Surface cleaning method on indium antimonide wafer after alkaline chemical mechanical polishing

An indium antimonide wafer and chemical mechanical technology, which is applied in the field of surface cleaning of semiconductor indium antimonide wafers after alkaline chemical mechanical polishing, can solve the problems of uneven corrosion on the surface of indium antimonide materials, lower device yields, and high wafer surface temperatures, etc. problems, to achieve the effect of preventing local continuous reaction, good temperature consistency and consistent temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

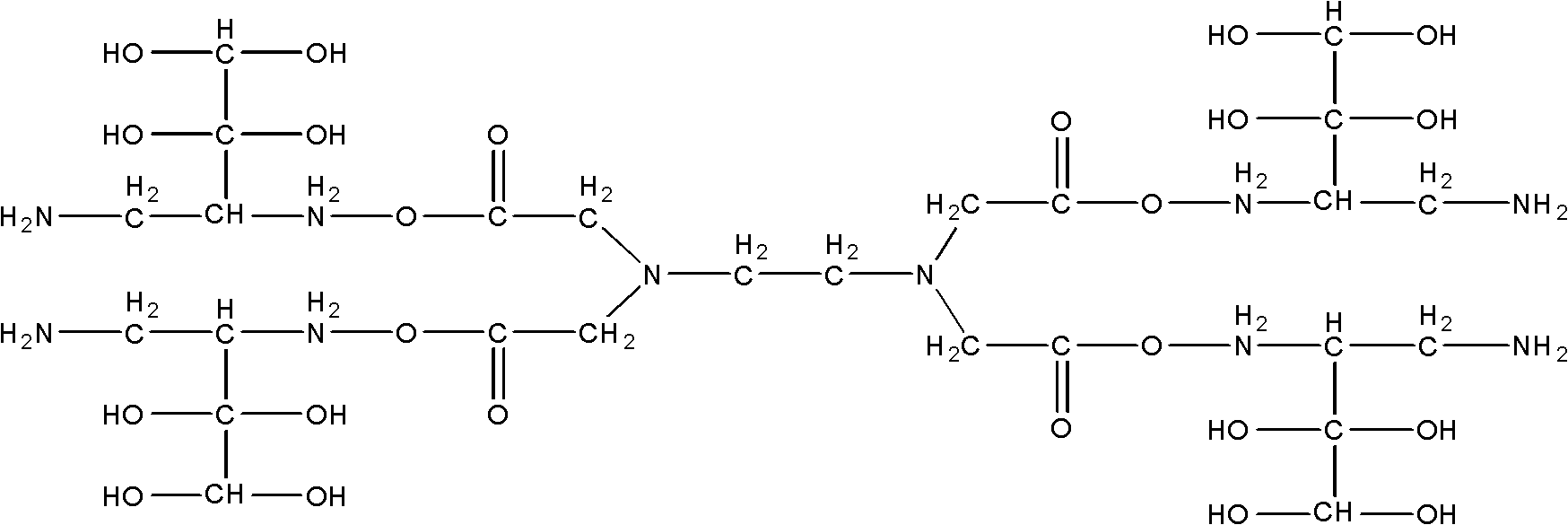

Image

Examples

Embodiment 1

[0025] (1) Take 497g of ultrapure water with a resistance of 18MΩ, add 2.5g of FA / OI type surfactant and 0.5g of FA / O II type chelating agent while stirring, and get a pH value of 6.7 after stirring evenly, which is approximately neutral Water-soluble surface cleaner.

[0026] (2) The semiconductor indium antimonide wafer after alkaline chemical mechanical polishing is quickly polished and cleaned for 30 s with the cleaning solution obtained in step (1) at a flow rate of 1000 ml / min and a pressure of its own weight.

[0027] (3) be 18MΩ ultrapure water 499.5g to dilute corrosion inhibitor benzotriazole 0.5g with resistance, be 1000ml to the indium antimonide wafer after step (2) cleaning rapidly with the benzotriazole solution after dilution / min, polishing and cleaning for 30s under the condition of self-weight pressure.

[0028] (4) Rinse the indium antimonide wafer cleaned in step (3) for 30 seconds with ultrapure water with a resistance of 18 MΩ under the conditions of ze...

Embodiment 2

[0031] (1) get the ultrapure water 2054g that resistance is 18MΩ, add surfactant O while stirring π -10 42g and 38g of FA / O II type chelating agent, after stirring evenly, the pH value is 6.9 and is approximately neutral water-soluble surface cleaning solution.

[0032] (2) The semiconductor indium antimonide wafer after alkaline chemical mechanical polishing was quickly polished and cleaned for 80 seconds with the cleaning solution obtained in step (1) at a flow rate of 1600 ml / min and a pressure of 0.01 atmosphere.

[0033] (3) be the ultrapure water 2096g dilution hexamethylenetetramine corrosion inhibitor 38g of 18M Ω with resistance, quickly to the indium antimonide wafer after step (2) cleaning at zero with the hexamethylenetetramine solution after dilution Polishing and cleaning for 80s under the conditions of pressure (self-weight pressure) and flow rate of 1600ml / min.

[0034] (4) Rinse the indium antimonide wafer cleaned in step (3) for 80 seconds with ultrapure wat...

Embodiment 3

[0037](1) Take 5643.56g of ultrapure water with a resistance of 18MΩ, add 12.42g of surfactant O-202 and 212.42g of FA / O II type chelating agent while stirring, and get a pH value of 7.3 after stirring evenly, which is approximately neutral. Non-toxic surface cleaner.

[0038] (2) Quickly use the cleaning liquid obtained in step (1) to polish and clean the semiconductor indium antimonide wafer after alkaline chemical mechanical polishing for 130 seconds under the conditions of a flow rate of 2800 ml / min and a pressure of 0.005 atmospheres.

[0039] (3) Dilute the benzotriazole corrosion inhibitor 212.42g with the ultrapure water 5855.98g of 18MΩ with resistance, carry out the indium antimonide wafer after step (2) cleaning rapidly with the flow rate of benzotriazole solution after dilution Polishing and cleaning for 130s under the conditions of 2800ml / min and zero pressure (self-weight pressure).

[0040] (4) Using ultrapure water with a resistance of 18 MΩ at zero pressure (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com