Reduced graphene oxide-polyurethane dual-sponge adsorption film, preparation method therefor and application of reduced graphene oxide-polyurethane dual-sponge adsorption film

A technology of graphene sponge and polyurethane sponge, which is applied in the field of membrane separation, can solve problems such as retention, poor mechanical properties, and secondary pollution of water bodies, and achieve the effects of large specific surface area, good adsorption performance, and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

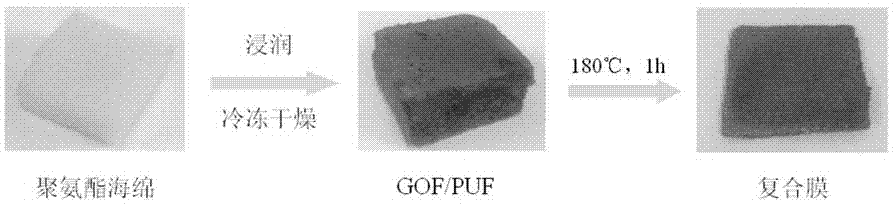

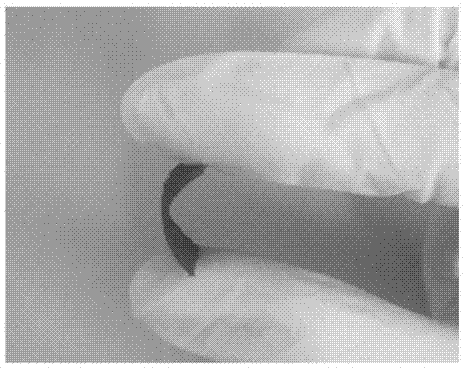

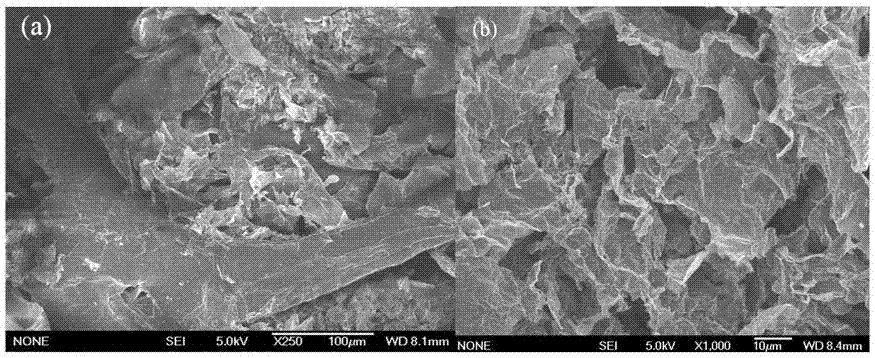

[0033] A reduced graphene oxide-polyurethane double-sponge adsorption film of the present invention comprises a reduced graphene oxide sponge and a polyurethane hot-pressed sponge film, and the reduced graphene oxide sponge is evenly filled in the pores of the polyurethane hot-pressed sponge film and The polyurethane heat-pressed sponge membrane is physically bonded.

[0034] In this embodiment, the thickness of the reduced graphene oxide-polyurethane double-sponge adsorption membrane is 1mm.

[0035] A kind of preparation method of the reduced graphene oxide-polyurethane double-sponge adsorption membrane of the present embodiment, such as figure 1 As shown, it is realized by the following steps:

[0036] (1) Preparation of graphene oxide-polyurethane sponge dispersion:

[0037](1.1) Take 5.0g of natural flake graphite powder and 2.5g of sodium nitrate and slowly add to pre-cooled 90ml of concentrated sulfuric acid to obtain a mixture A; put the mixture A in an ice bath and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com