Low-alloy cast iron spectrum complete set standard sample as well as preparation method and detection method thereof

A spectral standard sample and standard sample technology, which is applied in the field of low-alloy cast iron spectral standard samples and their preparation, can solve the problems of difficulty in forming full white, low chemical composition, high carbon content, etc., to improve long-term stability, Effect of reducing internal stress and processing stress and accurate applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The invention provides a method for preparing a complete set of low-alloy cast iron spectrum standard samples and the obtained standard samples. The method comprises the following steps:

[0065] (a) chemical composition design, the present invention follows the following principles in composition design: (1) the scope of composition will cover the upper and lower limits of the analysis product, and when extending the upper and lower limits, the needs of product furnace smelting will be fully considered; (2) each element composition The design should be distributed in a uniform gradient as much as possible; (3) Avoid the existence of two elements that are easy to form inclusions in the form of high content in each point; (4) Pay attention to the balance of the matrix.

[0066] The design of the chemical composition of the present invention is interrelated with the design of the subsequent smelting and molding process. Most of the existing standard samples contain few che...

Embodiment 1

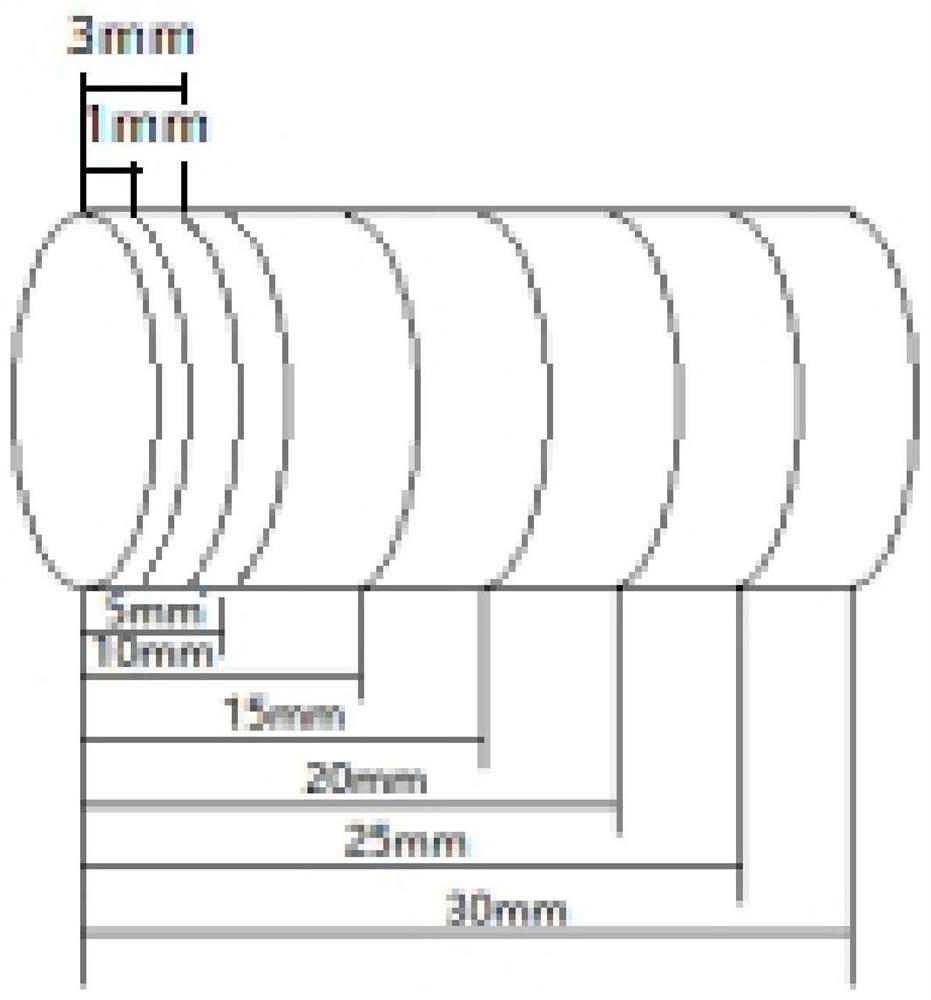

[0145] The present embodiment provides a kind of preparation method of low-alloy cast iron spectral complete standard sample, comprises the following steps:

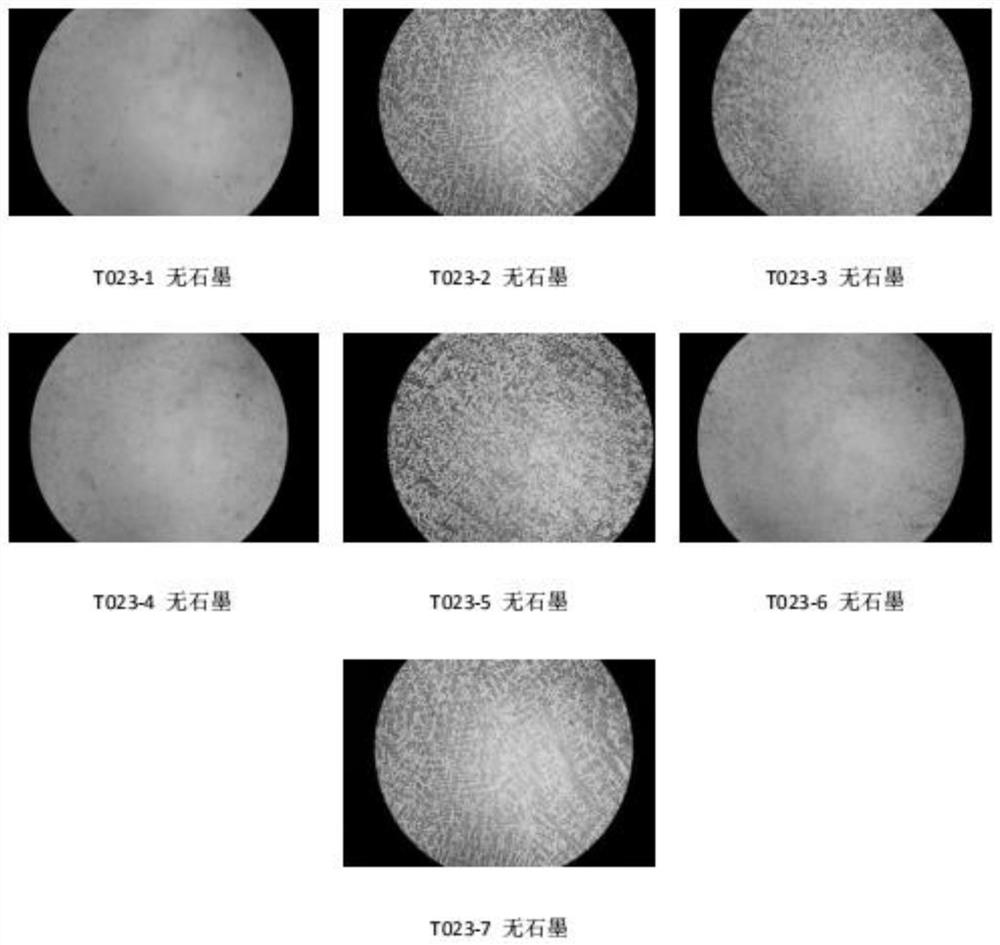

[0146] (a) Chemical composition design: Within the specified chemical composition range, 7 levels of chemical composition are designed according to the principles of equal gradient distribution, mutual interference between elements and the lowest probability of inclusions, as shown in Table 2;

[0147] Table 2 seven levels of chemical composition fixed value (w / %)

[0148] Numbering C Si mn P S Cr Ni Mo V Cu Mg T023-1 3.48 0.546 0.208 0.069 0.051 2.21 0.058 0.701 0.550 0.455 0.0005 T023-2 3.12 2.45 0.776 0.439 0.011 1.52 1.01 0.580 0.204 1.13 0.060 T023-3 2.91 1.51 0.965 0.234 0.0099 0.973 0.543 0.408 0.188 0.747 0.050 T023-4 3.62 2.06 1.22 0.165 0.043 1.21 0.773 0.313 0.360 0.535 0.011 T023-5 3.86 0.984 1.40 0.346 0.011 0.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com