Electrochemical battery and manufacture method thereof

An electrochemical and battery technology, applied in the field of electrochemical batteries, can solve the problems of miniaturization limit, increase in cost, increase in manufacturing man-hours, etc., and achieve the effects of low contact resistance, reduced manufacturing cost, and easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

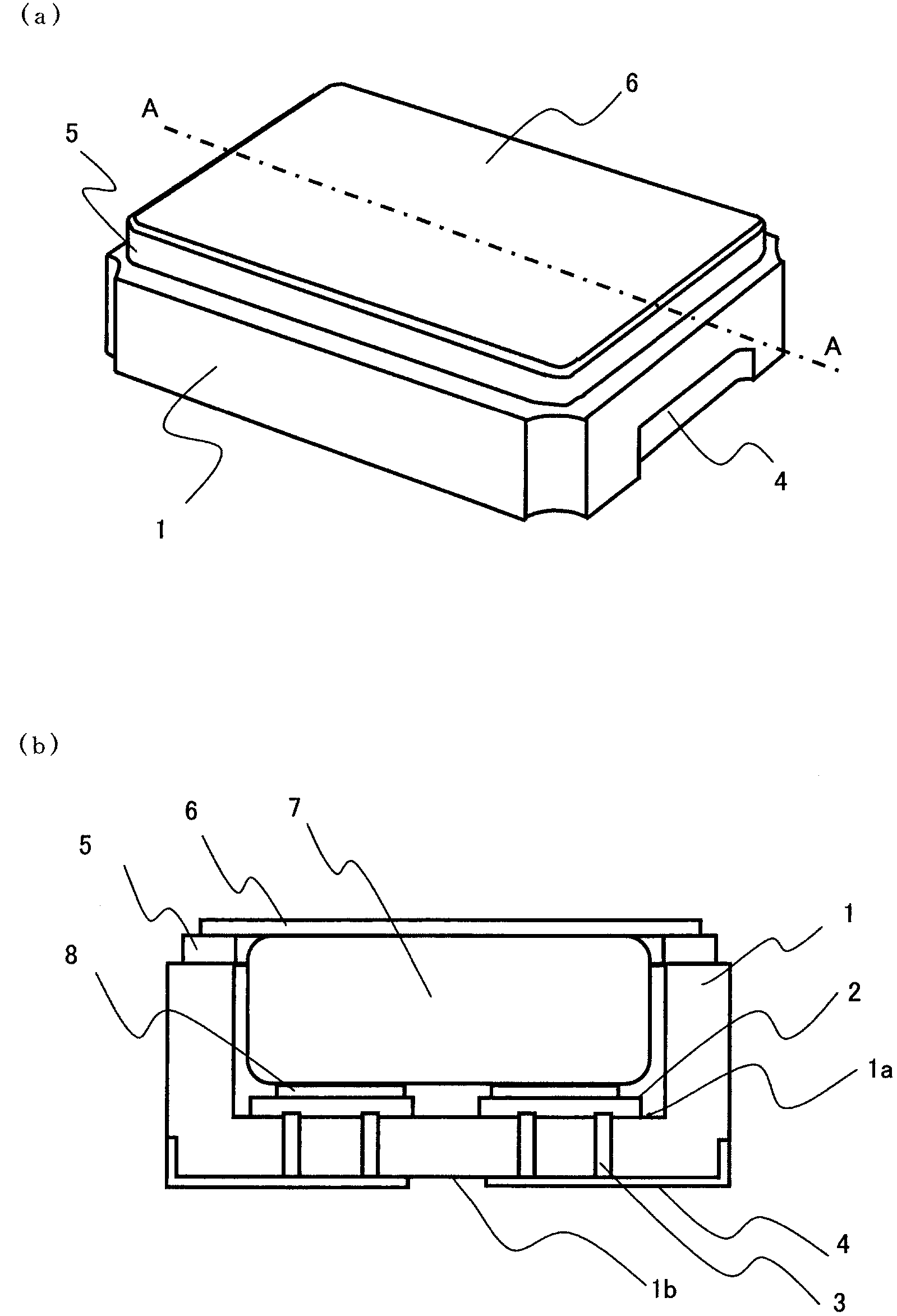

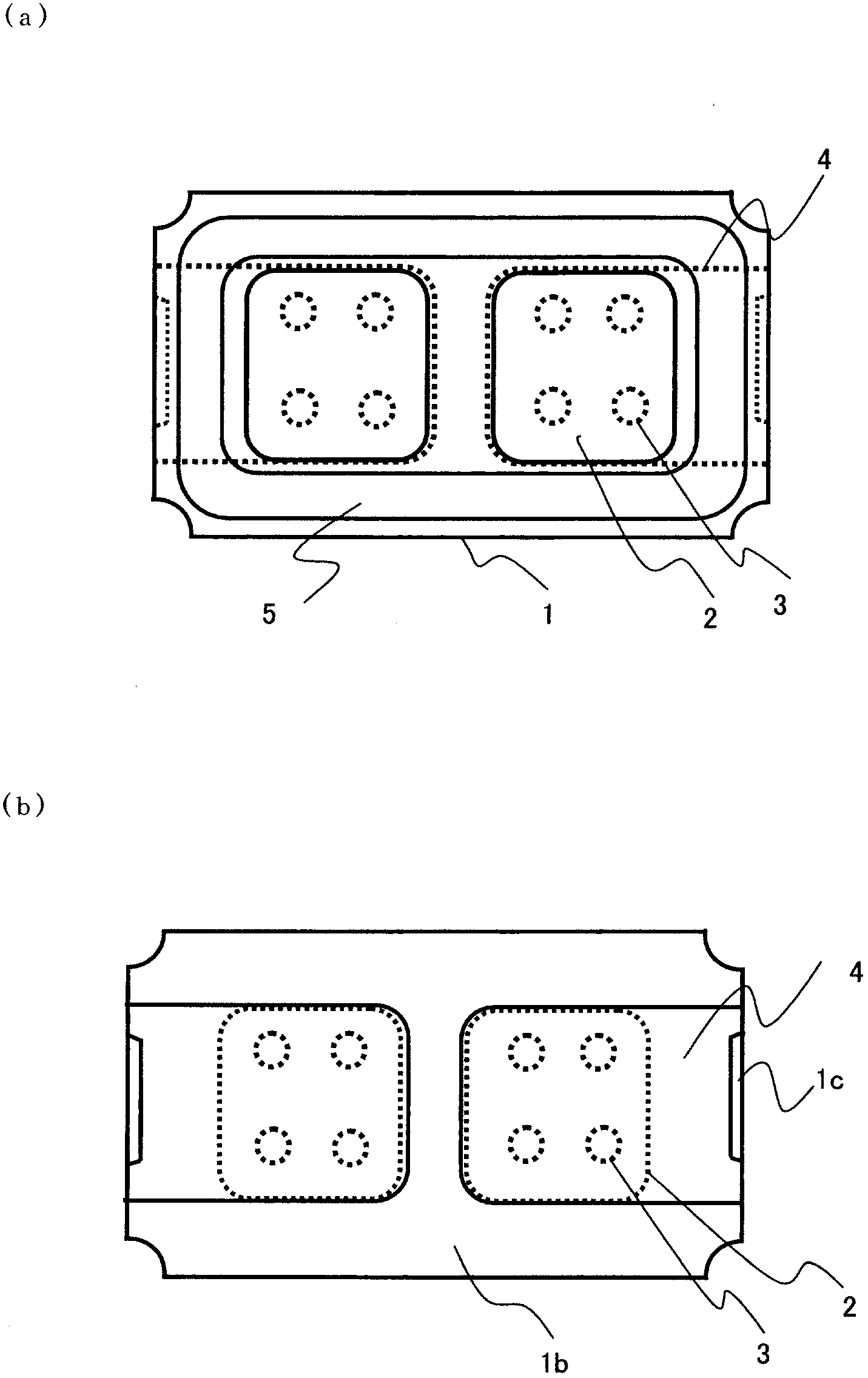

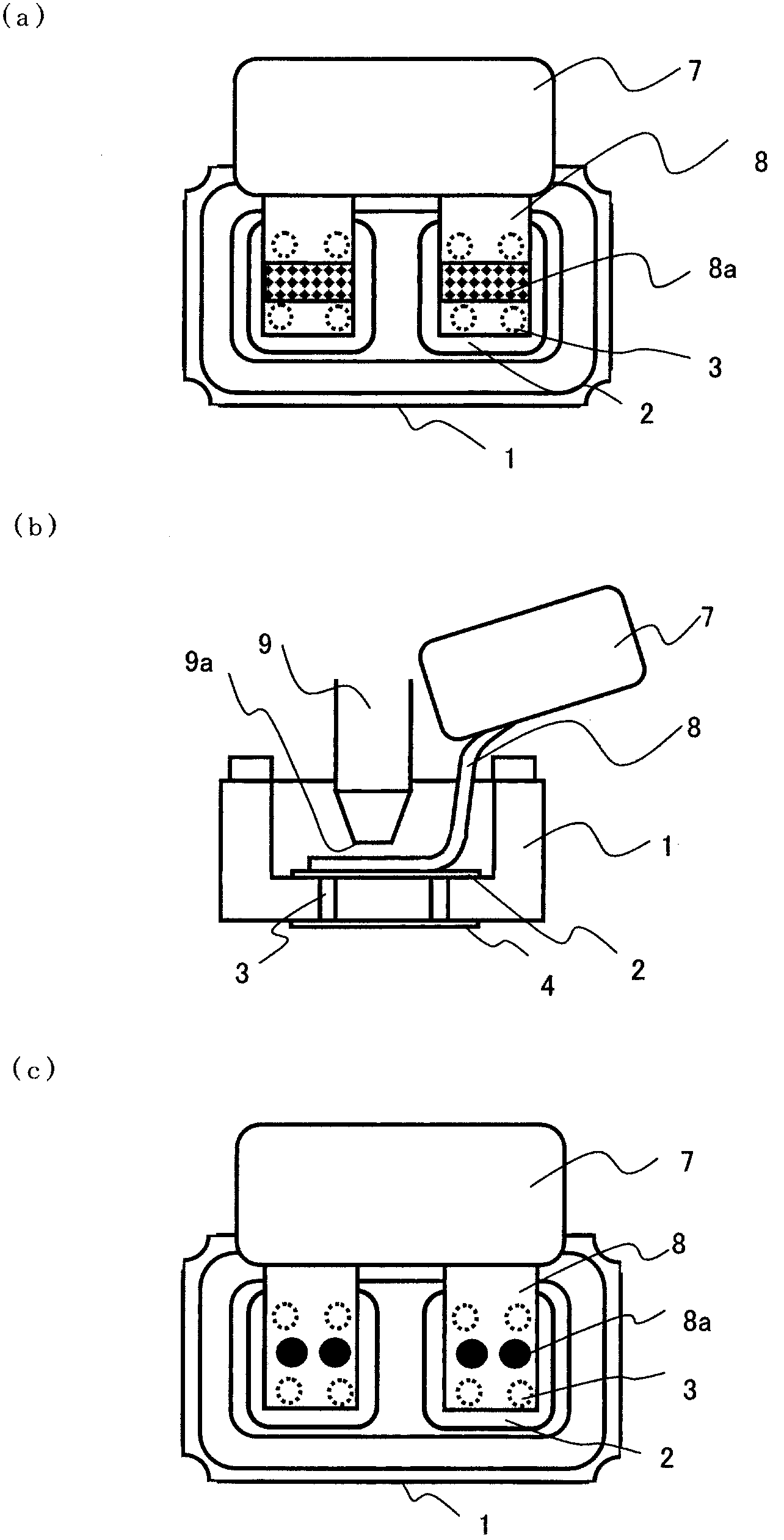

[0188] Below, refer to Figure 9 The manufacturing flow of the shown electric double layer capacitor will be described with respect to Example 1. FIG. First, as an outer container, prepare to form figure 1 (a) and figure 1 (b) The recessed seat 1 and cover 6 shown in (b). The seat 1 has a long side of 10 mm, a short side of 5 mm, and a height of 2.85 mm, and the bottom of the seat 1 has a thickness of 0.5 mm. As the material, a standard material used in the manufacture of packages of electronic components from ceramics was used. The flexural strength of the material is 400MPa, and the Young's modulus is 310GPa. The area where the liner film 2 is formed is filled with tungsten, and four socket internal terminals 3 with an inner diameter of 0.2mm plated with nickel and gold on the surface are respectively provided so as to directly penetrate the inner and outer surfaces of the seat. A pair of connection terminals 4 connected to the seat inner terminal 3 is arranged on the s...

Embodiment 2

[0215] The step of joining the cell lead 8 and the liner film 2 is performed by spot welding using a YAG laser. In addition, the oxidation of the junction part at the time of welding was prevented by blowing nitrogen gas.

[0216] The aluminum thin plate has a thickness of 80 μm and a width of 2 mm (the same as the aluminum thin plate used for the lead wire 8 of the battery cell in Example 1). The concave container made of ceramics is different from Embodiment 1, which is explained with Modification 2 Figure 4 The structure shown in (c) is the same structure, and the terminal inside the seat part which penetrates into the center of the seat part is provided with 6 pieces. The bottom surface of the seat had a thickness of 0.3 mm, which was thinner than in Example 1, and aluminum was formed on the inner surface of the seat to a thickness of about 25 μm by vapor deposition. The size of the backing film is a rectangle of 3 mm x 1.3 mm.

[0217] Soldering is performed as follow...

Embodiment 3

[0221] The materials of the seat parts of Embodiments 1 and 2 are all ceramics. In this embodiment, the case where the material of the seat is glass will be described. An aluminum film was formed on the surface (one side) of soda lime glass (about 1.3 mm in thickness) by ion plating. The thickness is 5 μm. Ultrasonic welding was used to weld an aluminum thin plate with a thickness of 80 μm and a width of 2 mm (the same aluminum thin plate used for the battery core lead 8 in Example 1) to the aluminum surface. The oscillation frequency of ultrasonic welding is 62.5KHz. The area of the tip of the ultrasonic horn was 2mm on the long side and 0.5mm on the short side, and the surface of the tip was roughened in a houndstooth pattern (houndstooth lattice).

[0222] Under the present welding conditions, the aluminum sheet was reliably welded to the aluminum film, and no cracks were induced in the soda-lime glass. The contact resistance value was calculated by subtracting the wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com