Preparation method for adsorbent for removing phosphorus in water

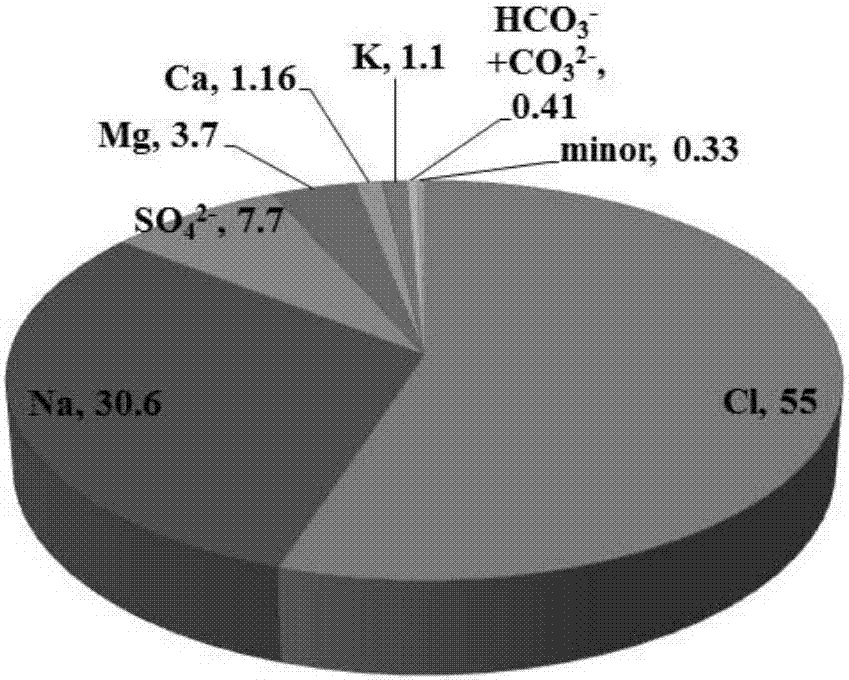

A phosphorus adsorbent, seawater technology, applied in the field of environmental engineering, can solve problems such as poor adsorption capacity, and achieve the effect of high phosphorus removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

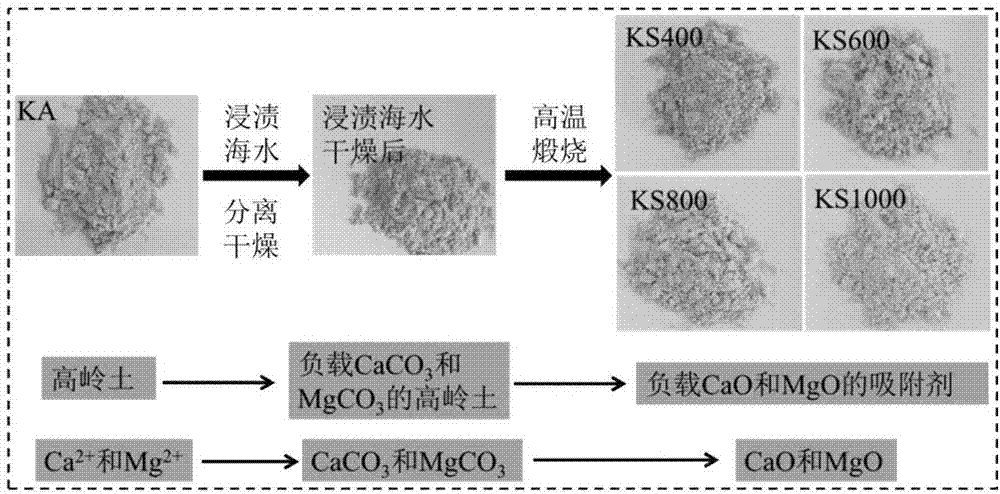

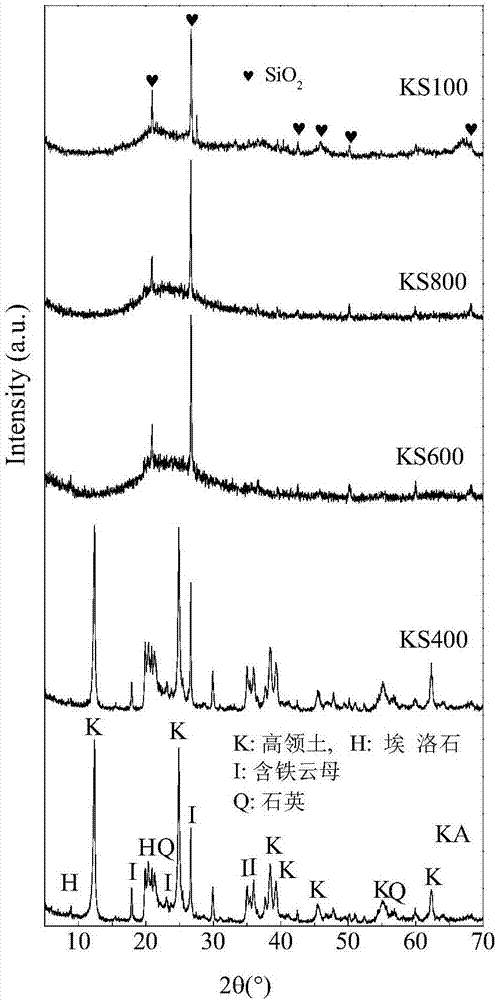

Method used

Image

Examples

Embodiment 1

[0026] Add 2L of seawater to 40g of kaolin (the seawater is first filtered to remove some solid impurities) and mix, and mechanically stir at room temperature for 6 hours, then allow the kaolin to precipitate naturally, remove the clarified liquid, and wash with water 3 times to obtain kaolin mud;

[0027] The kaolin mud is first dried at 105°C, then the agglomerated kaolin is pulverized, and then calcined at 600°C to obtain the water phosphorus removal adsorbent of the present invention, marked as KS600.

Embodiment 2

[0029] Add 3L of seawater to 40g of kaolin (the seawater is first filtered to remove some solid impurities) and mix, and mechanically stir at room temperature for 5 hours, then allow the kaolin to precipitate naturally, remove the clarified liquid, and wash with water twice to obtain kaolin mud;

[0030] The kaolin mud is first dried at 100°C, then the agglomerated kaolin is pulverized, and then calcined at 800°C to obtain the water phosphorus removal adsorbent of the present invention, marked as KS800.

Embodiment 3

[0032] Add 1L of seawater to 40g of kaolin (the seawater is first filtered to remove some solid impurities) and mix, and mechanically stir at room temperature for 8 hours, then allow the kaolin to precipitate naturally, remove the clarified liquid, and wash with water 3 times to obtain kaolin mud;

[0033] The kaolin slurry is first dried at 90°C, then the agglomerated kaolin is pulverized, and then calcined at 500°C to obtain the water phosphorus removal adsorbent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com