Machining and manufacturing method of 7055 aluminum alloy complex structure part

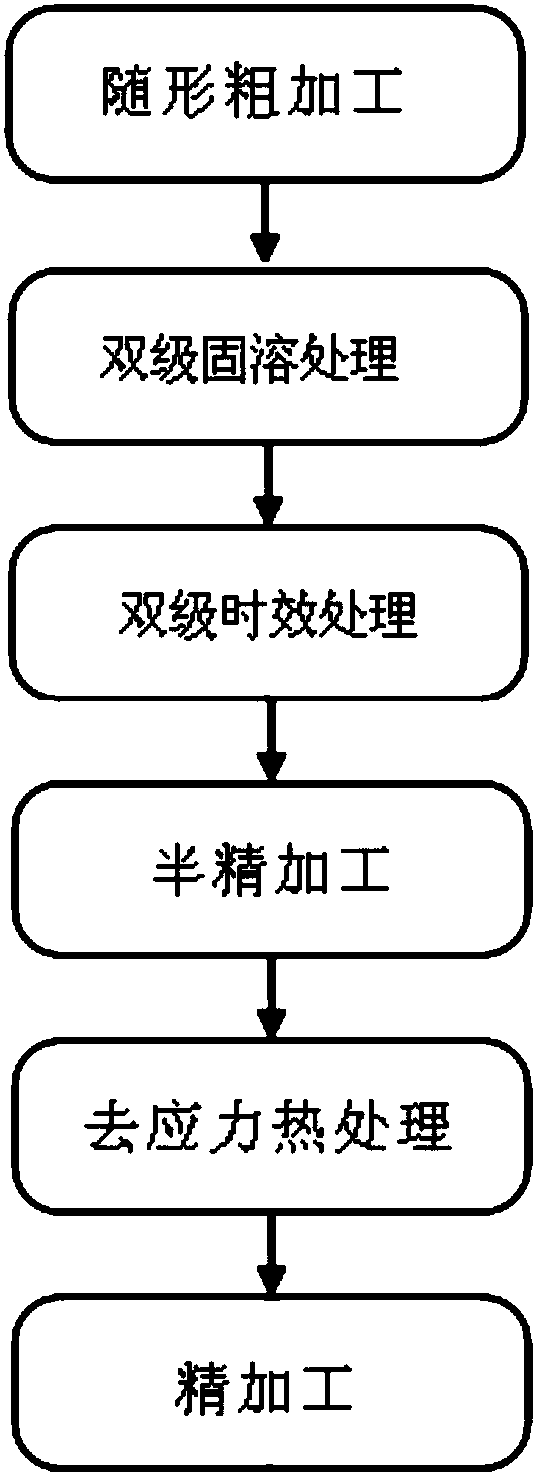

A complex structure, processing and manufacturing technology, applied in the field of non-ferrous metal processing technology, can solve the problems of difficult processing, easy cracking, large deformation of aluminum alloy parts, etc., to improve the quenching pass rate and processing efficiency, and reduce the level of stress concentration , the effect of preventing deformation and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A certain model uses stringers, which are thin-walled ribbed parts, with a T-shaped cross section, a non-planar bottom surface, and 3 small corners. The structure of the part is relatively complicated, and it requires high dimensional accuracy. During the process, it is necessary to comprehensively consider machining parameters, deformation, heat treatment and other processes, and strictly control the machining process. In the process of processing, multiple positioning and clamping are required, small amount of cutting is processed, and stabilization annealing is required after semi-finishing to prevent processing deformation.

[0043] The stringer parts are rough-machined into a mirror-image symmetrical structure; the feed rate of each rough machining pass is 0.5mm, the rough machining spindle speed is 4000r / min, the rough machining feed rate is 1.5m / min, and the unilateral machining allowance is kept at 2mm, the surface roughness is 6.3μm, all the inner and outer rig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com