Household water-based paint and preparation method thereof

A technology for water-based coatings and raw materials, applied in the field of coatings, can solve the problems of easy cracking in compatibility, affecting the service life of coatings, etc., and achieve the effects of high preparation efficiency and yield, less harsh reaction conditions, and abundant raw material sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

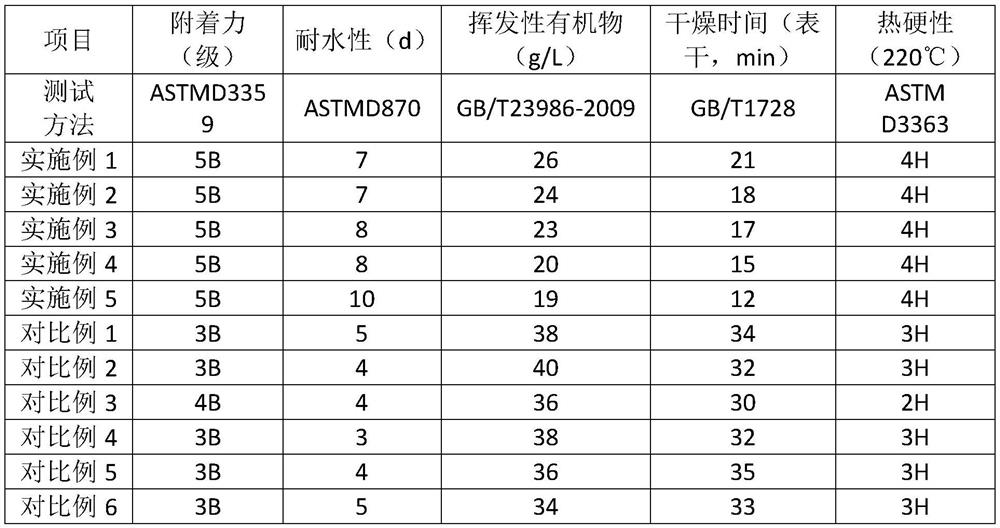

Examples

Embodiment 1

[0030] A household water-based paint, characterized in that it is made of the following parts by weight of various raw materials: 2 parts of triazine hyperbranched quaternary ammonium salt surfactant, 10 parts of water-soluble hyperbranched epoxy resin, and permethrin acid / 2-Methacryloyloxyethyl phosphocholine / Allyl β-D-glucopyranoside / Chloride 3-ethyl-2-[2-(1-ethyl-2,5-di Methyl-1H-pyrrol-3-yl)vinyl]benzoxazolium salt / sulfapentene copolymer 30 parts, polyphosphate ferric chloride 3 parts, leveling agent 1 part, inorganic filler 10 parts, defoaming 1 part of agent and 25 parts of water.

[0031] The defoaming agent is tributyl phosphate; the inorganic filler is talc; and the leveling agent is a polyacrylate leveling agent.

[0032] The trifluoromethrin acid / 2-methacryloxyethyl phosphorylcholine / allyl β-D-glucopyranoside / chloro 3-ethyl-2-[2-(1-ethyl The preparation method of the base-2,5-dimethyl-1H-pyrrol-3-yl)vinyl]benzoxazolium salt / sulfapentene copolymer includes the followin...

Embodiment 2

[0036] A household water-based paint, characterized in that it is made of the following parts by weight of various raw materials: 3 parts of triazine hyperbranched quaternary ammonium salt surfactant, 12 parts of water-soluble hyperbranched epoxy resin, and permethrin acid / 2-Methacryloyloxyethyl phosphocholine / Allyl β-D-glucopyranoside / Chloride 3-ethyl-2-[2-(1-ethyl-2,5-di Methyl-1H-pyrrol-3-yl)vinyl]benzoxazolium salt / sulfapentene copolymer 33 parts, polyphosphoric ferric chloride 4 parts, leveling agent 1.2 parts, inorganic filler 11 parts, defoaming The antifoaming agent is the defoaming agent Deqian 3100; the inorganic filler is nano titanium dioxide; the leveling agent is the cellulose acetate leveling agent.

[0037] The trifluoromethrin acid / 2-methacryloxyethyl phosphorylcholine / allyl β-D-glucopyranoside / chloro 3-ethyl-2-[2-(1-ethyl The preparation method of the base-2,5-dimethyl-1H-pyrrol-3-yl)vinyl]benzoxazolium salt / sulfapentene copolymer includes the following steps:...

Embodiment 3

[0041] A household water-based paint, characterized in that it is made of the following raw materials in parts by weight: 3.5 parts of triazine hyperbranched quaternary ammonium salt surfactant, 15 parts of water-soluble hyperbranched epoxy resin, and permethrin acid / 2-Methacryloyloxyethyl phosphocholine / Allyl β-D-glucopyranoside / Chloride 3-ethyl-2-[2-(1-ethyl-2,5-di Methyl-1H-pyrrol-3-yl)vinyl]benzoxazolium salt / sulfapentene copolymer 35 parts, polyphosphoric ferric chloride 4.5 parts, leveling agent 1.5 parts, inorganic filler 13 parts, defoaming The defoamer is a defoamer BYK088; the inorganic filler is light calcium carbonate; the leveling agent is a polyvinyl butyral leveling agent.

[0042] The trifluoromethrin acid / 2-methacryloxyethyl phosphorylcholine / allyl β-D-glucopyranoside / chloro 3-ethyl-2-[2-(1-ethyl The preparation method of the base-2,5-dimethyl-1H-pyrrol-3-yl)vinyl]benzoxazolium salt / sulfapentene copolymer includes the following steps: combining trifluthrin, 2- ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com