Twin tower type recovering sulfur resource ammonia desulfuration equipment and method

A technology for ammonia desulfurization and sulfur recovery, applied in the direction of separation methods, chemical instruments and methods, ammonium sulfite, etc., can solve problems that are difficult to popularize, achieve no secondary pollution, save process raw materials, and increase added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

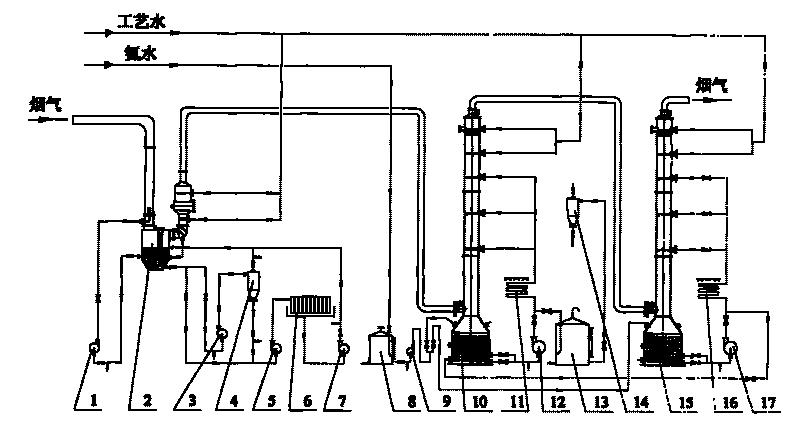

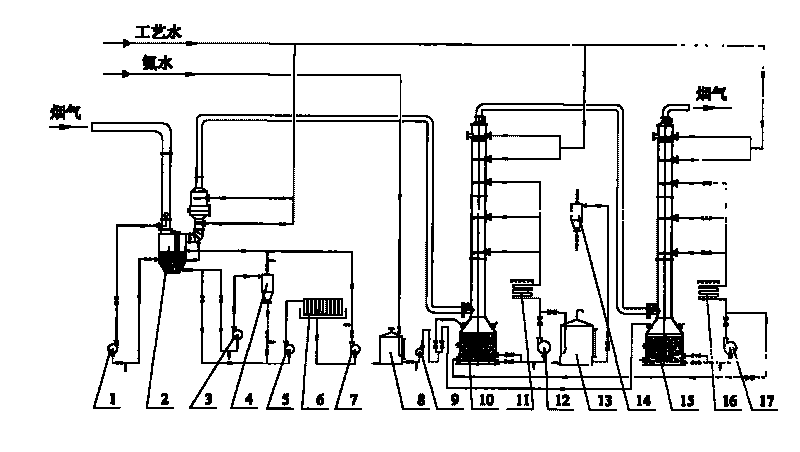

[0019] As shown in the attached figure, the double-tower ammonia desulfurization device for recovering sulfur resources includes a power wave circulation pump 1, a power wave scrubber 2, a power wave bottom pump 3, a cyclone 4, a filter press pump 5, and a plate and frame filter press Machine 6, filtrate pump 7, ammonia water tank 8, ammonia water pump 9, primary absorption tower 10, condenser 11, primary circulation pump 12, ammonium bisulfite storage tank 13, finished product filter 14, secondary absorption tower 15, Condenser 16, secondary circulation pump 17, the flue gas enters the power wave scrubber 2, and the power wave scrubber 2 is provided with an interface for adding industrial water. After being washed by the power wave scrubber 2, the flue gas enters the primary absorption tower 10 , enter the secondary absorption tower 15 after circulating spraying and absorbing under the action of the primary circulating pump 12 and condenser 11, and discharge after circulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com