Production method of concrete pipe pile

A technology of concrete pipe piles and production methods, which is applied in the field of concrete pipe piles, can solve the problems of low cost performance of residual slurry recovery and reuse, affecting the quality of pipe piles, hidden dangers of production safety, etc., achieve good promotion value, reduce environmental pollution and Energy consumption, effect of increasing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

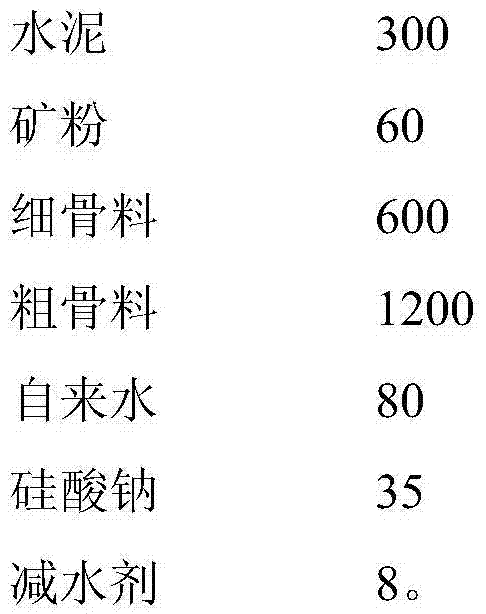

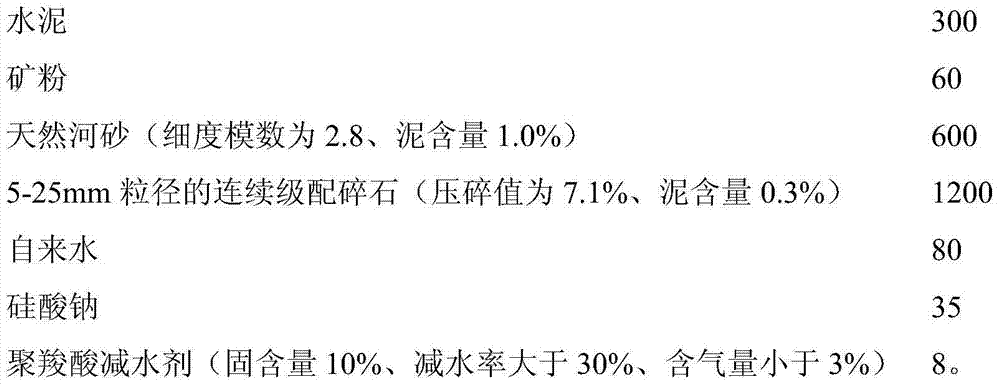

[0022] A kind of autoclaved prestressed concrete pipe pile without residual slurry, its raw material components and weight (Kg) are respectively:

[0023]

[0024] The steps of the production method of the above-mentioned non-residual slurry-free autoclaved prestressed concrete pipe pile are:

[0025] (1) Add fine aggregate and coarse aggregate to the reactor, stir for 10 seconds, then add cement, mineral powder and mineral additives, continue stirring for 30 seconds, and finally add water and water reducer, stir for 90 seconds to obtain a concrete mixture;

[0026] ⑵The concrete mixture is prestressed and stretched after being distributed and molded;

[0027] (3) Centrifuge the prestressed and stretched concrete mixture, and perform the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com