Patents

Literature

72results about How to "Reduce processing stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

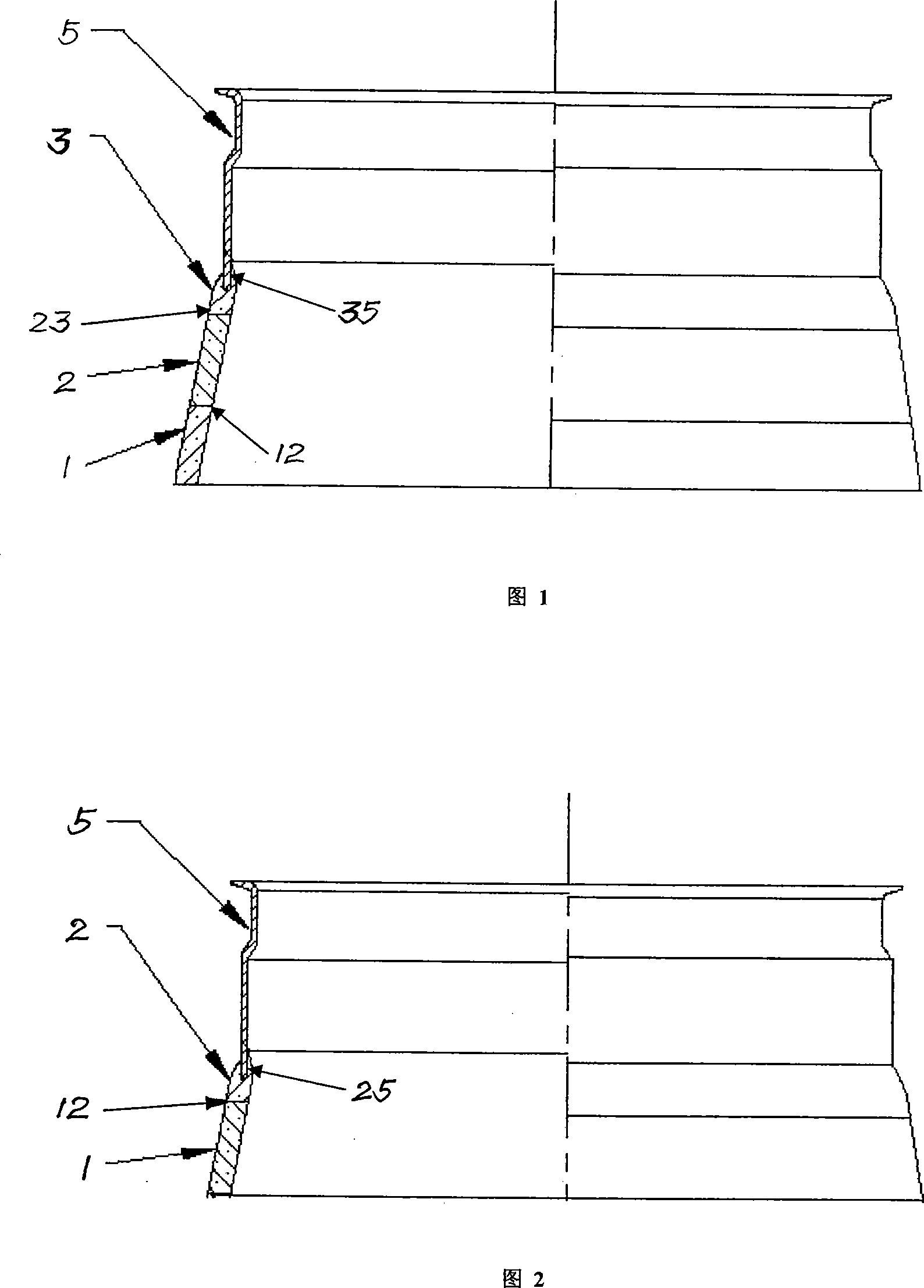

Machining process of middle-long thin-wall blades

ActiveCN103008741AReduce cumulative errorReduce processing stress deformationMilling equipment detailsEngineeringMachining process

The invention discloses a machining process of middle-long thin-wall blades, which belongs to the technical field of machining of blades. The machining process is implemented by a detailed process of integrated rough machining and integrated fine machining, wherein the integrated rough machining comprise the specific steps of rough machining of each surface of a blade tip, each surface of a blade root and a molded surface of a steam passage; and the integrated fine machining comprises the specific steps: semifinishing of each surface of the blade tip and each surface of the blade root, fine machining of each surface of the blade tip, each surface of the blade root and each residue, semifinishing of the steam passage and fine machining of the steam passage. According to the machining process of the middle-long thin-wall blades, the operation is simple and convenient, the use is convenient and fast, the cost is low, the machining efficiency is high, and the operation is easy and labor-saving; and the deformation of the middle-long thin-wall blades is controlled within 0 to 0.8mm, the normal machining of a subsequent mold correction process is facilitated, and the machining of each blade is finished once.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

Chemical mechanical polishing solution for processing surface of sapphire or carborundum wafer for LED (Light Emitting Diode) substrate slice and preparation method thereof

InactiveCN102888193AAvoid damageNo subsurface damageSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesActive agentSilicon oxide

The invention discloses a chemical mechanical polishing solution for processing a surface of a sapphire or carborundum wafer for an LED (Light Emitting Diode) substrate slice. The chemical mechanical polishing solution comprises the following raw materials by weight: 2 to 30% of grinding material, 0.01 to 5% of chelating agent, 0.01 to 10% of surface active agent, 0.01 to 10% of dispersing agent, 0.1 to 20% of oxidant and the balance of deionized water. The preparation method comprises the steps as follows: preparing a grinding material-silica sol; then, sequentially adding the chelating agent, surface active agent, dispersing agent, oxidant and deionized water to the obtained silica sol along with agitating; and continuously uniformly agitating to obtain the chemical mechanical polishing solution for processing the surface of the sapphire or carborundum wafer for the LED substrate slice. The chemical mechanical polishing solution disclosed by the invention can not bring damage, scratching and corrosive pits to the surface of the LED substrate and has no pollution to the environment; the raw materials are cheap, and the cost is low; and the chemical mechanical polishing solution is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

Lathe work method for thin-walled parts of middle-small diameter

ActiveCN101015863AImprove stabilityReduce distortionAutomatic control devicesTurning toolsEngineeringMechanical engineering

The invention discloses a method for turning middle and small thin-wall element, wherein the invention uses auxiliary clamper on general turning machine, first based on the outer diameter of element, produces a slim sheath with same diameter and middle slim as auxiliary clamper, machines the blank of object element, then puts the draw-in gear into the inner hole of slim sheath, puts them together into three-claw positioning clamping disc of turning machine, clamping and machining roughly and finely, and since the invention uses slim sheath as auxiliary clamper, the long-disc claw can obtain uniform dispersed clamping force on the surface of object element, to reduce unit clamping force, reduce vibration and deformation or the like. And the invention improves efficiency via transferring thin-wall element on three-claw automatic positioning clamping disc.

Owner:XIAN SHAANGU POWER

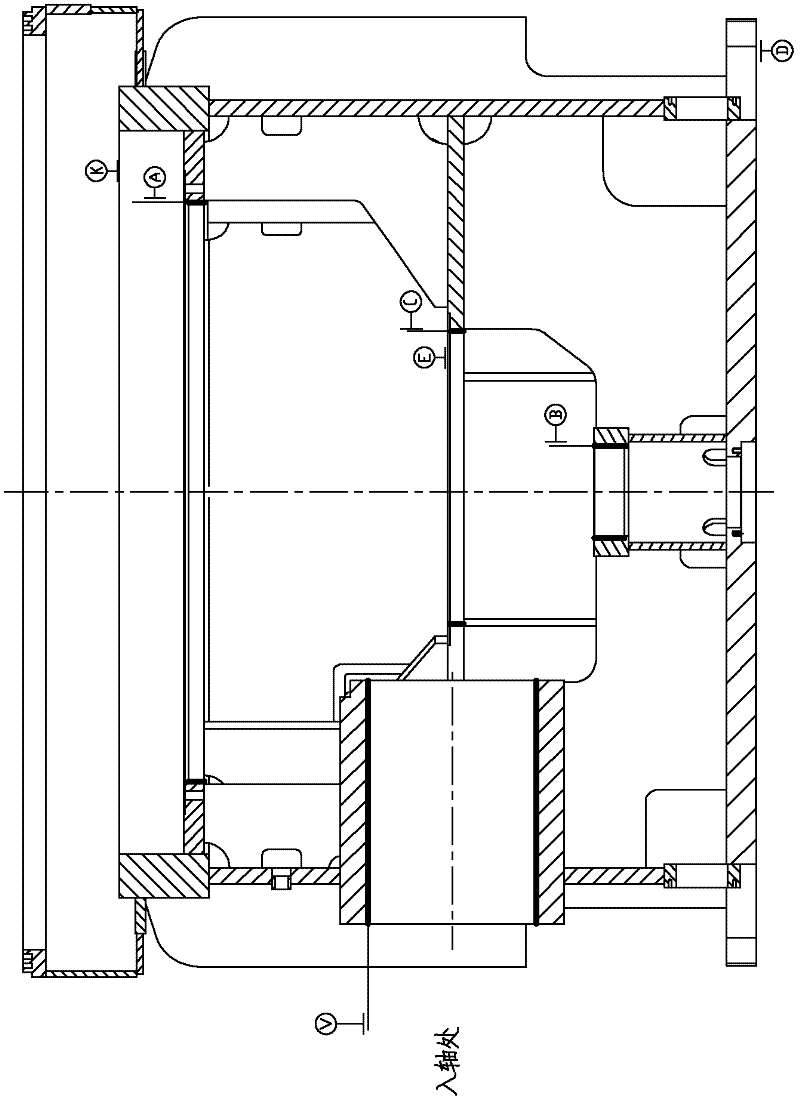

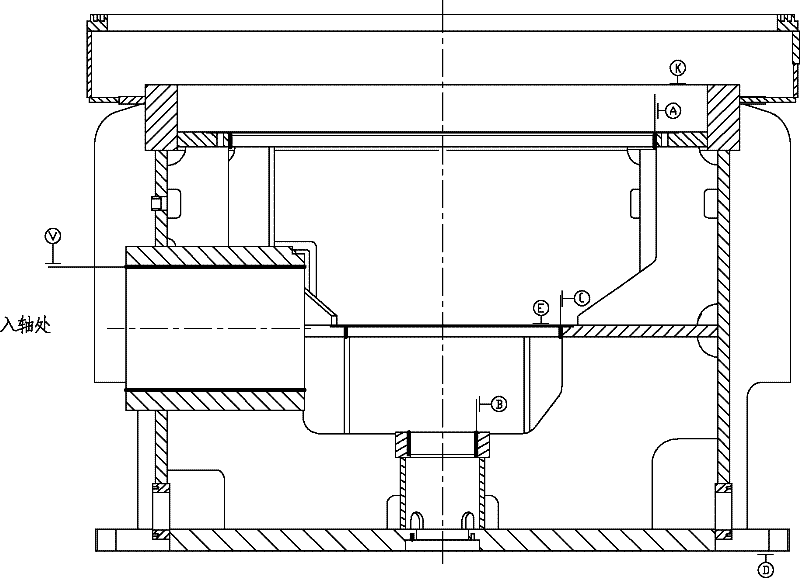

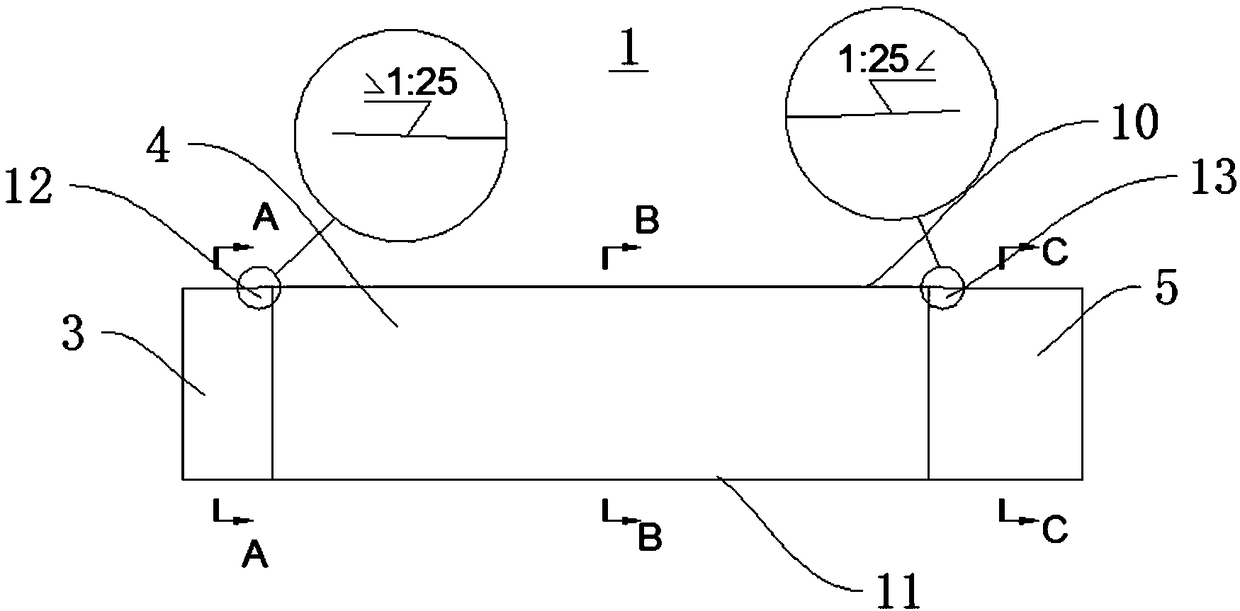

Machining method of perpendicularly intersected hole system of speed reducer body

InactiveCN102642114AReduce surface roughness requirementsGuaranteed shape and position accuracyMeasurement/indication equipmentsMetal working apparatusNumerical controlSurface finish

The invention discloses a machining method of a perpendicularly intersected hole system of a speed reducer body. Holes A-B on the vertical axis are machined by a vertical numerical control machining center so as to meet the concentric requirement of the holes on the axis, and simultaneously, a section of horizontal hole is bored based on the vertical axis; the horizontal hole is long in length, only a section of horizontal hole is bored to be used as an aligning basis in order to ensure the machining precision so as to avoid a mark error, so that the section of horizontal hole is used as an aligning basis for machining a horizontal hole V. In the same way, a hole V on the horizontal axis is machined by a high-precision numerical control boring and milling machine by not using a mark as an aligning basis but on the aligning basis on which the vertical holes are machined, and the aligning precision is high; and meanwhile, the space laser detection technology and the numerical control machining technology are matched to ensure the form-position precision of the perpendicularly intersected hole system of the body. The fine surface finishing technology and the numerical control simulation technology of a high-precision numerical control machine are applied to select reasonable cutting amount to meet the low roughness requirement of the surface of the perpendicularly intersected hole system of the body. Through the machining method, the amount of adjustment of assembly is greatly reduced, and the assembly precision is improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Method for processing ceramic bearing ball

ActiveCN101486145AReduce processing costsShorten the processing cycleLapping machinesOther manufacturing equipments/toolsBoron carbideZirconia ceramic

The invention provides a superfine processing method for silicon nitride ceramic bearing balls. The superfine processing method takes boron carbide, silicon carbide, tungsten carbide, corundum, chrome corundum, zirconia corundum, diamond micro powder, diamond ointment and the like as grinding materials, chrome oxide, cobalt oxide, ferric oxide and cerium oxide as grinding aids, and kerosene, gasoline, alcohol and the like as grinding media, and utilizes a vertical bearing ball grinder to release the processing pressure so as to realize low-stress precision processing of bearing balls. The technology is suitable for the silicon nitride ceramic bearing balls, alumina ceramic balls, zirconia ceramic balls, boron carbide ceramic balls and silicon carbide ceramic balls with a diameter between 0.5 and 50.4 millimeters, and obviously shortens the processing period and the processing stress so as to effectively improve the service life of the ceramic balls.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

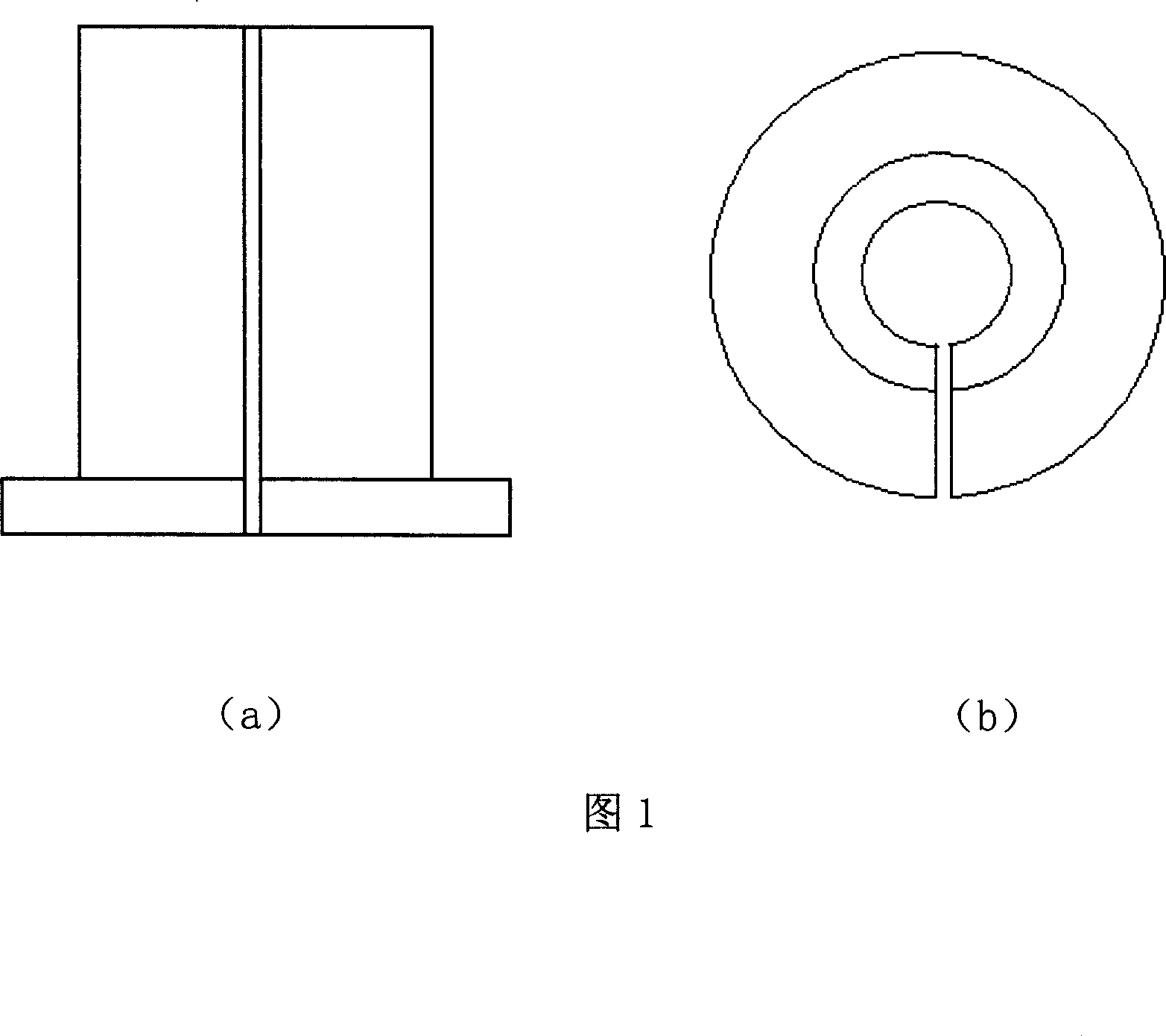

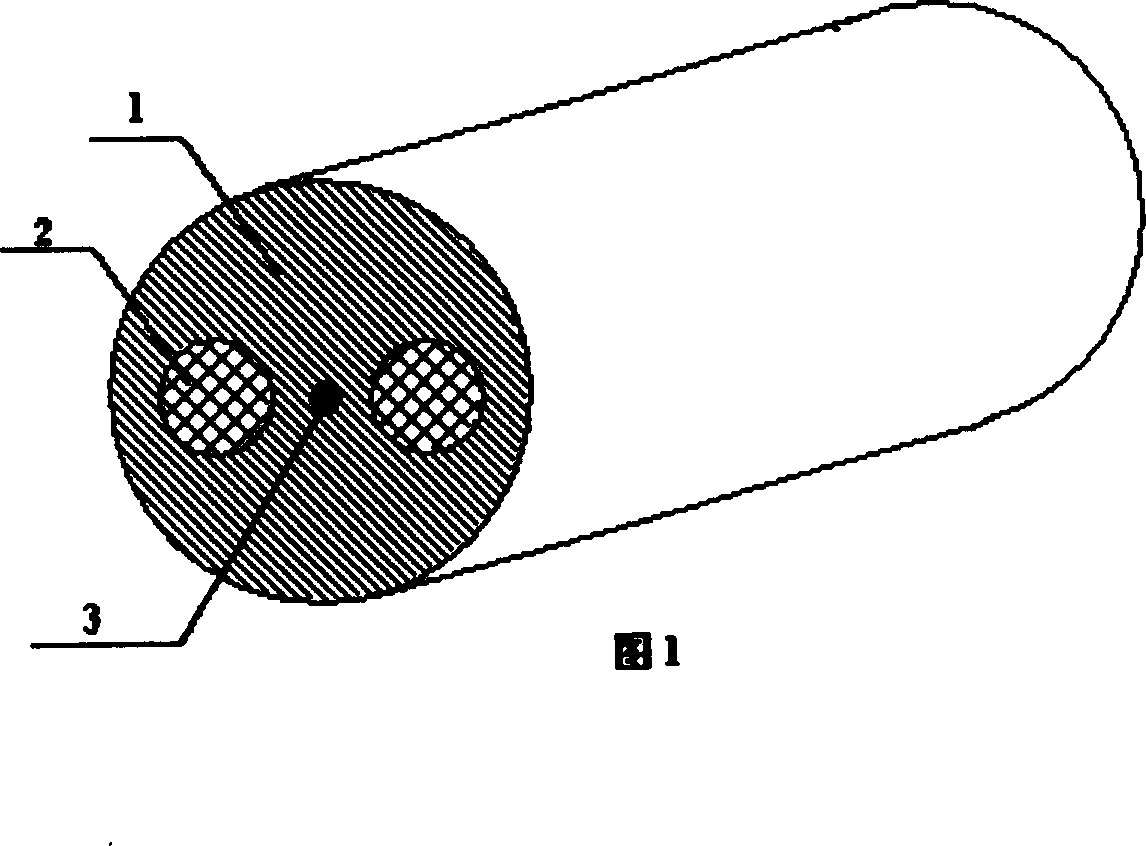

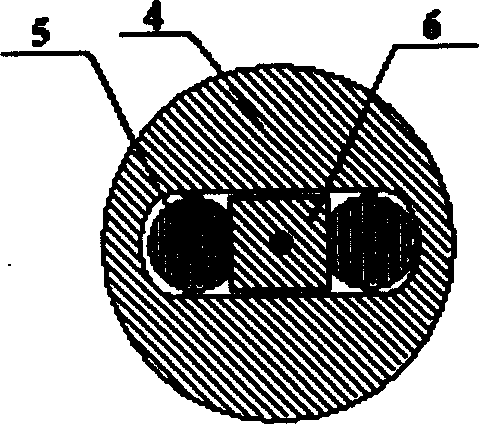

Method for producing polarization maintaining optical fibre

ActiveCN1557754AReduce processing stressReduce residual stressGlass making apparatusOptical light guidesPolarization-maintaining optical fiberEngineering

The making process of circular polarization maintaining fiber includes deposition process to make core rod and stress rod with preserved coating, machining mechanically the matched sides of the core rod and the stress rod to reach the matching interval requirement, machining mechanically the inner hole of quartz casing for fitting the combined cross section of the core rod and the stress rod, setting the machined core rod and stress rod into the quartz casing for matching tightly to constitute prefabricated rod for circular polarization maintaining fiber, drawing, cleaning, and re-drawing to form fiber. The making process has high precision, high product quality and powerful adaptability, and is suitable for mass producing circular polarization maintaining fiber product.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

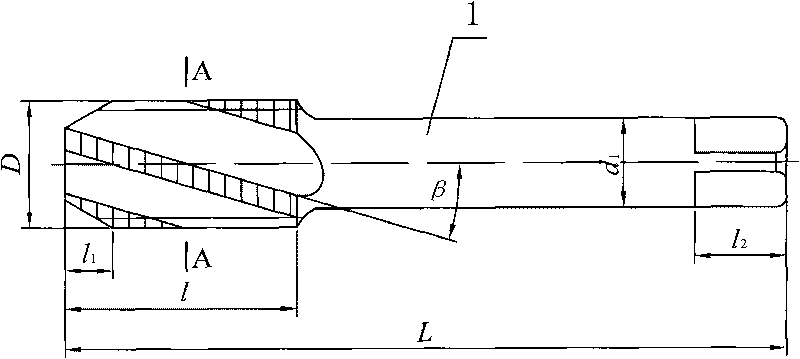

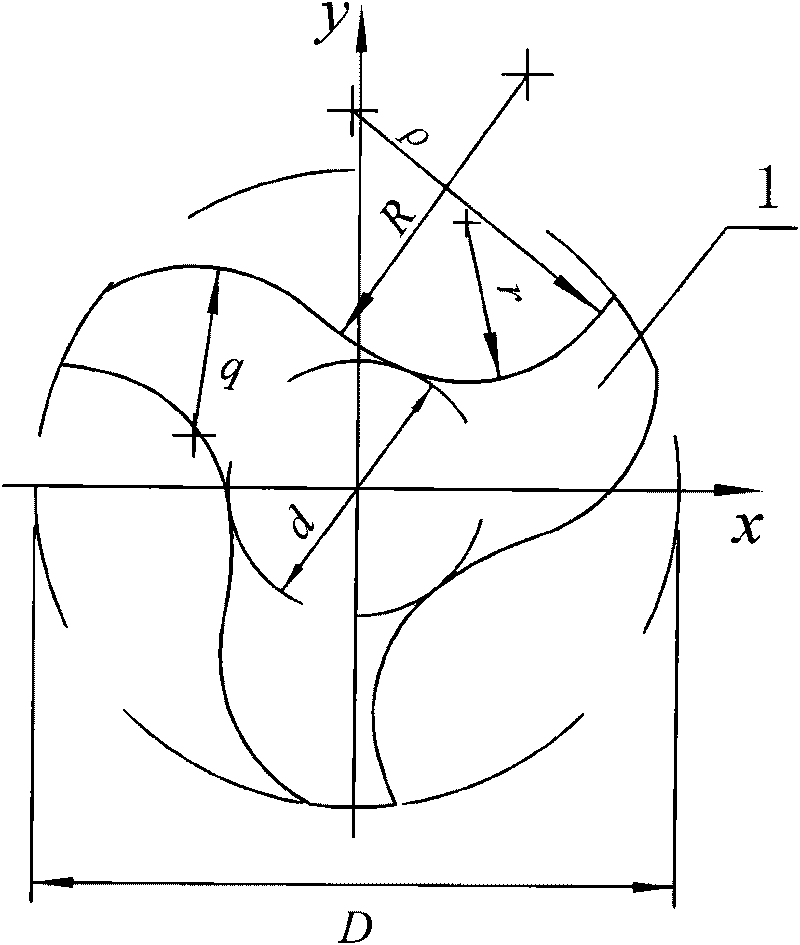

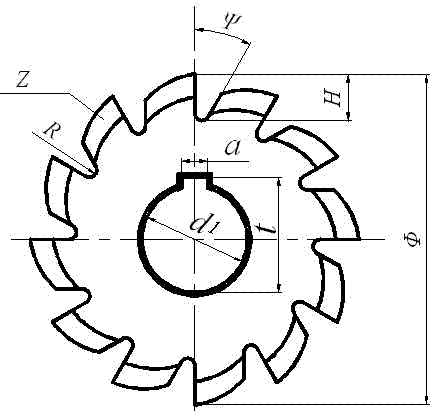

Spiral fluted tap and method for processing same

The invention discloses a spiral fluted tap and a method for processing the same. The spiral fluted tap comprises a tap body provided with a plurality of uniformly distributed spiral flutes on a front cut part, wherein the spiral flute is an S-shaped smooth curved groove formed by sequentially connecting four sections of tangential circular arcs end to end; and the four sections of tangential circular arcs are a cutting circular arc, a chip curling circular arc, a chip accommodating circular arc and a blade back circular arc respectively. The method for processing the spiral fluted tap comprises the following steps of: (1) preparing before processing; (2) processing the spiral flute by a special tool: fitting a blade shape of a cutter by a computer, and then manufacturing the cutter according to the fitted cutter blade shape so as to process the spiral flute; and (3) carrying out subsequent treatment by using a machining process so as to obtain a finished product of the tap body. The spiral fluted tap processed by the method has simple structure and can be molded in one step. Moreover, the processing method is suitable for different processing materials, particularly for processing fluted taps made of light alloys, such as an aluminum alloy and the like.

Owner:XIAN TECHNOLOGICAL UNIV

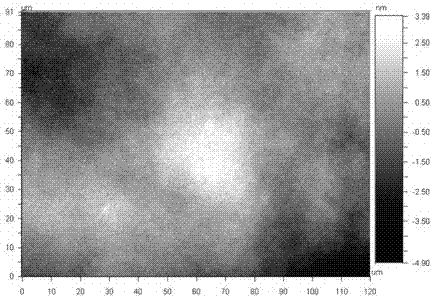

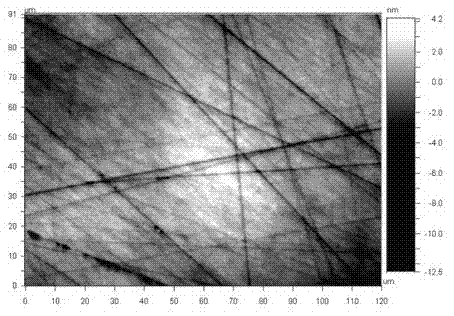

Polishing solution for silicon carbide substrate

InactiveCN102533124AAvoid damageLow subsurface damageSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSURFACTANT BLENDCorrosion

The invention relates to a chemically mechanical polishing solution for a silicon carbide substrate. The chemically mechanism polishing solution comprises the following components in percentage by weight: 1-50 percent of grinding material, 0.01-8 percent of chelant, 0.01-10 percent of surfactant, 0.01-10 percent of dispersing agent, 0.1-20 percent of oxidant and the balance of deionized water. The polishing solution has little damage to the surface of the silicon carbide substrate; the silicon carbide substrate has low roughness degree value and can reach the roughness Ra of being less than 0.5nm; no scratch and corrosion pit defect exists on the surface of the silicon carbide substrate; and the chemically mechanical polishing solution has high removing speed of scratch and corrosion pit, is easy to clean, does not corrode processing equipment and pollute the environment, and is low is price of raw materials, low in cost and easy to store. The chemically mechanical polishing solution is mainly used for chemically mechanical polishing of a silicon carbide wafer for the substrate.

Owner:上海上硅中试基地科技有限公司 +1

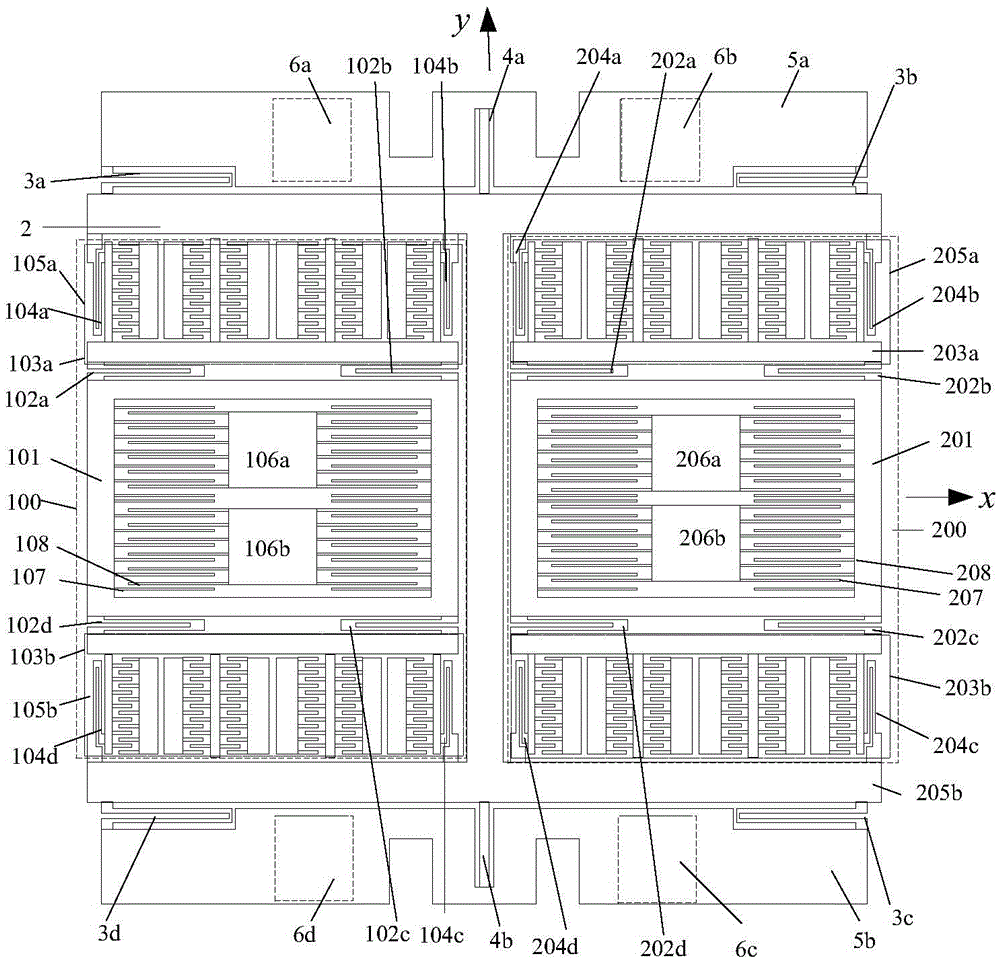

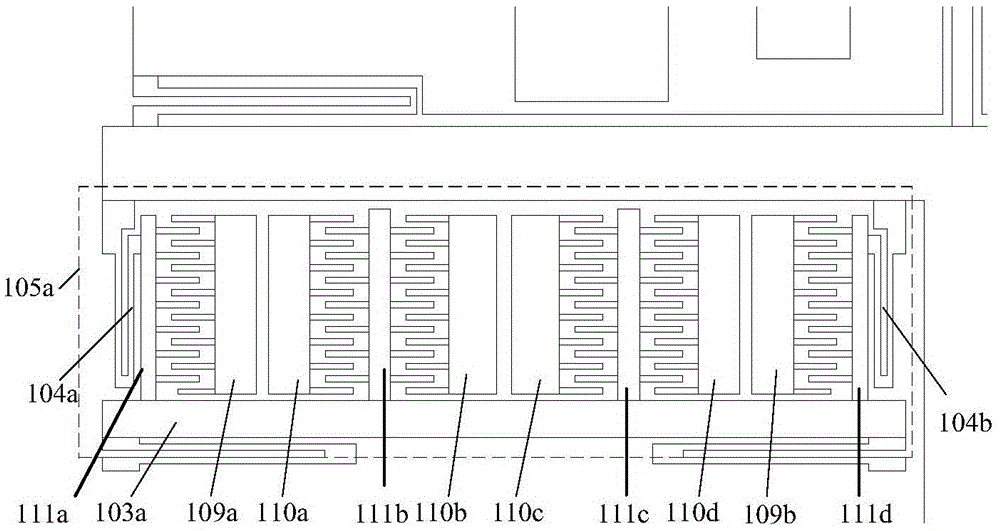

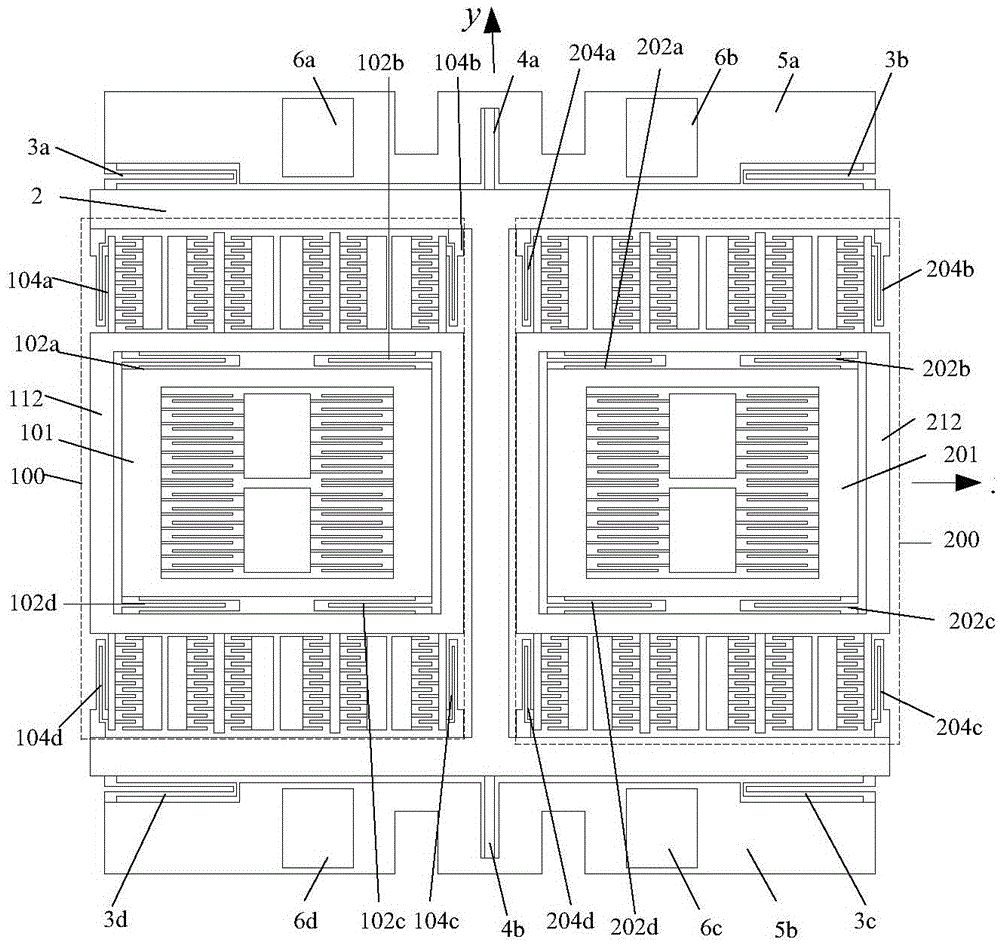

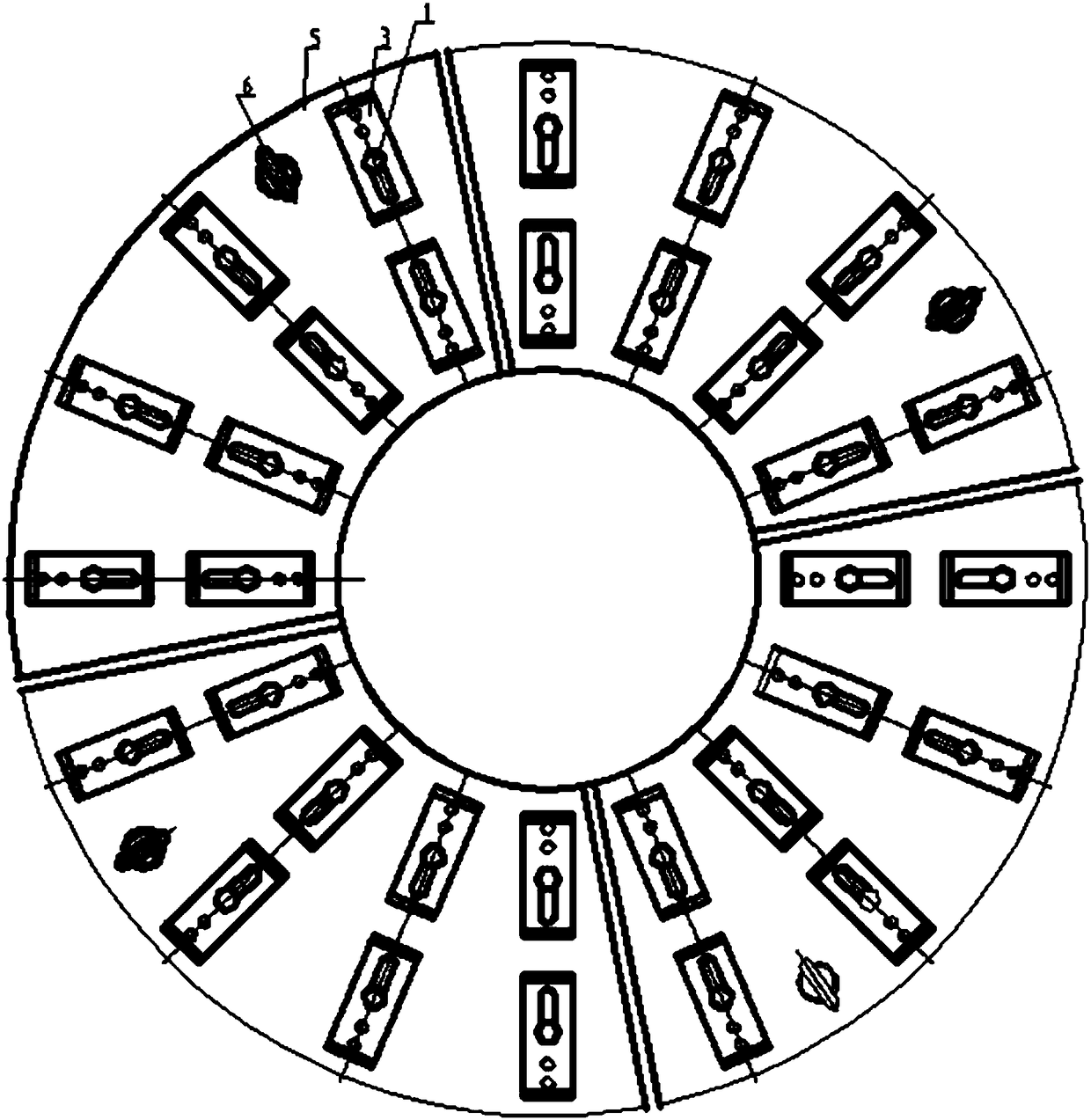

Silicon micromechanical vibrating gyroscope of I-shaped structure

ActiveCN105466406AImprove stabilityIncrease stiffnessSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesGyroscopeInter layer

The invention discloses a silicon micromechanical vibrating gyroscope of an I-shaped structure, which is used for measuring a measuring instrument vertical to the horizontal level of a base. The silicon micromechanical vibrating gyroscope is formed by upper-layer monocrystalline silicon, middle-layer monocrystalline silicon and lower-layer monocrystalline silicon, wherein the upper-layer monocrystalline silicon is a silicon micromachined gyroscope encapsulating cover plate with a signal input wire and a signal output wire; a gyroscope mechanical structure is formed on the middle-layer monocrystalline silicon; the lower-layer monocrystalline silicon is a gyroscope substrate provided with a fixed base; and the middle-layer monocrystalline silicon is sealed in a sealed cavity formed by the upper-layer monocrystalline silicon and the lower-layer monocrystalline silicon. The silicon micromechanical vibrating gyroscope is small in error, high in mechanical sensitivity, low in vibration sensitivity and low in temperature sensitivity, and can realize movement decoupling, violent vibration and detection output decoupling of a driving modal and a detection modal.

Owner:NANJING UNIV OF SCI & TECH

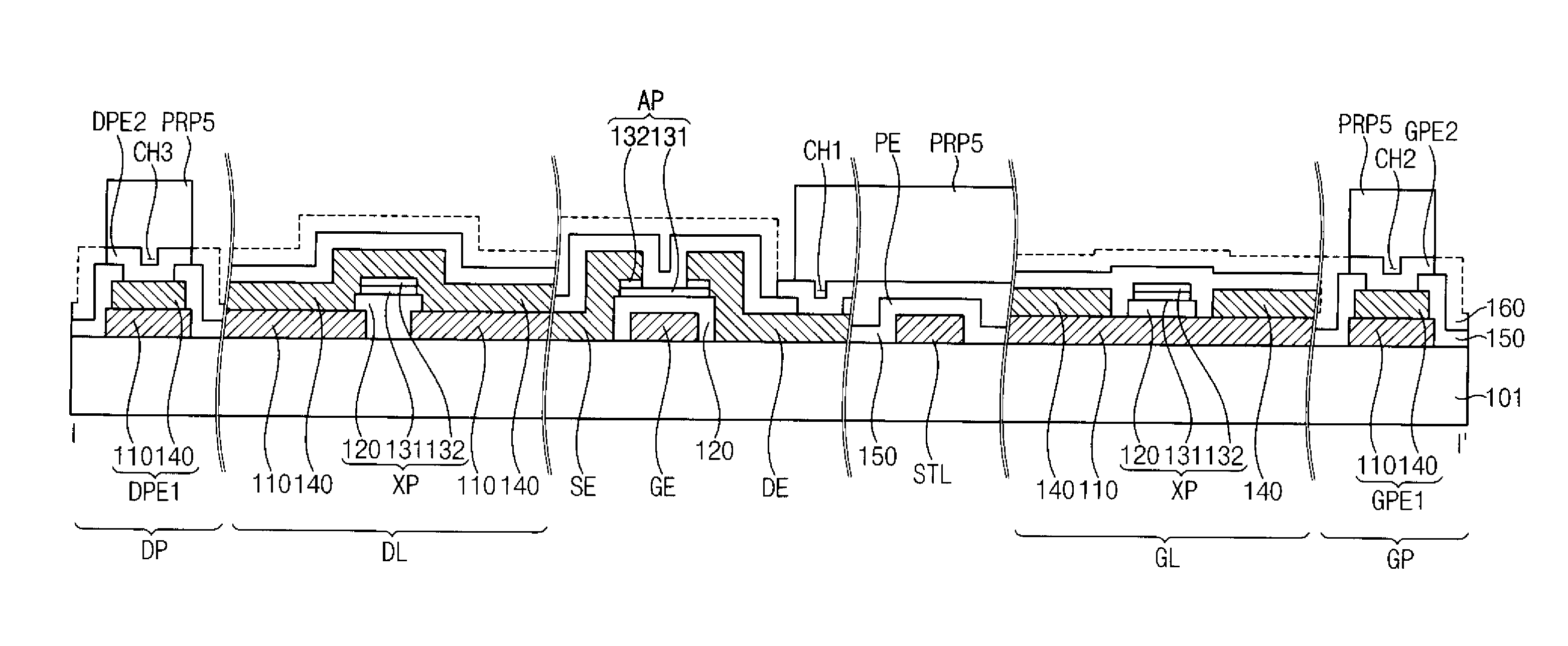

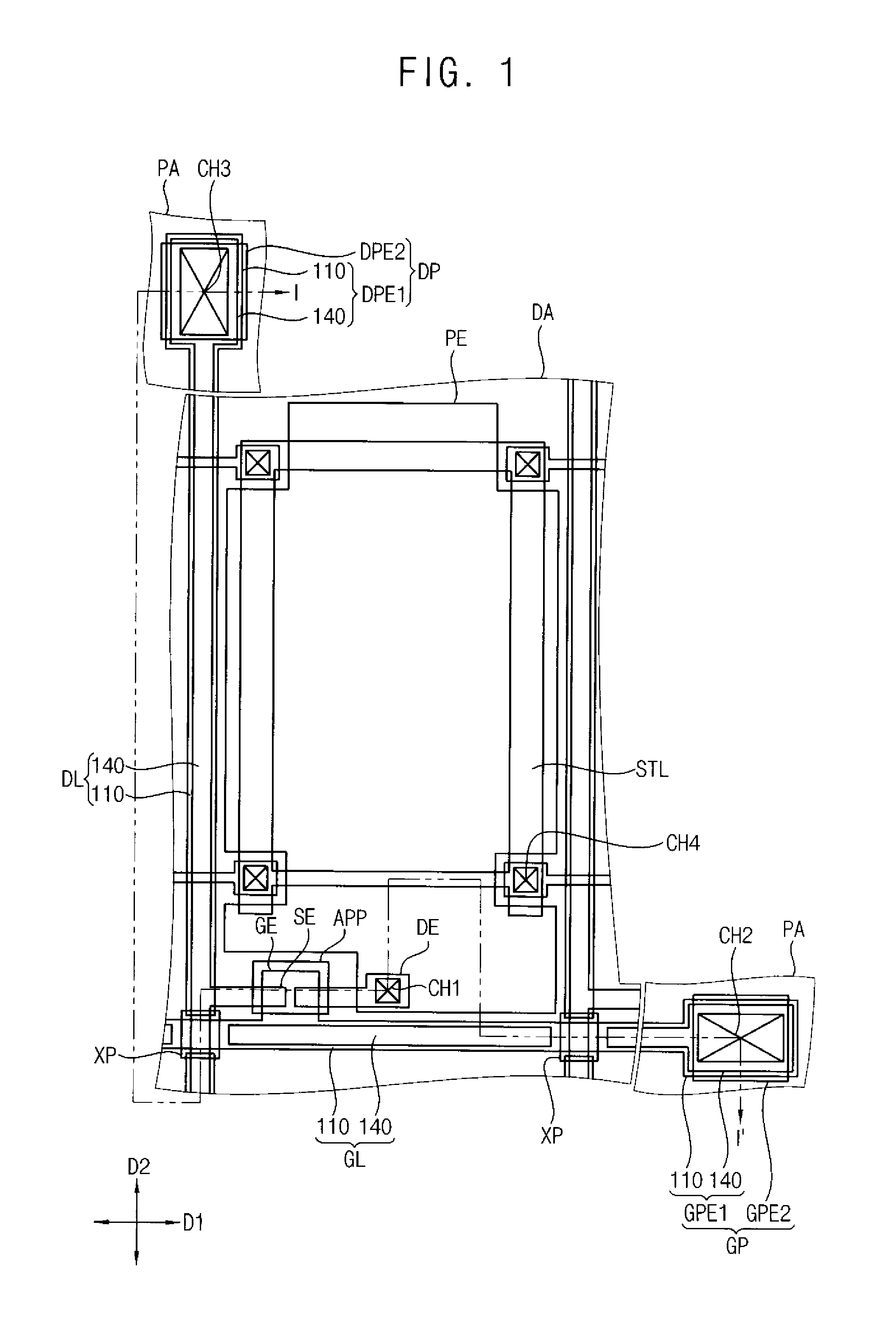

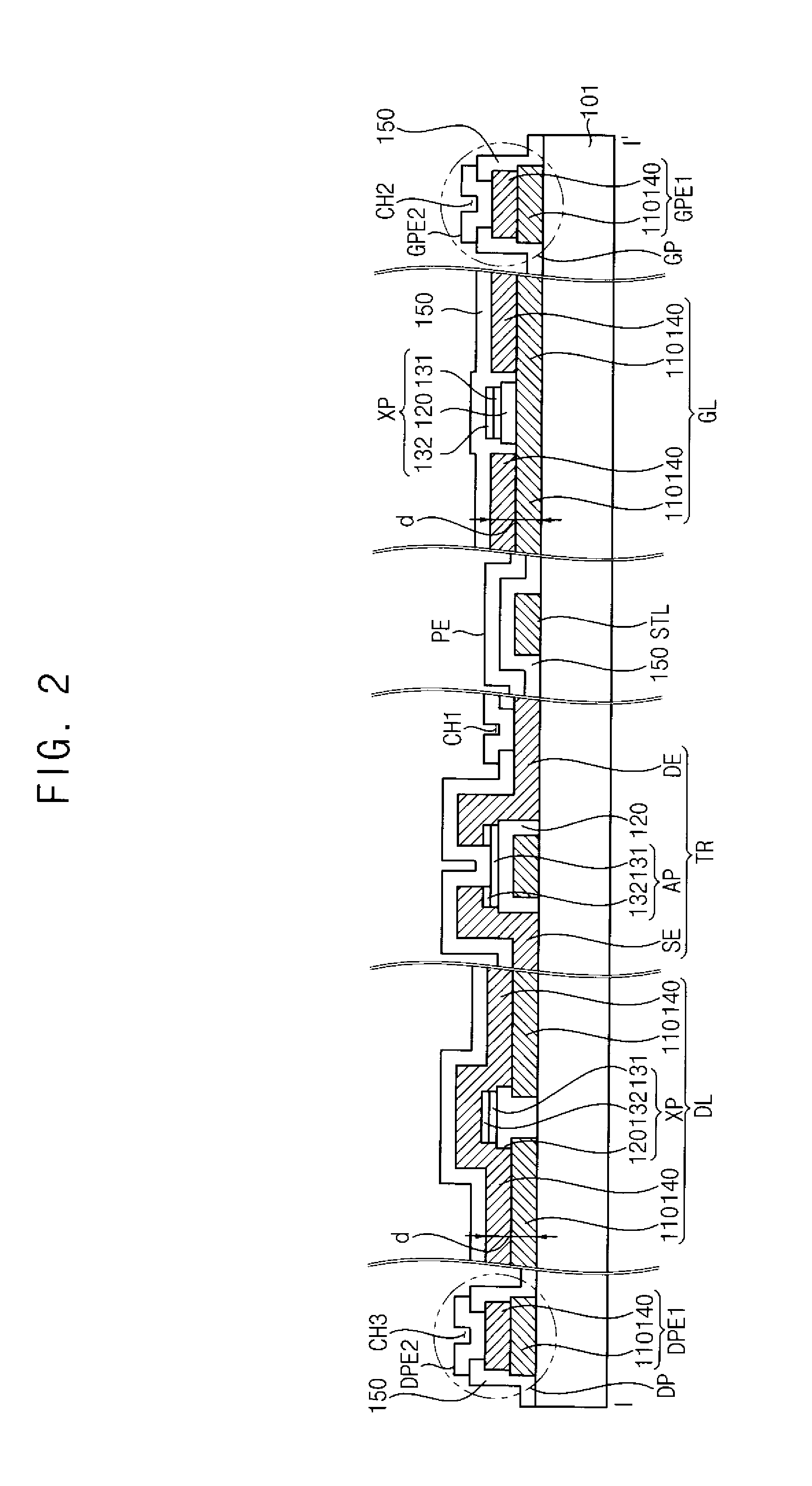

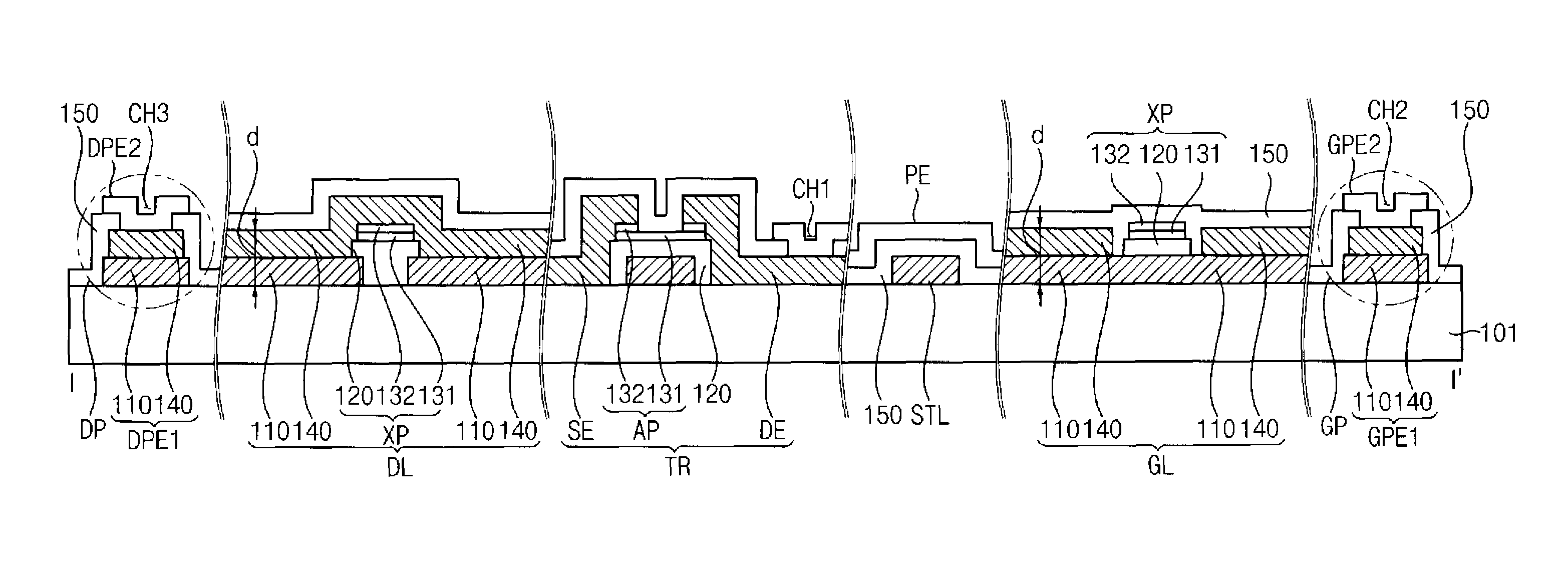

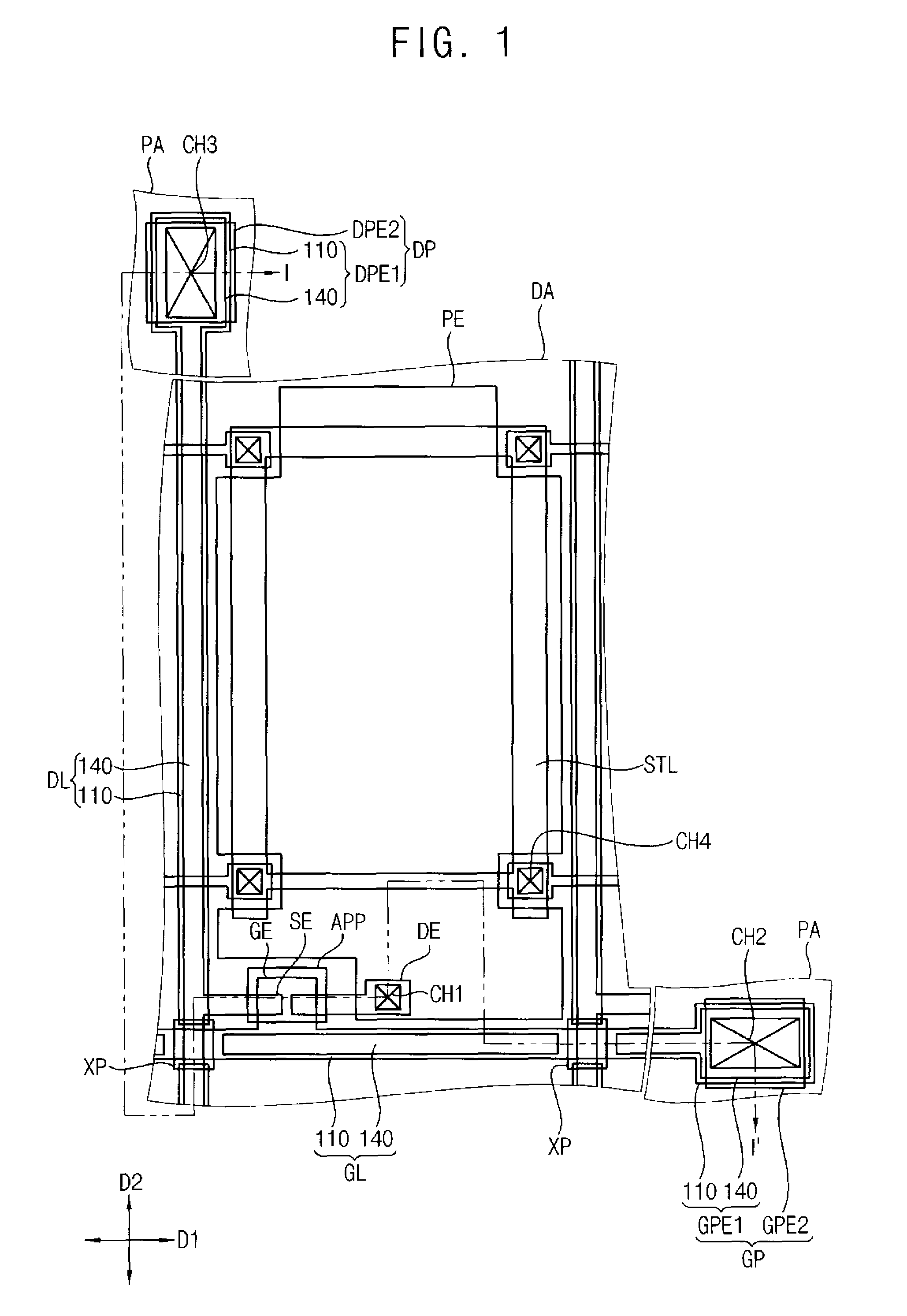

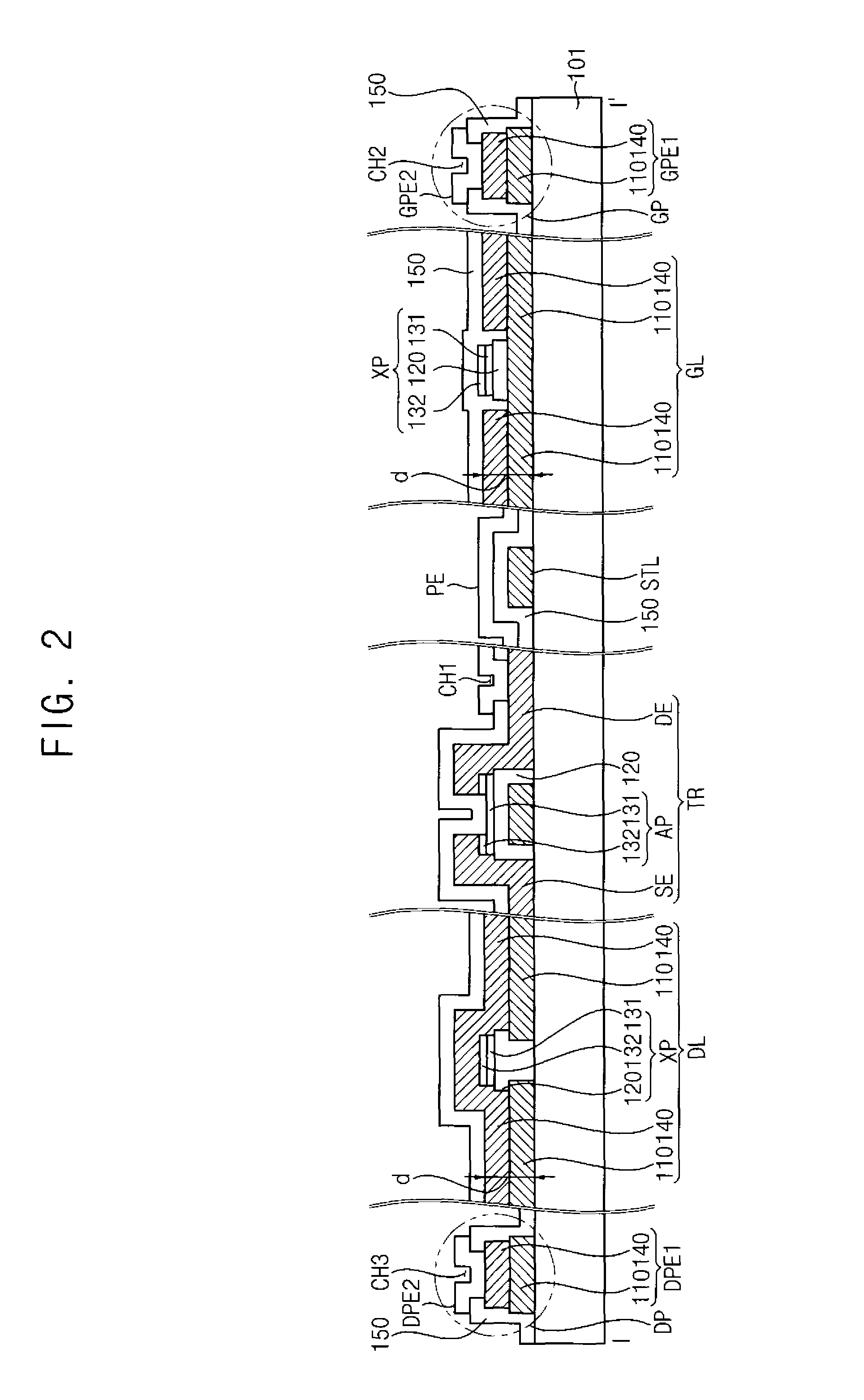

Display substrate and method of manufacturing the same

ActiveUS20130105826A1Reduce resistanceReduce processing stressSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMetal

A display substrate includes a base substrate, a switching element, a gate line, a data line and a pixel electrode. Each of the gate line and the data line includes a first metal layer, and a second metal layer directly on the first metal layer. The switching element is on the base substrate, and includes a control electrode and an input electrode or an output electrode. The control electrode includes the first metal layer and excludes the second metal layer, and extends from the gate line. The input electrode or the output electrode includes a second metal layer and excludes the first metal layer. The input electrode extends from the data line. The pixel electrode is electrically connected to the output electrode of the switching element through a first contact hole, and includes a transparent conductive layer.

Owner:SAMSUNG DISPLAY CO LTD

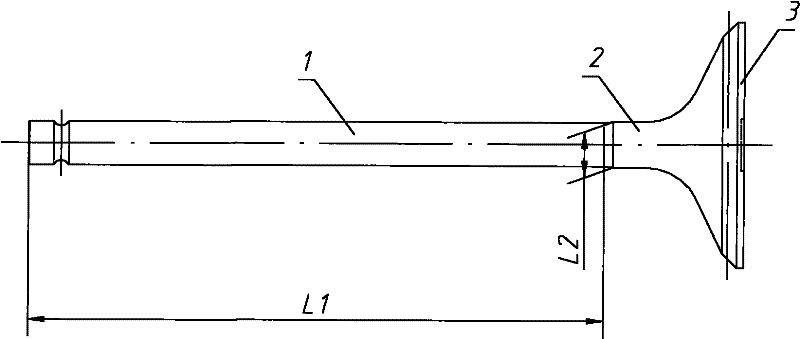

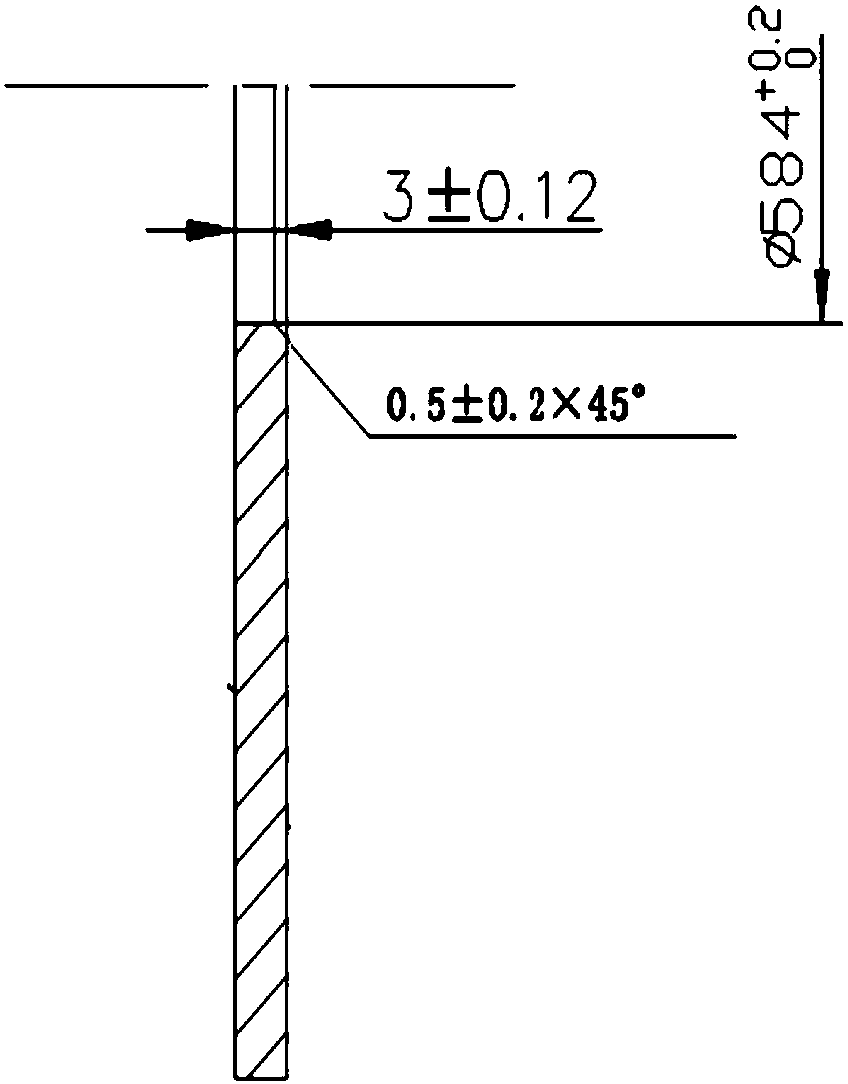

Gas inlet valve and gas outlet valve of engine and process for manufacturing same

InactiveCN101749066ASmall heat capacityReduce consumptionMachines/enginesLift valveExhaust valveInlet valve

Aiming at solving the problem of the failure of the product for the volume of the head part is too big, the weight is too heavy, the temperatures of the disk part and the second hot point are too high because the heat capacity is a little higher when an engine operates, the diameter of the second hot point is too small, the mechanical strength of the second hot point is poor, the heat transfer distance between the head part and the rod part is too far, the cooling of the second hot point is poor, the strength of the neck part is poor and the like existing in the present B series engine valve. The invention provides a gas inlet valve and a gas outlet valve of the engine and a process for manufacturing the same. The process has the advantages of improving the structure of the gas valve, optimizing the machine procedure, reducing the processing stress and improving the processing precision.

Owner:马勒三环气门驱动(湖北)有限公司

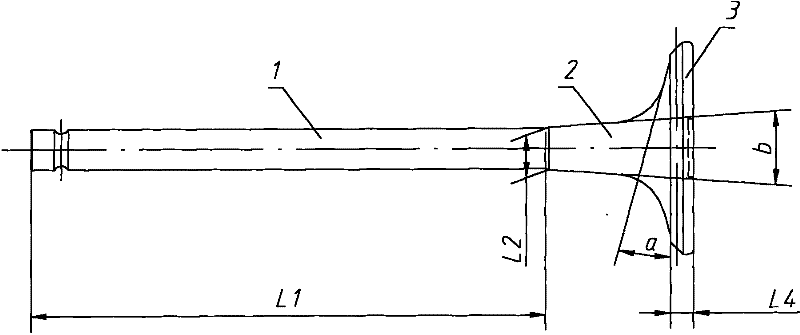

Machining and manufacturing method of 7055 aluminum alloy complex structure part

The invention discloses a machining and manufacturing method of a 7055 aluminum alloy complex structure part. By optimizing the structure of a rough machining part and optimizing subsequent heat treatment parameters, a stress concentration level is greatly reduced, so that deformation and cracking of the 7055 aluminum alloy part during quenching after rough machining can be effectively prevented;full process control is carried out on the heat treatment process and the machining process and parameters, the machining deformation of the complex part is effectively reduced, and the machining efficiency and the qualified rate of the part are improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

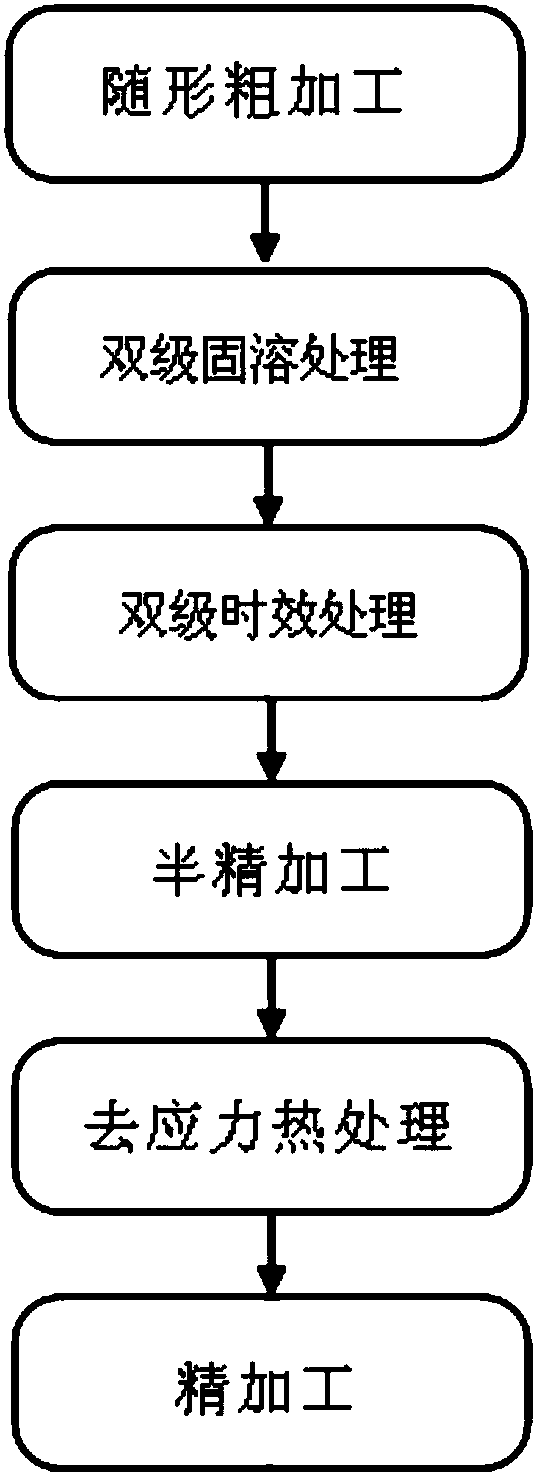

Bent pipe machining method and bent pipe

The invention provides a bent pipe machining method and a bent pipe, and belongs to the technical field of bent pipe machining. The method adopts an eccentric straight pipe and an induction heater. The method comprises the steps that S1, the eccentric straight pipe is mounted on a support table, a to-be-bent section is sleeved with an intermediate frequency induction heating ring, a first pipe section is movably mounted in a guiding assembly, the end of a second pipe section is clamped through a front chuck, and a rear pushing bent chuck clamps the end of the first pipe section and pushes thefirst pipe section to move in the direction of the to-be-bent section; and S2, intermediate frequency current is introduced into the intermediate frequency induction heating ring, the to-be-bent section is heated, when the temperature of the to-be-bent section is increased to a plastic state, the first pipe section is advanced through mechanical thrust, the to-be-bent section is bent, and the bentto-be-bent section is quickly cooled with a coolant. The bent pipe machining method adopts the eccentric straight pipe with the outer diameter being changed, the inner side thickening amount of the machined bent pipe is reduced, and the weight of a pipe system is reduced.

Owner:JIANGSU POWER EQUIP

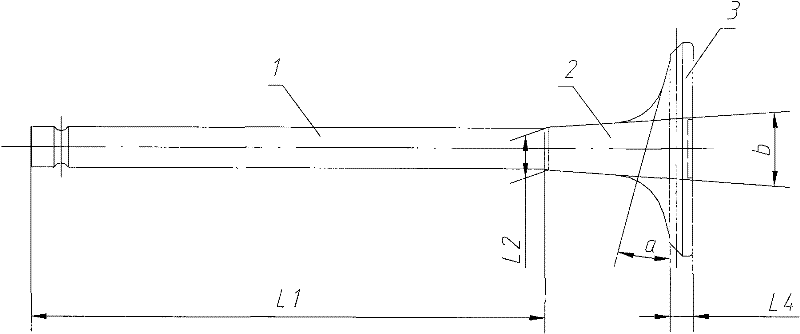

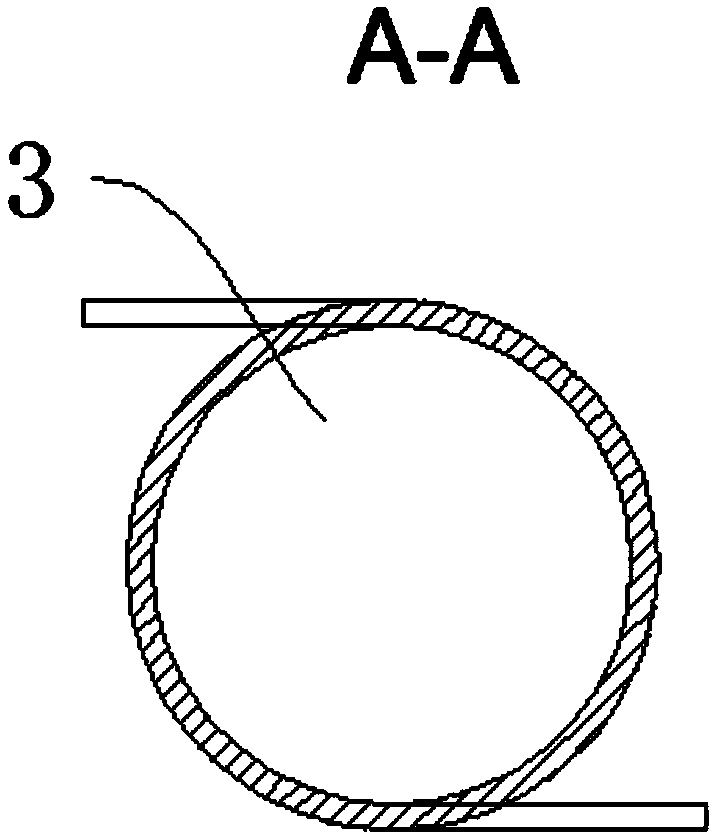

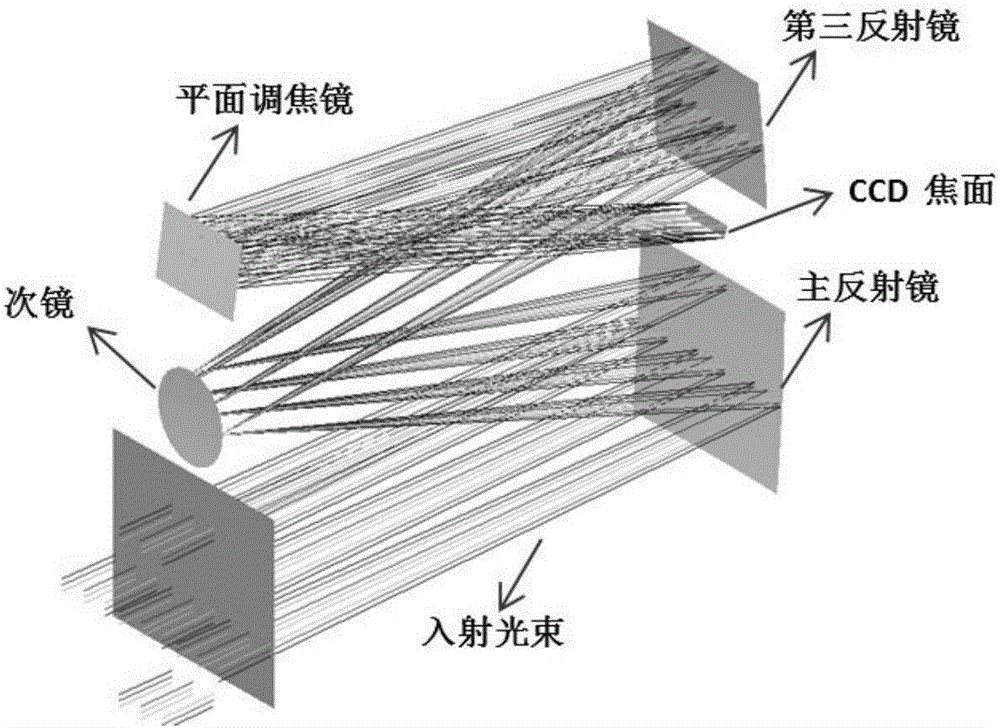

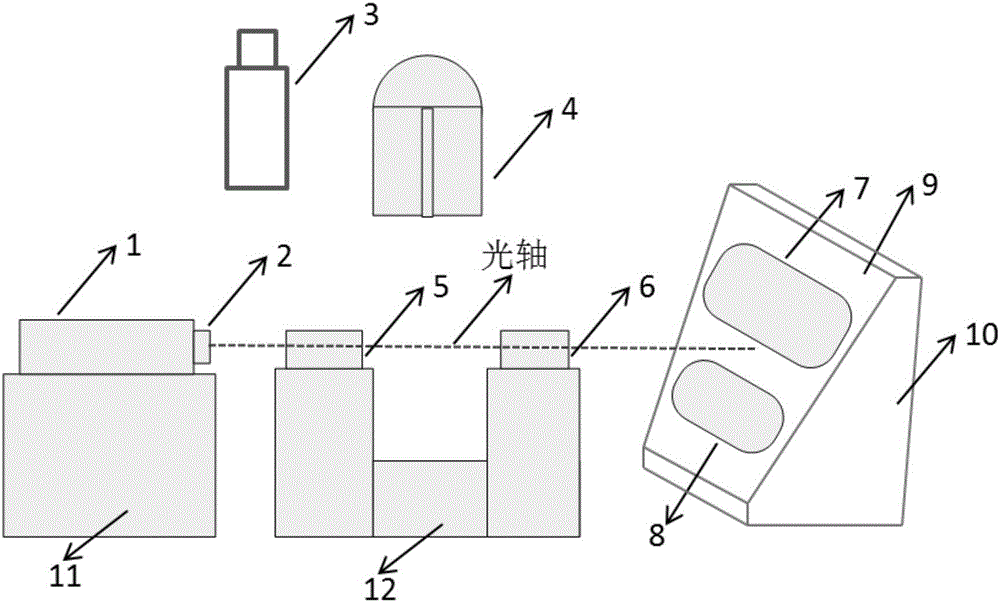

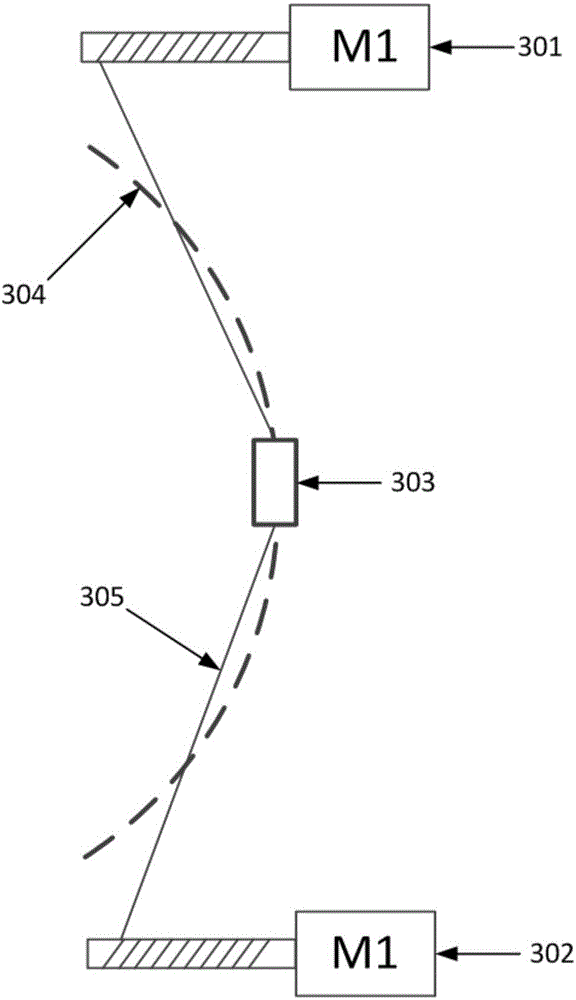

Common-reference detection and machining method of off-axis three-mirror aspheric optical system

InactiveCN106225712AShorten follow-up assembly timeHigh precisionUsing optical meansSimple lensIon beam

The invention discloses a common-reference detection and machining method of an off-axis three-mirror aspheric optical system. The method includes: firstly, machining of a main reflecting mirror and a third reflecting mirror are respectively performed until the RMS value of the full-aperture interference detection surface shape of each single reflecting mirror is greater than 1 / 10[Lambda], wherein Lambda refers to the laser interferometer operating wavelength; secondly, according to design parameters, an integrated backboard used for fixing the main reflecting mirror and the third reflecting mirror is designed and machined; thirdly, the main reflecting mirror and the third reflecting mirror are fixedly arranged on the integrated backboard, common-reference detection of the main reflecting mirror and the third reflecting mirror is performed, and the surface shapes of the main reflecting mirror and the third reflecting mirror are respectively obtained; fourthly, based on the surface shapes of the main reflecting mirror and the third reflecting mirror, which are obtained by common-reference detection, ion beam machining of the main reflecting mirror and the third reflecting mirror fixed on the integrated backboard is performed according to the design requirement; and fifthly, common-reference detection of the main reflecting mirror and the third reflecting mirror after ion beam machining is performed until the design requirement is satisfied. According to the method, the complicated assembling and adjusting processes of the off-axis three-mirror aspheric optical system can be avoided.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

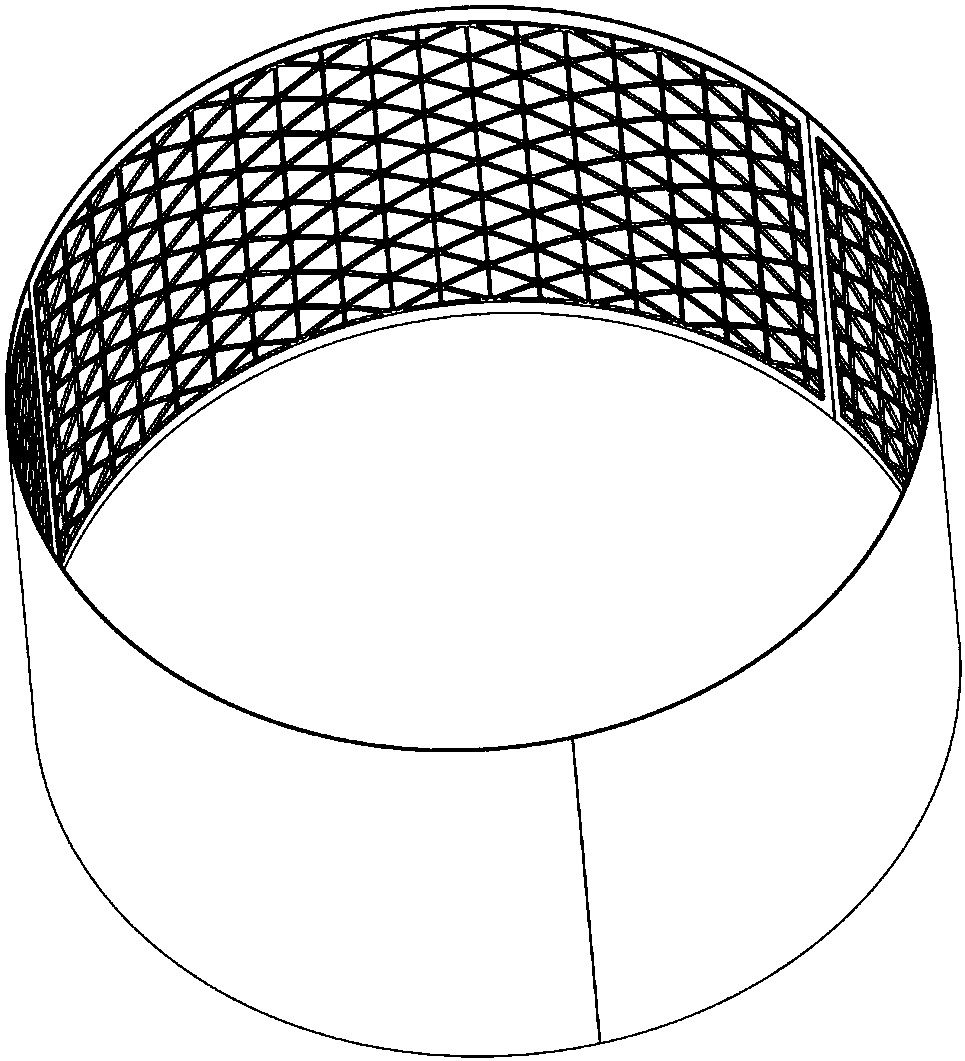

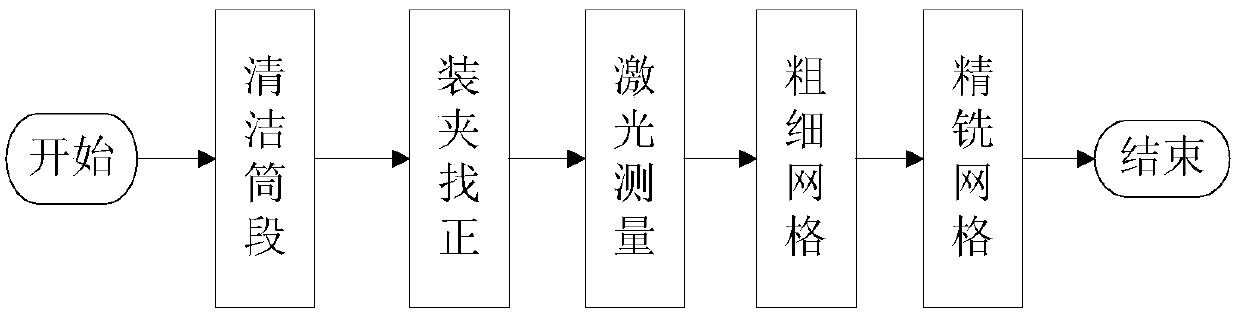

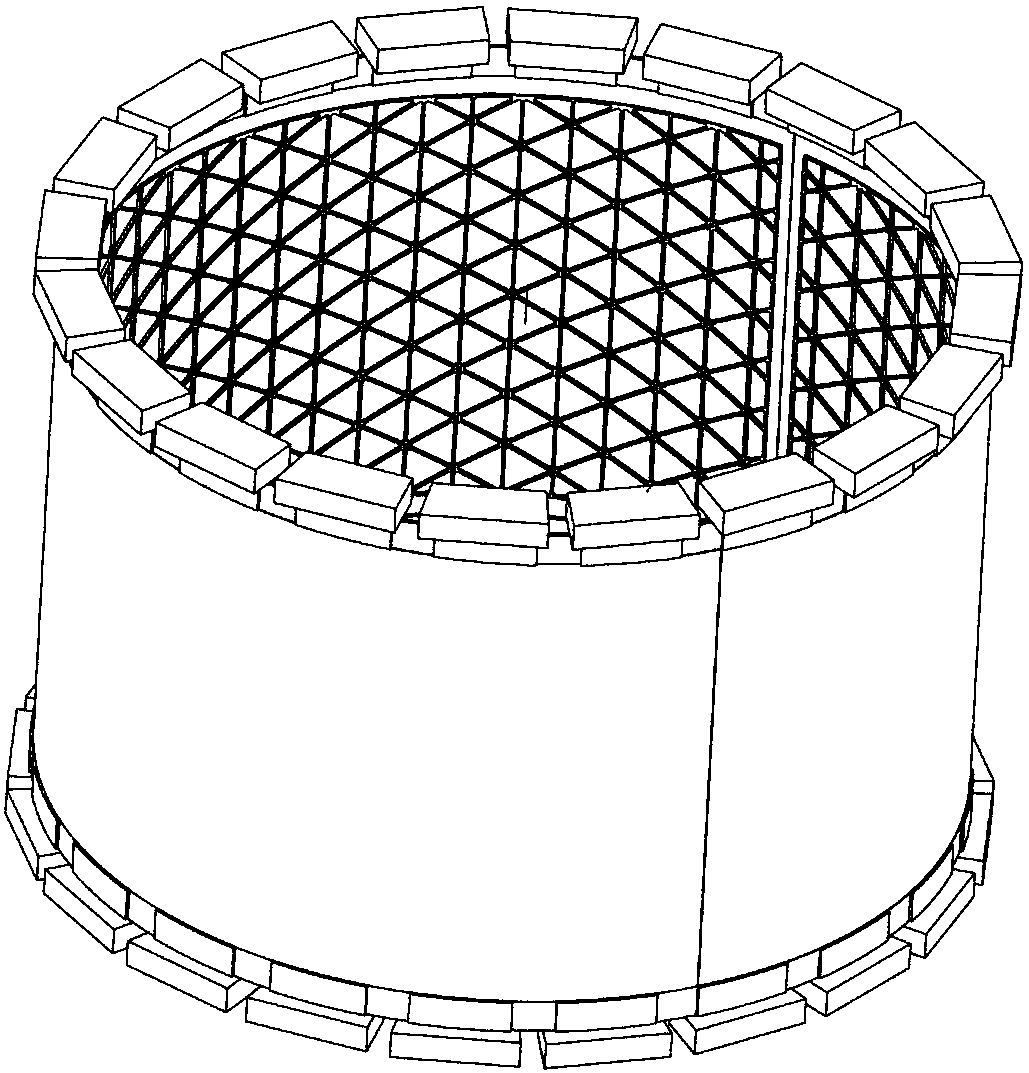

Low-deformation machining method of large aluminum alloy thin-wall mesh barrel section

ActiveCN107617771AReduce distortionImprove product qualityMilling equipment detailsMachining deformationMachining process

The invention belongs to the machine manufacturing and machining technology, and particularly discloses a low-deformation machining method of a large aluminum alloy thin-wall mesh barrel section. Themethod comprises the steps of barrel section cleaning, clamping alignment, deformation laser measurement, rough-milling mesh sinking and finish-milling mesh sinking. The low-deformation machining method of the large aluminum alloy thin-wall mesh barrel section is achieved, deformation in the machining process is reduced, and the product quality is improved. A machining path of achieving machiningfrom the middle of the barrel section to the upper end and the lower end is adopted, on one hand, part machining stress can be reduced, on the other hand, part internal stress can be redistributed more averagely, and machining deformation can be effectively reduced. Compensation methods are adopted for achieving precise machining of the large aluminum alloy thin-wall mesh barrel section, part theoretical appearance deviation is eliminated through the laser compensation method, and part mesh thickness precise machining is achieved through the ultrasonic thickness compensation method.

Owner:CAPITAL AEROSPACE MACHINERY +1

High temperature heat-collecting pipe hard glass and Kovar alloy sealing method

An objective of the invention is to provide a sealing method which has high reliability and practicability and is used between the high-temperature thermal-collecting tube hard glass and the metal. The method adopts one or more than one transition glass joint to do transition sealing, the expansion factor of the hard glass, transition glass joint and the kovar which are sealed in sequence gradually increases, the difference value of the expansion factor of the adjacent two sealing pieces is (6- 11)* <-7> / DEG C; when the adjacent two sealing pieces are sealed the heating temperature of the sealing area is 500-1500 DEG C, and the temperature is kept for 5-30min; from the hard glass to the kovar the heating temperature of each sealing area is 50-300 DEG C; and the hard glass, transition glass joint and the kovar which are executed with sealing are done with stress-relieving annealing.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP

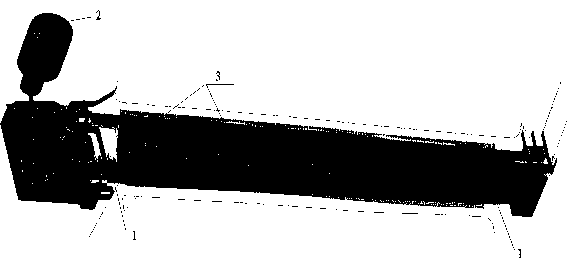

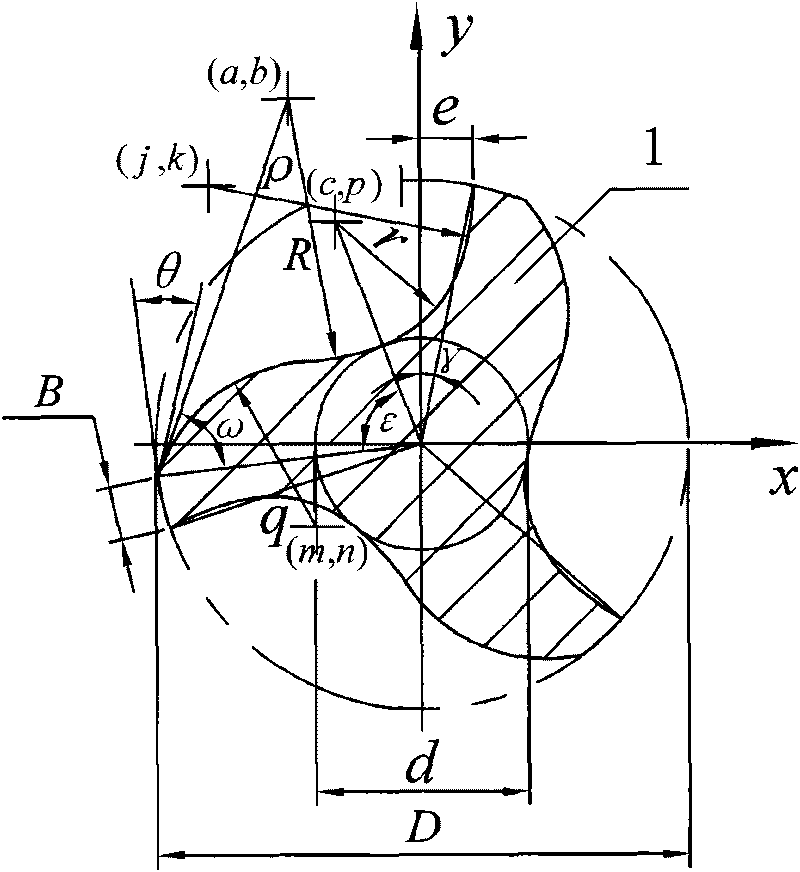

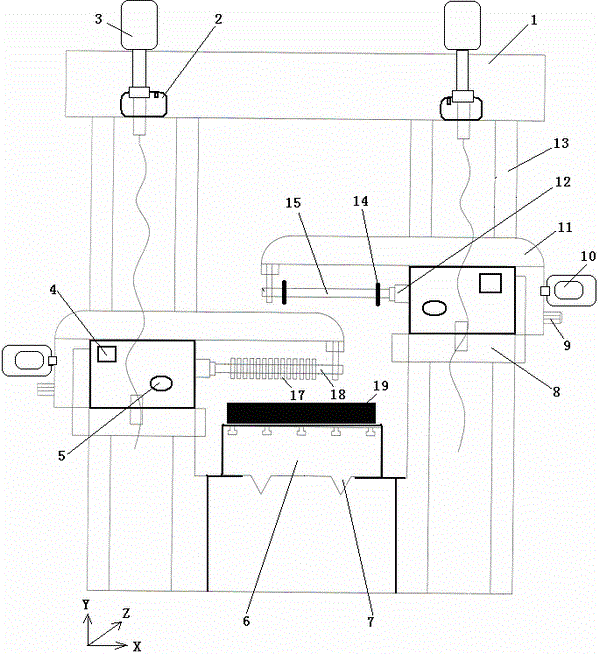

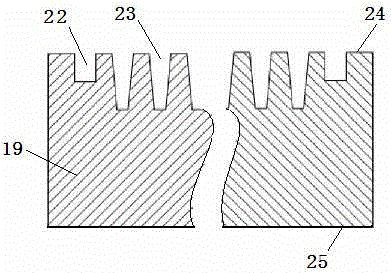

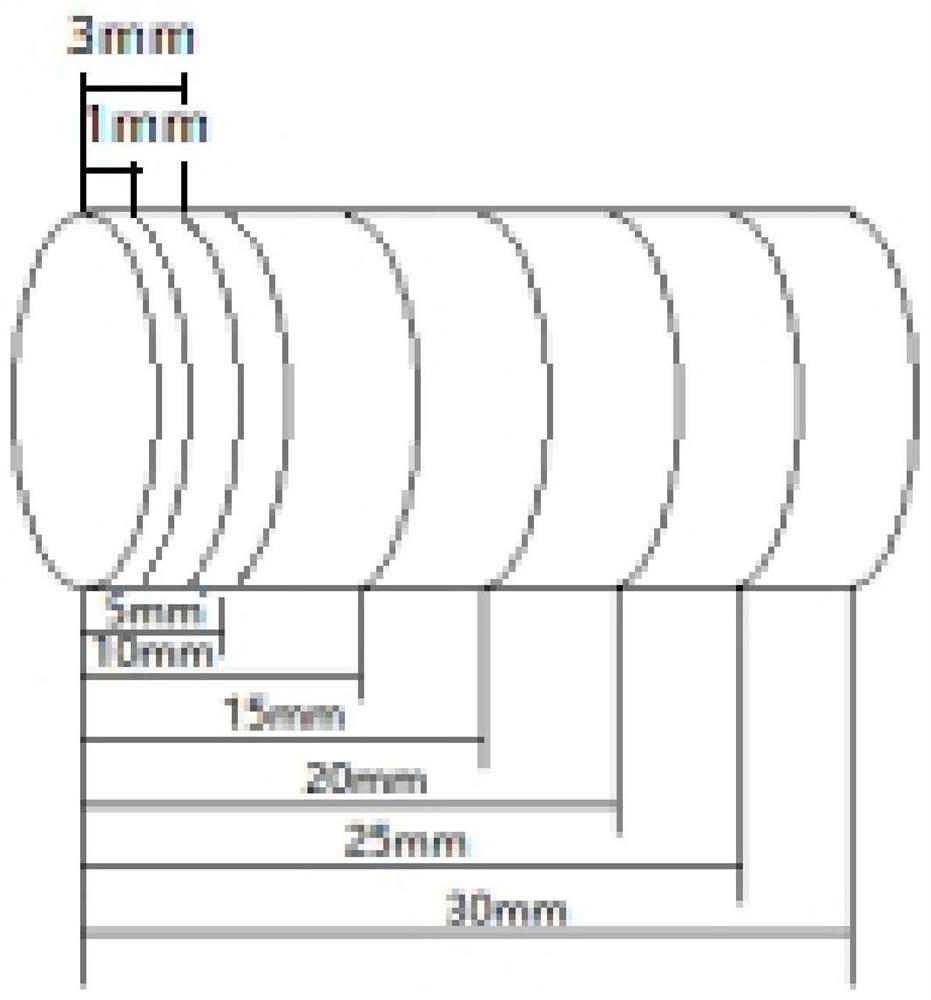

Double-cutter-shaft machine tool for graphite slotting and machining technology of machine tool

ActiveCN105291279ATo overcome the disadvantage of not being able to open multiple parallel grooves on the surface of brittle materials such as graphiteHigh shape accuracyStone-like material working toolsCantilevered beamElectric machinery

The invention discloses a double-cutter-shaft machine tool for graphite slotting. The machine tool is provided with a motor A, a horizontal guide rail and a working platform. Two motors B, a horizontally-arranged cross beam, two stand columns, two cutter shaft assemblies and a stand column lubricating system are included; the two motors B are arranged above the cross beam, motors B penetrate the cross beam to be connected, and each motor B can drive one cutter shaft assembly to vertically move on one stand column in the Z-axis direction; and each cutter shaft assembly comprises a cantilever beam, a cutter shaft, a cutter shaft bearing seat, a bracket and a motor C. During machining, one motor B drives one cutter shaft assembly to achieve slotting of a first set of grooves, and the other motor B drives the other cutter shaft assembly to achieve slotting of a second set of grooves. The production efficiency of forming of a plurality of parallel grooves in graphite is high, the shape and size precision of the grooves is high, and the automation control degree is high.

Owner:南通国阳新材料有限公司 +1

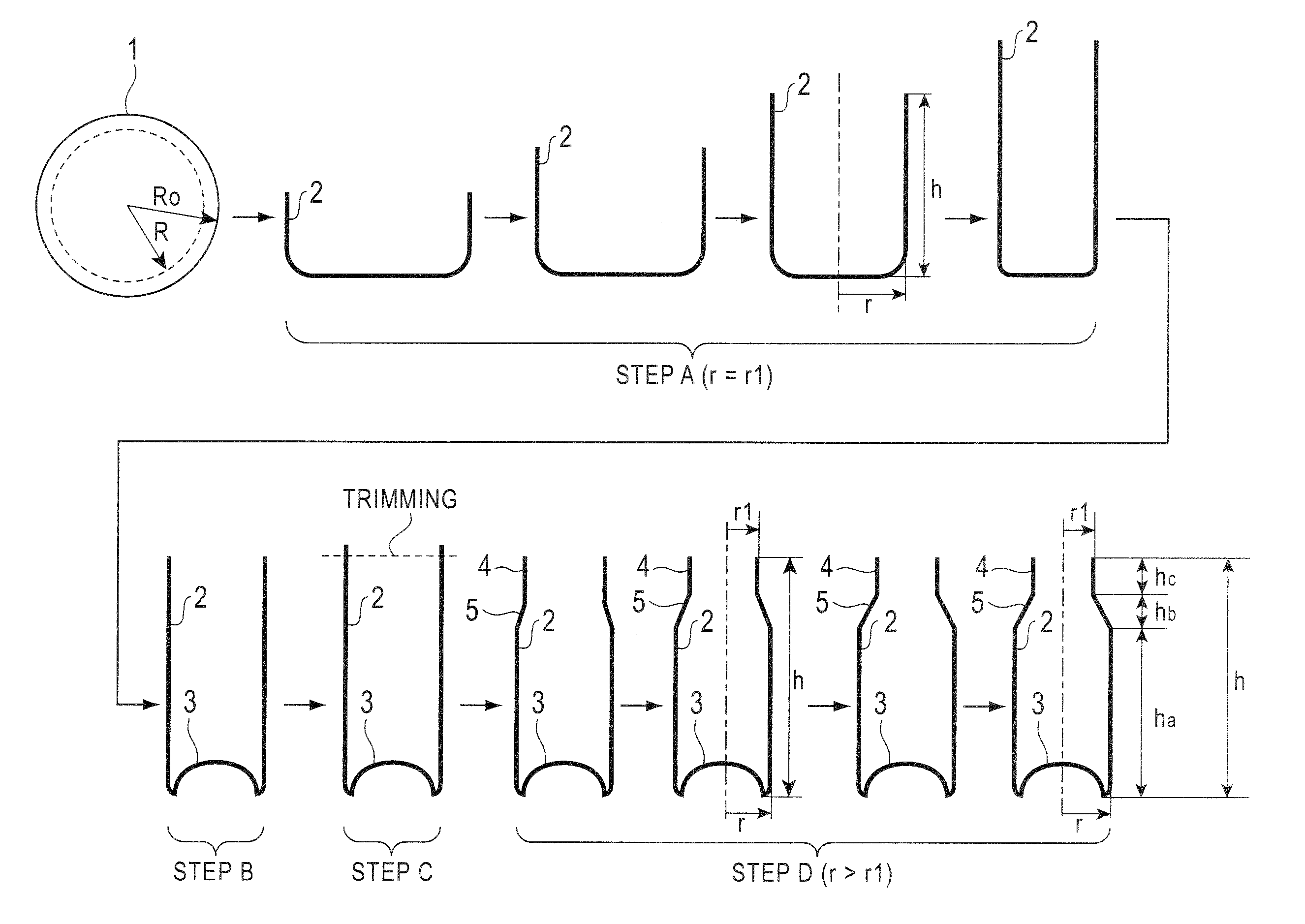

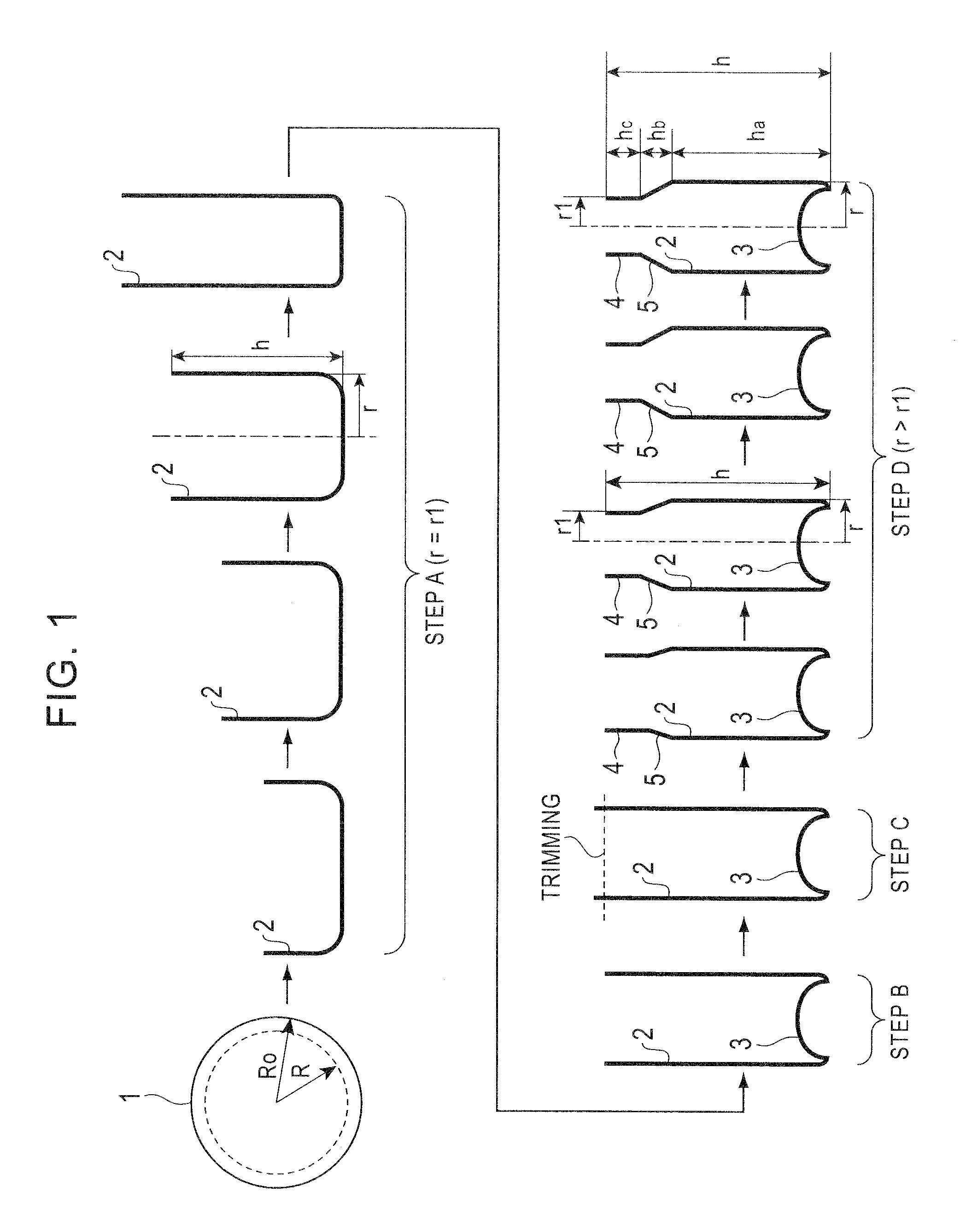

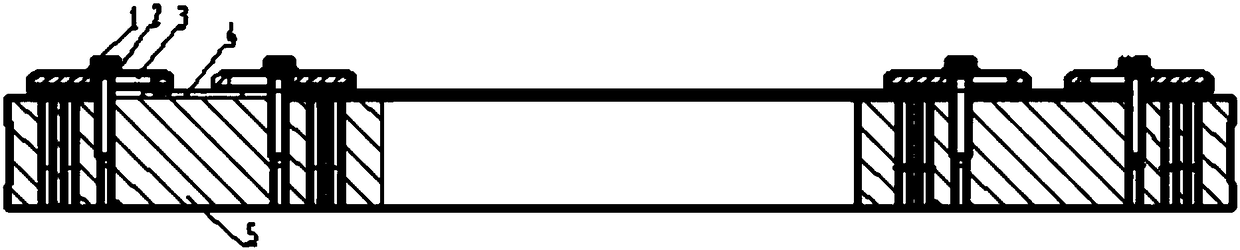

Laminate steel sheet for two-piece can, method for production of two-piece can, and two-piece laminate can

InactiveUS20100000632A1Reduce surface frictionReduce processing stressSynthetic resin layered productsCans/barrels/drumsSheet steelSurface roughness

A laminated steel sheet for a two-piece can body with a high strain level satisfying the following formulae, the polyester resin layer composing the laminated steel sheet having a center line surface roughness (Ra) of 0.2 μm to 1.8 μm:r1≦r, 0.1≦r1 / R≦0.25, and 1.5≦h / (R−r)≦4wherein h is the height of the two-piece can body, r is the maximum radius, r1 is the minimum radius, and R is the radius of the circular laminated steel sheet before forming having the same weight as the can body.

Owner:JFE STEEL CORP

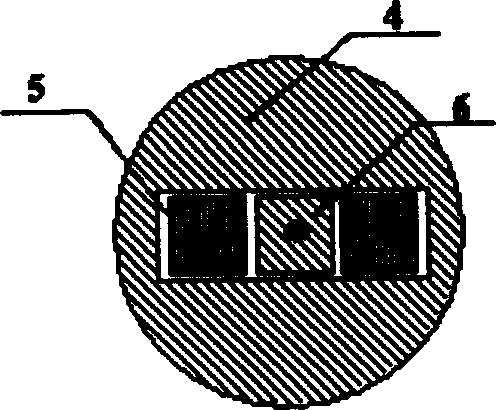

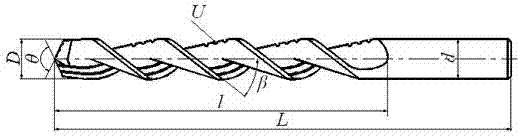

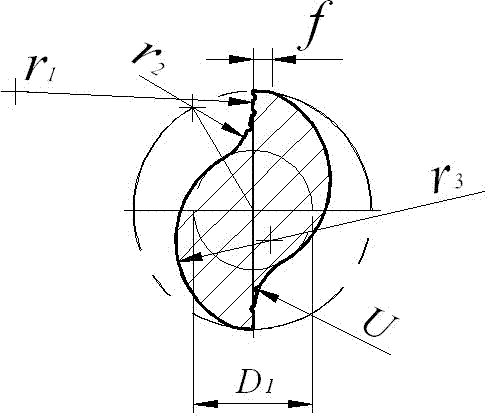

Self-lubricating twist drill and machining method thereof

InactiveCN102922010ABig spaceHigh strengthMilling equipment detailsTwist drillsEngineeringMachining process

The invention relates to a self-lubricating twist drill and a machining method of the self-lubricating twist drill. The invention provides the twist drill with a lubricating groove, which has the advantages of high strength, large scrap containing space, primary machining formation of the groove and a back, and capability of being designed according to different machining materials. Particularly, in a deep hole machining process, self-lubricating cutting is carried out without the cooling and lubricating effect of cutting liquid, so that the cutting friction is reduced and the effective scrap removing and scrap cutting are carried out. The technical scheme is as follows: an axial section of the self-lubricating twist drill is formed by a cutting circular arc, a scrap coiling circular arc and a tooth back circular arc; the structural size comprises an outer diameter D, a drilling core diameter D1, a blade belt f, a cutting circular arc r1, the scrap coiling circular arc r2, the tooth back circular arc r3, and the lubricating groove U on the cutting circular arc r1; the cutting circular arc r1 is smoothly tangent with the scrap coiling circular arc r2; the scrap coiling circular arc r2 is smoothly tangent with the tooth back circular arc r3; the scrap coiling circular arc r2 and the tooth back circular arc r3 are tangent with the drilling core diameter D1; and the cutting circular arc is provided with no less than one lubricating groove.

Owner:XIAN TECHNOLOGICAL UNIV

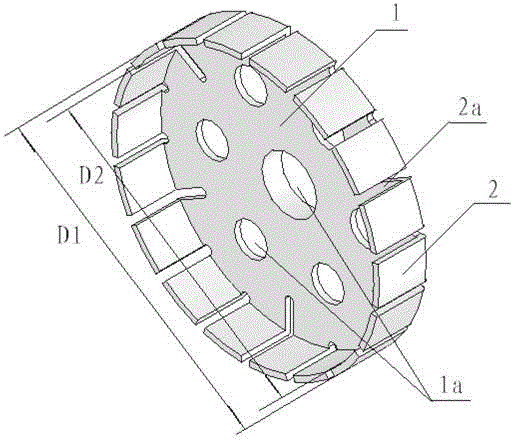

Processing method of magnetic powder clutch cup-shaped rotor

The invention belongs to a processing technology of magnetic powder clutch cup-shaped rotors and relates to an improved processing method of a magnetic powder clutch cup-shaped rotor. The processing steps include the following steps of rough processing, hydrogen annealing, inner hole grinding, outer circle grinding, chemical nickel plating, hydrogen high temperature annealing and low and high temperature aging treatment. By means of the new processing method of the magnetic powder clutch cup-shaped rotor, processing stress is reduced, the magnetic conductivity of the magnetic powder clutch cup-shaped rotor is improved and stabilized, and adhesion of a work surface of the magnetic powder clutch cup-shaped rotor and magnetic powders is improved.

Owner:LANZHOU FLIGHT CONTROL

Gear machining and heat treatment process

InactiveCN105714040AAdd depthImprove heating uniformitySolid state diffusion coatingMetal working apparatusGear grindingProduct inspection

The present invention discloses a gear machining and heat treatment process, and the gear machining process successively comprises forging, normalizing, quenching and tempering, vertical machining, gear shaping, annealing, vertical machining, gear shaping, vertical milling, stabilizing aging, gear grinding, nitriding and finished product inspection, wherein the step of normalizing is normalizing at (880 + / -10) DEG C for (3-4) h, and then cooling in air; the step of quenching and tempering is quenching and tempering at (850 + / -10) DEG C for (3-4) h, quenching with water, and cooling with oil; the step of the annealing is annealing at (530 + / -10) DEG C for (3-4) h, cooling in a furnace in the heating and cooling rate of less than or equal to 50 DEG C / h; the step of stabilizing aging is stabilizing aging at (510 + / -10) DEG C for (3-4) h, and cooling in the furnace in the heating and cooling rate of less than or equal to 2 5 DEG C / h; and the step of nitriding is nitriding at (510 + / -10) DEG C for (10-12) h, and cooling in the furnace in the heating and cooling rate of less than or equal to 2 5 DEG C / h. The gear machining and heat treatment process is more reasonable, and can reduce distortion after nitriding to improve the overall performance of a gear.

Owner:CHONGQING YUANHUANG MACHINERY MFG CO LTD

Display substrate and method of manufacturing the same

ActiveUS9025118B2Thick metal wiringReduce resistanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMetal

A display substrate includes a base substrate, a switching element, a gate line, a data line and a pixel electrode. Each of the gate line and the data line includes a first metal layer, and a second metal layer directly on the first metal layer. The switching element is on the base substrate, and includes a control electrode and an input electrode or an output electrode. The control electrode includes the first metal layer and excludes the second metal layer, and extends from the gate line. The input electrode or the output electrode includes a second metal layer and excludes the first metal layer. The input electrode extends from the data line. The pixel electrode is electrically connected to the output electrode of the switching element through a first contact hole, and includes a transparent conductive layer.

Owner:SAMSUNG DISPLAY CO LTD

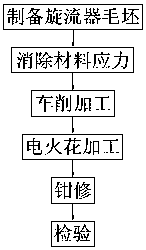

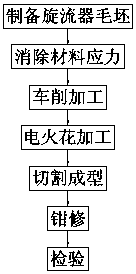

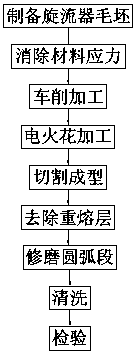

Technical method for manufacturing aero-engine cyclone through special processing technology

The invention relates to the field of aero-engines and gas turbines, and particularly relates to a technical method for manufacturing an aero-engine cyclone through a special processing technology. The method comprises the step of manufacturing a cyclone blank, wherein the cyclone bank is manufactured through a cylindrical forging piece. The method further comprises the step of manufacturing semi-finished cyclone and the step of finishing through pincers; the step of manufacturing the semi-finished cyclone is that the cyclone blank is sequentially subjected to turning processing and electric spark processing to obtain the semi-finished cyclone; the step of finishing through the pincers is that the semi-finished cyclone is finished based on the requirement on a finished cyclone so as to obtain the finished cyclone. According to the method, the forging piece is outstanding in mechanical property, and two processing modes are provided, so that the manufactured cyclone product is high in strength and toughness; the yield is increased; and the processing cost and the processing period are reduced; the manufactured cyclone product can stably run for a long time in an aero-engine combustion chamber; and the service life of the aero-engine combustion chamber cannot be influenced by the quality of the cyclone.

Owner:广汉天空动力机械有限责任公司

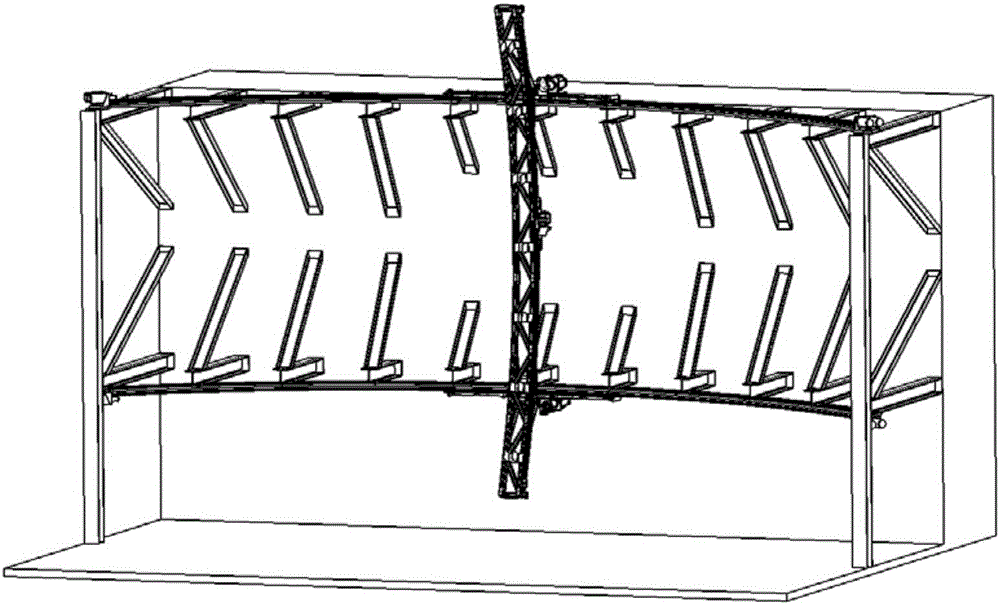

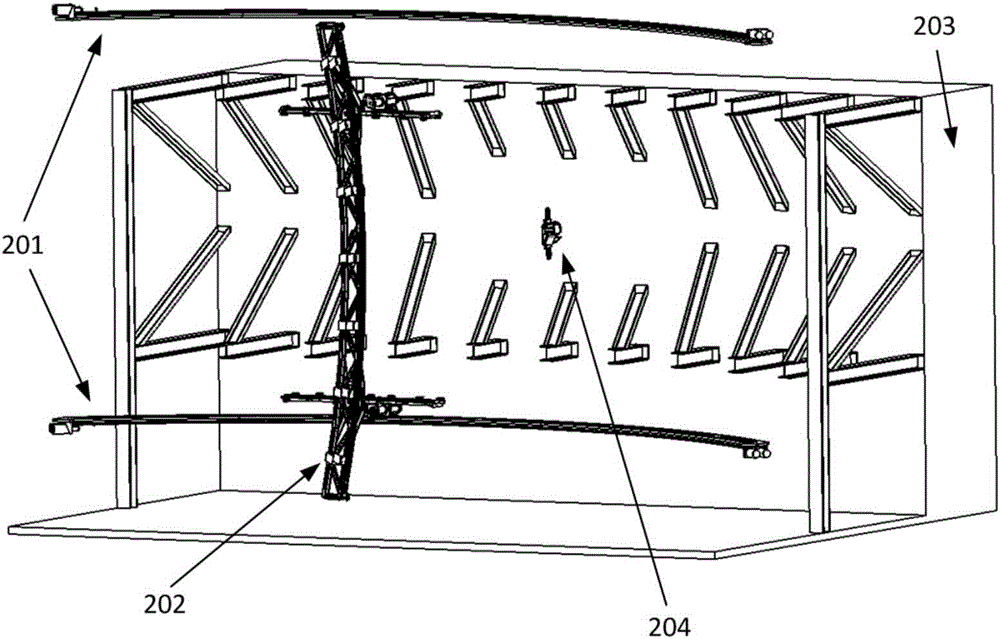

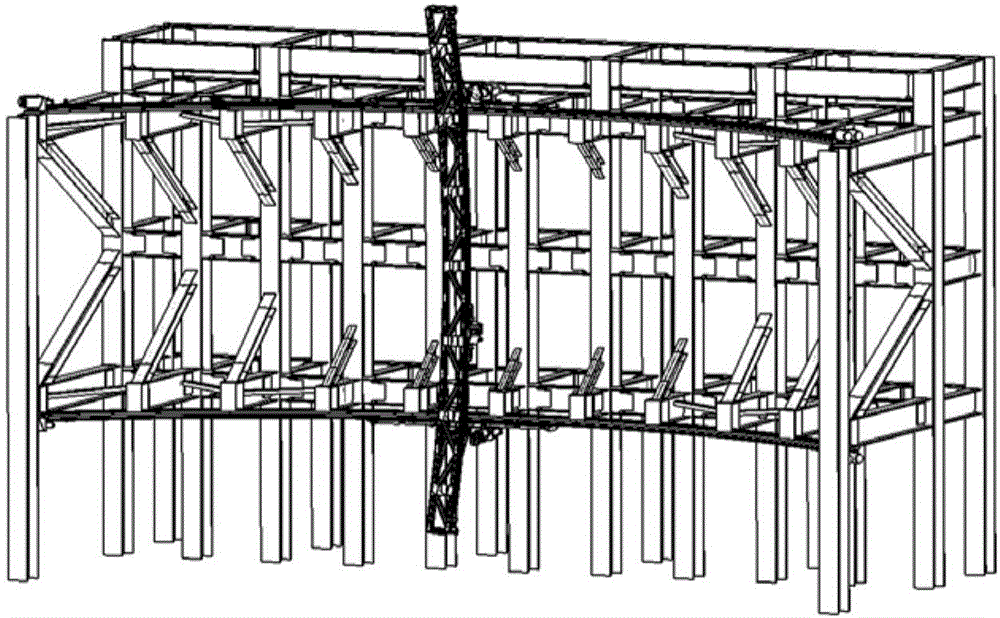

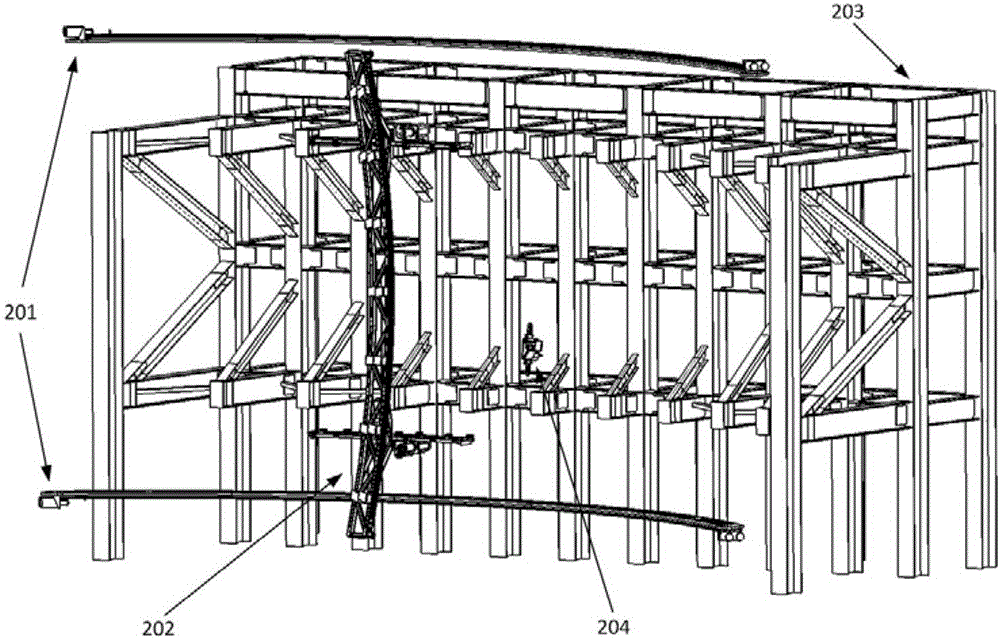

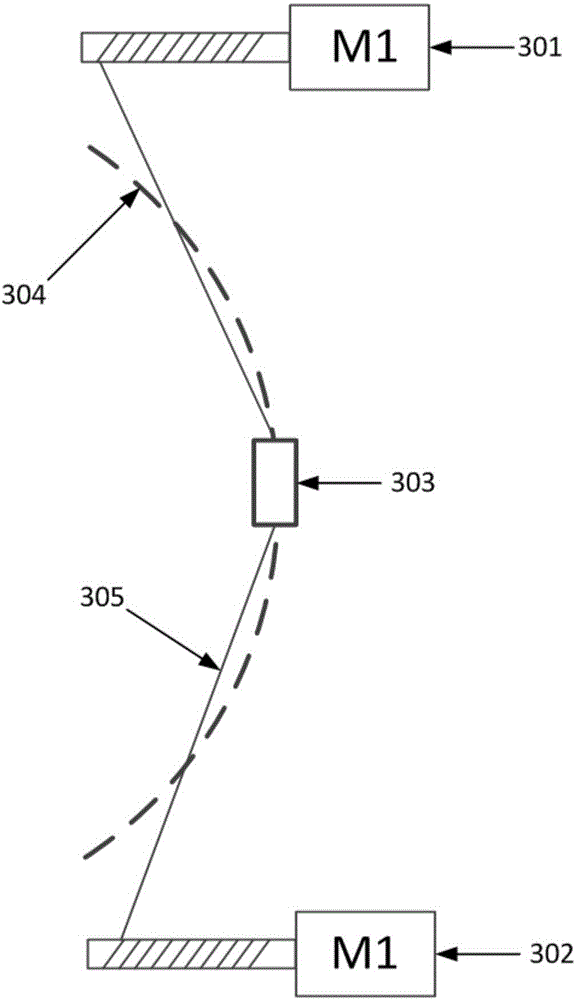

Remote target motion simulator

ActiveCN106288957AHigh precisionHigh accelerationWave based measurement systemsDirection controllersReinforced concreteEngineering

The invention provides a remote target motion simulator. The remote target motion simulator comprises a longitudinal component, wherein the longitudinal component comprises a longitudinal circular arc-shaped guide rail and at least one driving motor which is used for driving sliding blocks with target sources to perform longitudinal circular arc motion along the longitudinal circular arc-shaped guide rail, and a plurality of transverse components, wherein each of the transverse components comprises a transverse circular arc-shaped guide rail and a linear motor drive system which is used for driving the longitudinal component to perform transverse circular arc motion along the transverse circular arc-shaped guide rail. The remote target motion simulator further comprises a supporting component comprising a wall body made of reinforced concrete and cantilevers fixed to the wall body and used for supporting the transverse components.

Owner:BEIHANG UNIV

A process method for lathe processing of large-diameter, precision and complex-shaped thin-section parts

ActiveCN105397108BSolve the out-of-tolerance problemSolve technical problems that cannot be groundPositioning apparatusTurning machinesEngineeringMachining process

The invention discloses a method for turning a large-diameter precision complex molded surface thin sheet part and belongs to the technical field of machining. The method comprises the following steps that (1), it is ensured that the part leakage length is greater than or equal to a half of the width of the whole part, and the molded surface of the outer side of the first surface of the part is turned, namely a half of the molded surface of the outer side of the first surface of the part; (2), the molded surface of the inner side of the first surface of the part is turned, and smooth adaptation connection between a connection knife and the molded surface is noticed; (3), the molded surface of the outer side of the second surface of the part is turned, namely one third of the molded surface of the outer side of the first face of the part; (4), turning of part of the molded surface of the middle of the second surface of the part is finished under the state that the inner side and the outer side are compressed at the same time; and (5), machining of the molded surface of the left of the second surface is finished, smooth adaptation connection between the connection knife and the molded surface is noticed, and the whole machining process is finished. The technical bottleneck of turning of thin-walled sealed washers of high-precision, novel-structure and precision complex molded surfaces is effectively solved, and the far-reaching significance is achieved for improvement of the manufacturing technical level of a new generation of engines.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

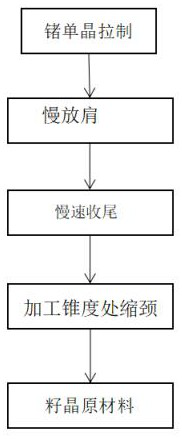

Manufacturing and processing method for improving seed crystal defects of germanium single crystal

PendingCN113957520AImprove resistivity uniformityReduce dislocation densityPolycrystalline material growthBy pulling from meltPhysical chemistrySeed crystal

The invention discloses a manufacturing and processing method for improving seed crystal defects of a germanium single crystal, and belongs to the field of crystal processing. The manufacturing and processing method for improving the seed crystal defects of the germanium single crystal comprises the following steps: step 1, drawing a single crystal with a proper size according to the size of a seed crystal chuck and the required size; step 2, necking a section at a taper part needing to be processed in the later period through more detailed manual control; and step 3, adopting slow shouldering, wherein the shouldering speed ranges from 10 mm / h to 15 mm / h, and the shouldering angle is larger than 45 degrees. The resistivity uniformity of the germanium seed crystal is greatly improved, the dislocation density and internal defects of the seed crystal are reduced, and a high-quality seed crystal raw material grows.

Owner:云南驰宏国际锗业有限公司

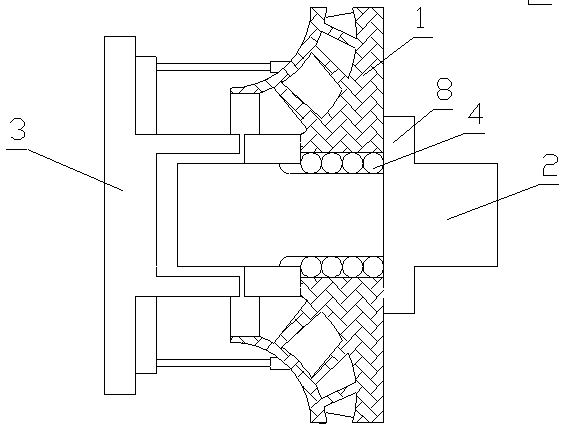

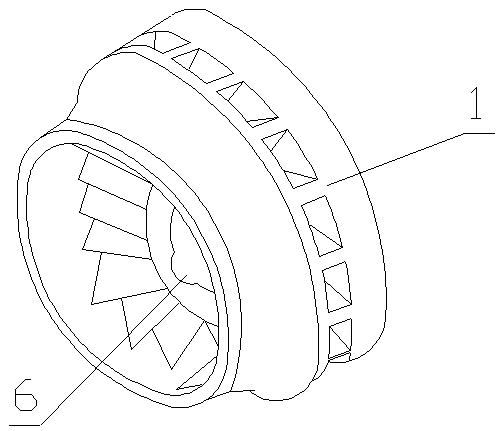

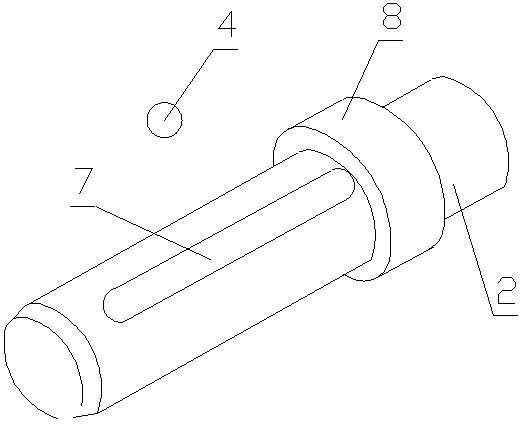

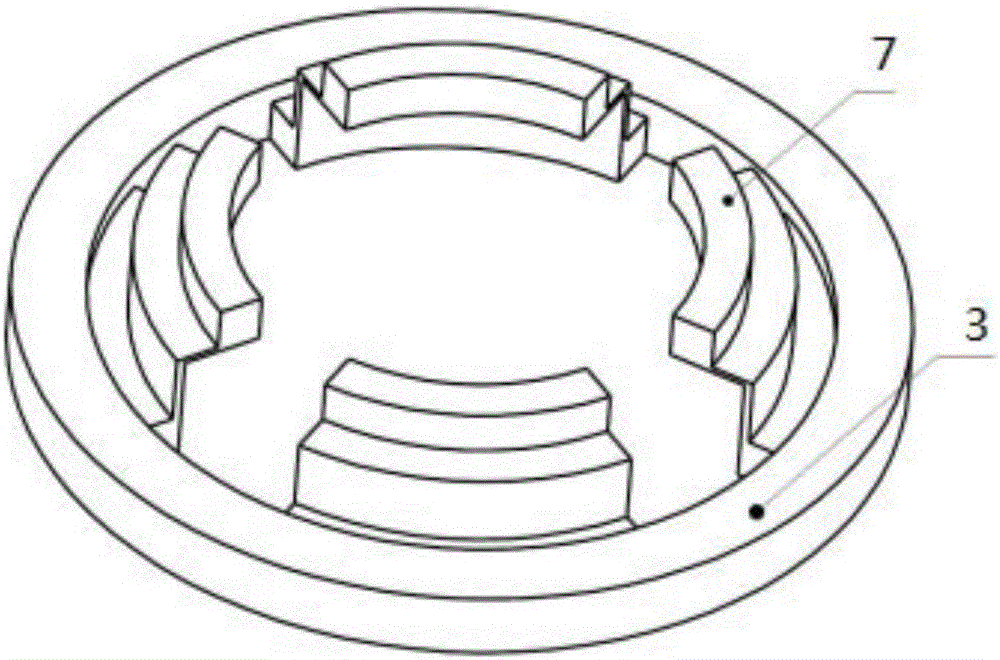

Impeller locking device for centrifugal compressor

The invention discloses an impeller locking device for a centrifugal compressor, and belongs to the field of compressors. The impeller locking device comprises an impeller, a main shaft, a base, a keyand a locking nut. An impeller keyway is arranged on the inner wall of the shaft hole of the impeller, and a main shaft keyway corresponding to the impeller keyway is arranged on the outer surface ofthe main shaft, and the radial cross sections of the impeller keyway and the main shaft keyway are smooth curves. The main shaft includes a threaded end and a shoulder end, wherein the threaded end is provided with an external thread, the shoulder end is provided with a shoulder, and the base is provided with a seat body and hydraulic jacks. The middle part of the seat body is provided with an action ring applying force on the locking nut, and the hydraulic jacks are symmetrically disposed on both sides of the seat body. The top end of each hydraulic jack is fixedly provided with a top blockacting on the outer ring of the impeller, and the inner part of the locking nut is provided with an internal thread matched with the external thread. The impeller locking device has the advantages ofmore convenient locking, less damage to the locking nut and improvement of the strength of the impeller.

Owner:四川聚亿重工有限公司

Arc-shaped remote target motion simulator

ActiveCN106288956AHigh precisionHigh accelerationWave based measurement systemsDirection controllersDrive motorEngineering

The invention provides an arc-shaped remote target motion simulator comprising: a longitudinal member including a longitudinal circular arc track and at least one drive motor for moving a slider with a target source longitudinally in an arc along the longitudinal arc-shaped guide rail, a plurality of transverse members each including a transverse circular arc guide and a linear motor drive system being operable to drive the longitudinal member to move horizontally in an arc along the horizontal arc-shaped guide rail, and a support member including a metal structural wall and a cantilever fixed to the metal structural wall and for supporting the horizontal members.

Owner:BEIHANG UNIV

Low-alloy cast iron spectrum complete set standard sample as well as preparation method and detection method thereof

ActiveCN113670829AImprove uniformityReduce inclusionsAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationChemical compositionPhysical chemistry

The invention relates to the technical field of spectrum standard sample preparation, in particular to a low-alloy cast iron spectrum complete set standard sample and a preparation method and a detection method thereof, and the preparation method comprises the steps of chemical component design, smelting, forming, standard sample treatment and preparation, standard sample initial detection, in-unit detection, inter-block uniformity detection, constant value analysis and standard value determination, stability inspection and linear inspection. The standard sample prepared by the method disclosed by the invention is wide in application range, good in sample uniformity, low in inclusion content in the sample and thorough in sample whitening, and the sample has the characteristics of long-term stability and good linearity and has a wide application prospect.

Owner:石家庄创谱科技有限公司

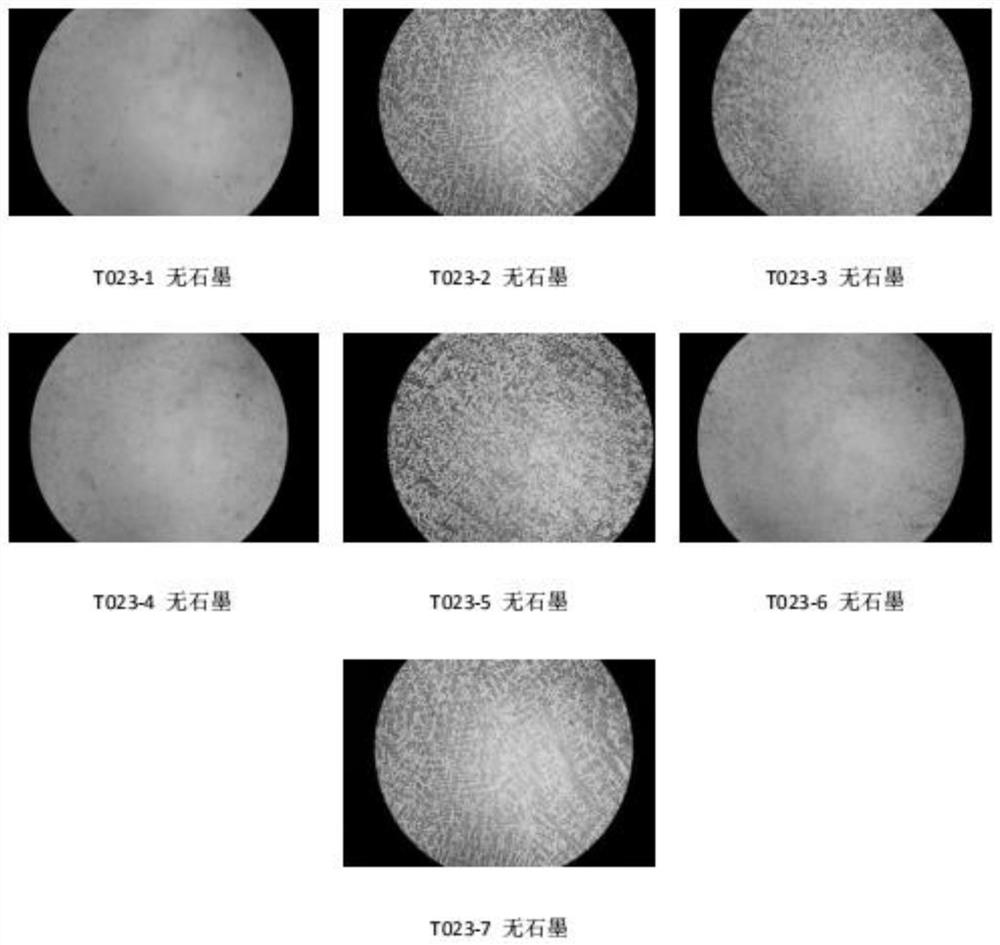

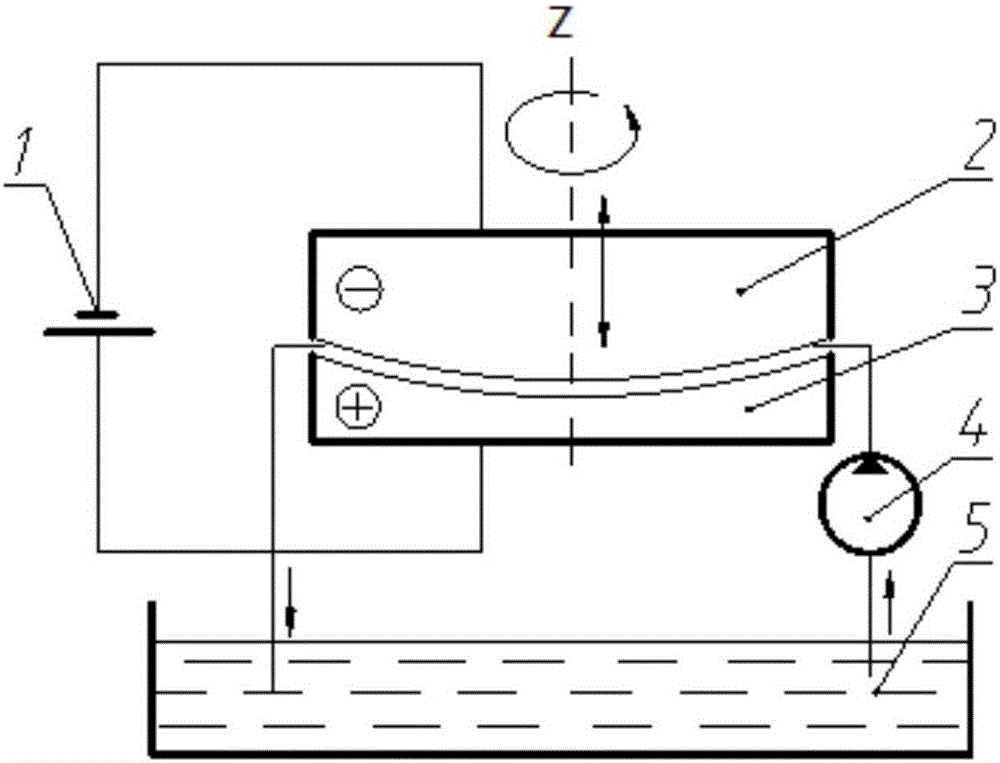

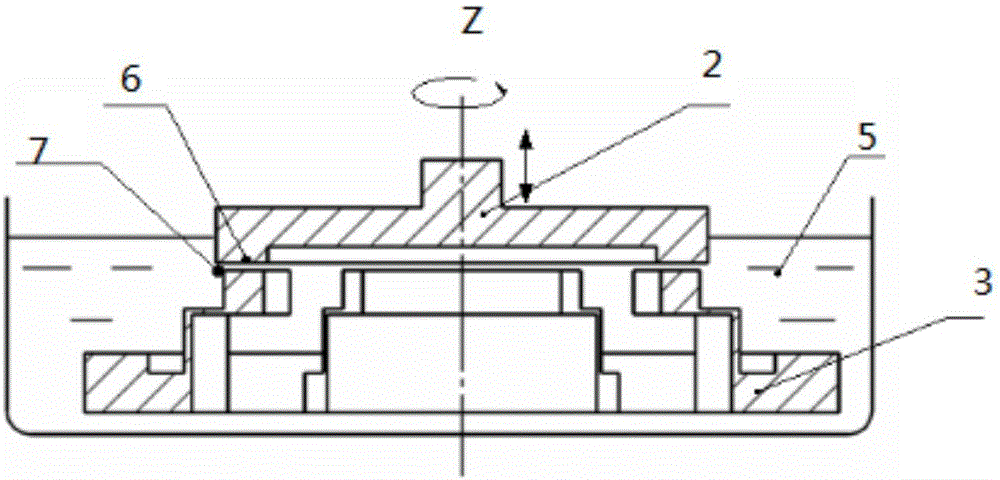

Processing method and device for flexible structural component

InactiveCN106334844AReduce processing stressNot easy to produce secondary deformationElectrochemical machining apparatusEngineeringVertical displacement

The invention discloses a processing method and device for a flexible structural component. The processing method comprises the following steps that an electrode is processed to enable the surface shape and the accuracy of the discharge surface of the electrode to be matched with those of the flexible structural component; the electrode is installed on a machine tool with the functions of rotation and vertical displacement to enable the electrode to be coaxial with a Z shaft of the machine tool; a workpiece is clamped on a workbench and is coaxial with the Z shaft of the machine tool; the discharge surface of the electrode and the workpiece are submerged into an electrolyte; the electrode is connected with a cathode of a direct-current power supply, the workpiece is connected with an anode of the direct-current power supply, and the machine tool is controlled to enable the electrode to rotate at a certain constant speed; the Z shaft of the machine tool is controlled to enable the discharge surface of the electrode to gradually approach the workpiece and generate the electrochemical corrosion effect; and the surface of the workpiece is continuously electrolysed until the shape of the surface of the workpiece is consistent to that of the discharge surface of the electrode so as to obtain the flexible structural component. According to the processing method, the flexible structural component can be processed with high accuracy.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com