Patents

Literature

49 results about "Tetrachlorophthalic anhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetrachlorophthalic anhydride is a cyclic dicarboxylic anhydride that is phthalic anhydride chlorinated at the 4-, 5-, 6- and 7-positions. It has a role as a cross-linking reagent. It has a role as a cross-linking reagent.

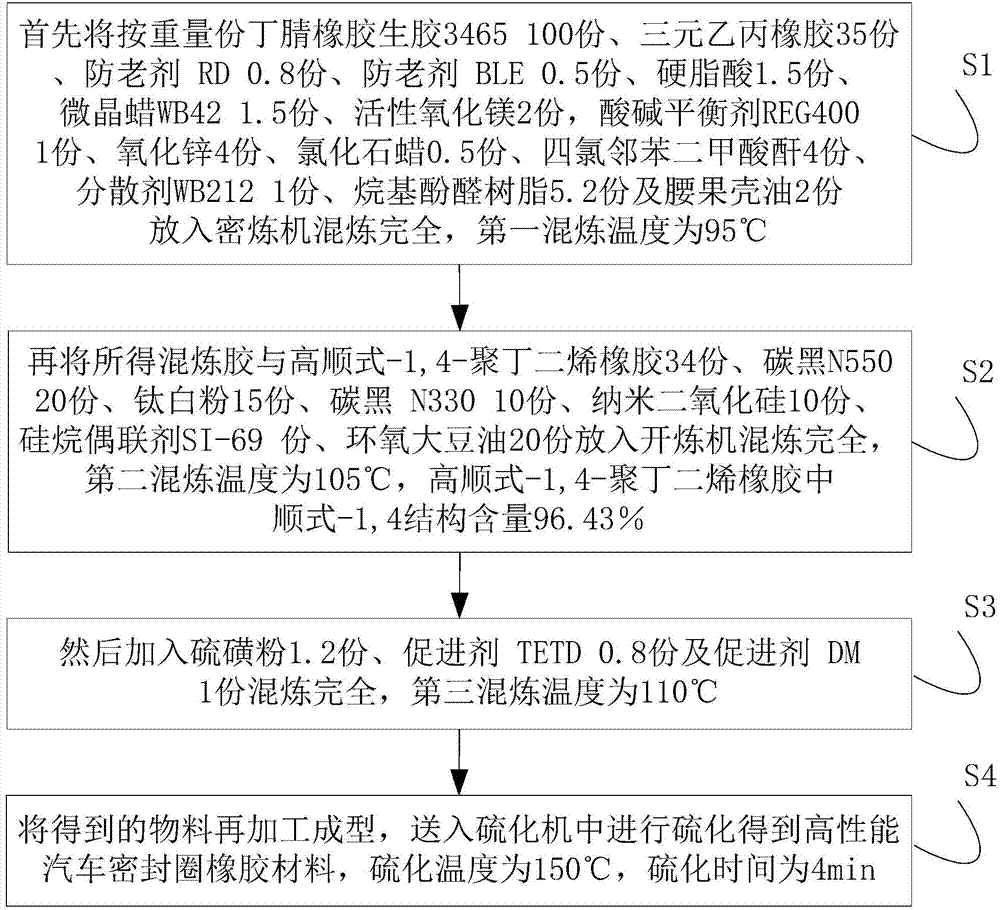

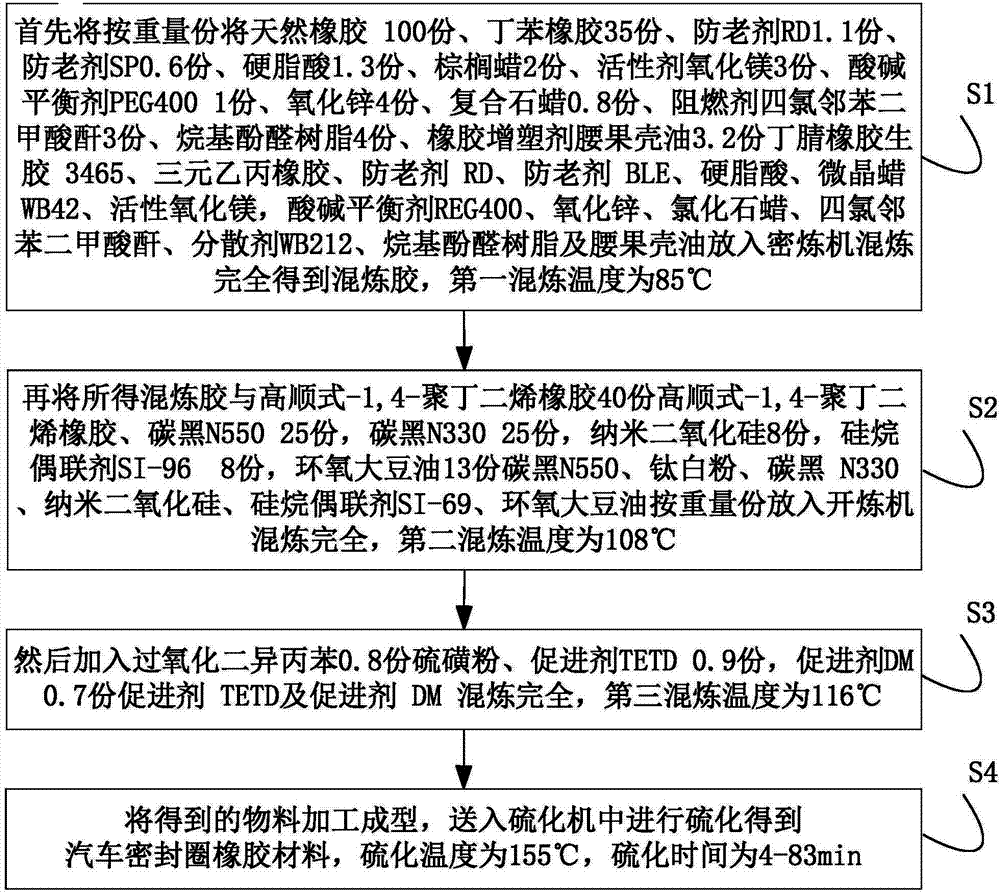

High-performance automobile seal ring rubber material and preparation technique thereof

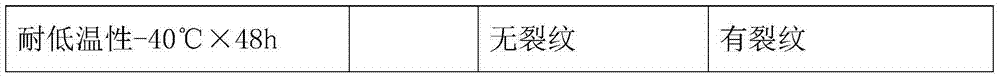

The invention discloses a high-performance automobile seal ring rubber material which is prepared from the following raw materials in parts by weight: unvulcanized nitrile-butadiene rubber 3465, high cis-1,4-polybutadiene rubber, ethylene propylene diene monomer rubber, anti-aging agent RD, anti-aging agent BLE, stearic acid, sulfur powder, microcrystalline wax WB42, activator magnesium oxide, acid-base balancing agent PEG 400, zinc oxide, chlorinated paraffin, tetrachlorophthalic acid anhydride, dispersing agent WB212, alkyl phenol aldehyde resin, rubber plastizing agent cashew nut shell oil, carbon black N550, titanium white, carbon black N330, nano silicon dioxide, silane coupling agent Si-96, epoxy soybean oil, accelerator TETD (tetraethyl thiuram disulfide) and accelerator DM. The invention also discloses a preparation technique of the high-performance automobile seal ring rubber material. The high-performance automobile seal ring rubber material has the advantages of excellent abrasion resistance, excellent aging resistance, excellent high / low temperature resistance, high hardness, favorable tear resistance, favorable processability and low cost.

Owner:安徽宁国尚鼎橡塑制品有限公司

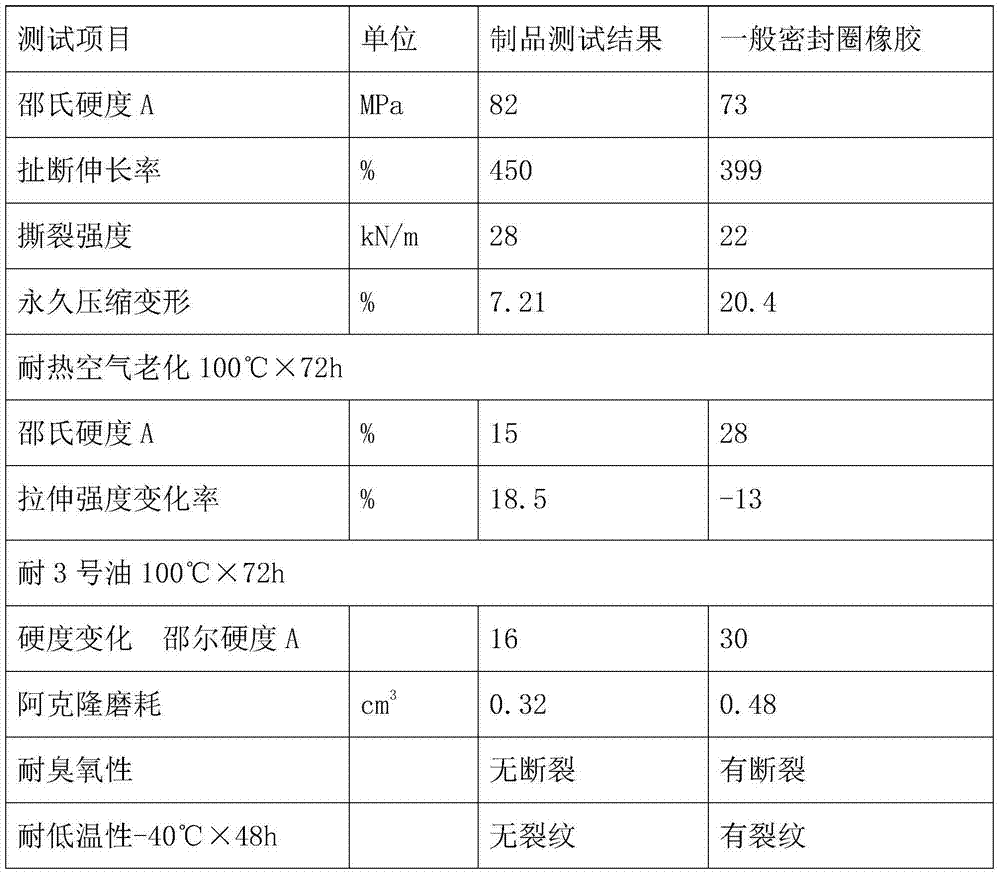

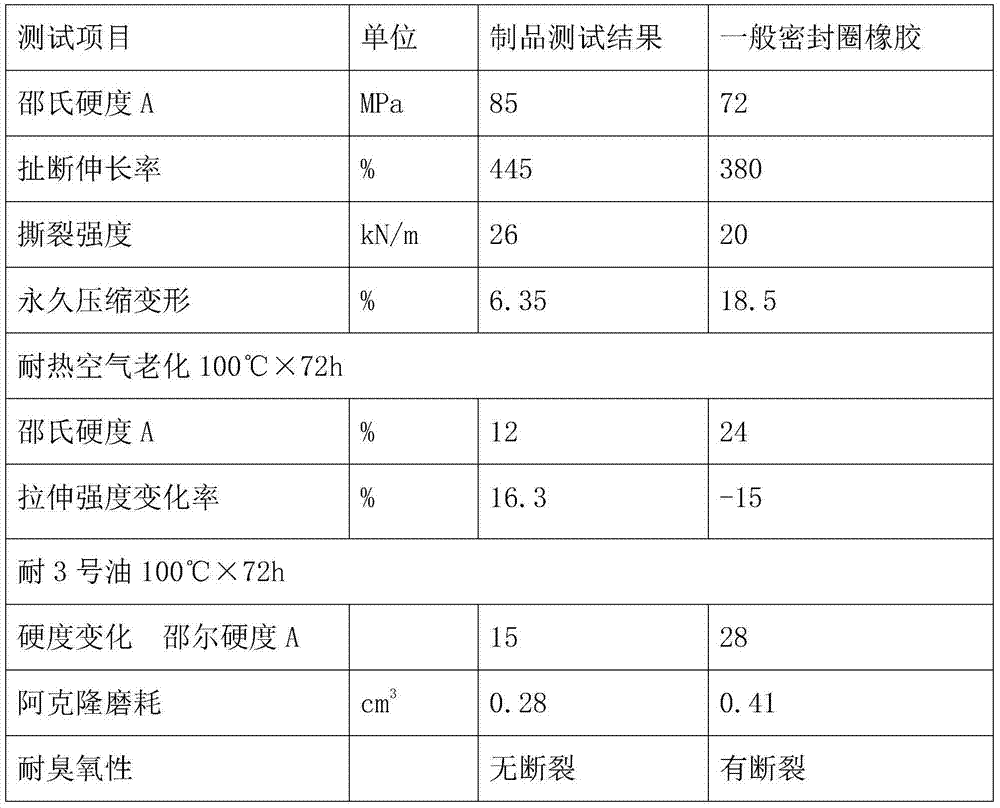

Preparation process of rubber material for seal ring of automobile

The invention discloses a preparation process of a rubber material for a seal ring of an automobile. The preparation process comprises the following steps: placing natural rubber, styrene-butadiene rubber, an anti-aging agent RD, an anti-aging agent SP, stearic acid, carnauba wax, an active agent magnesium oxide, an acid-base balancing agent PEG400, zinc oxide, composite paraffin, a flame retardant tetrachlorophthalic anhydride, alkyl phenolic resin, a rubber plasticizer cashew nut oil into an internal mixer and completely mixing to obtain mixed rubber; then placing mixed rubber, high cis-1,4-polybutadiene rubber, carbon black N550, carbon black N330, nano-silica, a silane coupling agent SI-96 and epoxy soybean oil in parts by weight into an open mill and completely mixing; and then adding dicumyl peroxide, an accelerator TETD, and an accelerator DM and completely mixing, processing and molding the obtained material, sending to a vulcanizing machine for vulcanizing to obtain the rubber material for the seal ring of the automobile. The product prepared from the rubber material disclosed by the invention has the advantages of heat resistance, aging resistance, good weather resistance, high hardness, good tear resistance performance, low cost, good processing performance.

Owner:安徽宁国尚鼎橡塑制品有限公司

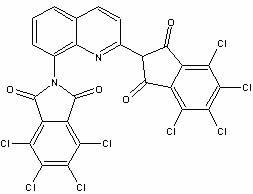

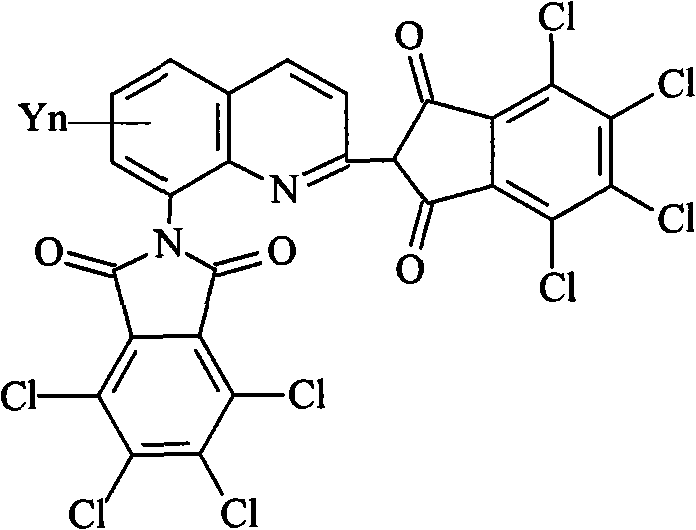

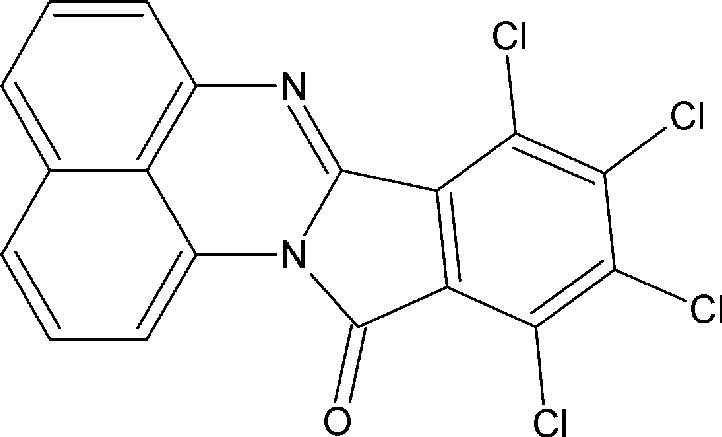

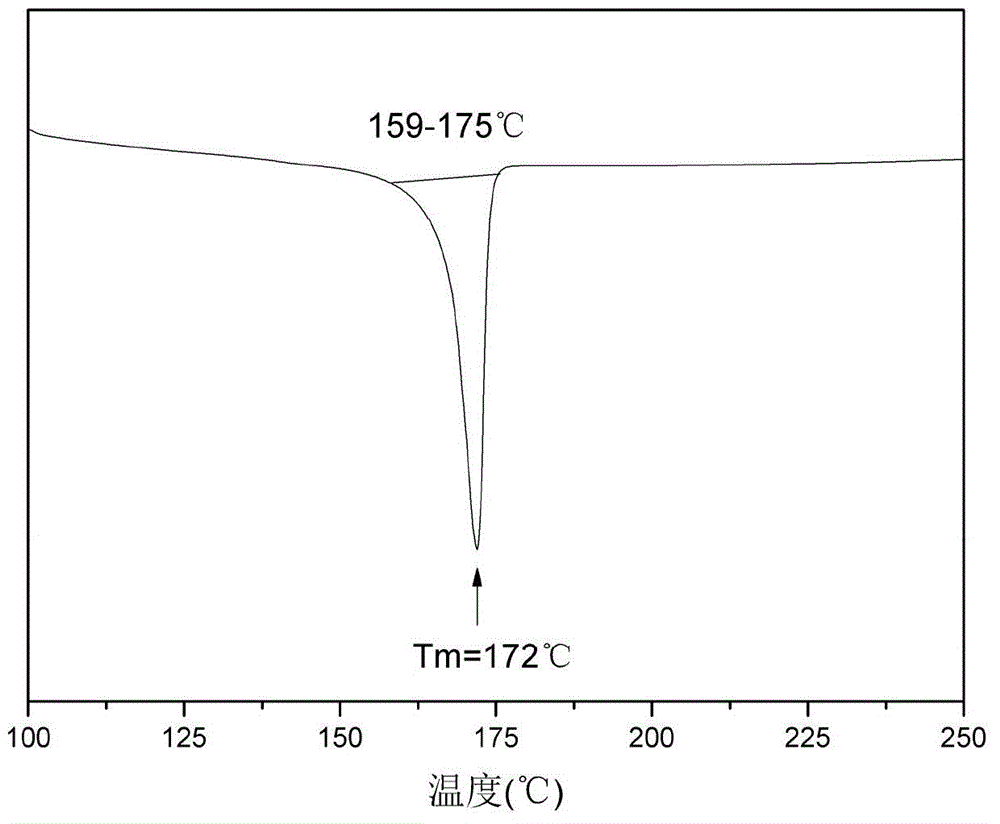

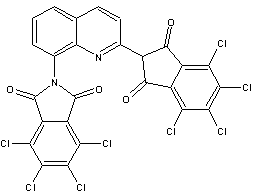

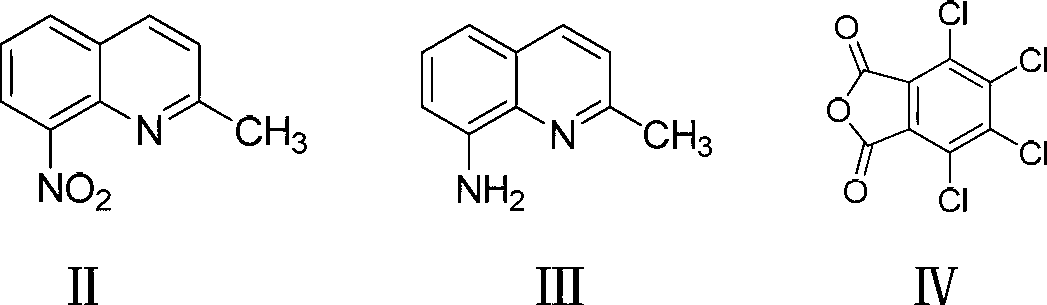

Preparation method of pigment yellow 138

The invention discloses a preparation method of pigment yellow 138, which comprises the following steps: synthesis: adding benzoic acid into a reactor, sequentially adding tetrachlorophthalic anhydride and 8-aminoquinaldine, heating to 140-160 DEG C, reacting for 1-3 hours, heating to 180-220 DEG C, reacting for 2-4 hours, cooling the reaction product to 130 DEG C, pouring into a previously prepared sodium hydroxide solution, reacting for 10-60 minutes, filtering, washing and drying to obtain a crude pigment yellow 138 product; and preparation of pigment: adding an organic solvent and the crude pigment yellow 138 product into a reactor, adding sodium methoxide or methanol solution thereof, heating to 40-80 DEG C, carrying out salification reaction for 1-3 hours, neutralizing by adding acid, precipitating the pigment in the form of molecules, distilling out low-boiling-point substances, heating to 80-150 DEG C, keeping the temperature for 1-6 hours to obtain slurry, filtering the slurry, washing, drying and pulverizing to obtain the pigment yellow 138. The invention has the advantages of high utilization ratio of raw materials, low environmental pollution, high product quality and favorable economic benefit.

Owner:南通龙翊新材料科技有限公司

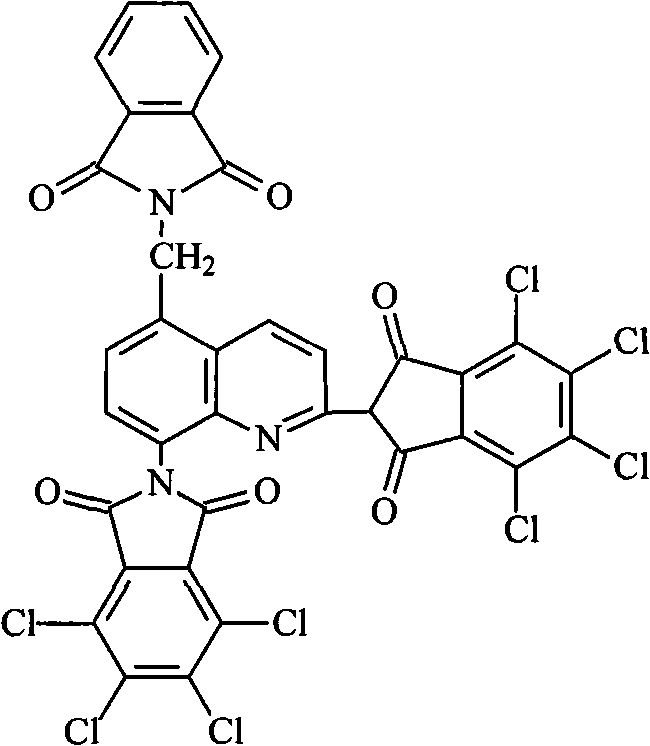

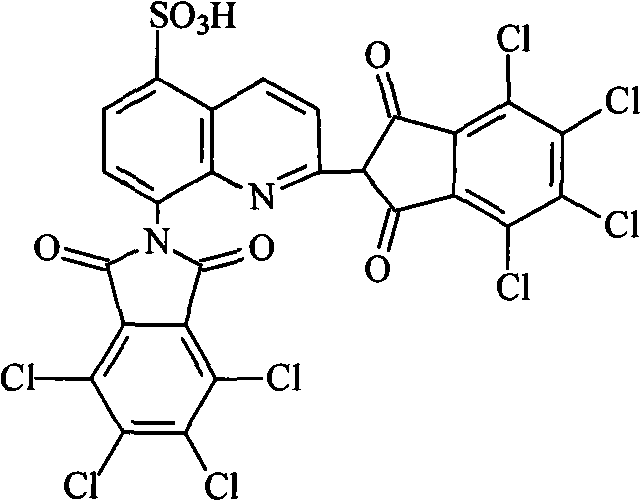

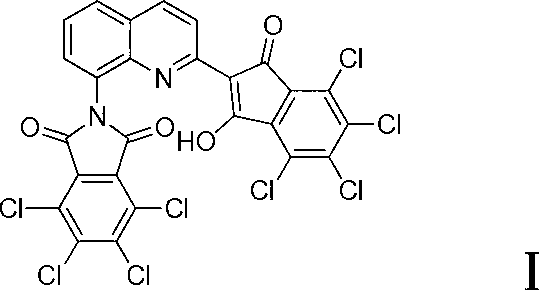

Yellow pigment for color liquid crystal filter and preparation method thereof

InactiveCN101948632AHigh transparencyIncrease brightnessOrganic dyesStructural formulaBrightness perception

The invention relates to a yellow pigment for a color liquid crystal filter, which consists of at least two compounds. The compounds include a compound I and a compound II. A preparation method for the pigment comprises the following procedures of: A, synthesizing a yellow pigment crude product of which the structural formula is the compound I by 2-methyl-8-aminoquinoline and tetrachlorophthalic anhydride serving as basic raw materials; and B, performing pigment processing on the yellow pigment crude product. The pigment processing procedure comprises the following steps of: 1, pre-grinding the yellow pigment crude product; and 2, performing pigment postprocessing on the pre-ground yellow pigment crude product. The yellow pigment prepared by the method has high transparency, brightness and contrast, and has good fluidity in a liquid dispersoid for coloring the color filter.

Owner:SHANGHAI JIEHONG PIGMENT TECH DEV

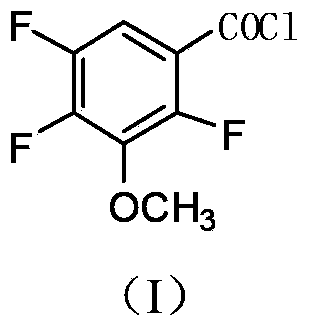

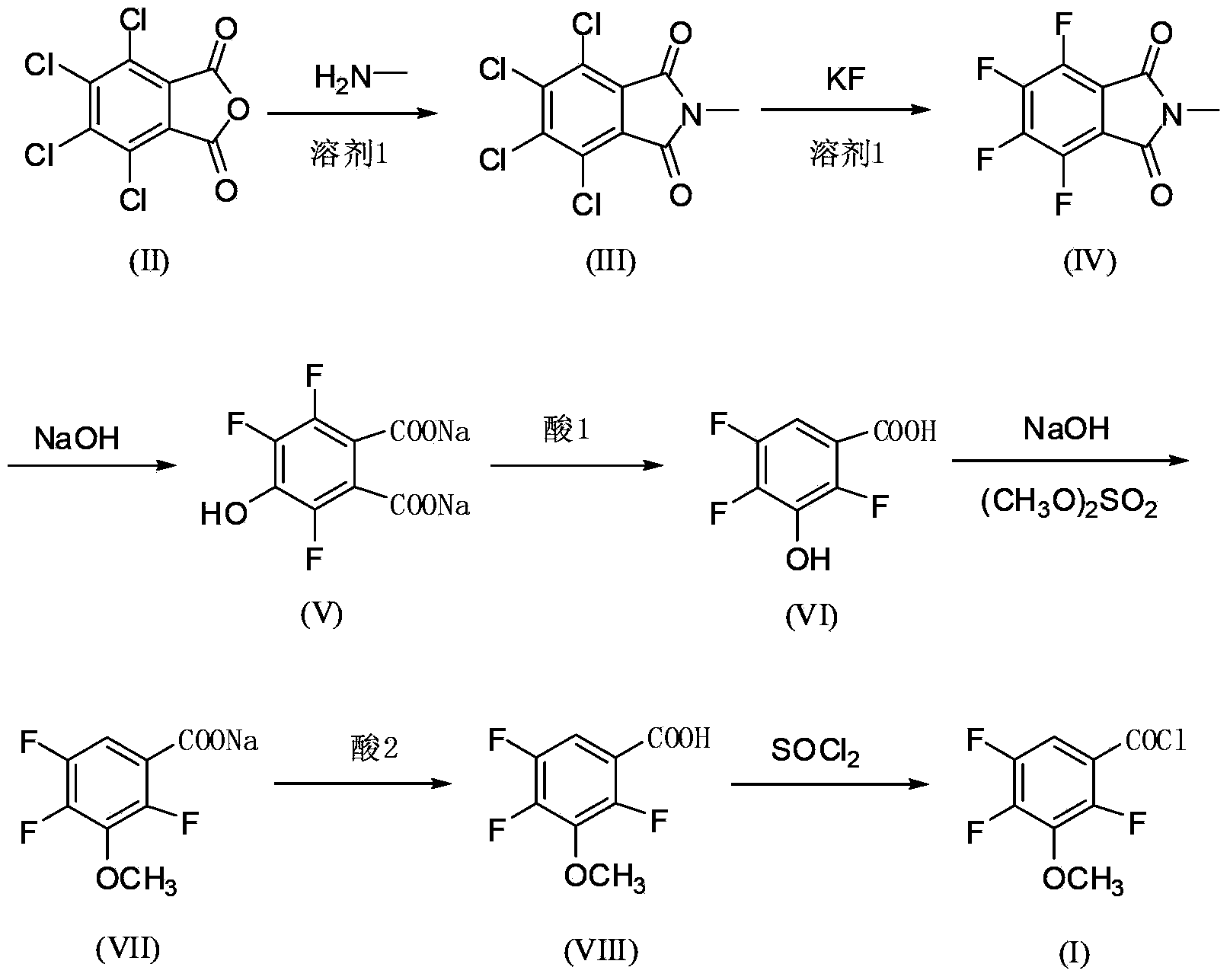

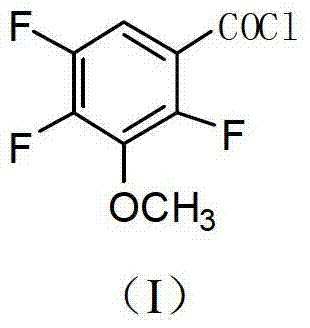

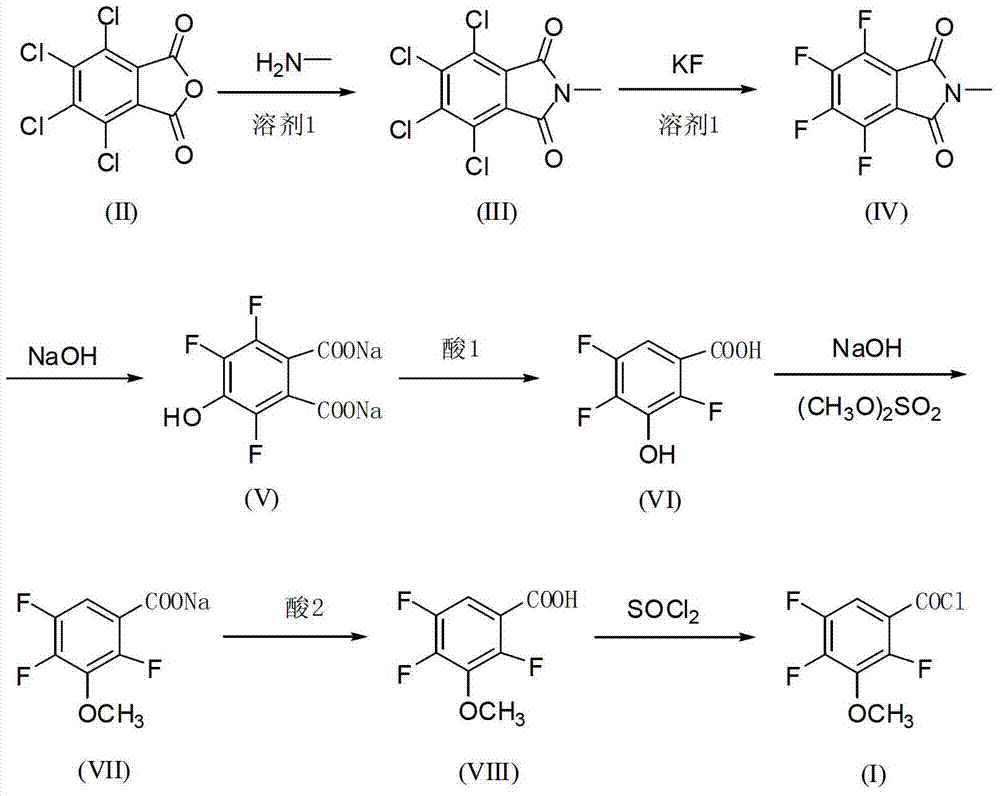

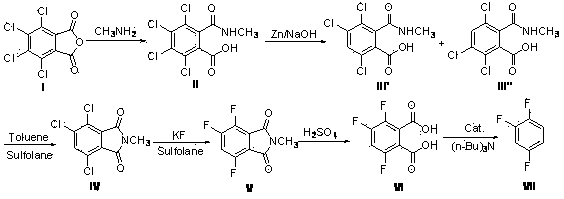

Industrial preparation method of 2,4,5-trifluoro-3-methoxybenzoyl chloride

ActiveCN103450013AAvoid pollutionSimple and fast operationOrganic compound preparationCarboxylic compound preparationN dimethylformamidePhthalate

The invention discloses an industrial preparation method of 2,4,5-trifluoro-3-methoxybenzoyl chloride. The industrial preparation method comprises the following steps: 1) using methylamine to react with tetrachlorophthalic anhydride to get N-methyl tetrachlorophthalimide; 2) enabling the N-methyl tetrachlorophthalimide obtained in the step 1) to react with an alkali metal fluoride to get N-methyl tetrafluorophthalimide; 3) enabling the N-methyl tetrafluorophthalimide obtained in the step 2) to perform mixed reaction with sodium hydroxide to get 2,4,5-trifluoro-3-hydroxy sodium phthalate and then performing decarboxylation and acidification to get 2,4,5-trifluoro-3-hydroxybenzoic acid; 4) enabling the 2,4,5-trifluoro-3-hydroxybenzoic acid obtained in the step 3) to react with dimethyl sulfate to get 2,4,5-trifluoro-3-methoxybenzoic acid sodium and then acidifying to get 2,4,5-trifluoro-3-methoxybenzoic acid; 5) enabling the 2,4,5-trifluoro-3-methoxybenzoic acid obtained in the step 4) to react with thionyl chloride and N,N-dimethylformamide to get the 2,4,5-trifluoro-3-methoxybenzoyl chloride.

Owner:YUEYANG YETOP FINE CHEM

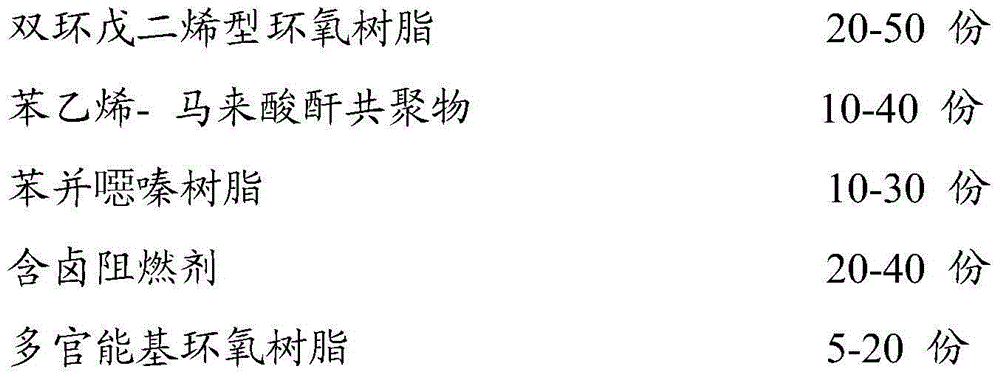

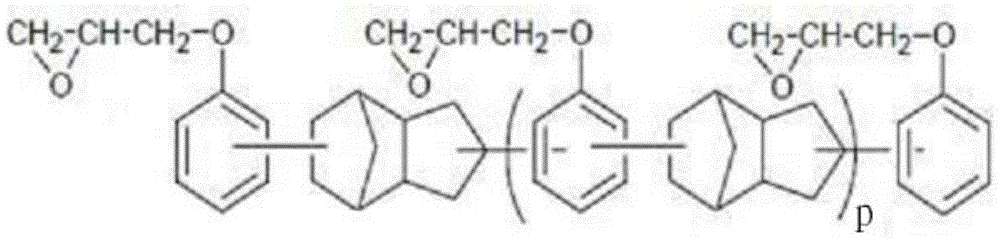

Halogen resin composition and application thereof

The invention relates to a halogen resin composition and an application thereof. The halogen resin composition is prepared from the following raw materials in parts by weight: 20-50 parts of dicyclopentadiene epoxy resin, 10-40 parts of styrene-maleic anhydride copolymer, 10-30 parts of benzoxazine resin, 20-40 parts of halogenous fire retardant, and 5-20 parts of multi-functional group epoxy resin, wherein the halogenous fire retardant is at least one of the decabrominated dipheny ethane, tri(tribromophenyl) triazine, brominated polyolefin, brominated polystyrene, ethyl-di(tetrabromobenzene o-dicarboximide), decabromodiphenyl ether, hexabromocyclododecane, eight bromo ether, tetrachlorophthalic anhydride, Hexachlorocyclopentadiene and perchlorinated cyclopentyl decane. A metal foil substrate made of the halogen resin composition has the advantages of low dielectric constant and dielectric loss, excellent heat resistance, good machinability and low swelling coefficient and can be well applied to a composite board.

Owner:GUANGZHOU GRACE ELECTRON CORP

Preparation technology of stroller seat fabric

The present invention provides a preparation technology of a stroller seat fabric, and relates to the technical field of seat fabrics. The preparation technology comprises the following steps of material preparation; pretreatment including the steps of respectively soaking white yarns and terry yarns in a soak solution, which comprises 3-4 parts of polyvinyl alcohol, 5-6 parts of polyacrylic acid, 1-3 parts of alkyl benzene sulfonic acid and 100-200 parts of water, for the first time for 5-6 hours, then pulling out the white yarns and terry yarns for secondary soak in another soak solution, which comprises, by weight, 1-2 parts of chlorendic acid, 3-4 parts of gold potassium chloride, 5-6 parts of tetrachlorophthalic anhydride, and 100-150 parts of water, in the temperature of 60-80 DEG C, and then pulling out and drying the white yarns and terry yarns after being soaked for two times; dyeing; weaving, fabric cutting, plaiting, needle detection and cropping; and composition. The stroller seat fabric has good flame-retardant effect, good environmental protection property, good elasticity, good hand feeling and strong toughness, and is not easy to bend.

Owner:安徽博朗凯德织物有限公司

Corrosion resistant sealing material and preparation method thereof

The invention discloses a corrosion resistant sealing material and a preparation method thereof. The corrosion resistant sealing material is prepared from the following raw materials in parts by weight: 80-85 parts of polyacrylate rubber, 35-38 parts of butadiene styrene rubber, 8-10 parts of carbon black, 5-7 parts of epoxidized soybean oil, 0.4-0.6 part of aluminium hydroxide, 1-3 parts of nano mica, 1-3 parts of an active agent magnesium oxide, 10-12 parts of a fire retardant tetrachlorophthalic anhydride, 1-3 parts of sulphur, 1-3 parts of calcium hydroxide, 6-8 parts of an anti-aging agent 4010 NA, 1-3 parts of an acid-base balance agent PEG 400, 2.2-2.6 parts of zinc oxide, 4-8 parts of calcium stearate, 0.6-0.9 part of an accelerant TMTD, 3-5 parts of an accelerant CZ, 1-2 parts of cobalt naphthenate, 2-4 parts of fluororubber and 2-5 parts of graphite powder.

Owner:SUZHOU TONGMING MACHINERY

Environmental-friendly long-lasting preservative packaging steel bucket

ActiveCN107353783AImprove anti-corrosion performanceLong lastingAnti-corrosive paintsEpoxy resin coatingsDefoaming AgentsBisphenol A

The invention discloses an environmental-friendly long-lasting preservative packaging steel bucket and a preparation method thereof. The inner wall of the packaging steel bucket is coated by an anti-corrosion coating, and the anti-corrosion coating comprises the following components in parts by weight: a bisphenol A epoxy resin, an organic silicon modified epoxy resin, nano titanium dioxide, kieselguhr, tetrachloro phthalic anhydride, paraffin, propylene glycol, talcum powder, ethylene glycol, a thickening agent, a coupling agent, a surfactant, a defoaming agent and deionized water. As the inner wall and the surface of the packaging steel bucket are coated by the special anti-corrosion coating, the anti-corrosion property of the packaging steel bucket is effectively improved, the anti-corrosion coating is non-toxic and smellless, green and environmental-friendly, long-lasting in effect, low in production cost and good in economic benefit.

Owner:TAICANG DATIAN MINGBO PACKING CONTAINER CO LTD

Novel process for producing pigment yellow PY138

The invention discloses a novel process for producing pigment yellow PY138. The novel process comprises two steps, i.e. a condensation reaction step and a refining reflux step, wherein firstly tetrachlorophthalic anhydride and 2-methyl-8-aminoquinoline is added into a solvent to be heated to react, then after the decompression and distillation, the distilled gas is introduced into 98 percent sulfuric acid to be acid cooked, the acid cooked solution is hydrolyzed and filtered, then the filtrate is heated and press filtered in an alcohol solvent, the press filtered filter cake is dissolved, heated, stirred and thermally insulated in a reflux solvent, finally the solution is evaporated and refluxed, cooled, press filtered and dried to obtain the pigment yellow 138. In the process for preparing the pigment yellow 138, the raw material utilization rate is high, the production cost is lower than that of the prior art, the prepared pigment yellow 138 is high in purity, the color is bright, the coloring capability is high, the heat resistance, acid resistance and alkali resistance are more excellent compared with that available on the market, the environmental pollution is small, the production efficiency is high, and the novel process is suitable for the mass production.

Owner:滨海明昇化工有限公司

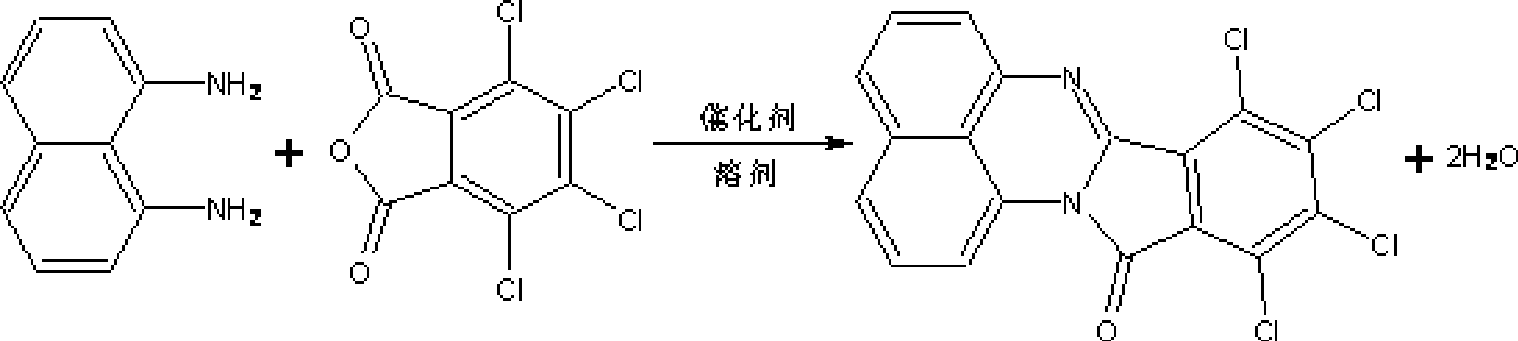

Process for producing solvent of red 135

ActiveCN101508849AAvoid separabilityAvoids the need for solvent recyclingOrganic chemistryAzo dyesOrganic solventSubstance amount

The invention relates to a method for preparing solvent red 135, belonging to the field of chemical engineering. Tetrachlorophthalic anhydride and 1, 8-naphthylenediamine which have the substance amount ratio being 1:1, aqueous hydrochloric acid solution with the mass concentration of 10-15%, polar organic solvent that can be mixed and dissolved with the water and non-ionic surface activity catalyst are mixed in a reaction device provided with stirring and reflow equipment, and then the mixture is stirred and heated up to a reflow state to react for 8-15h; after being filtered, filter mass is washed by clear water until the filtrate is neutral; at last, the solvent red 135 is obtained after being dried; the dosage of the aqueous hydrochloric acid solution is 10-20 times more than that of the 1, 8-naphthylenediamine, the dosage of the polar organic solvent is 1-50% of the total content of reaction medium, and the dosage of the catalyst is 0.01-2% of the total content of reaction medium. The invention has the advantages of good product quality of a solvent method and low cost of an aqueous phase method.

Owner:NANTONG LONGXIANG NEW MATERIALS TECH CO LTD

Unsaturated polyester resin with excellent insulating property, and preparation method thereof

The present invention discloses an unsaturated polyester resin with excellent insulating property, wherein the raw materials comprise maleic anhydride, m-phthalic anhydride, tetrachlorophthalic anhydride, a D-33 monomer, pyrogallol, hydroquinone, cobalt naphthenate, styrene, phosphate melamine, methyl ethyl ketone peroxide, a silane coupling agent KH-550, nanometer titanium dioxide, nanometer alumina, micro-nano-fiber, raw ramie, palm fiber, a modified filler, ethylene glycol, diethylene glycol and propylene glycol. The present invention further provides a preparation method of the unsaturated polyester resin with excellent insulating property. The prepared unsaturated polyester resin of the present invention has excellent insulating property.

Owner:滁州常源新材料有限公司

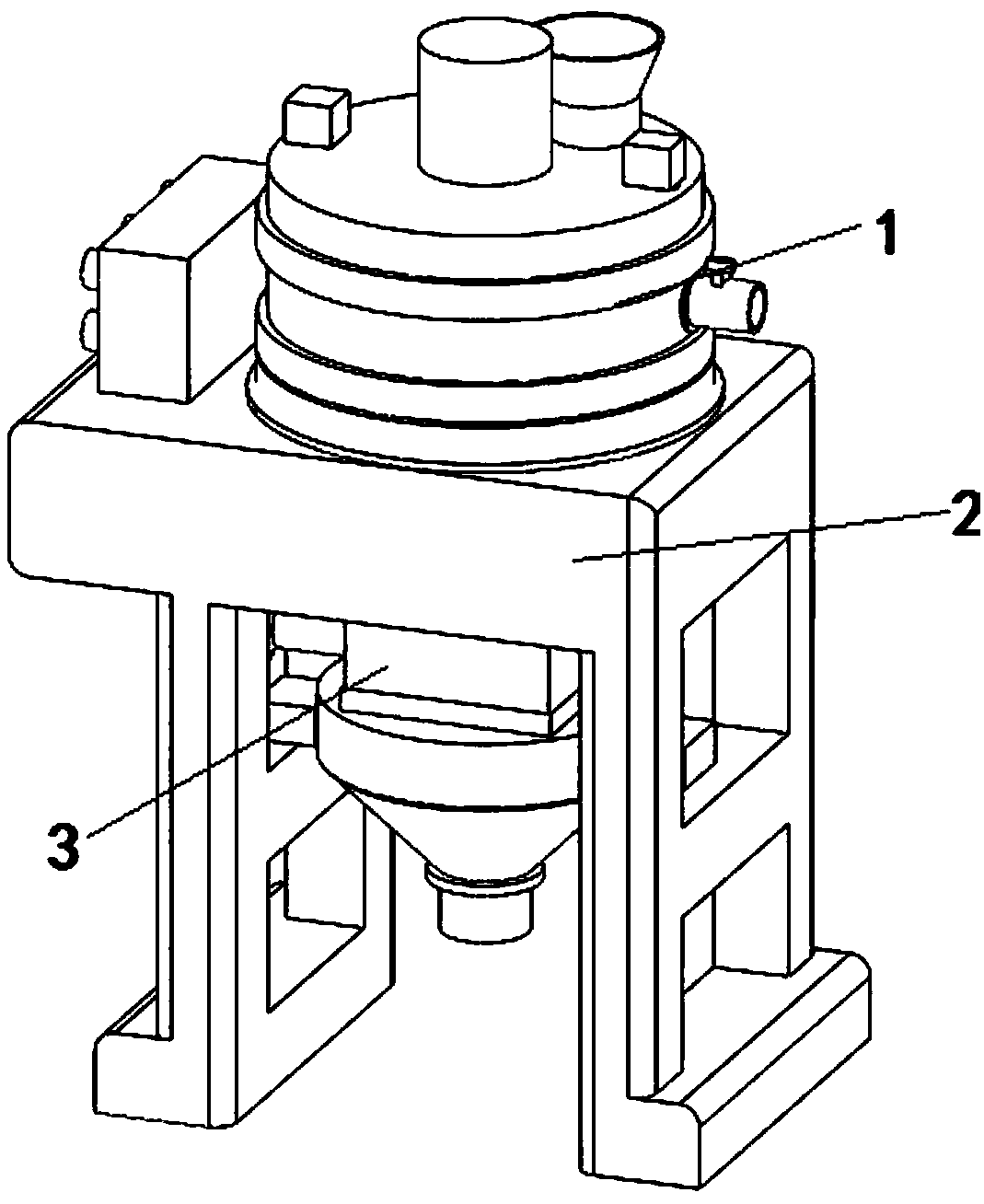

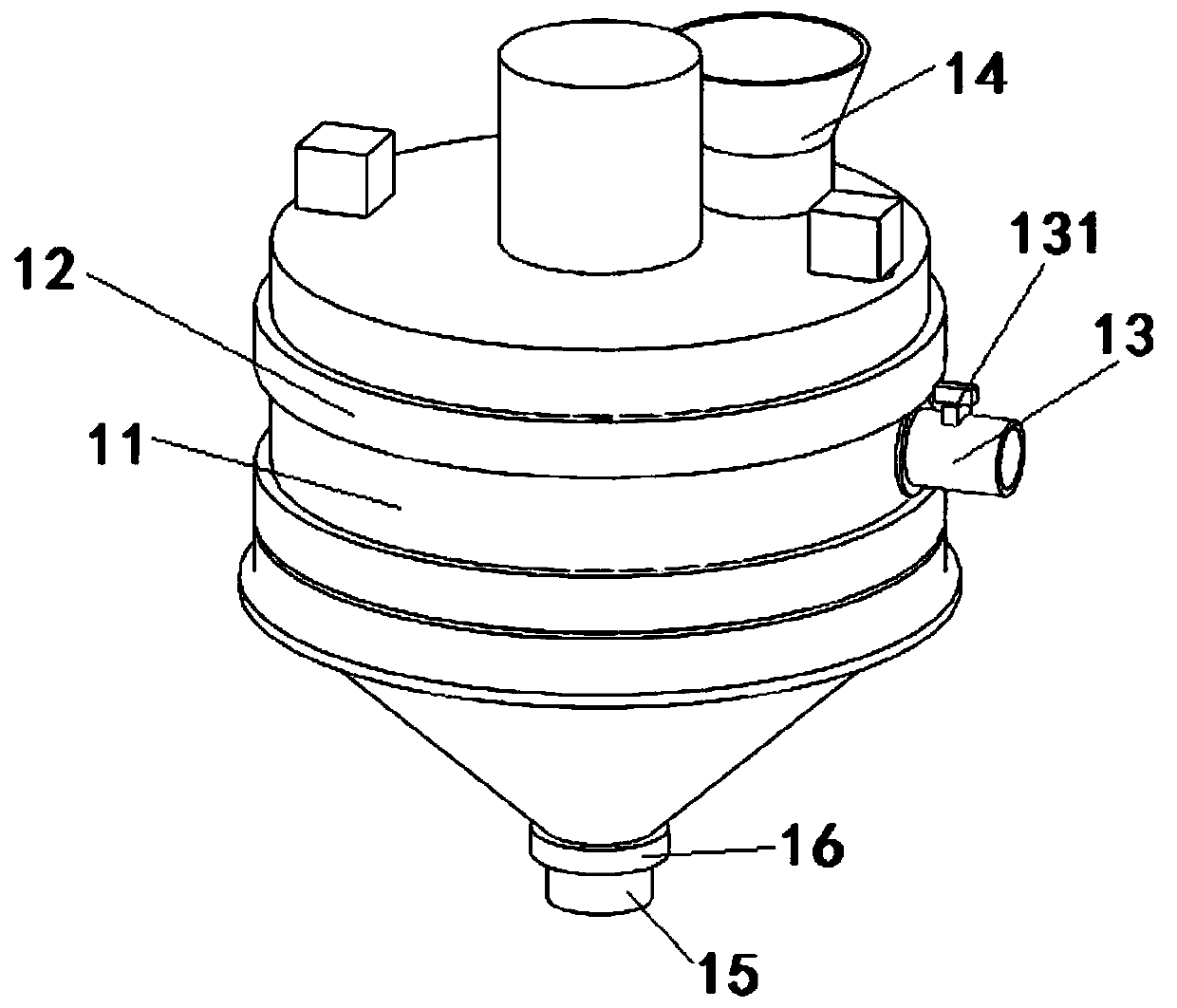

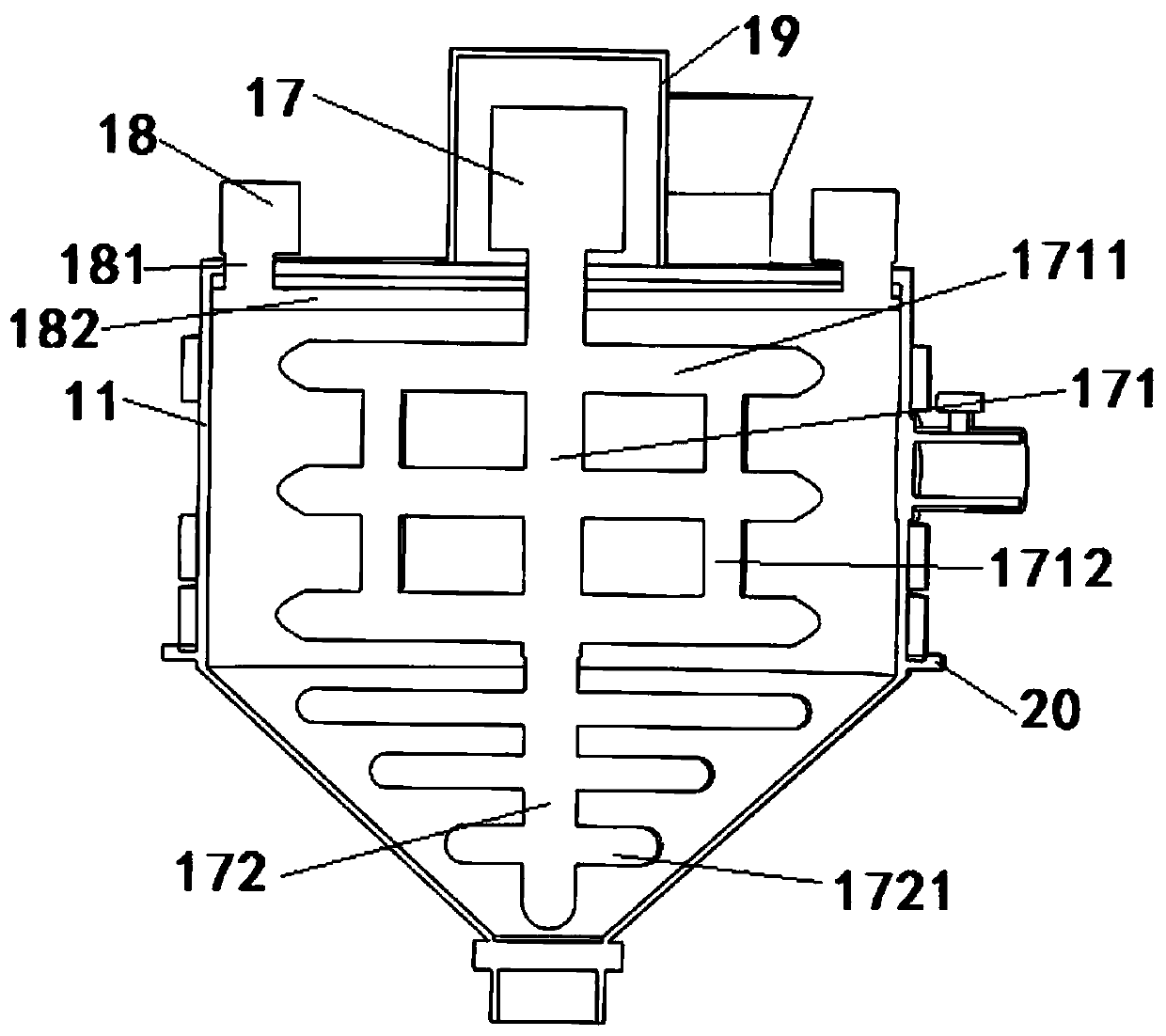

Polyester resin as well as stirring reactor and application thereof

ActiveCN108676154AGood weather resistanceImprove flame retardant performanceChemical/physical/physico-chemical stationary reactorsPolyester coatingsWater basedCross-link

The invention provides a polyester resin as well as a stirring reactor and application thereof. The polyester resin is prepared from the following raw materials: tetrabromophthalic anhydride, chlorendic anhydride, tetrachlorophthalic anhydride, neopentyl glycol, polycarbonate diol, a tin catalyst, a cross-linking monomer, acetone, triethylamine and deionized water. A water-based coating is prepared from the polyester resin, a pigment, a filler, a film formation additive, a wetting dispersant, a polyether defoaming agent, a flatting agent, a cobalt salt dryer, an antibacterial agent and deionized water. The polyester resin has excellent water resistance, abrasion resistance, weather resistance and flame resistance. A polyester resin stirring reactor is capable of more uniformly stirring theraw materials of the polyester resin, directly filtering the mixed polyester resin and improving the quality of the polyester resin. When the polyester resin is applied to a water-based coating, thewater resistance, the abrasion resistance, the weather resistance and the flame resistance of the water-based coating can be improved; and the comprehensive properties of the water-based coating can be improved.

Owner:安徽恒隆新材料有限公司

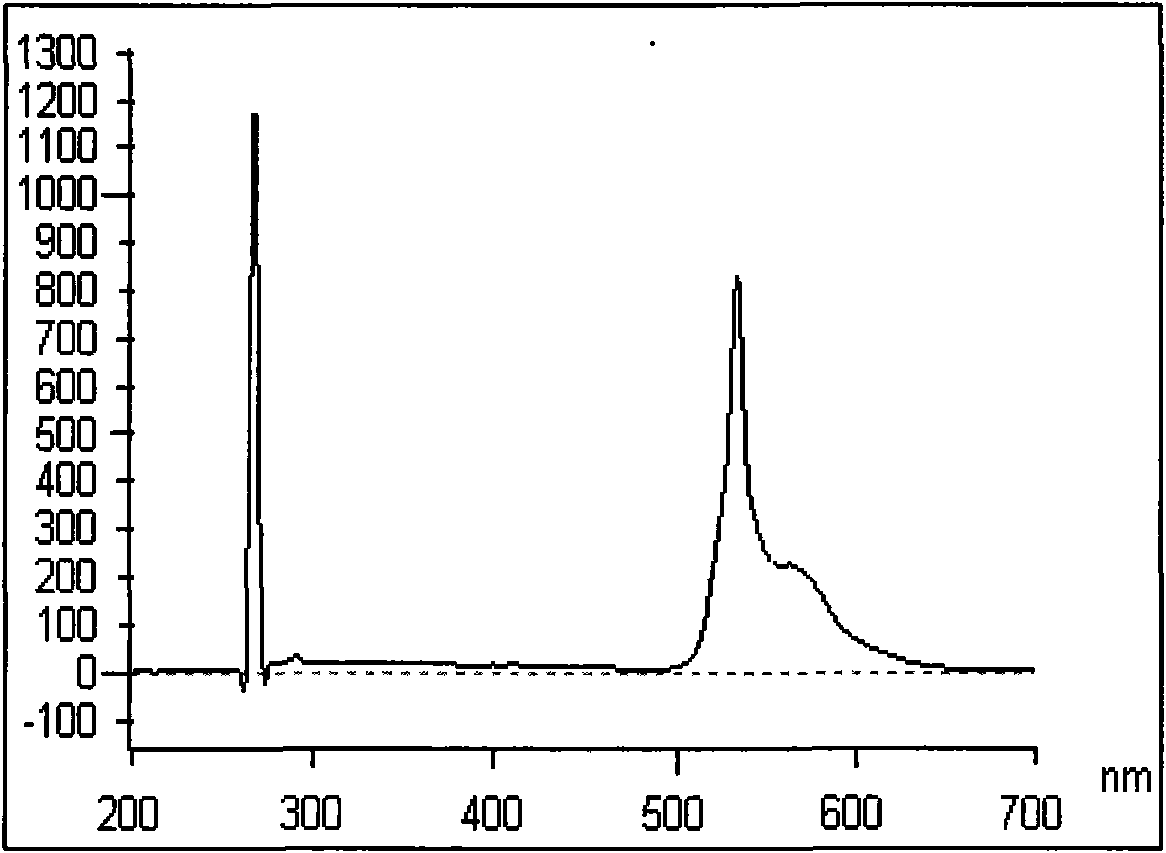

Solid magnetic and fluorescent organic compound of 4-chlorobiindenylisolactone and synthesis method thereof

InactiveCN101591317AFunctionalReduce lossOrganic chemistryOrganic/organic-metallic materials magnetismSodium methoxideSynthesis methods

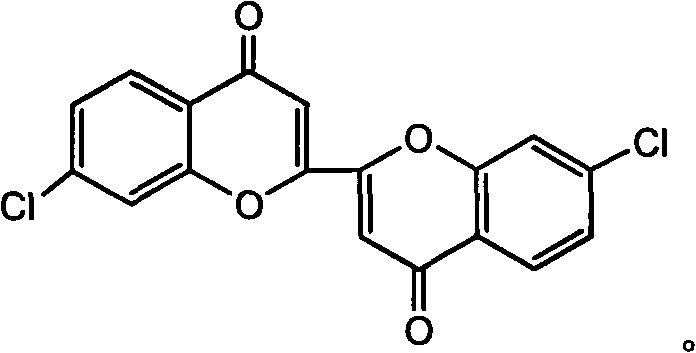

The invention discloses a solid magnetic and fluorescent difunctional organic compound of 4-chlorobiindenylisolactone and a synthesis method thereof. The method synthesizes the 4-chlorobiindenylisolactone of the structural formula below by using tetrachlorophthalic anhydride and succinic acid as raw materials. The synthesis method comprises the following steps that: the tetrachlorophthalic anhydride and the succinic acid are mixed to form an intermediate for synthesizing the 4-chlorobiindenylisolactone; and then the intermediate is used to synthesize the 4-chlorobiindenylisolactone in the presence of a sodium methoxide catalyst. The 4-chlorobiindenylisolactone provided by the invention is a difunctional organic compound having fluorescent and magnetic functions and can be used in the fields of fluorescent marks and fluorescent recognition as well as the fields of new-generation high storage capacity information materials, insulating materials, light bandwidth microwave absorbent, magnetic sensors, low-loss high-frequency microwave communication apparatuses, magnetically sealing apparatuses, magnetic shielding, magnetic separation and microwave communication.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

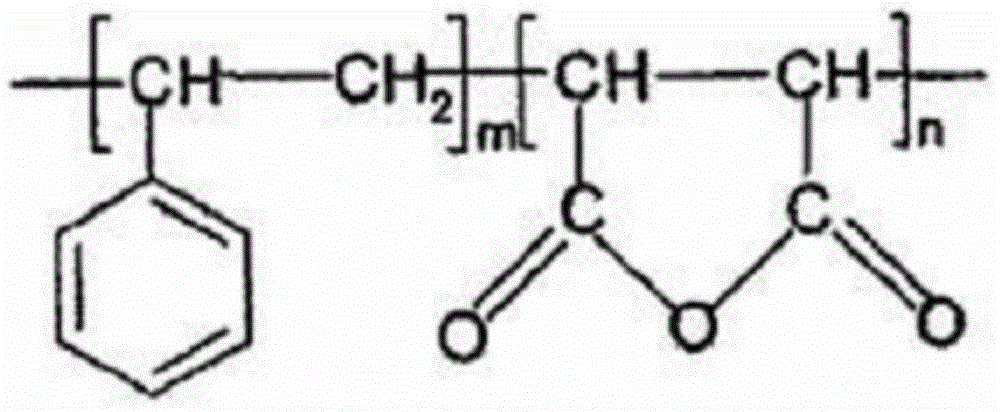

Flame retardant type high polymer emulsion and preparation method thereof

InactiveCN104293057AImprove flame retardant performanceGood physical propertiesFireproof paintsMonocarboxylic acid ester polymer adhesivesPolymer scienceChlorobenzene

The invention discloses flame retardant type high polymer emulsion and a preparation method thereof. The flame retardant type high polymer emulsion consists of the following components in percentage by weight: 75-90% of high polymer emulsion, 3-10% of a flame retardant polymer and 7-15% of ammonium polyphosphate, wherein the high polymer emulsion is pure acrylic emulsion, styrene-acrylic emulsion, silicone acrylic emulsion or acetic styrene-acrylic emulsion; the flame retardant polymer is vinyl chloride-2-ethyl hexyl acrylate, N-(2,4,6-tribromophenyl) maleimide, tetrachlorophthalic anhydride, propylene alkyl (aryl) phosphorothioate or pentachlorobenzene acrylate. The preparation method of the flame retardant type high polymer emulsion comprises the following steps: mixing and uniformly stirring the high polymer emulsion, the flame retardant polymer and ammonium polyphosphate to obtain the flame retardant type high polymer emulsion. Due to the synergistic effects of the flame retardant polymer and ammonium polyphosphate, the flame retardant type high polymer emulsion disclosed by the invention has good flame retardant effect, so that the V-0 flame retardant level or the V-1 flame retardant level can be achieved by only finally using 10-25% of the flame retardant.

Owner:SHANGHAI INST OF TECH

PIA (meta-phthalic acid)/nanometer titania modified alkyd resin and preparation method thereof

The invention discloses a PIA (meta-phthalic acid) / nanometer titania modified alkyd resin and a preparation method thereof. The PIA / nanometer titania modified alkyd resin comprises the following raw materials: acrylic acid, methylacrylic acid, methyl methacrylate, vinyltriethoxysilane, nanometer titania, epoxy resin, castor oil, trimethylolpropane, 2,2,4-trimethyl-1,3-pentanediol, tetrachlorophthalic anhydride, PIA waste, trimellitic anhydride, triethylamine, ethyl eneglycol monobutyl ether, propylene glycol mono-n-butyl ether, lauric acid, catalytic auxiliary, benzoyl peroxide, dimethylbenzene and water. The PIA / nanometer titania modified alkyd resin provided by the invention is good in water resistance, high in hardness and excellent in comprehensive performance; the PIA waste is used, so that the cost is saved.

Owner:ANHUI JINDUN PAINT

1,3,5-tris(4-aminophenylmercapto)benzene as well as preparation method and application thereof

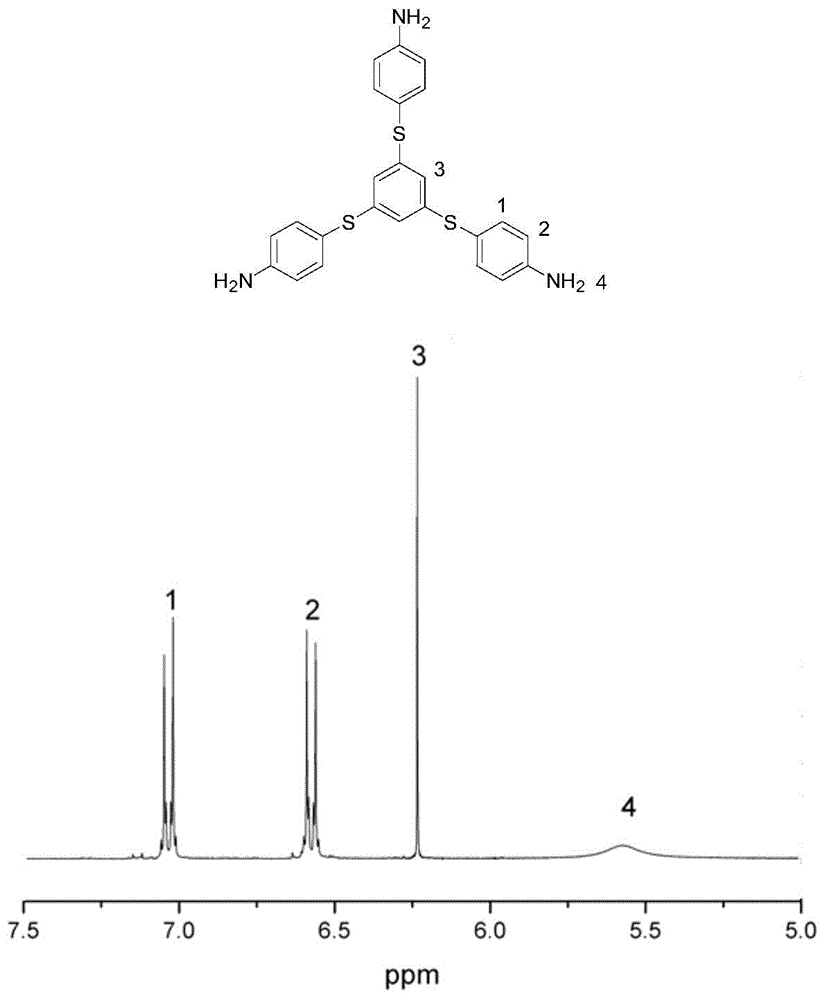

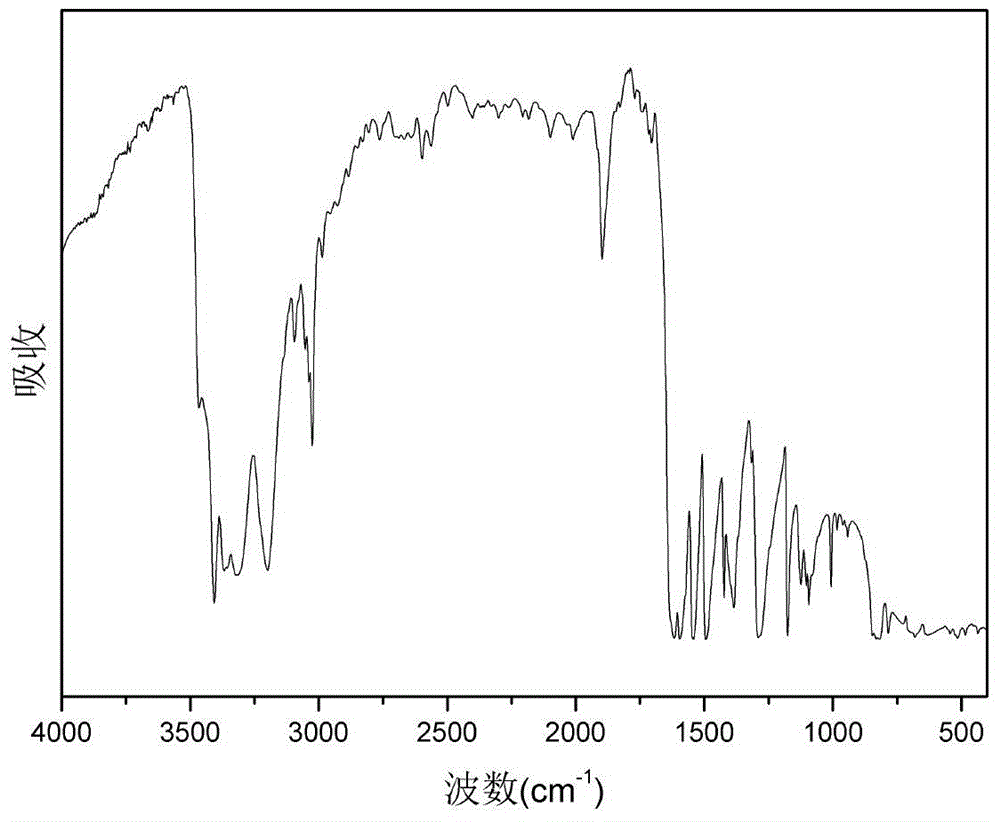

InactiveCN104592069AHigh sulfur contentAffect thermal stabilitySulfide preparationEnd-groupRefractive index

The invention belongs to the field of polymer materials and technical synthesis thereof, and particularly relates to 1,3,5-tris(4-aminophenylmercapto)benzene as well as a preparation method and application thereof. Thioether bonds are introduced into a triamine monomer to obtain 1,3,5-tris(4-aminophenylmercapto)benzene; and 1,3,5-tris(4-aminophenylmercapto)benzene and dianhydride, dianhydride and tetrachlorophthalic anhydride, or dianhydride and 3,5-dichloroaniline are taken as raw materials to prepare an anhydride-terminated, tetrachlorophthalic anhydride-terminated or 3,5-dichloroaniline-terminated A2+B3 type hyperbranched polyimide. According to the invention, the 1,3,5-tris(4-aminophenylmercapto)benzene monomer contains thioether bonds, so that the sulfur content of the hyperbranched polyimide is increased, and the thermal stability, solvent resistance, high refractive index and the like of the polymer are improved. Meanwhile, the branched structure and the end groups of the hyperbranched polyimide can be subjected to termination modification, so that the hyperbranched polyimide has a wide application prospect in many fields.

Owner:JILIN UNIV

Preparation method of pigment yellow 138

Owner:南通龙翊新材料科技有限公司

Method for preparing 2,3,4,5-tetrafluoro methyl benzoate in series reaction

ActiveCN102603531AHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationChemical synthesisMethyl benzoate

The invention discloses a method for preparing 2,3,4,5-tetrafluoro methyl benzoate in series reaction, belonging to the technical field of fine chemical synthesis. The method comprises the following steps: carrying out fluorination reaction at 20-150 DEG C for 1-15 hours using ionic liquid, fluoride, a solid base catalyst and 2,3,4,5-tetrachlorophthalic anhydride, cooling the reaction solution to room temperature after the reaction is complete, adding methanol to perform esterification and decarboxylation reaction, and carrying out post treatment to obtain 2,3,4,5-tetrafluoro methyl benzoate. The preparation method provided by the invention uses ionic liquid and magnetic solid base catalyst, and performs series reaction between various components; the method is simple in operation, convenient in post treatment, good in technical performance, and low in environmental pollution; the yield of the obtained 2,3,4,5-tetrafluoro methyl benzoate is above 92%, and the content is >= 99.2%. The method is a green chemical synthesis technology and is suitable for industrialized production.

Owner:浙江东晖药业有限公司

Reaction type flame-retardant polyester polyol and preparation method thereof

InactiveCN106633011AImprove flame retardant performanceIt has the flame retardant effect of phosphorus and halogen compoundsPolyesterHalogen

The invention relates to a method for preparing a reaction type flame-retardant polyester polyol. The reaction type flame-retardant polyester polyol comprises the following raw materials in parts by mass: 45-50 parts of tetrachlorophthalic anhydride, 40-45 parts of polyhydric alcohols, 5-10 parts of a phosphorus-containing flame retardant, 0.003-0.005 part of an antioxidant and 0.005-0.01 part of a catalyst. The method for preparing the reaction type flame-retardant polyester polyol disclosed by the invention overcomes the defects of additive flame-retardant polyesters, has the characteristics of environment friendliness, high efficiency, low toxicity and long-lasting effect, and plays a more and more important role in flame retardancy study of the polyurethane. The polyester polyol prepared by the method has a phosphorus-halogen compound flame-retardant effect, so the polyester polyol has excellent and long-lasting flame-retardant property. Moreover, due to high degree of functionality, the prepared hard bubble has excellent strength and can be widely applied to hard bubbles of spray and piping.

Owner:SHANDONG INOV POLYURETHANE

An environmentally friendly long-term anti-corrosion packaging steel drum

ActiveCN107353783BImprove anti-corrosion performanceLong lastingAnti-corrosive paintsEpoxy resin coatingsDefoaming AgentsBisphenol A

The invention discloses an environmental-friendly long-lasting preservative packaging steel bucket and a preparation method thereof. The inner wall of the packaging steel bucket is coated by an anti-corrosion coating, and the anti-corrosion coating comprises the following components in parts by weight: a bisphenol A epoxy resin, an organic silicon modified epoxy resin, nano titanium dioxide, kieselguhr, tetrachloro phthalic anhydride, paraffin, propylene glycol, talcum powder, ethylene glycol, a thickening agent, a coupling agent, a surfactant, a defoaming agent and deionized water. As the inner wall and the surface of the packaging steel bucket are coated by the special anti-corrosion coating, the anti-corrosion property of the packaging steel bucket is effectively improved, the anti-corrosion coating is non-toxic and smellless, green and environmental-friendly, long-lasting in effect, low in production cost and good in economic benefit.

Owner:TAICANG DATIAN MINGBO PACKING CONTAINER CO LTD

Industrial preparation method of 2,4,5-trifluoro-3-methoxybenzoyl chloride

ActiveCN103450013BAvoid pollutionSimple and fast operationOrganic compound preparationCarboxylic compound preparationN dimethylformamidePhthalate

Owner:YUEYANG YETOP FINE CHEM

Synthesis method of 1,2,4-trifluoro benzene

ActiveCN103435440AStable market supplyEase of industrial scale productionHalogenated hydrocarbon preparationChemical synthesisSulfolane

The invention discloses a synthesis method of 1,2,4-trifluoro benzene, and belongs to the technical field of chemical synthesis. The synthesis method is characterized by comprising the following reaction steps that (1) tetrachloro phthalic anhydride reacts with a methylamine aqueous solution, and 6-carboxyl-2,3,4,5-tetrachlorobenzene formyl methylamine is obtained; (2) 6-carboxyl-2,3,4,5-tetrachlorobenzene formyl methylamine reacts with zinc powder, and a mixture of 6-carboxyl-2,3,5-trichloro benzene formyl methylamine and 6-carboxyl-2,4,5-trichloro benzene formyl methylamine is obtained; (3) the mixture of 6-carboxyl-2,3,5-trichloro benzene formyl methylamine and 6-carboxyl-2,4,5-trichloro benzene formyl methylamine is subjected to backflow water diversion cyclization in sulfolane and toluene, and a mixture of 3,4,6-trichloro phthalic methylamine and sulfolane is obtained; (4) the mixture of 3,4,6-trichloro phthalic methylamine and sulfolane reacts with potassium fluoride, and 3,4,6-trifluoro phthalic methylamine is obtained; (5) 3,4,6-trifluoro phthalic acid is obtained by hydrolyzing 3,4-6-trifluoro phthalic methylamine; and (6) 1,2,4-trifluoro benzene is obtained by decarboxylizing 3,4,6-trifluoro phthalic acid. The synthesis method has the advantages that a raw material is easy to obtain; the method is easy and simple to operate; the purity of a product is good; and the method has a higher industrial application value.

Owner:ZHEJIANG ZHONGXIN FLUORIDE MATERIALS CO LTD

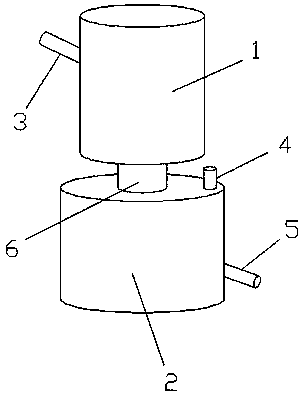

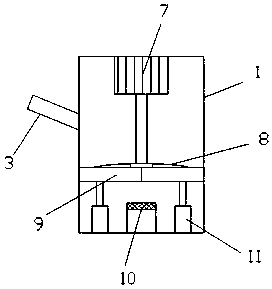

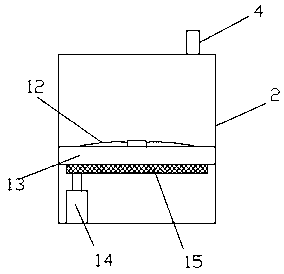

External methylene tetrachlorophthalic anhydride purification equipment

The purification equipment of exomethylenetetrachlorophthalic anhydride of the present invention comprises a melting chamber and an evaporation chamber, the left side of the melting chamber is provided with a guide tube, the guide tube is fixedly connected with the melting room by welding, and the inside of the melting room is There is a motor, a melting frame and a first hydraulic device, the motor is fixedly connected to the top of the melting chamber by welding, a connecting pipe is provided between the melting chamber and the evaporation chamber, and an air outlet pipe and a discharge pipe are provided outside the evaporation chamber An evaporation frame and a second hydraulic pressure device are arranged inside the evaporation chamber, and one end of the evaporation frame is fixedly connected with the inside of the evaporation chamber through a rotating shaft. For the purification equipment of exomethylene tetrachlorophthalic anhydride, acetic acid is poured into the dissolving box, tetrachlorophthalic anhydride is dissolved in acetic acid, and the impurities in tetrachlorophthalic anhydride are insoluble in acetic acid, and then the purification of tetrachlorophthalic anhydride is realized, and the solution passes through The filter screen enters the evaporation frame. Since the acetic acid is volatile, it is easy to dry the solution. The whole process is convenient and simple to operate, and the purity of tetrachlorophthalic anhydride is greatly improved.

Owner:嘉兴清洋新材料股份有限公司

Wear-resistant sealing material and preparation method thereof

InactiveCN104804348AImprove corrosion resistanceImprove high temperature resistanceOther chemical processesBenzoic acidActive agent

The invention discloses a wear-resistant sealing material and a preparation method thereof. The wear-resistant sealing material comprises the following components in parts by weight: 60-65 parts of acrylate rubber, 21-23 parts of carbon black, 5-7 parts of benzotriazole, 1-3 parts of stearic acid, 3-5 parts of an active agent magnesium oxide, 2-4 parts of a fire retardant tetrachlorophthalic anhydride, 1-3 parts of tung oil, 1-2 parts of an anti-aging agent 4010NA, 0.5-0.8 part of graphite powder, 0.3-0.5 part of talcum powder, 1-3 parts of dioctyl adipate, 3-5 parts of zinc oxide, 0.5-0.8 part of copper powder, 1-2 parts of ethyl chrysanthemate, 1-3 parts of an accelerant TMTD, 7-9 parts of high styrene resin and 1-2 parts of benzoic acid.

Owner:SUZHOU TONGMING MACHINERY

Method for improving flame retardance of fraxinus mandshurica wood

InactiveCN107199610AImprove flame retardant performanceImprove permeabilityRadiation/waves wood treatmentWood treatment detailsFraxinusEpoxy polyamide

The invention relates to the technical field of wooden product processing and manufacturing and discloses a method for improving flame retardance of fraxinus mandshurica wood. A used flame retardant is prepared from the following components of, by mass, 12.5-13.0% of tricresyl phosphate, 11.0-12.0% of tetrachlorophthalic anhydride, 7.5-8.0% of tripolycyanamide- formaldehyde resin, 7.0-7.5% of epoxy polyamide resin, 6.2-6.5% of ethidene diamine, 5.0-5.5% of dialkyl p-phenylenediamine, 4.5-5.0% of pentaerythritol, 2.8-3.0% of 2,6 ditert-butyl-4-cresol, 2.5-3.0% of bioctadecyl methylamino quaternary ammonium salt and the balance water. The flame retardant is applicable to the wood characteristic of fraxinus mandshurica, and meanwhile, a vacuum pressure treatment technology and microwave treatment are applied to wood flame retardance treatment, and the flame retardance effect is enhanced.

Owner:FUNAN XINGGUANG ARTS & CRAFTS CO LTD

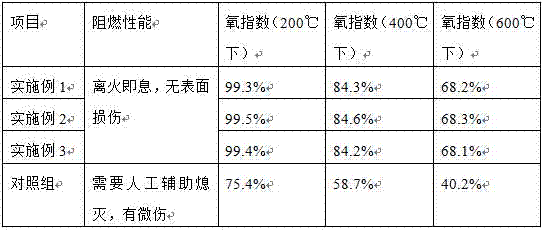

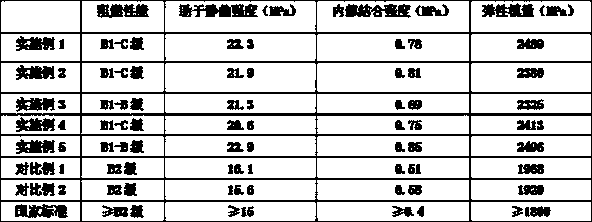

Flame retardant resin and preparation method thereof

The invention discloses a flame retardant resin and a preparation method thereof, and relates to the technical field of polymer composite materials. The flame retardant resin comprises following raw materials: styrene dichloride, maleic anhydride, tetrachlorophthalic anhydride, neopentylene glycol, methyl methacrylate, polyester fibers, copper naphthenate, cobalt iso-octoate, calcium carbonate, silica, urotropine, perlite powder, aluminosilicate, graphite, diammonium phosphate, magnesium hydroxide, and aluminum hydroxide. The flame retardant performance of prepared flame retardant resin can reach the B1 level; the static bending intensity of a coated product can reach 20 MPa or more, the inner binding strength can reach 0.6 MPa or more, the elastic modulus can reach 2300 MPa or more and isgreater than the national standard, the performance is excellent, and the market prospect is good.

Owner:河南省华昌高新技术有限公司

High-temperature-resistant sealing material and preparation method thereof

InactiveCN104804350AImprove corrosion resistanceImprove high temperature resistanceActive agentFire retardant

The invention discloses a high-temperature-resistant sealing material and a preparation method thereof. The wear-resistant sealing material comprises the following components in parts by weight: 70-72 parts of acrylate rubber, 22-25 parts of butadiene styrene rubber, 11-13 parts of carbon black, 5-7 parts of glycerol trioleate, 15-18 parts of high styrene resin, 2-4 parts of an active agent magnesium oxide, 5-8 parts of a fire retardant tetrachlorophthalic anhydride, 1-3 parts of sulphur powder, 2-4 parts of triethyl citrate, 3-5 parts of an anti-aging agent 4010NA, 1-3 parts of ceramic powder, 3-6 parts of dioctyl adipate, 2-6 parts of zinc oxide, 4-8 parts of ethyl chrysanthemate, 0.2-0.8 part of an accelerant TMTD and 1-2 parts of palm wax.

Owner:SUZHOU TONGMING MACHINERY

Flame retardant resin

InactiveCN108559231AImprove flame retardant performanceHigh temperature resistantFiberPolyester resin

The invention discloses a flame retardant resin. The resin is prepared from, by mass, saturated polyester resin 30-50%, tetrachlorophthalic anhydride 10-20%, carclazyte fiber 5-10%, copper naphthenate5-8 %, cobalt iso-octoate 2-5%, calcium carbonate 10-20%, chlorinated styrene 5-10% and silica 5-10%. The flame retardant resin has no toxicity, long service life of a workpiece, excellent high temperature flame retardant performance and high bonding strength.

Owner:HUZHOU WUSHI TECH CO LTD

Method for synthesizing quinaphthalone yellow

The invention relates to a method for synthesizing quinaphthalone yellow (C.I.P.Y. 138). The method comprises the steps of (1) obtaining 8-aminoquinaldine via a reduction reaction of 8-nitroquinaldine; and (2) obtaining a target compound via a condensation reaction of 8-aminoquinaldine and tetrachlorophthalic anhydride. The method is characterized in that in the step (1), the temperature of the reduction reaction is 25 DEG C-40 DEG C; the pressure of the reduction reaction is 0.1 MPa-1 MPa; and the reduction reaction is carried out in a protonic polar solvent having a low boiling point; and in the step (2), the catalyst employed by the condensation reaction is an organic Lewis catalyst; and the condensation reaction is carried out in a solvent (Dowthem A) composed of phenylate and biphenyl, wherein phenylate accounts for 73.5%; and biphenyl accounts for 26.5%. The synthetic method has the advantages of high product yield and mild reaction conditions, and is environment-friendly.

Owner:LILY GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com