Double-cutter-shaft machine tool for graphite slotting and machining technology of machine tool

A cutter shaft and graphite technology, which is applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problem of not being able to open multiple parallel grooves on the surface of brittle materials such as graphite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

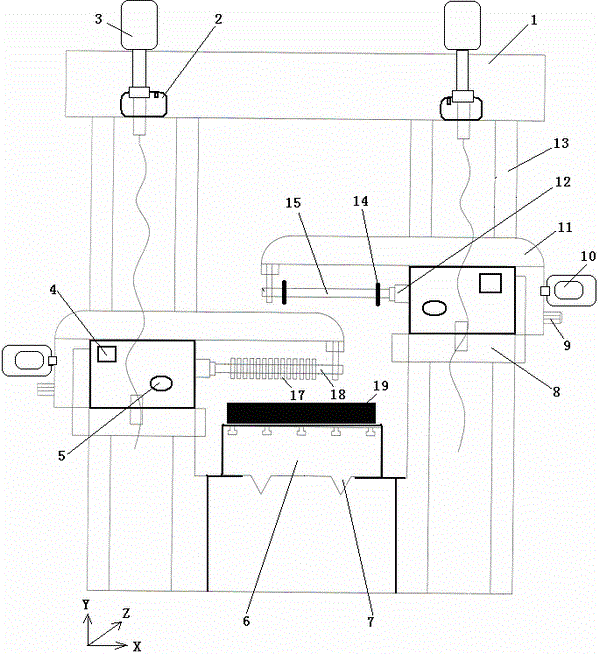

[0031] Such as figure 1 The shown double-spindle machine tool for graphite slotting is used to open multiple parallel grooves on the surface of graphite materials. It has a motor A, a horizontal guide rail 7, and a working platform 6. The motor A can drive the working platform 6 through a screw drive. Move on the horizontal guide rail 7 set in the Y-axis direction; it has 2 sets of motors B3, a horizontally set beam 1, two columns 13, two sets of cutter shaft assemblies, column lubrication system 2, and 2 sets of motors B3 above the beam 1 , two columns 13 are placed under the beam 1 and support the beam 1, and each motor B3 is respectively connected through the beam 1 and can drive a set of cutter shaft assembly to move up and down in the Z-axis direction on a column 13.

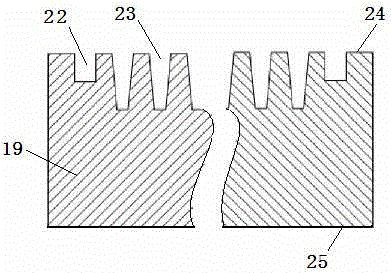

[0032] Each cutter shaft assembly includes a cantilever beam 11, a cutter shaft (consisting of a main shaft 15 and a set of milling cutters 14, with two milling cutters on one cutter shaft and multiple mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com