Impeller locking device for centrifugal compressor

A centrifugal compressor and locking device technology, applied in the field of compressors, can solve the problems of complex structure, low impeller strength, inconvenient operation, etc., and achieve the effects of reducing processing stress, improving assembly technology, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

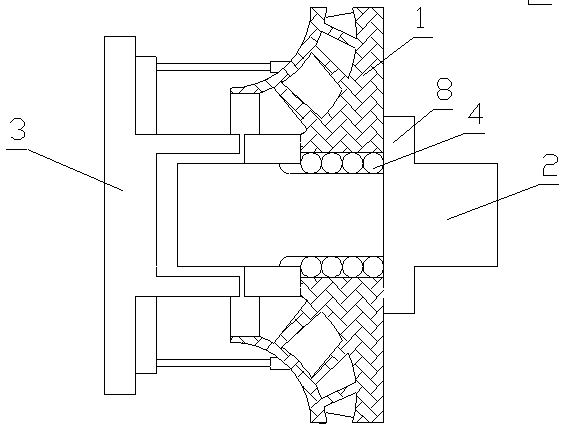

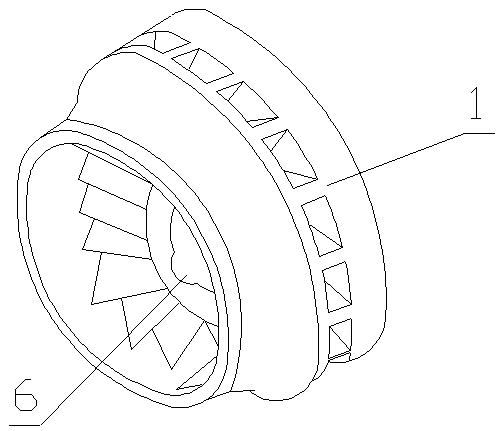

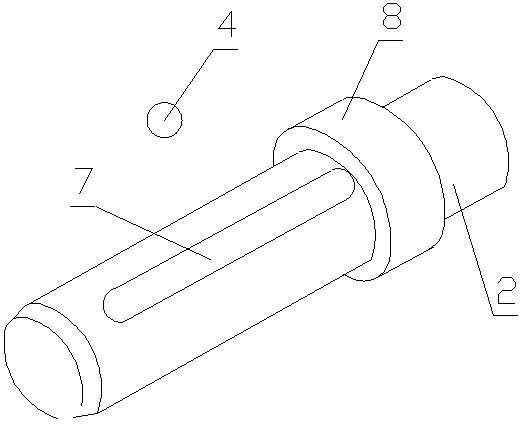

[0035] As a most basic implementation of the present invention, the present embodiment discloses an impeller locking device for a centrifugal compressor, such as figure 1 — Figure 5 As shown, it includes an impeller 1, a main shaft 2, a base 3, a key 4 and a lock nut 5. The inner wall of the shaft hole of the impeller 1 is provided with an impeller keyway 6, and the outer surface of the main shaft 2 is provided with an impeller keyway 6. Corresponding to the main shaft keyway 7, the radial sections of the impeller keyway 6 and the main shaft keyway 7 are smooth curves, the main shaft 2 includes a threaded end and a shoulder end, the threaded end is provided with external threads, and the shaft shoulder A shaft shoulder 8 is provided on the end, a seat body 9 and a hydraulic jack 10 are arranged on the base 3, and an action ring 11 applied to the force of the lock nut 5 is arranged in the middle of the seat body 9, and the hydraulic jack 10 is symmetrical Arranged on both sid...

Embodiment 2

[0038] As a preferred embodiment of the present invention, this embodiment discloses an impeller locking device for a centrifugal compressor, such as figure 1 — Figure 5 As shown, it includes an impeller 1, a main shaft 2, a base 3, a key 4 and a lock nut 5. The inner wall of the shaft hole of the impeller 1 is provided with an impeller keyway 6, and the outer surface of the main shaft 2 is provided with an impeller keyway 6. Corresponding to the main shaft keyway 7, the radial sections of the impeller keyway 6 and the main shaft keyway 7 are smooth curves, the main shaft 2 includes a threaded end and a shaft shoulder end, the threaded end is provided with external threads, and the shaft shoulder A shaft shoulder 8 is provided on the end, a seat body 9 and a hydraulic jack 10 are arranged on the base 3, and an action ring 11 applied to the force of the lock nut 5 is provided in the middle of the seat body 9, and the hydraulic jack 10 is symmetrical Arranged on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com