Composite material precision molding tool for airplane and precision molding manufacturing method

A technology for composite materials and forming tooling, which is applied in the field of precision forming tooling and precision forming manufacturing of composite materials for aircraft, and can solve problems affecting the accuracy of composite material parts and the complexity of the affecting mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

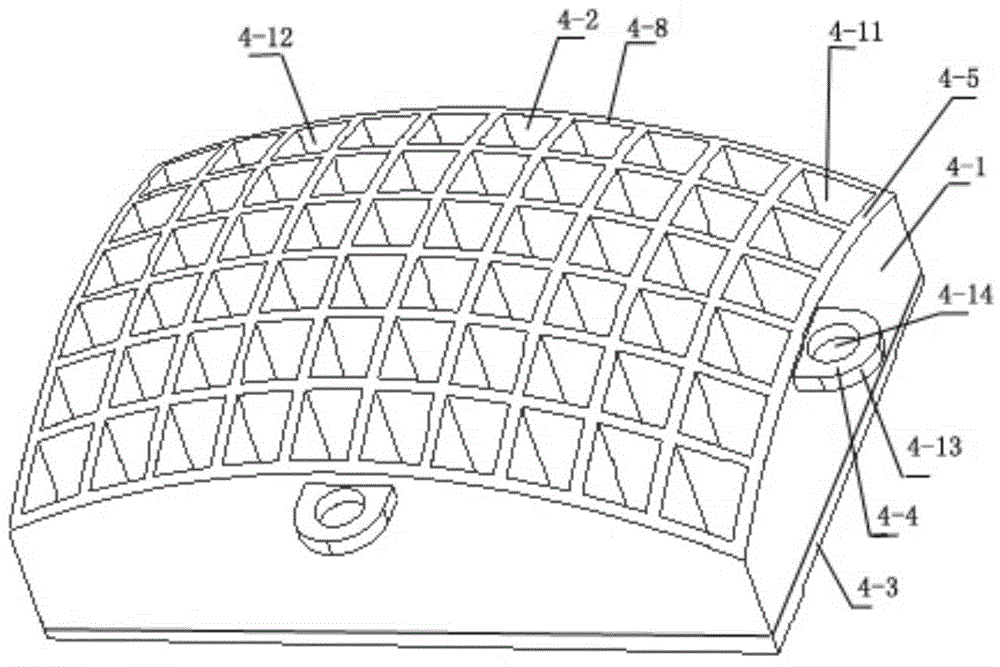

[0019] The technical solution can also be realized through the following technical measures and the present invention will be further described below in conjunction with the accompanying drawings:

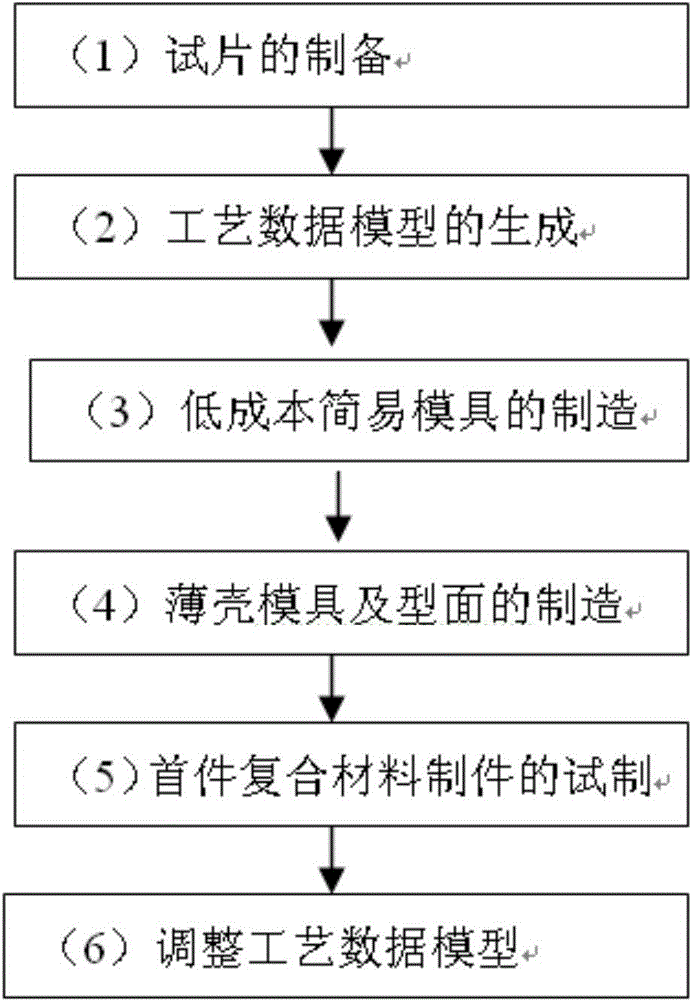

[0020] figure 1 It is a flow chart of the precise forming manufacturing method of the present invention, mainly illustrating the flow chart of the precise forming manufacturing method of composite materials, specifically including the following steps:

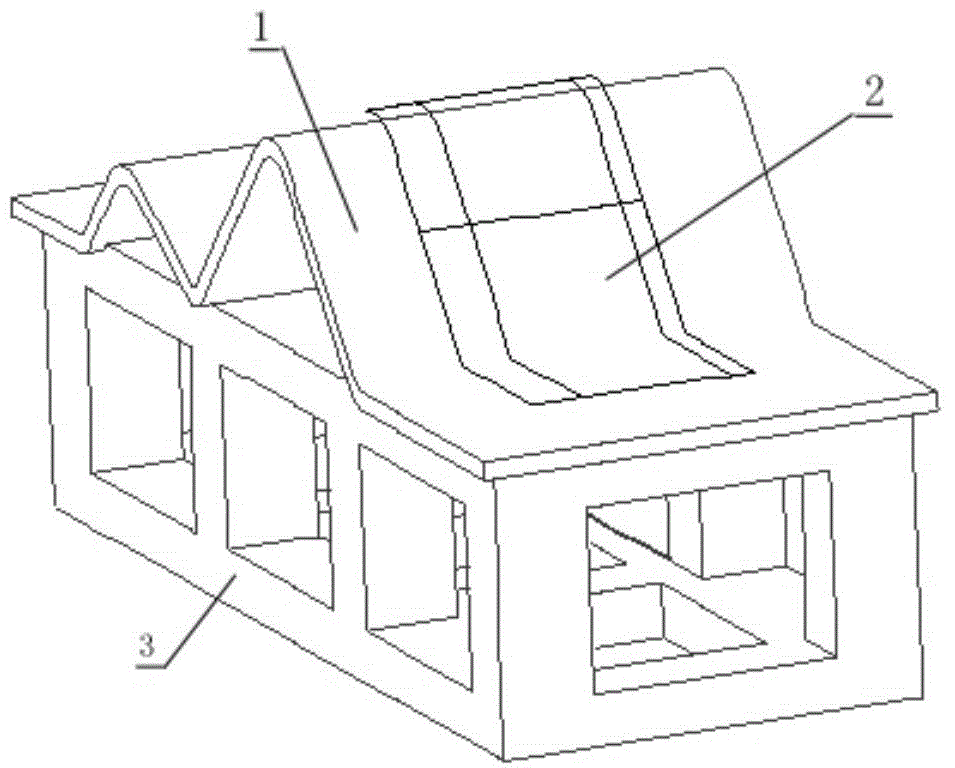

[0021] (1) The preparation of the composite material test piece (2), according to the characteristics of the composite material part, select a suitable area to manufacture the composite material test piece (2) on the special mold for test piece preparation (1), the composite material test piece (2) Lay-up angle, number of layers, curing process, etc. are all the same as the composite material parts to be manufactured, so as to ensure the similarity between the composite material test piece (2) and the composite material parts;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com