Preparation method of fluoride-free super-hydrophobic surface

A technology of super-hydrophobic surface and super-hydrophobic coating is applied in the field of preparation of fluorine-free super-hydrophobic surface, which can solve problems such as application limitations, and achieve the effects of dimensional stability, improved anti-fouling and anti-scaling, and increased mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of superhydrophobic coating solution

[0029] 2 g of polymethyl methacrylate (PMMA) and 2 g of polydimethylsiloxane (PDMS) were dissolved in 50 mL of tetrahydrofuran solvent, and the dissolution was promoted by ultrasound to prepare a superhydrophobic coating solution.

[0030] Preparation of superhydrophobic surfaces

[0031] Get 2Ml of super-hydrophobic coating solution and spray it on the substrate glass plate through a spray gun, the spraying pressure is set to 0.2MPa, and the distance between the spray gun and the substrate is set to 15cm to make a super-hydrophobic surface.

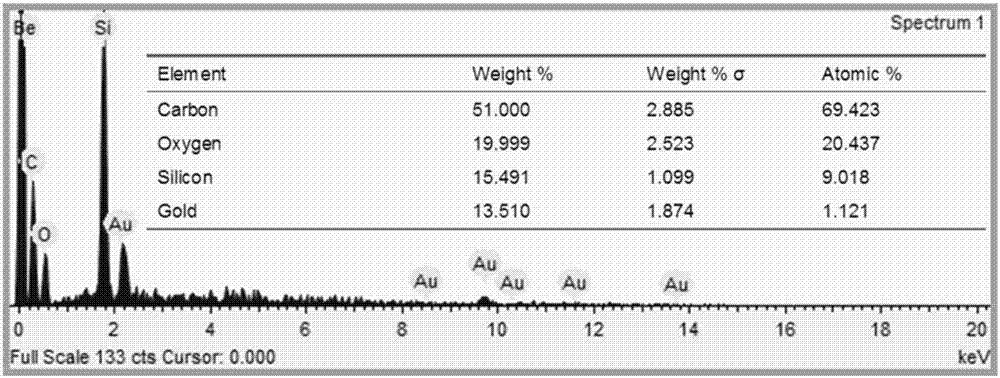

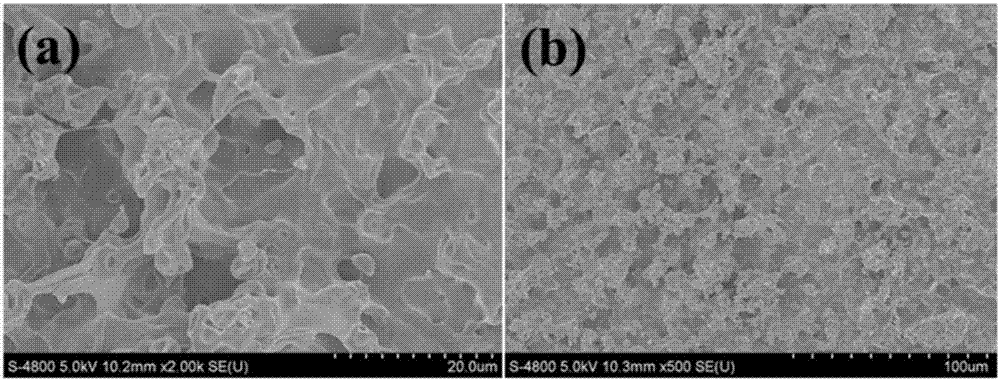

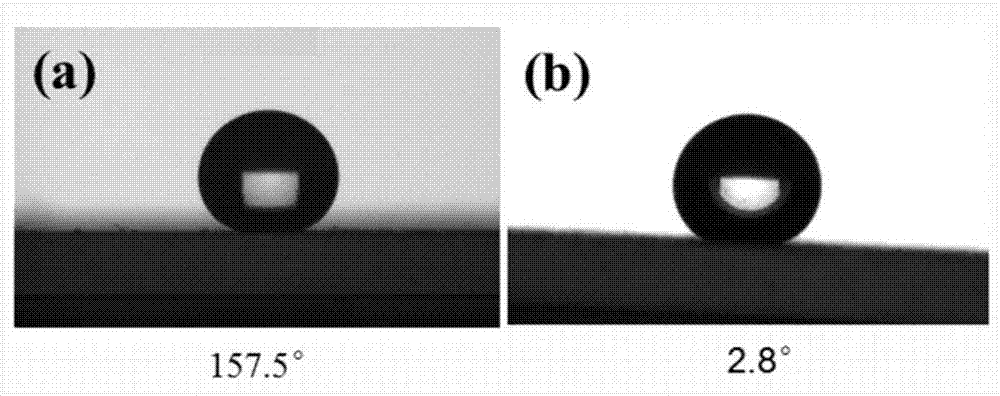

[0032] Such as figure 1 As shown, the peak of the Si element in the EDS energy spectrum of the fluorine-free superhydrophobic surface prepared in this embodiment is relatively obvious, indicating that the surface of the glass plate substrate has been covered by the coating. Such as figure 2 As shown, the surface of the coating presents a concave-convex micro-nano structure. S...

Embodiment 2

[0035] Preparation of superhydrophobic coating solution

[0036] 2 g of polymethyl methacrylate (PMMA) was dissolved in 50 mL of tetrahydrofuran solvent, and the dissolution was promoted by ultrasound to prepare a superhydrophobic polymer coating liquid.

[0037] Preparation of superhydrophobic surfaces

[0038] Take 2mL of the superhydrophobic polymer coating solution and spray it on the substrate glass plate through the spray gun, the spray pressure is set to 0.2MPa, and the distance between the spray gun and the substrate is set to 15cm to obtain a superhydrophobic surface.

[0039] The hydrophobicity of the fluorine-free super-hydrophobic surface after 50g of sand with a particle size of 300 microns falls from a height of 50cm to the surface of the coating and after 5000 drops of 22 microliters of water drop from a height of 50cm to the coating The hydrophobic properties of the surface are as follows Figure 5 As shown, PDMS further plays a role in enhancing the bonding ...

Embodiment 3

[0041] Preparation of superhydrophobic coating solution

[0042] 2 g of polydimethylsiloxane (PDMS) was dissolved in 50 mL of tetrahydrofuran solvent, and ultrasonic waves were used to promote the dissolution to prepare a superhydrophobic polymer coating liquid.

[0043] Preparation of superhydrophobic surfaces

[0044] Take 2mL of the super-hydrophobic polymer coating solution and spray it on the base glass plate through a spray gun, the spraying pressure is set to 0.2MPa, and the distance between the spray gun and the glass plate is set to 15cm to obtain a super-hydrophobic surface.

[0045] The fluorine-free superhydrophobic surface prepared by this embodiment has the hydrophobic properties after being immersed in acid-base solution for 24h as Image 6 As shown, the fluorine-free superhydrophobic surface still maintains good hydrophobic properties after being immersed in acid and alkali for 24 hours, and the water contact angle remains above 150°. Such as Figure 7 As sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com