Breaker

A circuit breaker and moving piece technology, applied in the direction of circuits, contacts, electrical components, etc., can solve the problems that the manufacturing process cannot be fully inspected, the operating temperature bandwidth is wide, and cannot be used multiple times, so as to achieve miniaturization, suppress damage, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

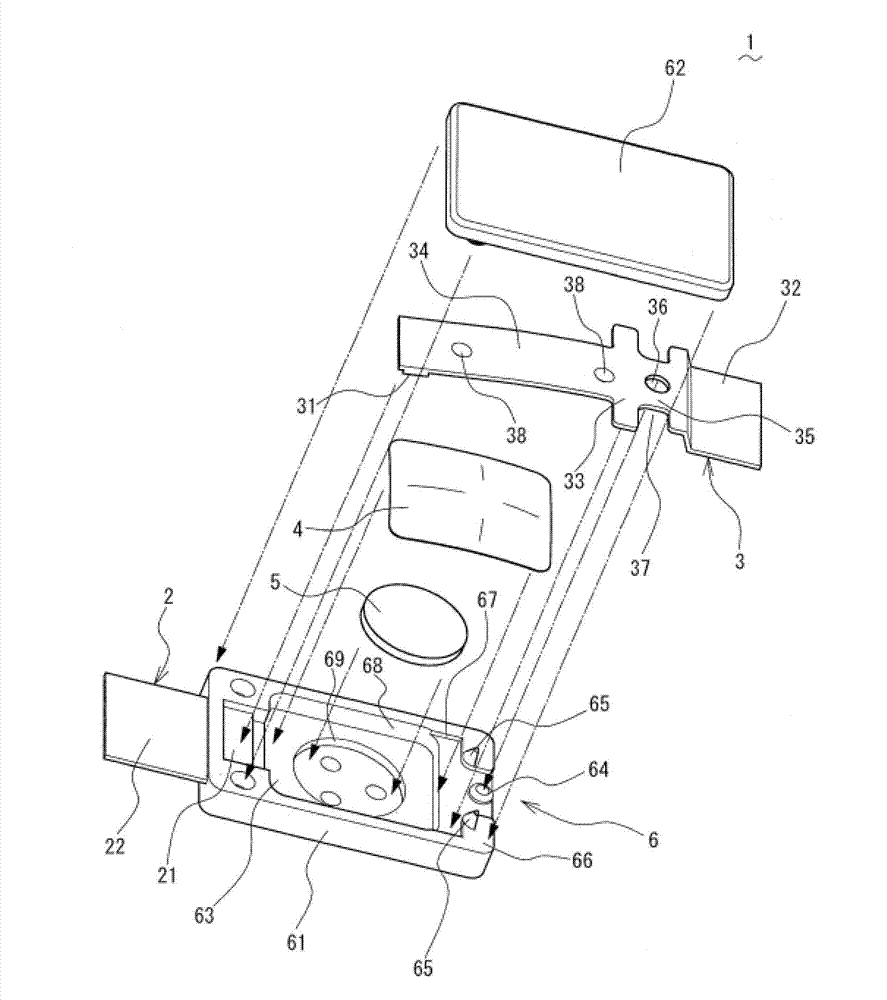

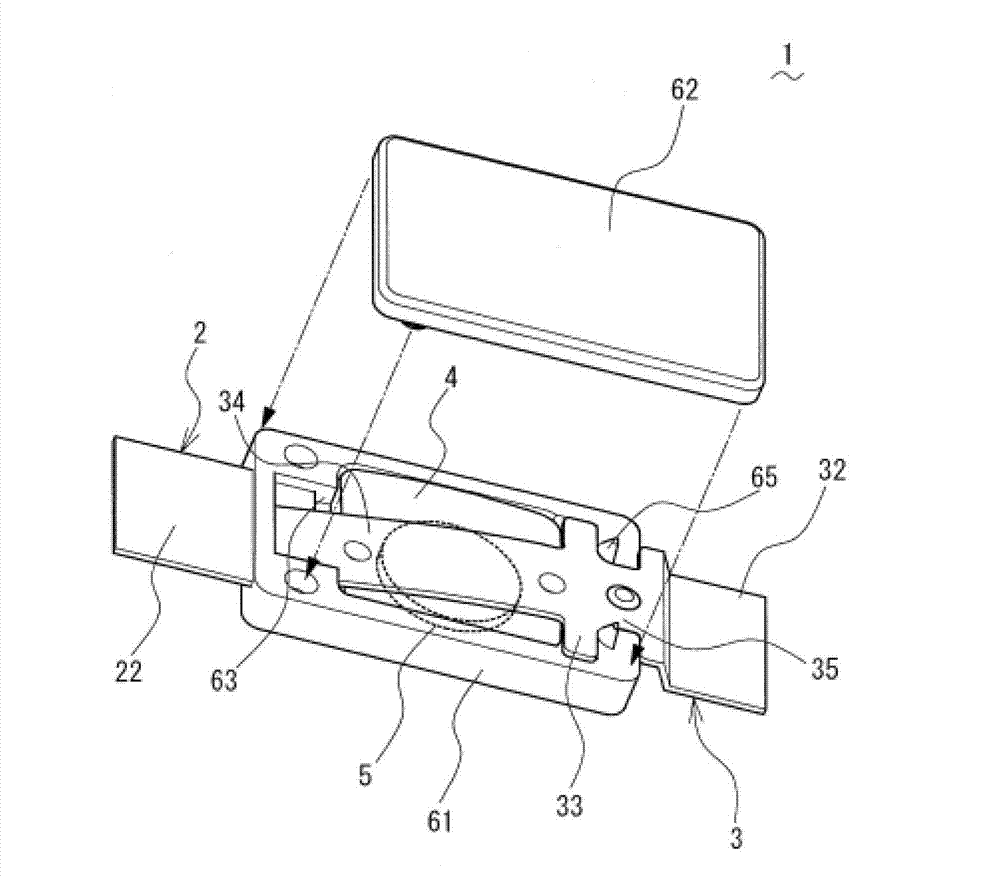

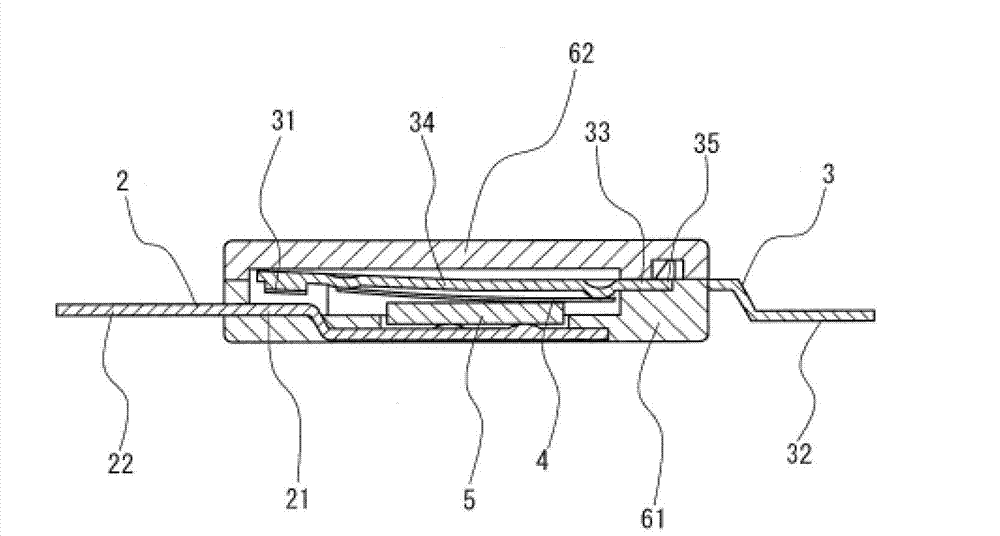

[0043] A circuit breaker according to one embodiment of the present invention will be described with reference to the drawings. figure 1 as well as figure 2 Shows the structure of the circuit breaker. The circuit breaker 1 includes: a fixed piece 2 with a fixed contact 21; a movable piece 3 with a movable contact 31 at the front end; a thermal response element 4 that deforms with temperature changes; a PTC (positive temperature coefficient) thermal sensor Resistor 5; box body 6 for accommodating fixed piece 2, movable piece 3, thermal response element 4 and PTC thermistor 5, etc. The case 6 is composed of a case main body 61 , a cover member 62 mounted on the upper surface of the case main body 61 , and the like.

[0044]The fixed piece 2 is formed by stamping a metal plate mainly composed of phosphor bronze (it can also be a metal plate such as copper-titanium alloy, nickel brass, brass, etc.), and is formed by insert molding or caulking. It is assembled into the box main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com