Machining process of middle-long thin-wall blades

A processing technology and blade technology, applied in the processing field of turbine generator blades, can solve the problems of large blade deformation, high energy consumption, labor-intensive and other problems, so as to reduce cumulative errors, reduce processing stress and deformation, and ensure processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

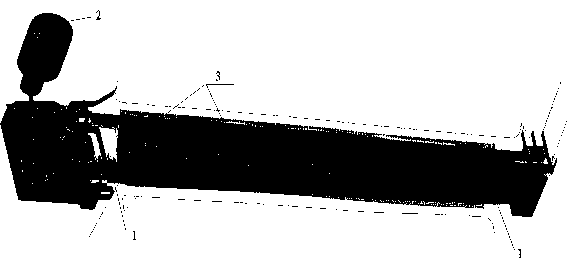

Image

Examples

Embodiment Construction

[0027] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0028] Any feature disclosed in this specification (including any appended claims, abstract), unless otherwise stated, may be replaced by alternative features that are equivalent or serve a similar purpose. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

[0029] The processing technology of the medium-length thin-walled blade of the present invention is realized through the following process steps:

[0030] Step 1. Install the blade blank on the fixture of the machine tool. The machine tool adopts a front and rear double drive structure, and the front and rear of the machine tool adopts floating commands. Given a most suitable force, the machine tool always maintains a balanced force when the blade is stretching or sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com