Gas inlet valve and gas outlet valve of engine and process for manufacturing same

A production process and intake valve technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of overheating of heat capacity, insufficient mechanical strength, heavy weight, etc., and achieve high-temperature corrosion resistance and enhanced oxidation resistance , Reduction of material cost and processing cost, effect of structure and process improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

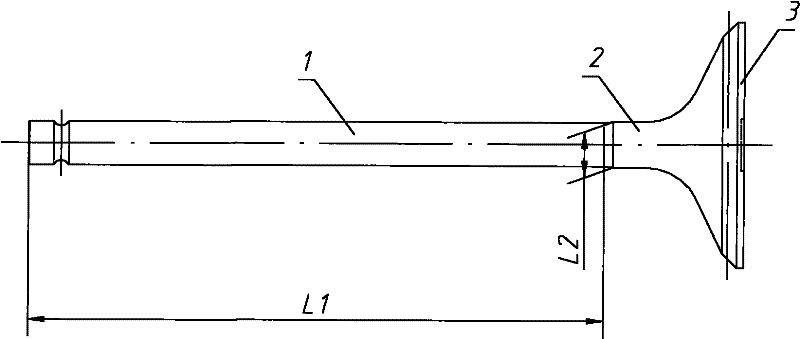

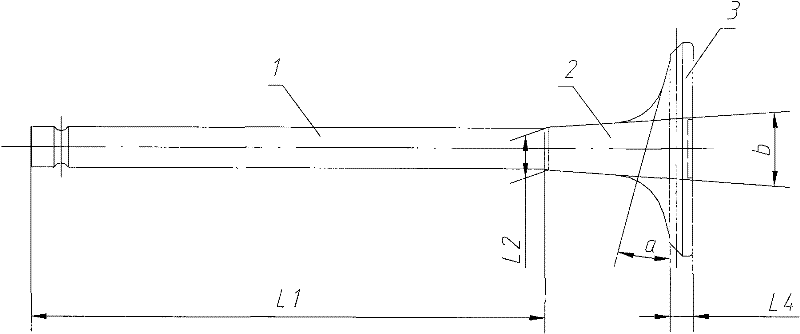

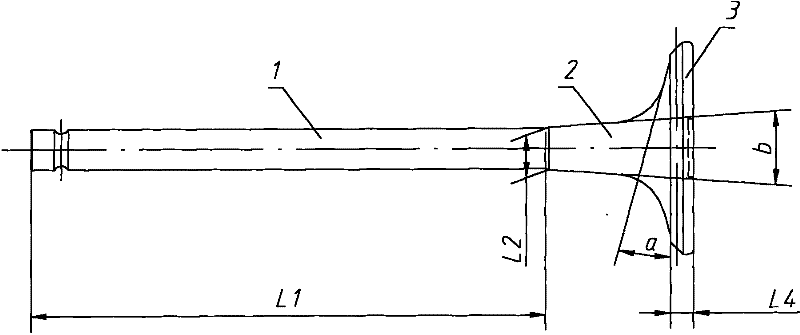

[0035] figure 1 As shown, the intake valve of the engine at least includes a valve stem 1, a valve head made up of a valve neck 2 and a valve disc 3, the valve neck 2 is connected to the valve stem 1 and the valve disc 3, and the length L1 of the valve stem is 100-101mm, specifically refers to the polished length of the valve stem, the minimum diameter L2 of the valve neck is 8.7-8.9mm, which increases the minimum diameter of the valve neck of the original B series engine, thereby increasing the rigidity of the position, and at the same time In terms of technology, we pay attention to the smooth transition without steps and protrusions when grinding the transition between the disc and the rod, and eliminate the stress effect of sharp corners, thus solving the failure problems such as early fatigue fracture of the intake valve at the transition between the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com