Common-reference detection and machining method of off-axis three-mirror aspheric optical system

An off-axis three-mirror, optical system technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of vertex curvature radius error, complicated process, difficult to achieve imaging effect, etc., to achieve stable removal function and high certainty , the effect of shortening the follow-up assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

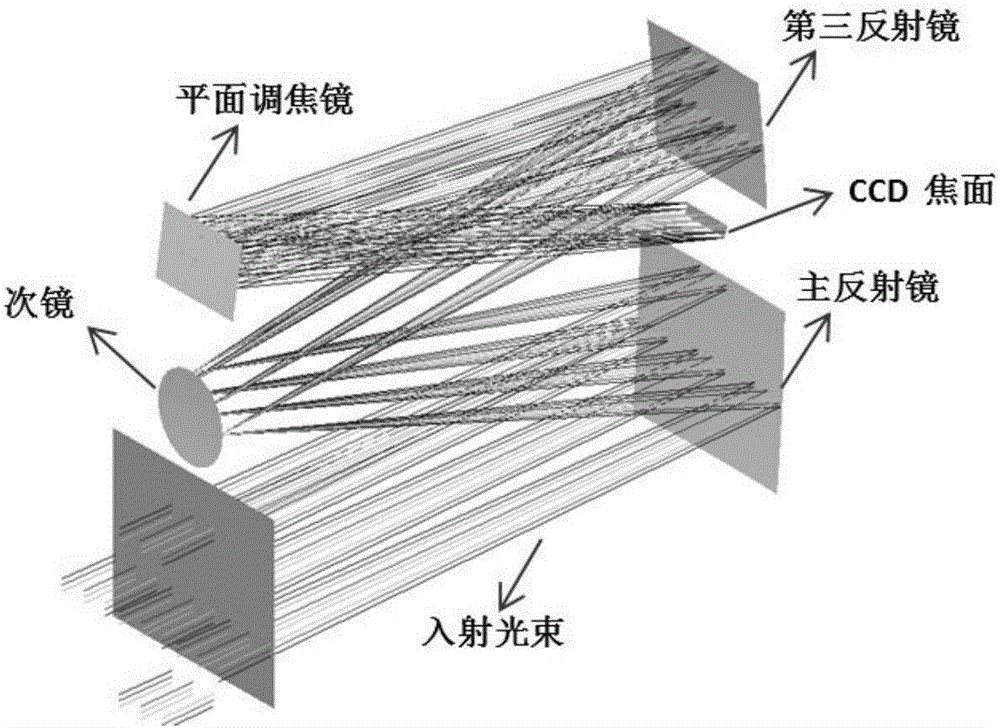

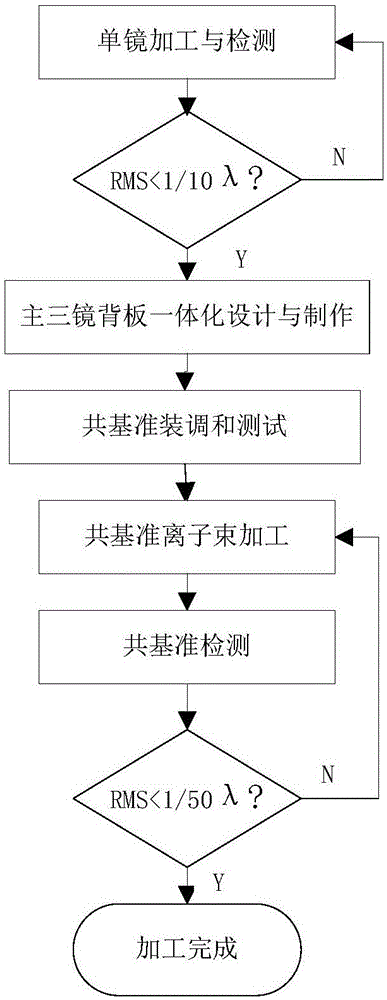

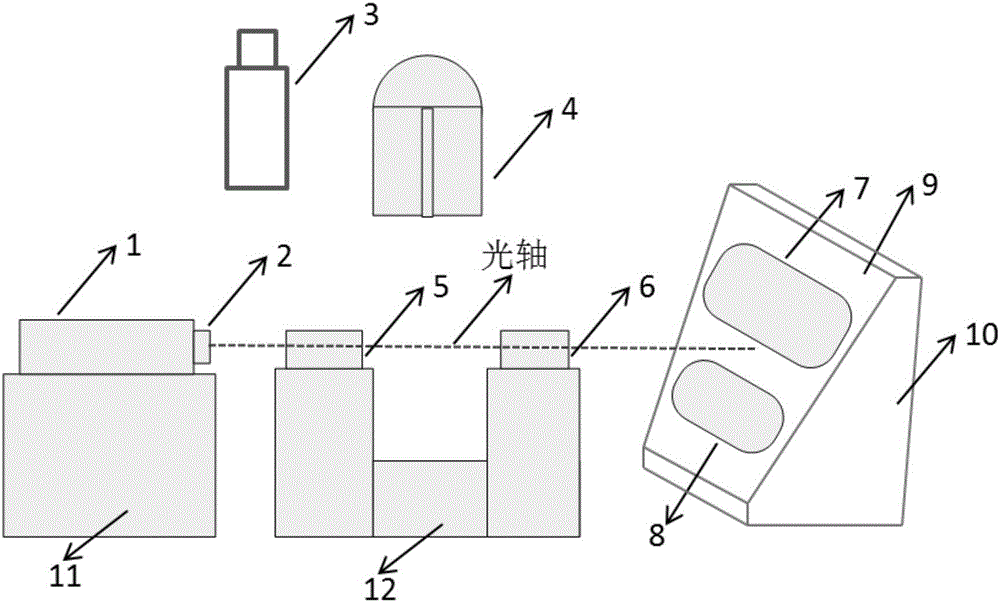

[0030] Such as figure 2 As shown, the present invention provides a common reference detection and processing method for an off-axis three-mirror aspheric optical system. The device required by the method of the present invention mainly includes a laser interferometer, a standard plane reference mirror, an optical compensator, a main reflector, a second Three mirrors, integrated backplane, ion beam processing center, laser tracker and adjustment mechanism, etc. Include the following steps:

[0031] Step 1. Single mirror processing and testing

[0032] Using Computer Controlled Optical Surfacing (CCOS, Computer Controlled Optical Surfacing) technology to deterministically process the primary mirror and the third mirror respectively, that is, grinding and rough polishing. The reflector and the third reflector are subjected to contact measurement respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com