Halogen resin composition and application thereof

A technology of resin composition and epoxy resin, applied in the field of resin composition, can solve the problems of affecting the stability of the resin composition, unable to achieve lead-free process, reducing the heat resistance of copper clad laminates, etc. Dielectric loss, the effect of overcoming poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

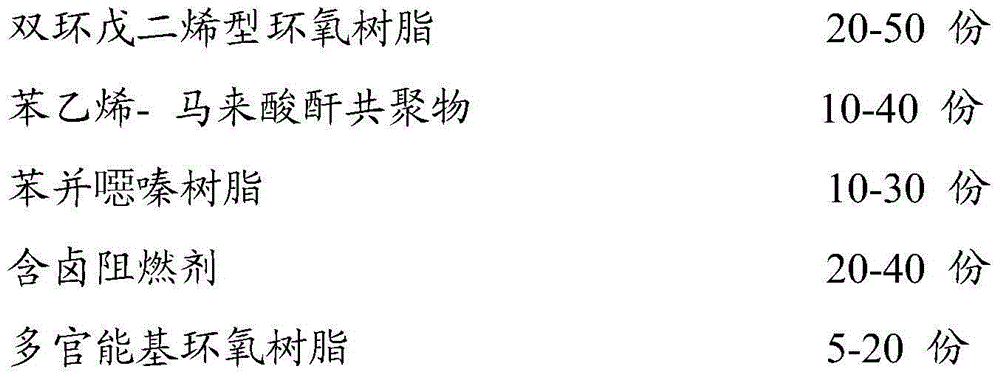

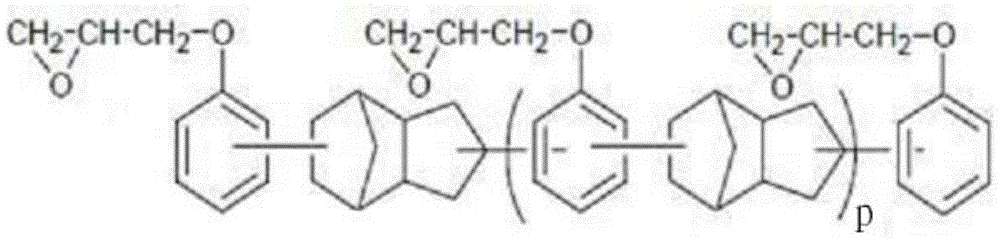

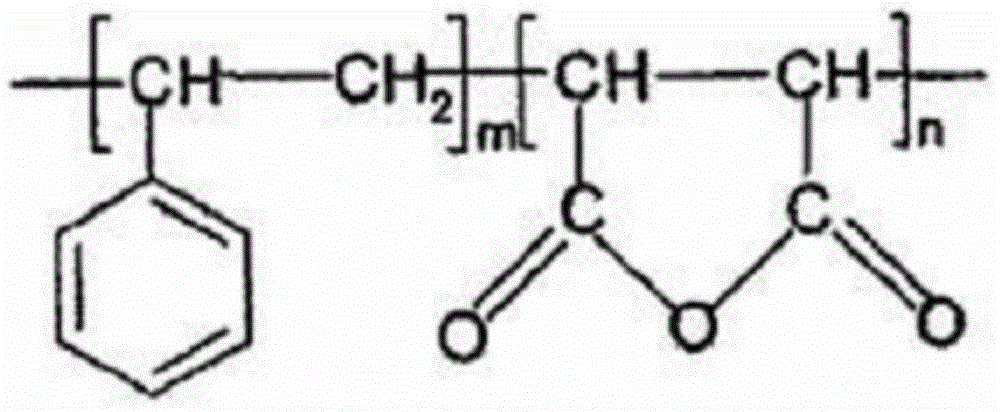

[0051] A halogen-containing resin composition prepared from the following raw materials in parts by weight:

[0052]

[0053] The halogen-containing resin composition of this example is selected to prepare a metal foil substrate, and the preparation method is as follows:

[0054] (1) dissolve.

[0055] Take the above-mentioned halogen-containing resin composition, use methyl ethyl ketone as a solvent, and stir at room temperature at high speed to obtain a resin glue solution with a solid content of 60 wt%.

[0056] (2) Impregnated and glued.

[0057] Take the glass fiber cloth of 2116 specifications and impregnate the above resin glue.

[0058] (3) drying.

[0059] Dry the glass fiber cloth impregnated with the resin glue solution at 160°C-190°C to obtain a prepreg.

[0060] (4) Take the prepreg prepared above and copper foil with a thickness of 1 ounce (35 μm thick), and press them with a hot press. The pressing specification is 2116×6ply. After 60 minutes, the metal ...

Embodiment 2

[0062] A halogen-containing resin composition prepared from the following raw materials in parts by weight:

[0063]

[0064] The metal foil substrate was prepared by using the halogen-containing resin composition of this example, and the metal foil substrate was prepared according to the preparation method in Example 1.

Embodiment 3

[0066] A halogen-containing resin composition prepared from the following raw materials in parts by weight:

[0067]

[0068] The metal foil substrate was prepared by using the halogen-containing resin composition of this example, and the metal foil substrate was prepared according to the preparation method in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com