High temperature heat-collecting pipe hard glass and Kovar alloy sealing method

A hard glass and heat collecting tube technology, applied in the sealing field of hard glass and Kovar alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

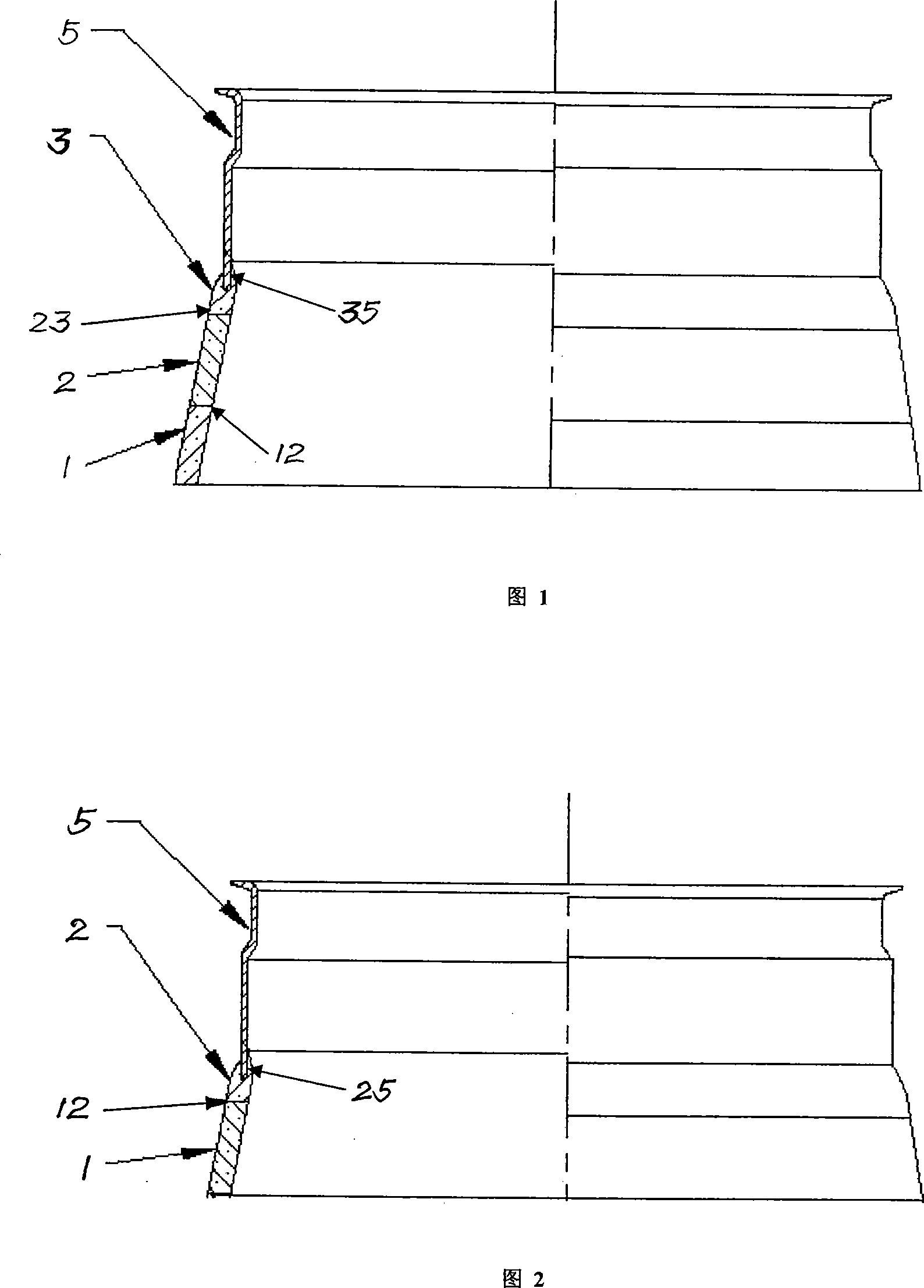

[0011] Referring to Fig. 1, hard glass 1, two transition glass joints 2, 3, and Kovar tube 5 are sequentially sealed (butted). The expansion coefficient of hard glass, two transition glass joints, and Kovar alloy is (32-34)*10 -7 / °C, (39-41)*10 -7 / °C, (46-48)*10 -7 / °C, (50.3-53.7)*10 -7 / °C.

[0012] The heating temperature and holding time for the sealing area between two adjacent sealing parts are as follows:

[0013] seal area

Sealing zone 12 between hard glass 1 and transition glass joint 2

900-1250

The sealing area 23 between the transition glass joint 2 and the transition glass joint 3

600-900

The sealing area 35 between the transition glass joint 3 and the Kovar tube 5

500-800

[0014] The heating temperatures of the sealing areas 12, 23, and 35 are gradually reduced, and the heating temperature difference of each sealing area is 250-300°C;

[0015] The combustion gas for sealing t...

Embodiment 2

[0020] The difference between embodiment 2 and embodiment 1 is that the heating temperatures of the sealing areas 12, 23, and 35 are different, and the heating temperature difference of each sealing area is 50-100°C, as shown in the following table:

[0021] seal area

[0022] For the high-temperature heat collecting tube of this embodiment, a tensile test is carried out, and the tensile strength reaches 700 kg. In the fatigue test, the stretching cycle was more than 38,000 times. Carry out small batch production, and the finished product rate reaches 88%.

Embodiment 3

[0024] The difference between Embodiment 3 and Embodiment 1 is that the heating temperatures of the sealing areas 12, 23, and 35 are different, and the heating temperature difference of each sealing area is 100-200°C, as shown in the following table:

[0025] seal area

[0026] For the high-temperature heat collecting tube of this embodiment, a tensile test was carried out, and the tensile strength reached 760 kg. In the fatigue test, the stretching cycle was more than 44,000 times. Carry out small batch production, and the finished product rate reaches 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com