Production method of non-residual slurry non-autoclaved prestressed concrete pipe pile

A technology for a concrete pipe pile and a production method, which is applied in the direction of strengthening forming, etc., can solve the problems of low cost performance affecting the quality of pipe piles, recovery and reuse of residual slurry, hidden dangers in production safety, etc., and achieve good promotion value, reduce environmental pollution and Energy consumption, the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

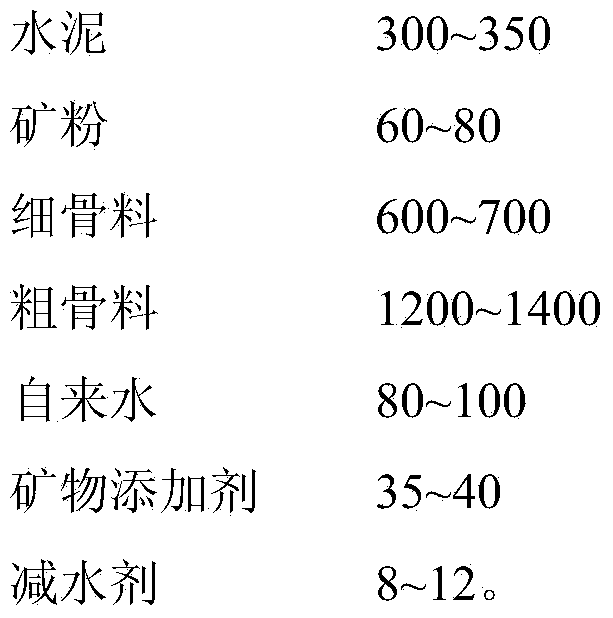

[0035] A kind of autoclaved prestressed concrete pipe pile without residual slurry (diameter 400mm, pipe wall thickness 95mm), its raw material components and weight (Kg) are:

[0036]

[0037]

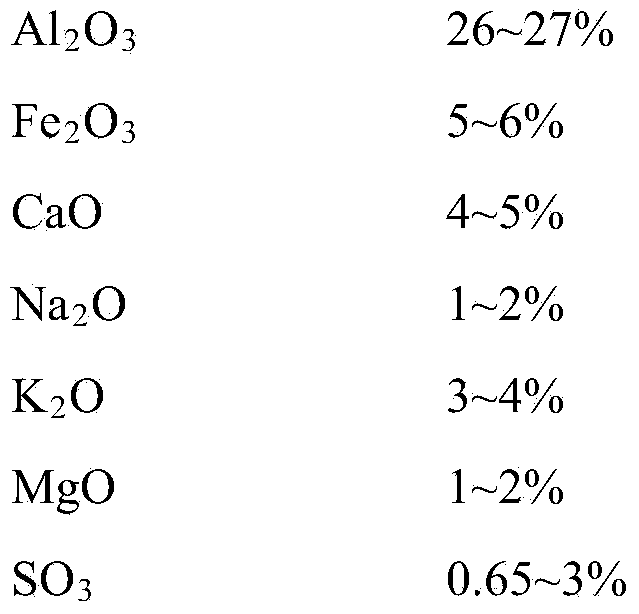

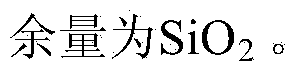

[0038] Described mineral additive is solid microbead, and its raw material component and percentage content are respectively:

[0039]

[0040] The loss on ignition of the above-mentioned solid microspheres is ≤5%, and the density of the spheres is 2.52Kg / dm 3 , the apparent density in the natural state is 0.67Kg / dm 3 , the apparent density after compression is 0.89Kg / dm 3 , water content ≤ 1%, water demand ratio of mortar sand is 90±1%, fineness d 90 ≤10μm.

[0041] The steps of the production method of the above-mentioned non-residual slurry-free autoclaved prestressed concrete pipe pile are:

[0042] (1) Add fine aggregate and coarse aggregate to the reactor, stir for 10 seconds, then add cement, mineral powder and mineral additives, continue to stir for 30 seconds, an...

Embodiment 2

[0065] A prestressed concrete pipe pile without residual slurry (diameter 500mm, pipe wall thickness 100mm), its raw material components and weight (Kg) are:

[0066]

[0067]

[0068] Described mineral additive is with embodiment 1.

[0069] The parameters of each centrifugation step in the production method are set as:

[0070] Low-speed centrifugation: the speed is set at 62r / min, and the time is 4min±10s;

[0071] Low and medium speed centrifugation: the speed is set to 122r / min, and the time is 1min±10s;

[0072] Medium-speed centrifugation: the speed is set at 223r / min, and the time is 3min±10s;

[0073] High-speed centrifugation: the speed is set at 390 / min, the time is 4min±10s, and there is no residual slurry during the centrifugation process.

[0074] All the other production methods are the same as in Example 1, and the finished product inspection: after steam curing, the demoulding strength is greater than 80MPa for 1 day.

[0075] Product Strength Test: ...

Embodiment 3

[0079] A kind of autoclaved prestressed concrete pipe pile without residual slurry (diameter 500mm, pipe wall thickness 125mm), its raw material components and weight (Kg) are:

[0080]

[0081]

[0082] Described mineral additive is with embodiment 1.

[0083] The parameters of each centrifugation step in the production method are set as:

[0084] Low-speed centrifugation: the speed is set at 62r / min, and the time is 4min±10s;

[0085] Low and medium speed centrifugation: the speed is set to 122r / min, and the time is 1min±10s;

[0086] Medium-speed centrifugation: the speed is set at 223r / min, and the time is 3min±10s;

[0087] High-speed centrifugation: the speed is set at 400 / min, the time is 4min±10s, and there is no residual slurry during the centrifugation process.

[0088] All the other production methods are the same as in Example 1, and the finished product inspection: after steam curing, the demoulding strength is greater than 80MPa for 1 day.

[0089] Prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com