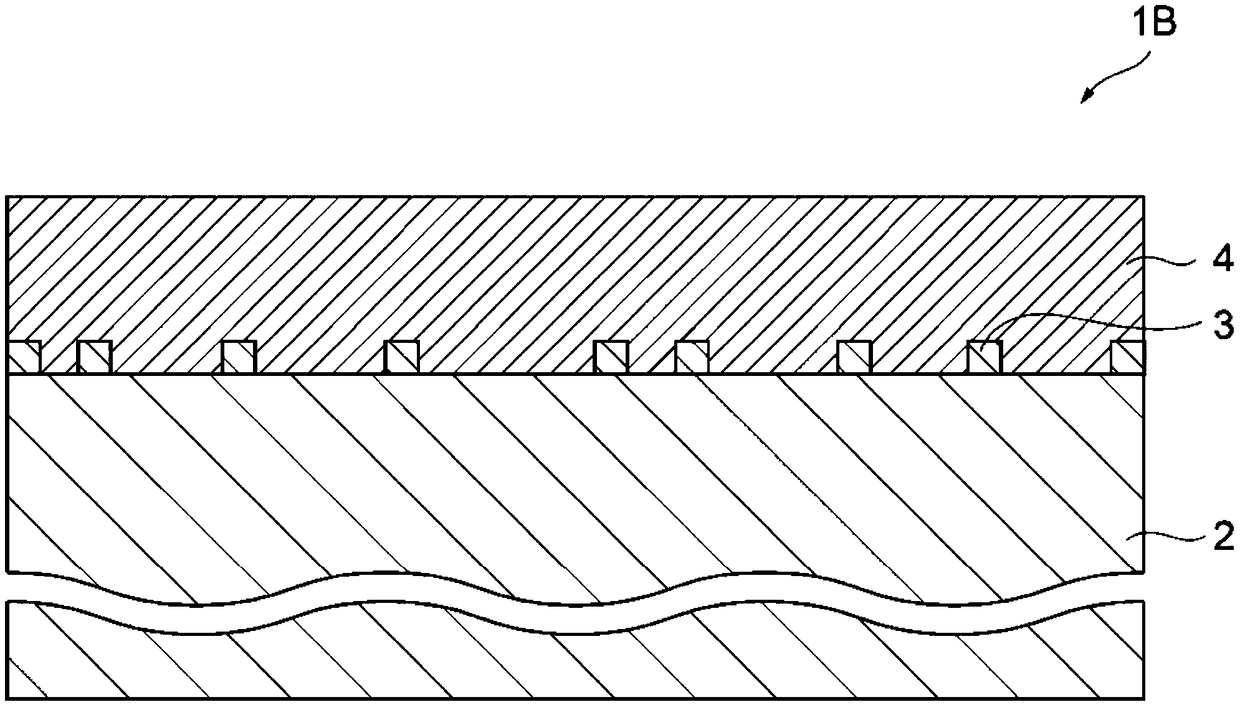

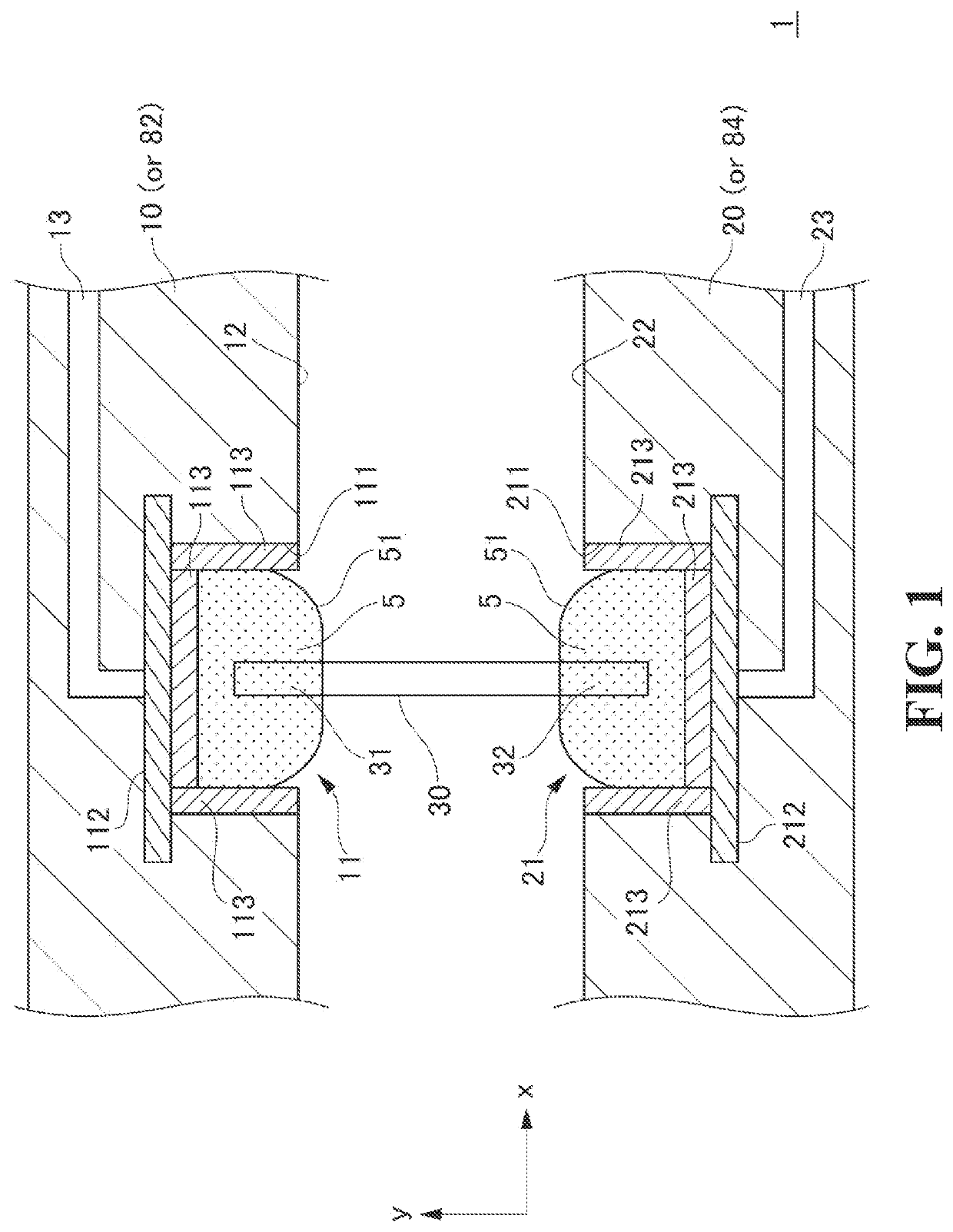

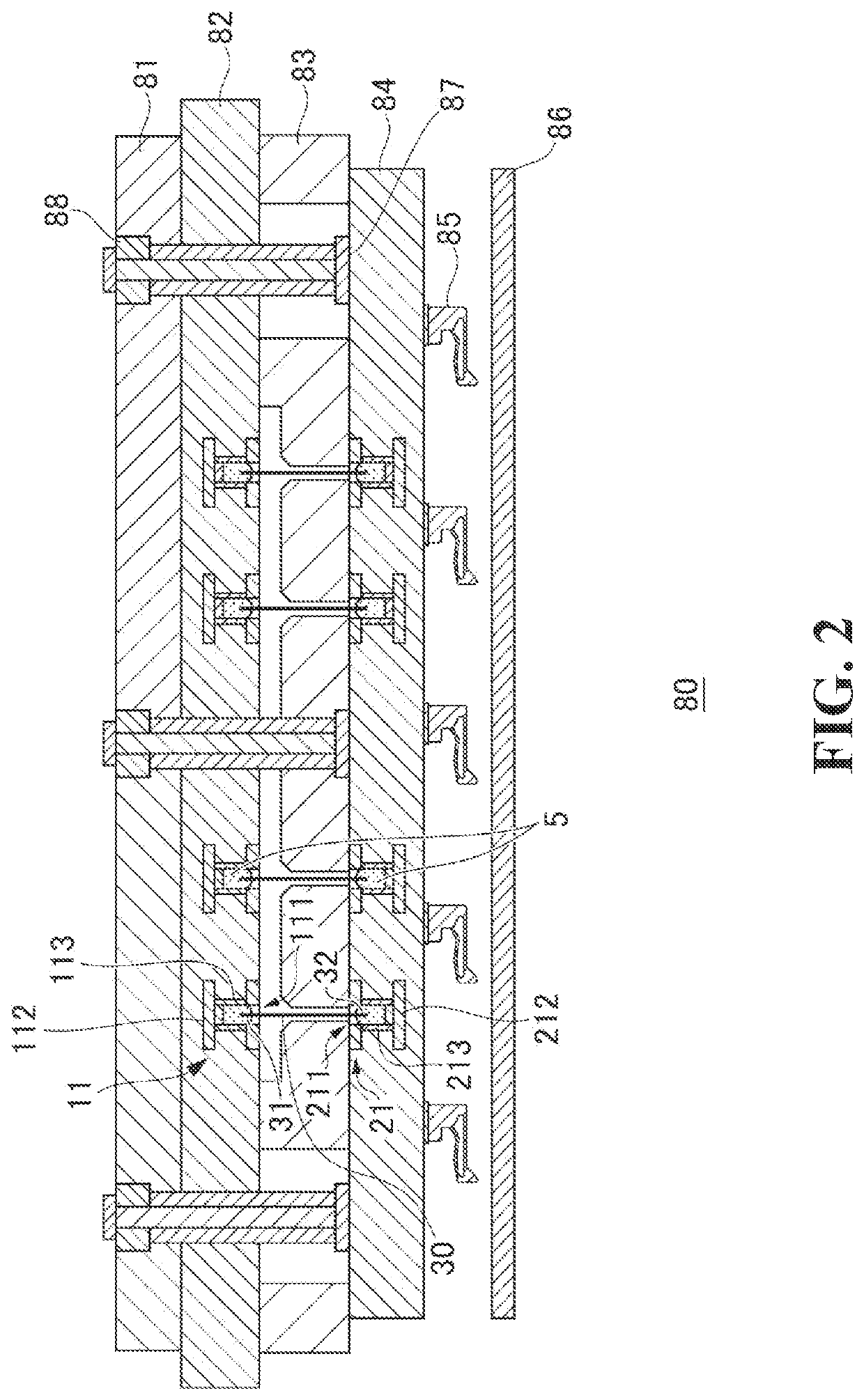

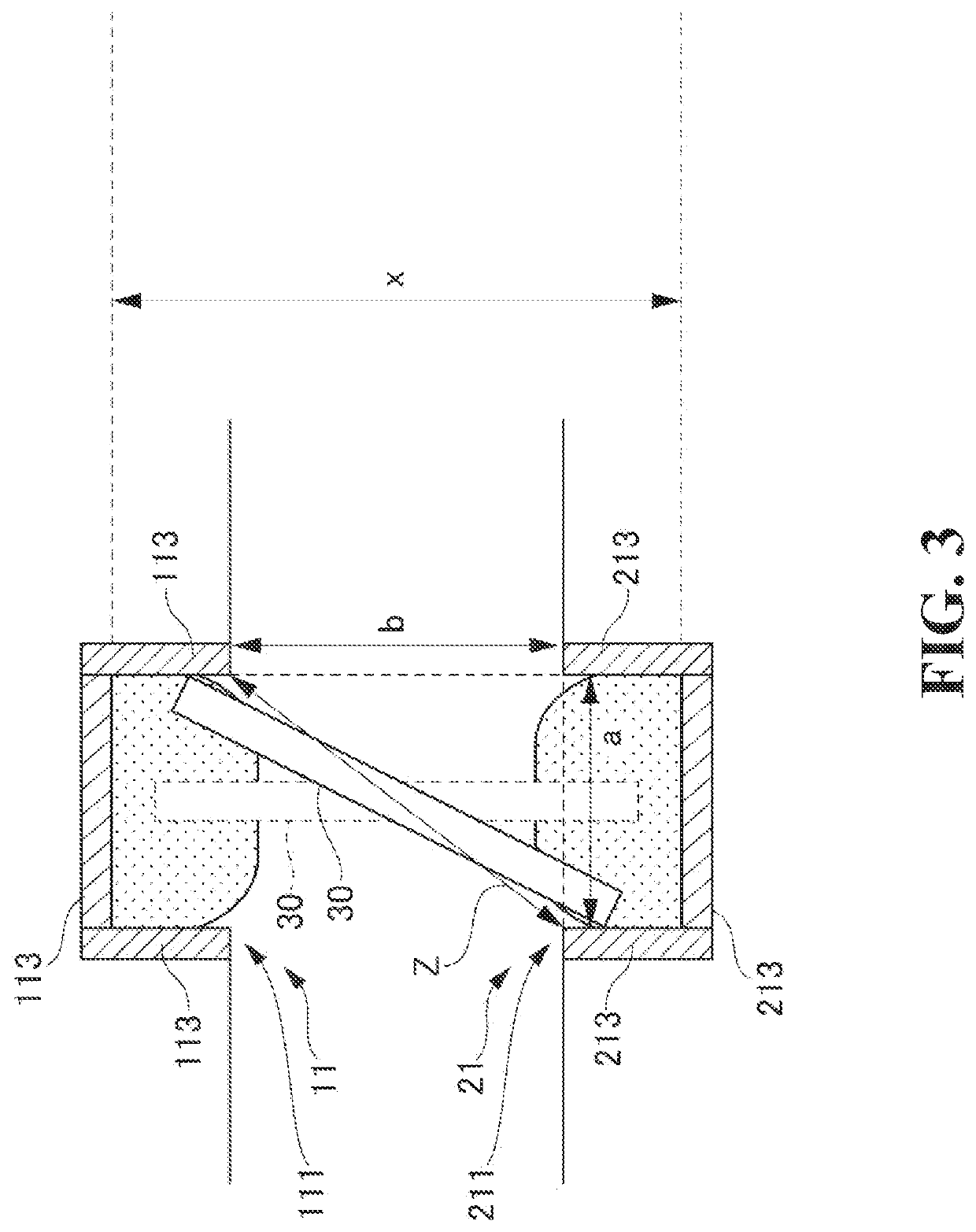

PendingUS20220149549A1Reliable electrical connectionSuppression of contact resistanceCoupling device connectionsConnections to liquidElectrical resistance and conductanceElectrical connection

[Problem] To provide an electrical connecting apparatus that can realize a stable electrical connecting property by expanding a contact area between an electrode region of a wiring substrate and a connector as compared to the prior art, and suppressing contact resistance.[Solution] An electrical connecting apparatus according to the present disclosure is characterized in including a first electrode region in which a liquid metal is filled in a first recessed part that is capable of conducting with a substrate electrode of a first wiring substrate, a second electrode region in which a liquid metal is filled in a second recessed part that is capable of conducting with a substrate electrode of a second wiring substrate opposing the first wiring substrate, and a connector that causes conduction between the first electrode region and the second electrode region by bringing one end part into contact with the liquid metal of the first electrode region and bringing the other end part into contact with the liquid metal of the second electrode region.

Owner:NIHON MICRONICS

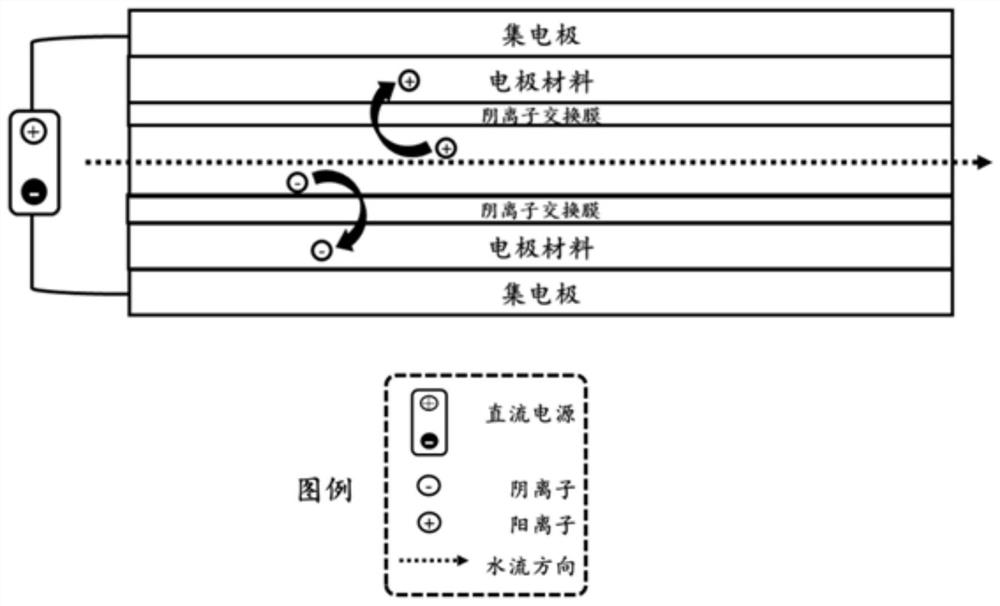

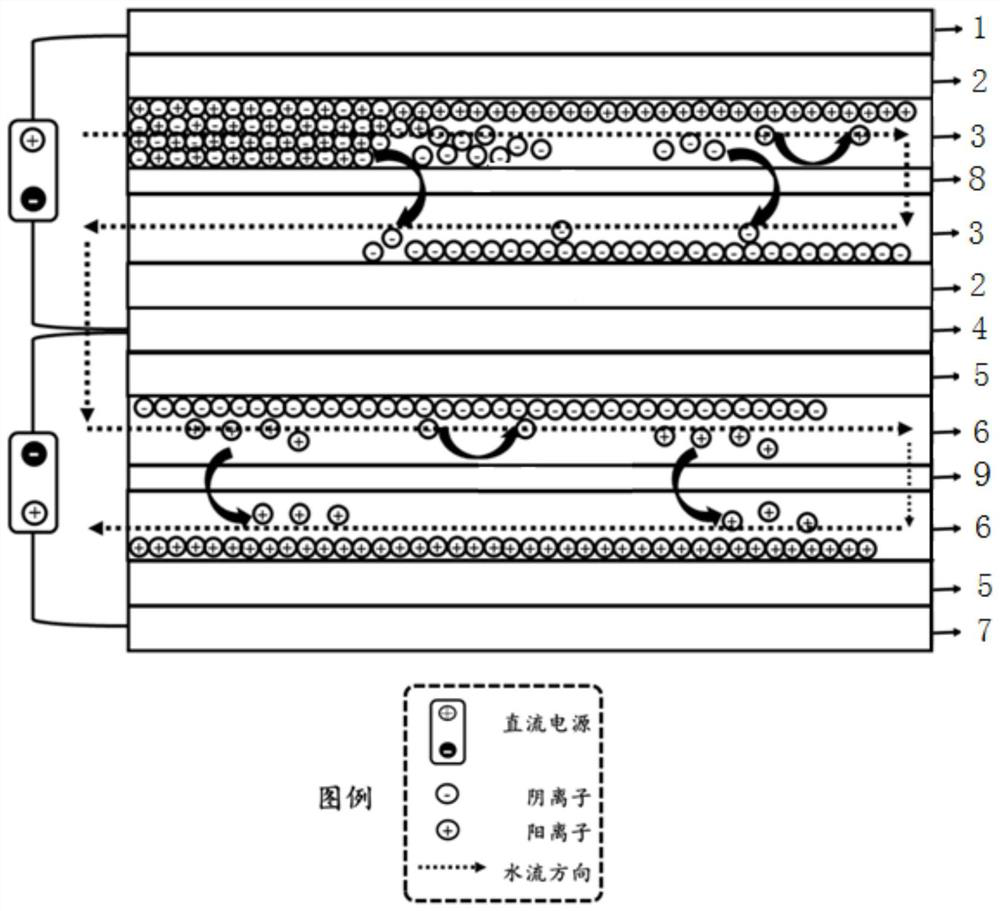

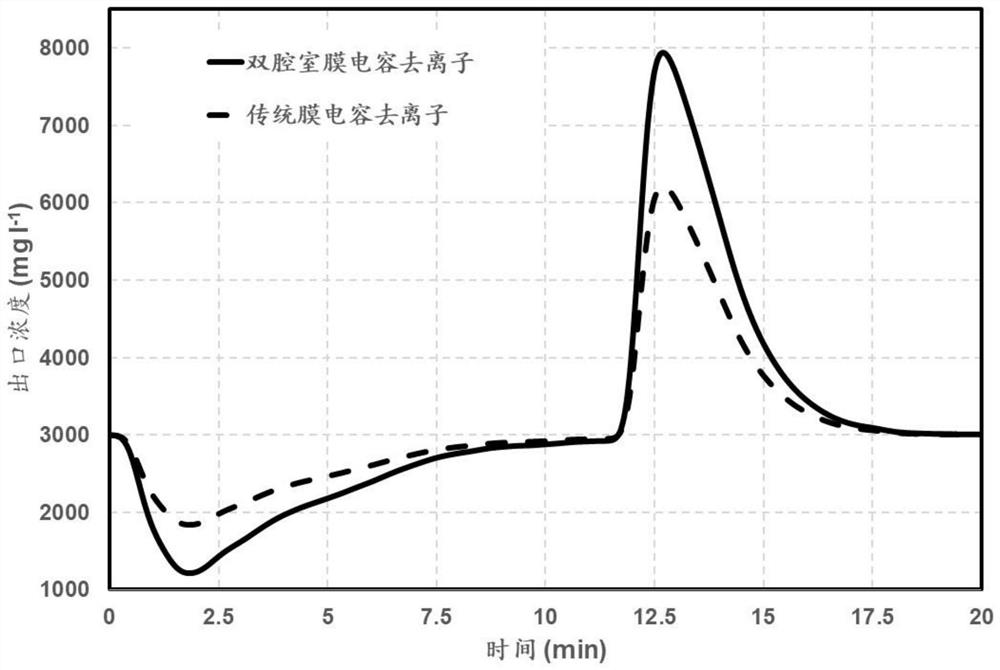

A dual-chamber membrane capacitive deionization device

ActiveCN109692575BLow movement resistanceImprove adsorption capacityGeneral water supply conservationElectrodialysisCapacitanceCapacitive deionization

The invention belongs to the technical field of membrane capacitive deionization devices, and discloses a double-chamber membrane capacitive deionization device. The membrane capacitive deionization device has a double-chamber structure. The first chamber and the second chamber are respectively provided with water flow channel diaphragms at the upper and lower ends of the anion / cation exchange membrane, so that the raw water is in the water flow channel diaphragm of the double chambers. Serpentine flow. The membrane deionization device has small mass transfer resistance, low desalination energy consumption, and better desalination effect.

Owner:QINGDAO UNIV OF SCI & TECH

Semiconductor device

ActiveUS20140346508A1Increase the on-currentHigh currentTransistorSolid-state devicesPower semiconductor deviceEngineering

Provided is a semiconductor device including a transistor with large on-state current even when it is miniaturized. The transistor includes a pair of first conductive films over an insulating surface; a semiconductor film over the pair of first conductive films; a pair of second conductive films, with one of the pair of second conductive films and the other of the pair of second conductive films being connected to one of the pair of first conductive films and the other of the pair of first conductive films, respectively; an insulating film over the semiconductor film; and a third conductive film provided in a position overlapping with the semiconductor film over the insulating film. Further, over the semiconductor film, the third conductive film is interposed between the pair of second conductive films and away from the pair of second conductive films.

Owner:SEMICON ENERGY LAB CO LTD

breaker

InactiveCN102782793BMiniaturizationSuppression of contact resistanceThermal switch detailsContact electric connectionContact positionContact resistance

[Problems] Providing a compact breaker which enables to reduce contact resistance and to miniaturization much more by maintaining contact positions of a stationary contact and a movable contact appropriately. [Means to solve the Problems] In a breaker comprising a stationary piece 2, a movable piece 3, a bimetal 4 and a case 6, the movable piece 3 has a second elastic portion 35 having an elastic coefficient lower than that of a first elastic portion 34, and is fixed on the case 6 at a fixation portion 33 between the first elastic portion 34 and the second elastic portion 35.

Owner:KOMATSULITE MFG

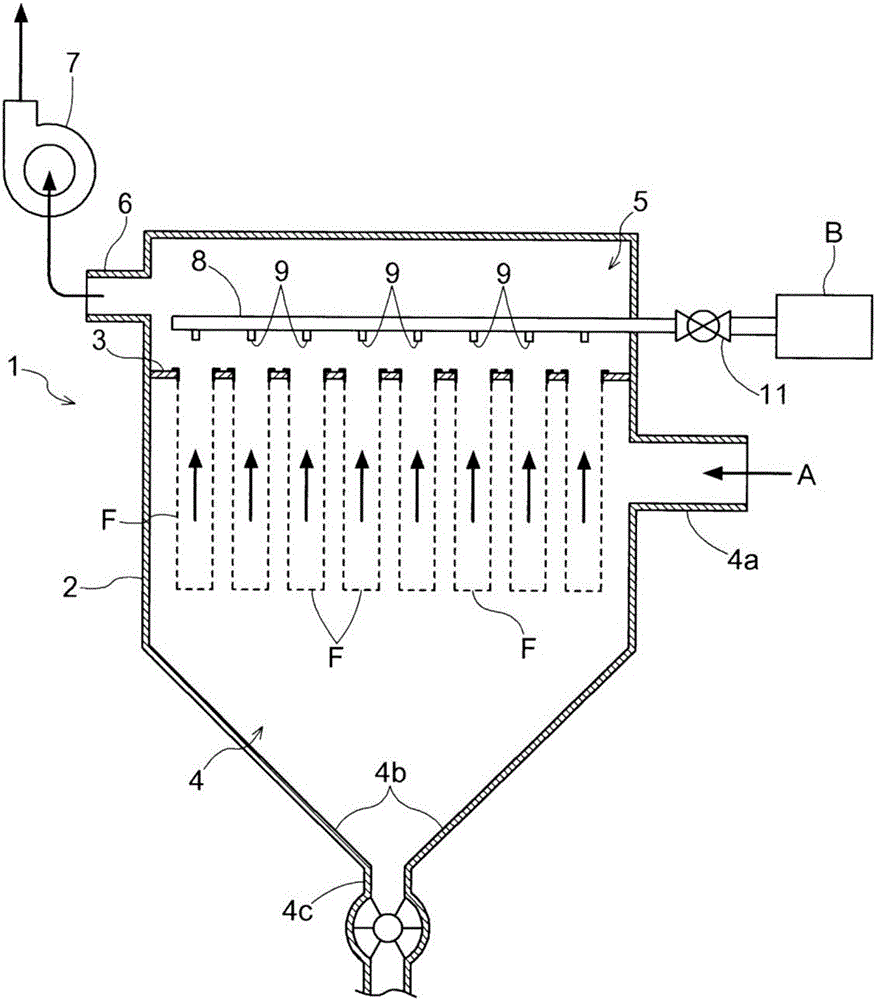

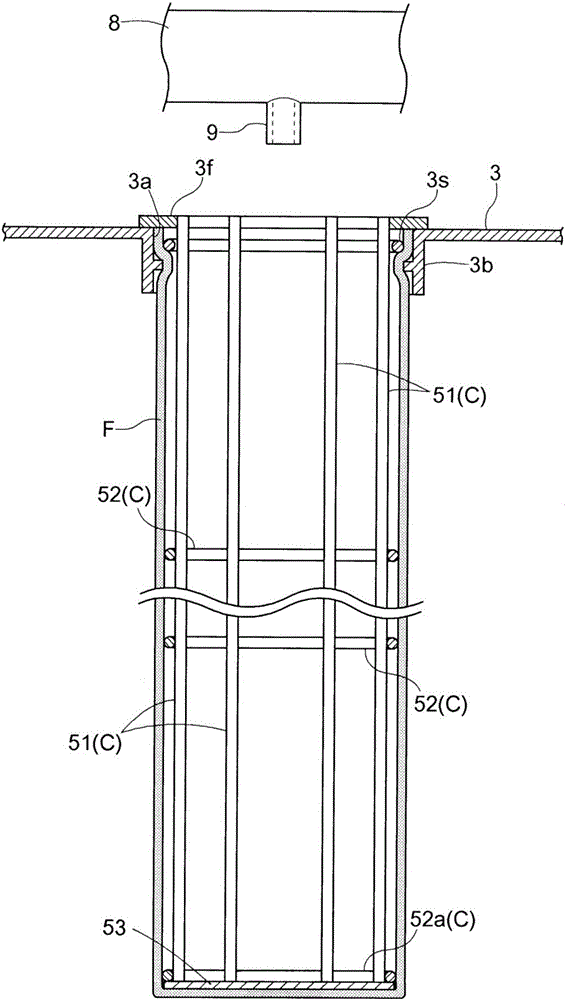

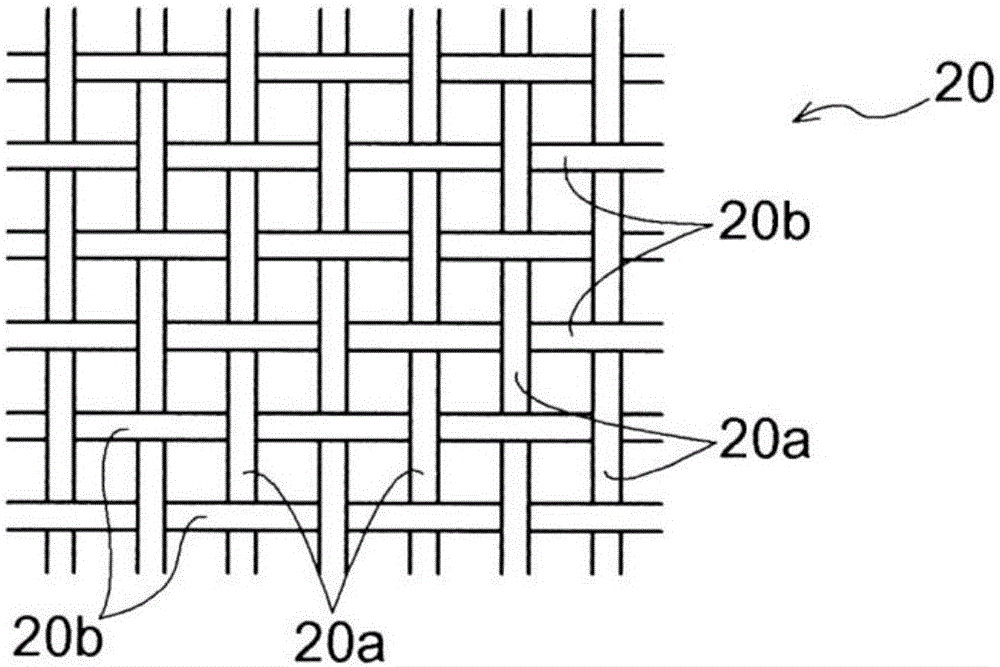

Filter bag structure

ActiveCN106039837ASuppression of contact resistanceImprove dust removal efficiencyDispersed particle filtrationTransportation and packagingBiochemical engineering

The invention provides a filter cloth structural body, and the structural body can improve the dust cleaning efficiency during the regeneration of filter cloth, can save energy because of the reduction of the loss of mean pressure of the filter cloth, and can prolong the service life of the filter cloth. The structural body is formed in a manner that the filter cloth (F) is installed on a holder (C), wherein the length (Lf) of the filter cloth is shorter than the length (Lc) of a filter cloth installation part (Ca) of the holder (C). The filter cloth (F) is installed at the filter cloth installation part (Ca) of the holder (C) in an extending manner.

Owner:NIHON SPINDLE MFG CO LTD

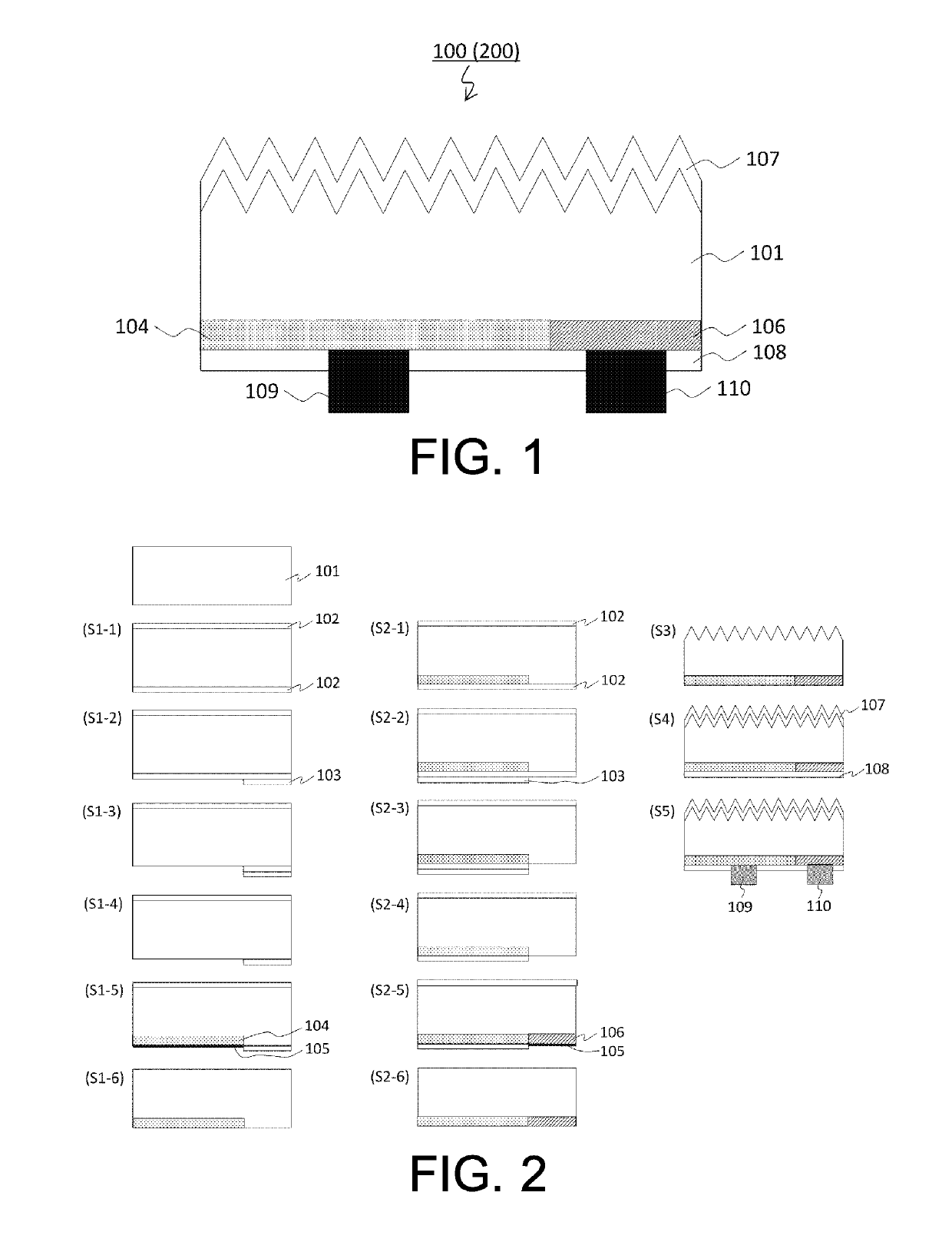

High efficiency back contact type solar cell, solar cell module, and photovoltaic power generation system

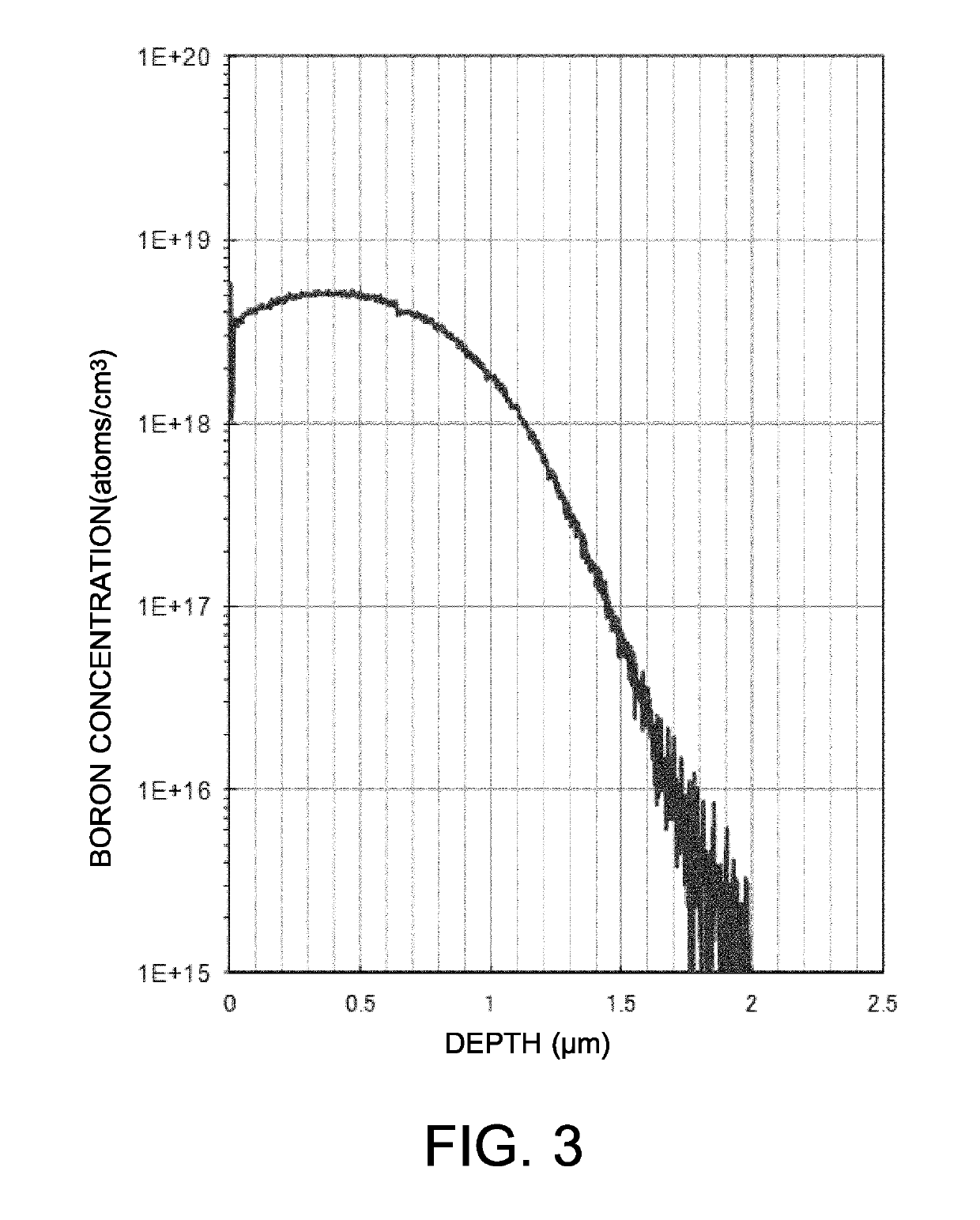

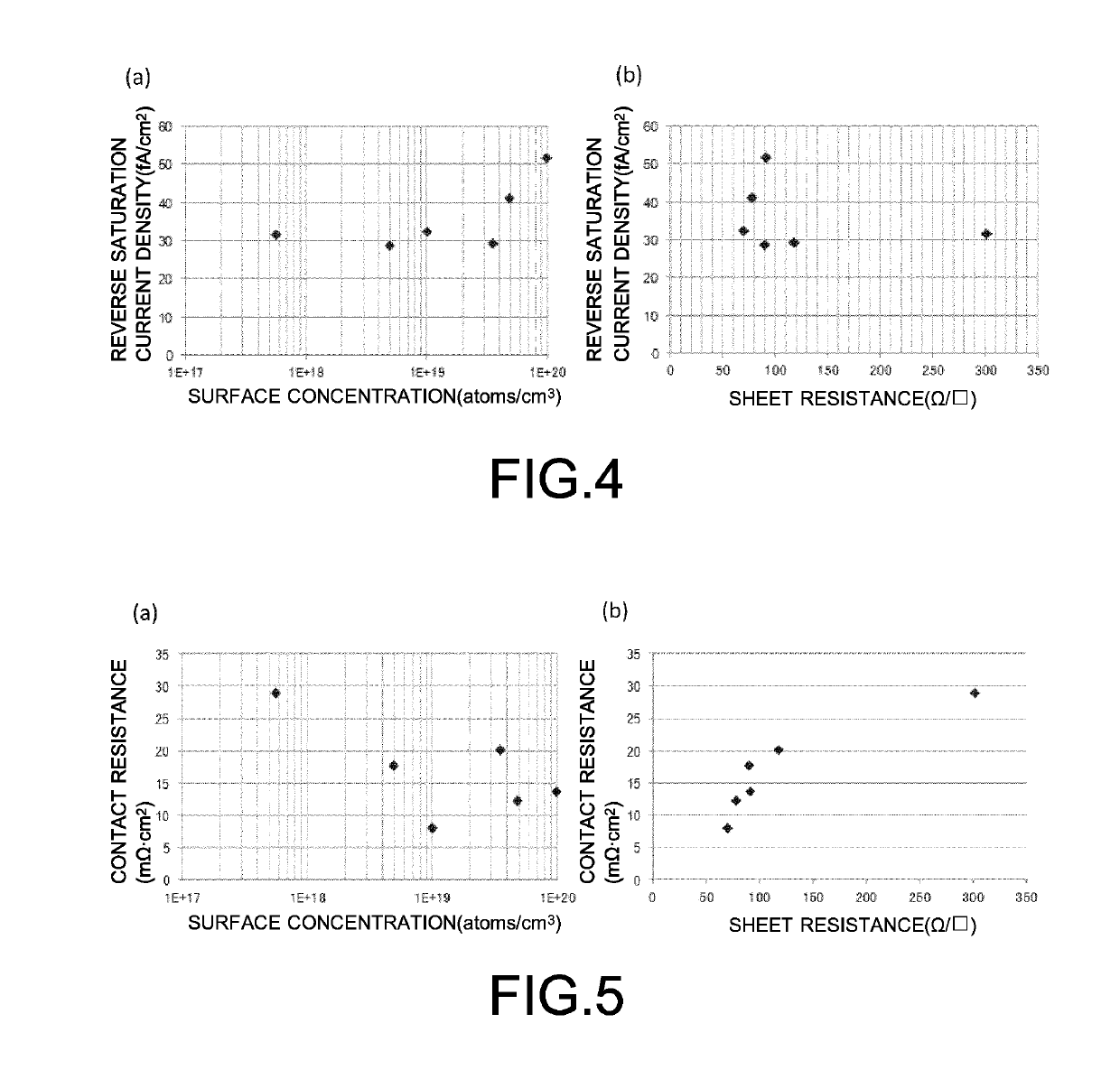

ActiveUS20190221700A1Improve conversion efficiencyRelative density is smallFinal product manufacturePhotovoltaic energy generationSurface concentrationImpurity diffusion

In a back contact type solar cell in which an impurity diffusion layer where second conductive type impurities are diffused is formed on a back surface, as a non-light receiving surface, of a first conductive type semiconductor substrate, and an electrode in contact with the impurity diffusion layer is provided, a surface concentration of the impurities in the impurity diffusion layer is not less than 5×1017 atms / cm3 and not more than 5×1019 atms / cm3, and a diffusion depth of the impurities in the impurity diffusion layer is not smaller than 1 μm and not larger than 2.9 μm from a top of the back surface. It is thereby possible to provide a high efficiency back contact type solar cell which can be manufactured by a simple method at low cost.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com