Oil refinery sewage treatment and reusing process system and operation method thereof

A sewage treatment and process system technology, applied in the direction of flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of long-term operation failure, affecting standard discharge, operation and operation High cost and other problems, to achieve the effect of saving fresh water consumption, simple process flow, and cost saving of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

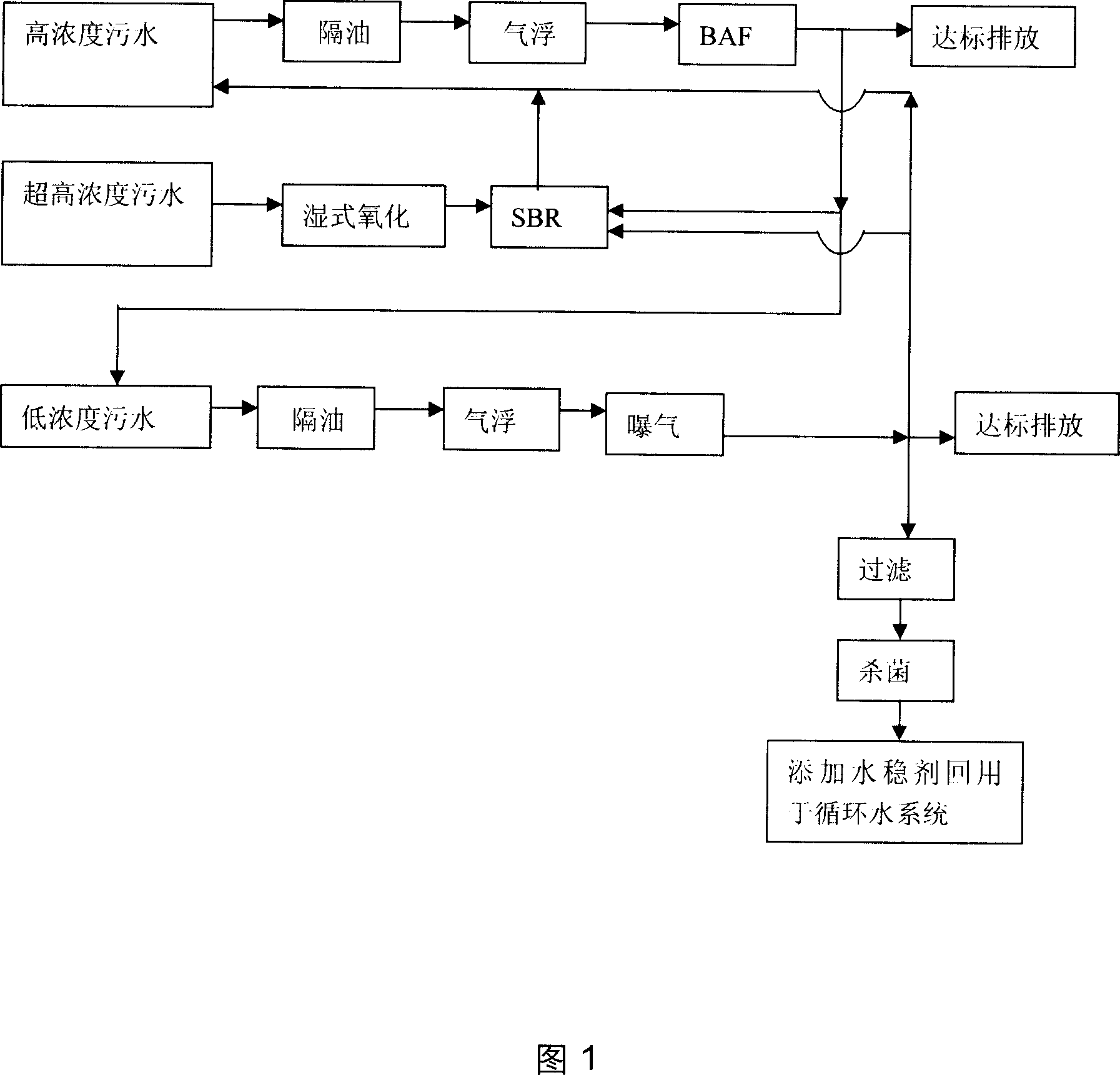

[0028] Process flow of ultra-high concentration sewage treatment unit:

[0029] The mixed sewage such as liquefied gas alkali washing water, gasoline, kerosene and diesel alkali washing water is called ultra-high concentration sewage, and the COD concentration is very high, with a content of about 250,000-350,000 mg / L. It is pumped into the wet oxidation tower, At a high temperature of about 190°C and a high pressure of 2.5MPa, most of the mercaptans and phenols are removed to reduce the COD to 20,000-50,000 mg / L, and then sent to the sequencing batch bioreactor SBR for biological treatment. The COD of the SBR effluent is about 800-1000mg / L, which is pumped into the high-concentration sewage treatment unit for further treatment. The dilution water of SBR comes from two streams of water: 1. Water discharged up to standard after high-concentration BAF treatment; 2. Water discharged up to standard after biochemical treatment of low-concentration sewage.

[0030] The advantages o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com