Method for producing polarization maintaining optical fibre

A technology of polarization-maintaining optical fiber and manufacturing method, which is applied in the directions of manufacturing tools, glass manufacturing equipment, glass fiber products, etc., can solve the problems of destroying the performance of polarization-maintaining optical fiber, reducing the performance of polarization-maintaining optical fiber, and positioning consistency, and achieving geometric shape And the effect of good precision control, small processing stress and good product processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

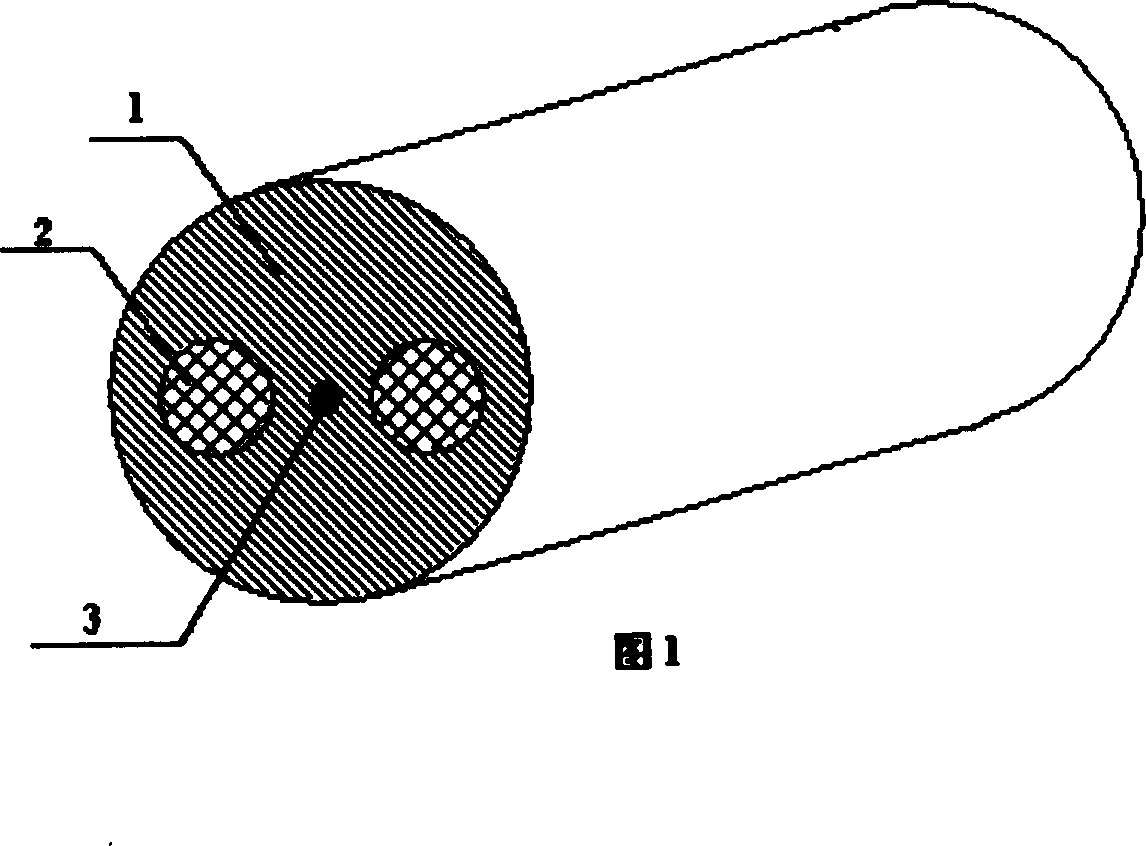

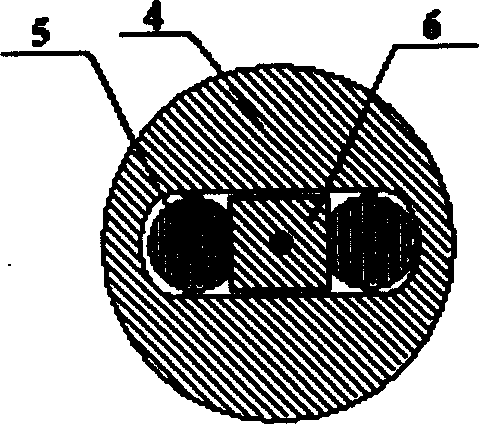

[0032] PCVD method is used to deposit the core rod 6 and the stress rod 5, wherein the core rod 6 includes a high refractive index core part 10 and a cladding part 9, such as Figure 7 As shown, the core 10 is germanium-doped silica, which has a relatively high optical refractive index, and the cladding 9 is pure silica glass. The structure of the stress rod 5 includes a stress zone 8 and a cladding 7, such as Image 6 As shown, the stress region 8 is boron-doped quartz glass, which has a low optical refractive index and a large thermal expansion coefficient, and the cladding layer 7 is pure quartz glass. Machined pure quartz glass sleeve 4 (see figure 2 ). The casing 4 is a pure quartz glass cylinder with a circular inner hole, and the inner hole wall is obtained by grinding the inner hole wall, and then the inner hole wall is polished. Mandrel 6 and stress rod 5 are processed into suitable shape by machining simultaneously (see Image 6, 7), that is, a mandrel rod with a...

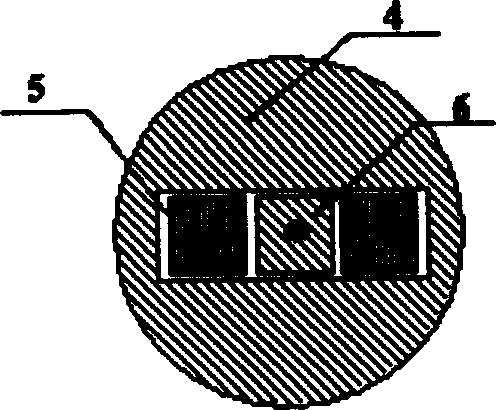

Embodiment 2

[0034] PCVD method is used to deposit the core rod 6 and the stress rod 5, wherein the core rod 6 includes a high refractive index core part 10 and a cladding part 9, the core 10 is germanium-doped quartz, which has a higher optical refractive index, and the cladding 9 For pure quartz glass. The structure of the stress rod 5 includes a stress zone 8 and a cladding 7, wherein the stress zone 8 is boron-doped quartz glass with a low optical refractive index and a large thermal expansion coefficient, and the cladding 7 is pure quartz glass. Machining casing 4. The casing 4 is a pure quartz glass cylinder with a circular inner hole. By grinding the inner hole wall, the cross-section of the inner hole with three circles connected side by side is obtained (see Figure 5 ). Polish the bore wall. Simultaneously corrode the mandrel and stress rods to the appropriate outer diameter. The mandrel and stress rods are then inserted into the formed casing, the stress rods being located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com