Novel high molecular composite phosphorus removal coagulant special for MBR (membrane bioreactor) process and application of novel high molecular composite phosphorus removal coagulant

A polymer and coagulant technology, applied in the chemical industry, can solve the problems of poor removal of total phosphorus and other problems, and achieve the effects of significant technological progress, mild operating conditions and improved phosphorus removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A new type of polymer composite dephosphorization coagulant specially used in MBR process is composed of ferrous iron, citric acid, NaCl, H 2 o 2 、Al(HO) 3 , silicic acid, stabilizer and pure water are produced by polymerization in proportion, ferrous, citric acid, NaCl, H 2 o 2 、Al(HO) 3 The mass ratio of silicic acid, stabilizer and purified water is 0.45:0.15:0.05:0.1:0.1:0.05:0.05:0.05.

[0018] Described ferrous iron is ferrous chloride.

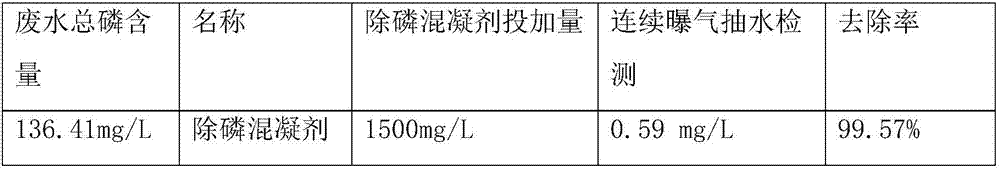

[0019] Mix the high-phosphorus-containing wastewater with the above-mentioned new polymer composite phosphorus-removing coagulant specially used in the MBR process according to the mass ratio (phosphorus-containing wastewater / phosphorus-removing coagulant): 1:0.015, and continuously aerate and pump water at room temperature The detection can make the phosphorus removal rate of high phosphorus-containing wastewater reach 99.57%.

[0020] Table 1: The test wastewater was sampled as phosphorus-containing wastewater from a phot...

Embodiment 2

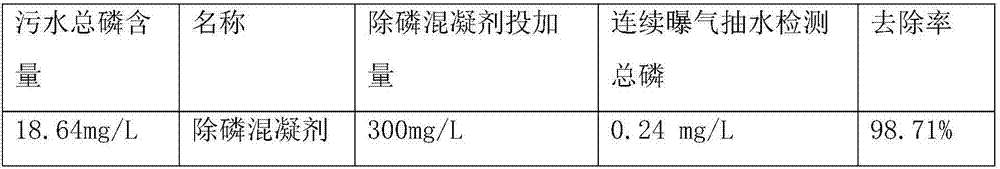

[0023] Same as the components and operating conditions of Example 1, the difference is: the mass ratio of the components of the polymer novel composite phosphorus removal coagulant specially used in the MBR process is 0.40:0.15:0.05:0.10:0.15:0.05:0.05 :0.05. Mix phosphorus-containing sewage with the new polymer composite phosphorus removal coagulant specially used in the MBR process according to the mass ratio (phosphorus-containing sewage / phosphorus removal coagulant): 1:0.003, and add it to the MBR membrane process to remove For the phosphorus tank, after 10 minutes of aeration, the water pump is turned on to pump the water for detection, and the aeration is continued under normal temperature conditions without standing still, so that the phosphorus removal rate of high-phosphorus wastewater can reach 98.71%. Table 2: Test wastewater sampling is the influent of a sewage treatment plant

[0024]

Embodiment 3

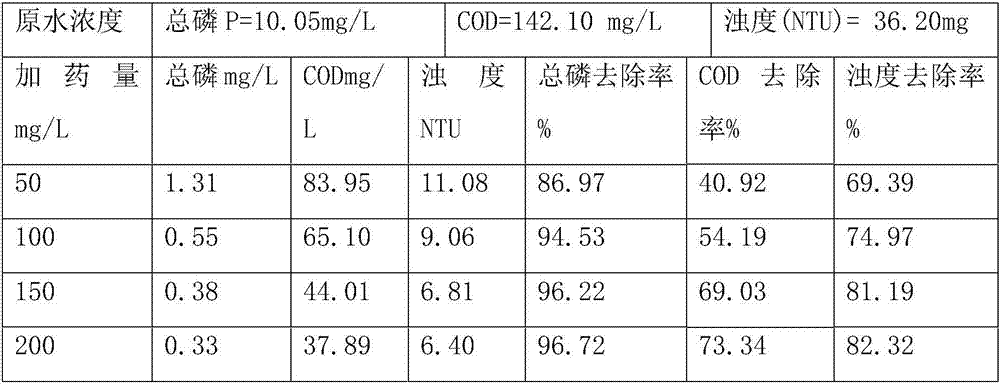

[0026] Identical to the components and operating conditions of Example 1, the difference is that the sewage belongs to a sewage plant influent raw water (total phosphorus content 10.05mg / L, COD content 142.10mg / L, turbidity (NTU) 36.20mg / L ,) The proportion of waste water / polymer new compound phosphorus removal coagulant specially used in MBR process is shown in Table 3. Continuous aeration at room temperature, pumping water for 30 minutes of aeration detection, can make the total phosphorus removal rate of waste water reach 86.97~ 96.72%, COD removal rate reached 40.92-73.34%, turbidity removal rate reached 69.39-82.32%.

[0027] Table 3: Test wastewater sampling is the influent of a sewage treatment plant

[0028]

[0029] Note: The dosing amount is the dosage of the new polymer composite phosphorus removal coagulant specially used in the MBR process, and the data of the 30-minute pumping test under continuous aeration conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com