Patents

Literature

37 results about "Hexachlorocyclopentadiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexachlorocyclopentadiene (HCCPD), also known as C-56, Graphlox, and HRS 1655, is an organochlorine compound with the formula C₅Cl₆. It is a precursor to pesticides, flame retardants, and dyes. It is a colourless liquid although commercial samples appear lemon-yellow liquid sometimes with a bluish vapour. Many of its derivatives proved to be highly controversial, as studies showed them to be persistent organic pollutants. An estimated 270,000 tons were produced until 1976. Two prominent manufacturers were Velsicol Chemical Corporation in the US and by Jiangsu Anpon Electrochemicals Co. in China.

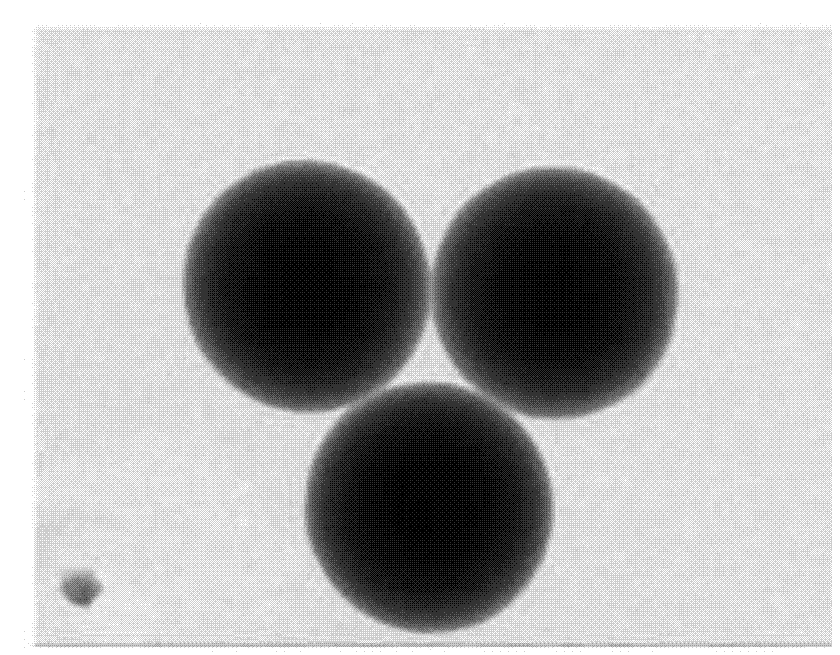

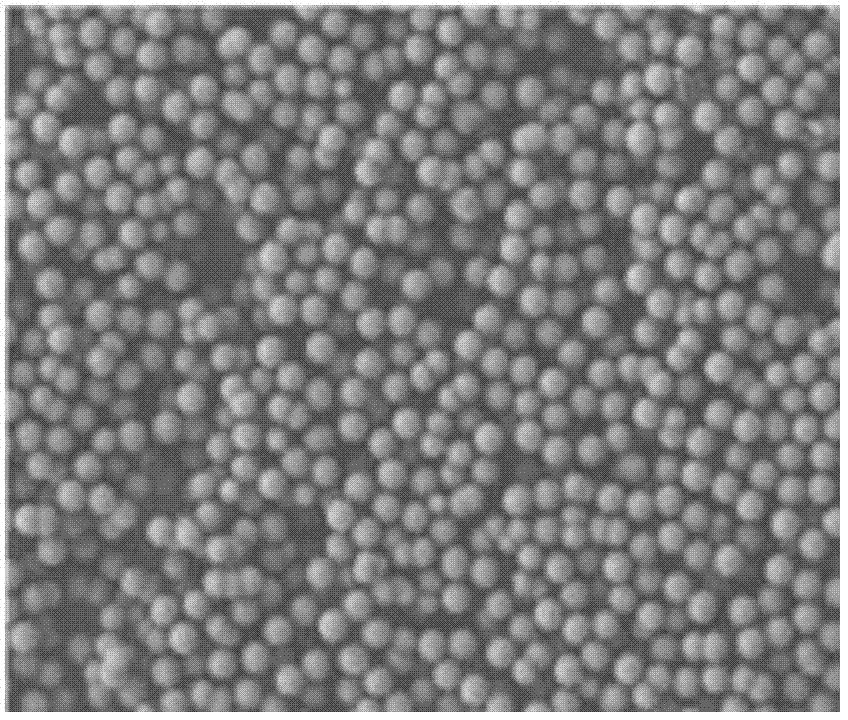

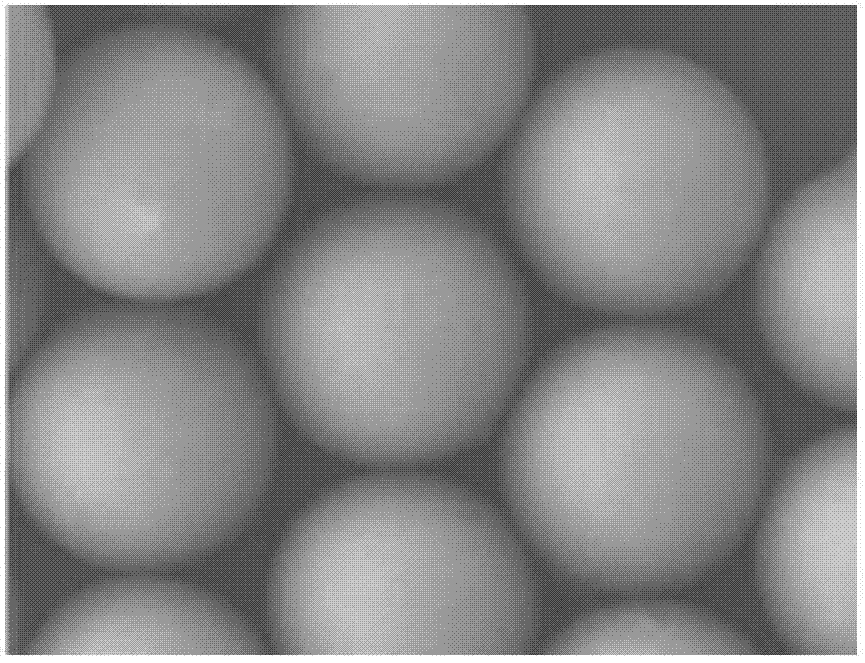

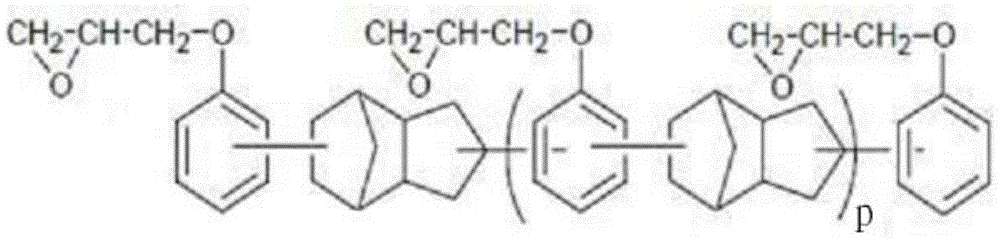

High-temperature resistant polyphosphazene microsphere and preparation method thereof

InactiveCN103113410AImprove thermal stabilityGood workmanshipGroup 5/15 element organic compoundsWater bathsPolyphosphazene

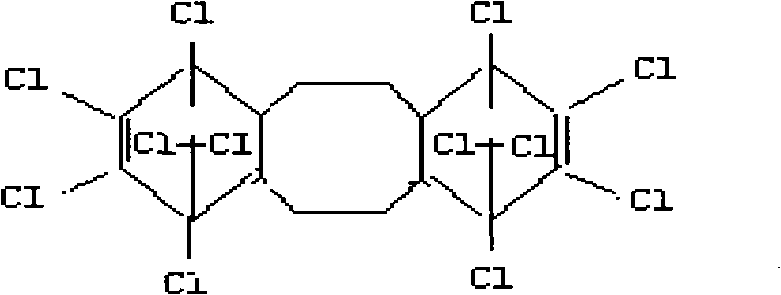

The invention relates to a high-temperature resistant polyphosphazene microsphere and a preparation method thereof and belongs to the organic micro-nanometer filed. The method comprises the following steps: performing reaction among hexachlorocyclopentadiene, phloroglucinol and triethylamine in an ultrasonic water bath environment to obtain a product; and washing the product, thereby obtaining the high-temperature resistant polyphosphazene microsphere. The high-temperature resistant polyphosphazene microsphere has a chemical structural formula shown in the specification. According to the microsphere and the method provided by the invention, the defects of the existing polymer microsphere preparation method and the existing polymer performance are overcome. Therefore, the polymer microsphere with better performance is synthetized by utilizing a simpler method.

Owner:SHANGHAI JIAO TONG UNIV

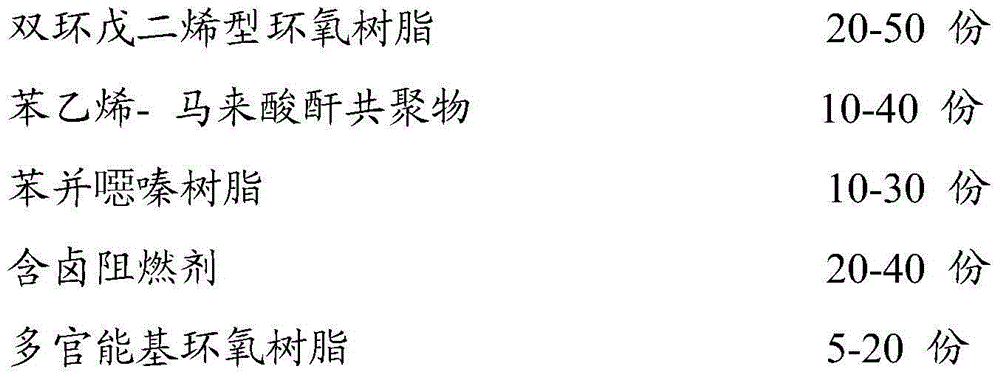

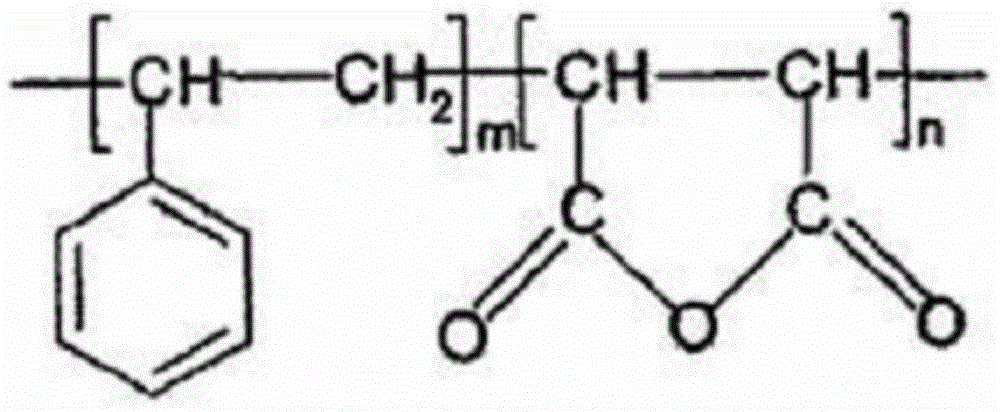

Halogen resin composition and application thereof

The invention relates to a halogen resin composition and an application thereof. The halogen resin composition is prepared from the following raw materials in parts by weight: 20-50 parts of dicyclopentadiene epoxy resin, 10-40 parts of styrene-maleic anhydride copolymer, 10-30 parts of benzoxazine resin, 20-40 parts of halogenous fire retardant, and 5-20 parts of multi-functional group epoxy resin, wherein the halogenous fire retardant is at least one of the decabrominated dipheny ethane, tri(tribromophenyl) triazine, brominated polyolefin, brominated polystyrene, ethyl-di(tetrabromobenzene o-dicarboximide), decabromodiphenyl ether, hexabromocyclododecane, eight bromo ether, tetrachlorophthalic anhydride, Hexachlorocyclopentadiene and perchlorinated cyclopentyl decane. A metal foil substrate made of the halogen resin composition has the advantages of low dielectric constant and dielectric loss, excellent heat resistance, good machinability and low swelling coefficient and can be well applied to a composite board.

Owner:GUANGZHOU GRACE ELECTRON CORP

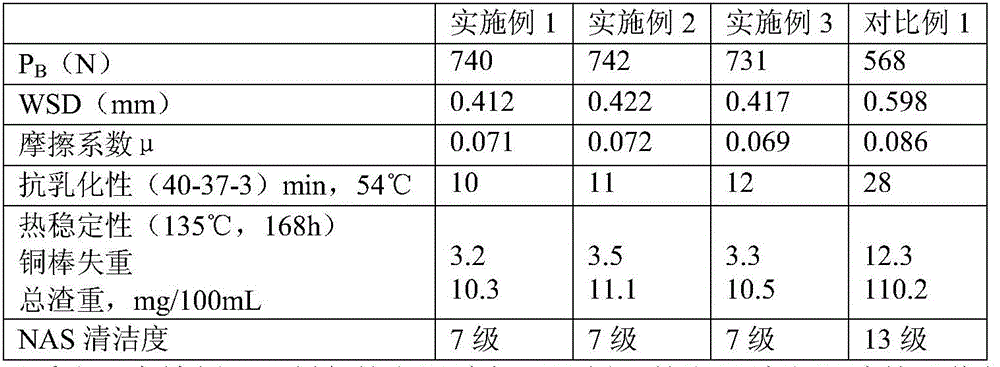

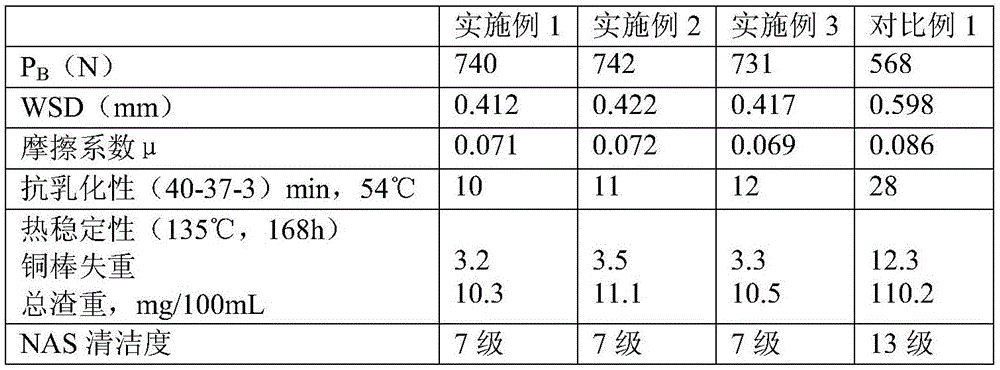

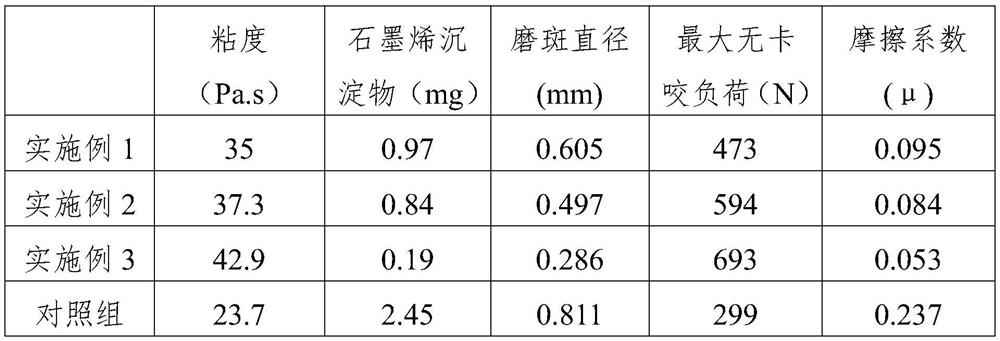

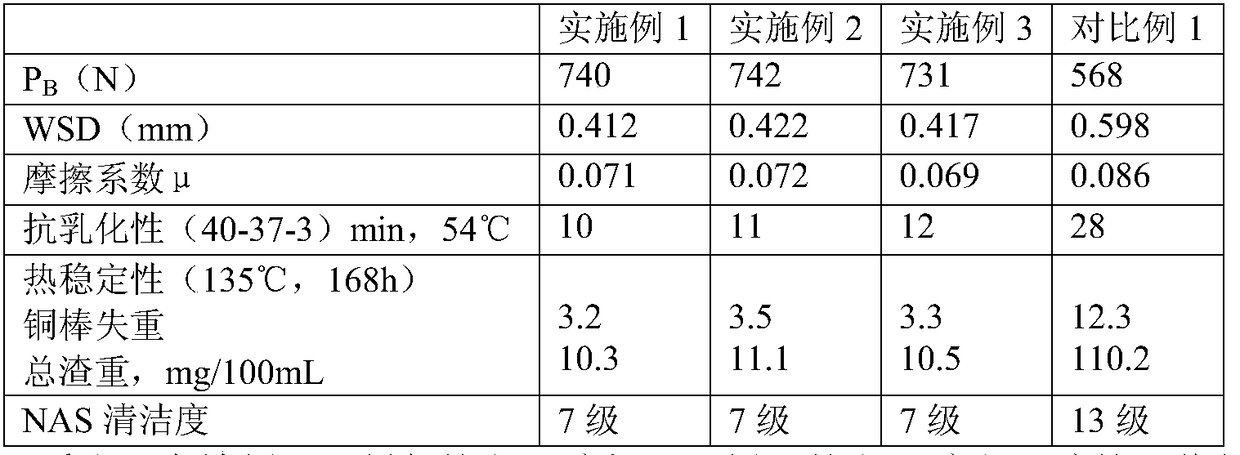

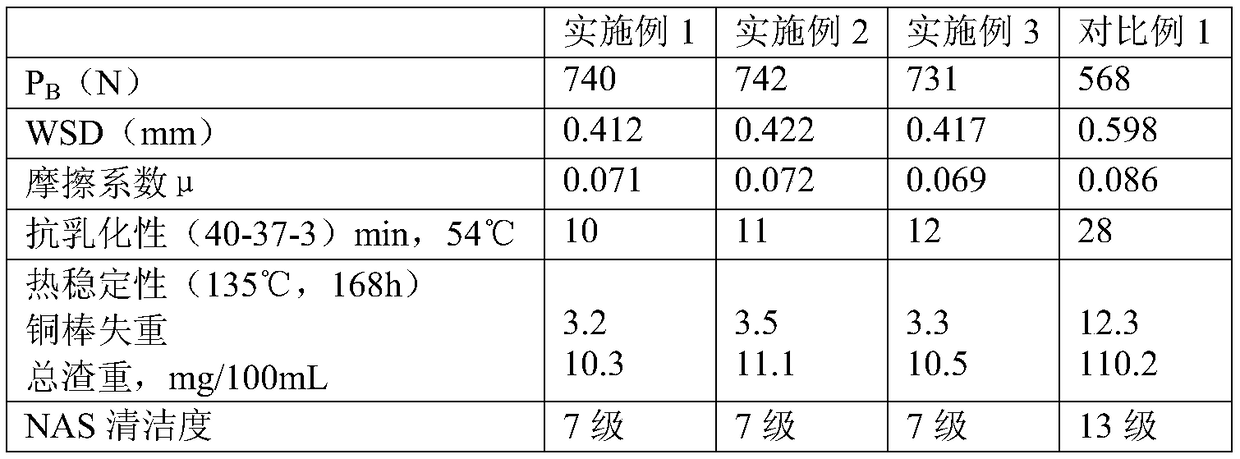

Lubricating oil for joints of injection molding machine

ActiveCN106010755AImprove wear resistanceImprove corrosion resistanceAdditivesMethyl carbamatePhenyl Ethers

The invention relates to a lubricating oil for joints of an injection molding machine. The lubricating oil is prepared from the following raw materials by weight: 85 to 95 parts of mineral-based oil, 15 to 25 parts of polyoxyethylene nonyl phenyl ether, 3 to 5 parts of hexachlorocyclopentadiene, 3 to 5 parts of dithioglycol, 5 to 10 parts of propolis extract, 5 to 10 parts of alga extract, 10 to 15 parts of graphene, 5 to 10 parts of modified zircon powder, 1 to 3 parts of methyl carbamate and 2 to 4 parts of benzimidazole. The lubricating oil provided by the invention has good abrasion resistance, resistance to tarnishing, heat stability, anti-foaming performance, good sealing adaptability and high cleanliness and can meet requirements of the hydraulic system of the injection molding machine on lubricating oil. The lubricating oil has high adhesion and is not prone to rapid loss. A preparation method for the lubricating oil is simple, convenient for industrial production and low in cost.

Owner:NINGBO RUNBEI WANLING LUBRICANT

Heat-conducting polyurethane with insulating and flame-retardant properties

InactiveCN111574680AImprove insulation performanceImprove flame retardant performancePolymer scienceBoronic acid

The invention belongs to the technical field of polyurethane, and particularly relates to heat-conducting polyurethane with excellent insulating and flame-retardant properties. The invention providesheat-conducting polyurethane with insulating and flame-retardant properties, which comprises the following components in parts by weight: 20-25 parts of polyisocyanate, 38-42 parts of polyol, 5-7 parts of a chain extender, 0.2-1 part of an antioxidant, 8-12 parts of a filler, 16-22 parts of a flame retardant and 0.2-0.6 parts of an auxiliary agent. The polyurethane disclosed by the invention has excellent insulating property (the insulating resistance is greater than 10<12> ohm cm), flame retardant property and heat-conducting property, and is low in hardness. The isocyanate, the polyhydric alcohol and the chain extender generate a polyurethane material, the flame-retardant effect of the polyurethane obtained through mutual cooperation of decabromodiphenyl ethane, bis (hexachlorocyclopentadiene) cyclooctane, Sb2O3 and zinc borate reaches UL94-V0, and aluminum oxide and silicon nitride are uniformly dispersed in the polyurethane, so that the hardness and the heat-conducting property ofthe polyurethane are improved.

Owner:东莞市英捷工程塑料有限公司

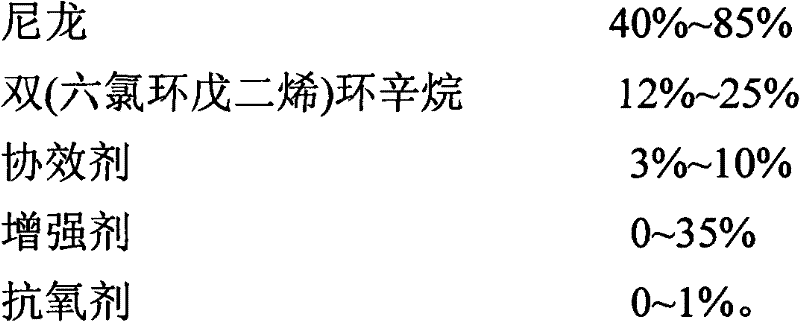

Bromine-free flame-retardant nylon

InactiveCN102532878AImprove flame retardant performanceImprove electrical performanceNylon materialZinc borate

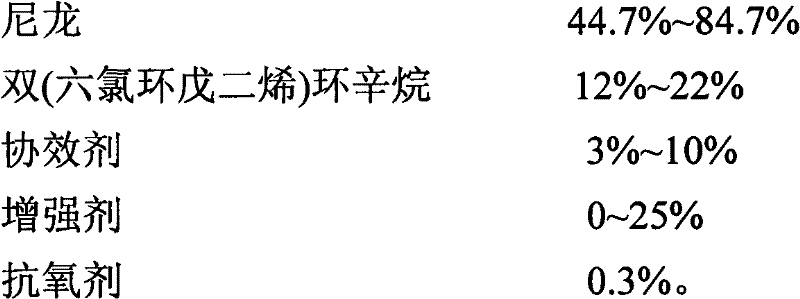

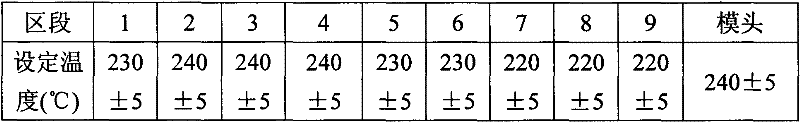

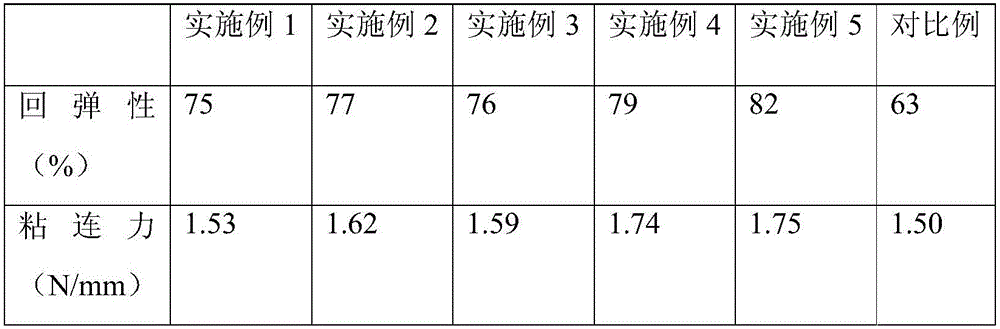

The invention discloses a bromine-free flame-retardant nylon which comprises the following raw materials by weight percent: 40-85% of nylon, 12-25% of bis (hexachlorocyclopentadiene) cyclooctane, 3-10% of synergist, 0-35% of enhancer and 0-1% of antioxidant. The bromine-free flame-retardant nylon which is prepared from the specific raw materials has excellent flame retardance and good electrical properties. Because the flame-retardant synergist can be one or more of the zinc oxide, the diantimony trioxide, the zinc borate and the ferric oxide, the complete dependence on the diantimony trioxide is avoided. The problems that high flame retardance and low cost of the existing fire-retardant nylon are difficult to meet at the same time are solved.

Owner:中广核俊尔(上海)新材料有限公司 +1

Low-temperature-resistant lubricating oil formula

The invention discloses a low-temperature-resistant lubricating oil formula. Raw materials in the formula comprise, in weight percent, 5-15% of base oil, 1-5% of lubricating oil additives, 1-10% of graphite, 5-15% of bentonite, 3-9% of coupling agents, 2-3% of nonylphenol polyoxyethylene ether, 1-5% of hexachlorocyclopentadiene, 11-19% of dithioglycol, 5-7% of propolis extracts, 3-5% of sea algaeextracts, 3-5% of graphene, 1-5% of modified zircon powder, 5-10% of methyl carbamate, 1-1.55 of benzimidazole, 4-5% of monopotassium phosphate and 2-4% of compound ash-free dispersing agents. Low-temperature-resistant lubricating oil has high low-temperature resistance.

Owner:徐州市邦达液压机械有限公司

Protective coating for gate valve outer layer

The invention provides a protective coating for a gate valve outer layer and relates to the technical field of valve processing production. The protective coating is characterized by being prepared from materials in parts by weight as follows: 6 parts of bisphenol A epoxy resin, 3 parts of wollastonite powder I, 1 part of sebacic dihydrazide, 1 part of polyvinyl ether, 4 parts of modified asphalt, 3 parts of hexachlorocyclopentadiene, 1 part of sodium benzoate, 2 parts of acetic acid, 2 parts of dicyanodiamide, 2 parts of carboxymethyl cellulose, 3 parts of amino resin, 1 part of wollastonite powder II, 1 part of alkylolamides, 3 parts of nano carbon powder and 9 parts of a finishing agent. The method is reasonable, the operation is convenient, and the ratio is reasonable.

Owner:HEXIAN KEJIA VALVE CASTING

PVC (polyvinyl chloride) stretch film and method for preparing same

InactiveCN105885283AIncrease elasticityExcellent adhesionFlat articlesAdhesion forcePolyvinyl chloride

The invention discloses a PVC (polyvinyl chloride) stretch film and a method for preparing the same. The PVC stretch film comprises, by weight, 41-55 parts of PVC resin, 3-20 parts of polypropylene carbonate, 3-16 parts of epoxidized soybean oil, 2-15 parts of sodium laureth sulfate, 1-19 parts of dioctyl phthalate, 4-12 parts of polyisobutene, 7-17 parts of tributyl phosphate, 4-14 parts of triethyl citrate, 2-13 parts of hexachlorocyclopentadiene and 5-16 parts of hydroxypropyl methyl celluloses. The method includes mixing components with one another according to the weights and evenly stirring the components in a stirrer to obtain mixtures; extruding the mixtures by the aid of a double-screw extruder; forming a film by means of casting and cooling and packaging the film to obtain the PVC stretch film. The PVC stretch film and the method have the advantages that the elastic resilience and adhesion force of the PVC stretch film can be improved under the synergic effects of the components, and the PVC stretch film can be widely applied to the field of packaging.

Owner:SUZHOU DINGLI PACKAGING

Flame-retardant and anti-rusting anti-adhesion epoxy paint and preparation method thereof

InactiveCN104293090AImprove flame retardant performanceLow costFireproof paintsAnti-corrosive paintsXylyleneBenzoic acid

The invention discloses flame-retardant and anti-rusting anti-adhesion epoxy paint which is characterized by being prepared from the following raw materials in parts by weight: 30-40 parts of E-51 epoxy resin, 12-17 parts of fluorosilicone resin, 8-12 parts of polybutadiene epoxy resin, 3-5 parts of vinyl triamine, 2-3 parts of urotropine, 0.4-0.8 part of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 12-15 parts of modified asphalt, 2-4 parts of asbestos, 1-2 parts of sodium silicate, 3-6 parts of modified waste clay sand, 3-4 parts of hexachlorocyclopentadiene, 1-3 parts of p-nitrobenzoic acid, 3-4 parts of single methyl phosphinic acid calcium, 0.5-1.0 part of phenethyl naphthol polyoxyethylene ether, 2-4 parts of nano calcium carbonate, 5-7 parts of diethylene glycol, 7-9 parts of xylene and 9-13 parts of acetic ether. The fluorosilicone resin added into the paint disclosed by the invention is excellent in temperature resistance, adhesion prevention, chemical resistance, antifouling property and rain corrosion resistance; the mutual synergistic effects of pentaerythritol phosphate, single methyl phosphinic acid calcium and hexachlorocyclopentadiene added into the paint are brought into play, so that the flame retardancy of the paint is improved; as the waste clay sand is modified and added into the paint, both the cost of the paint is lowered, the weather resistance and corrosion resistance of the paint are improved, and the environment pollution is also alleviated.

Owner:TIANCHANG YINHU PAINT

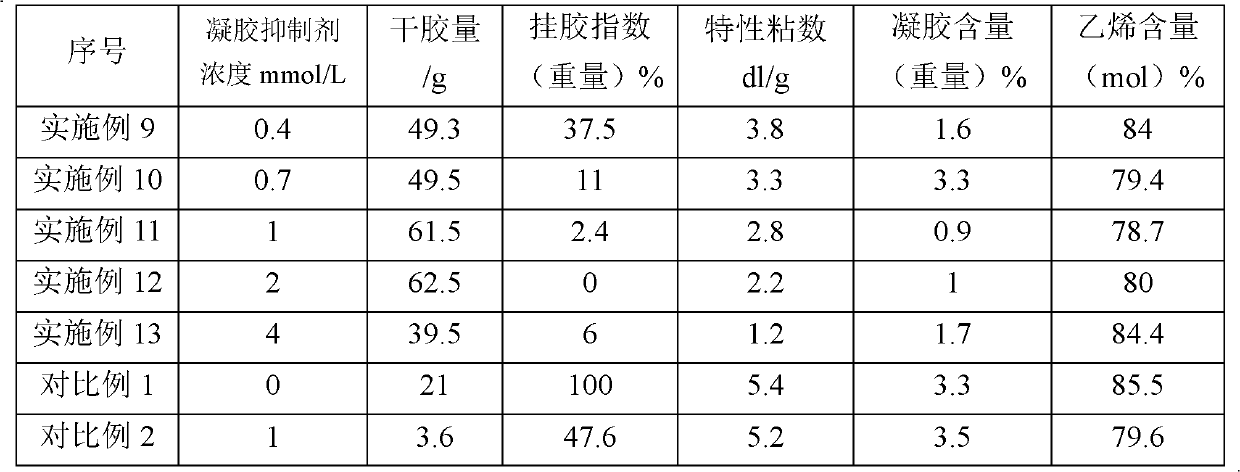

Ethylene-alpha olefin copolymer and preparation method thereof

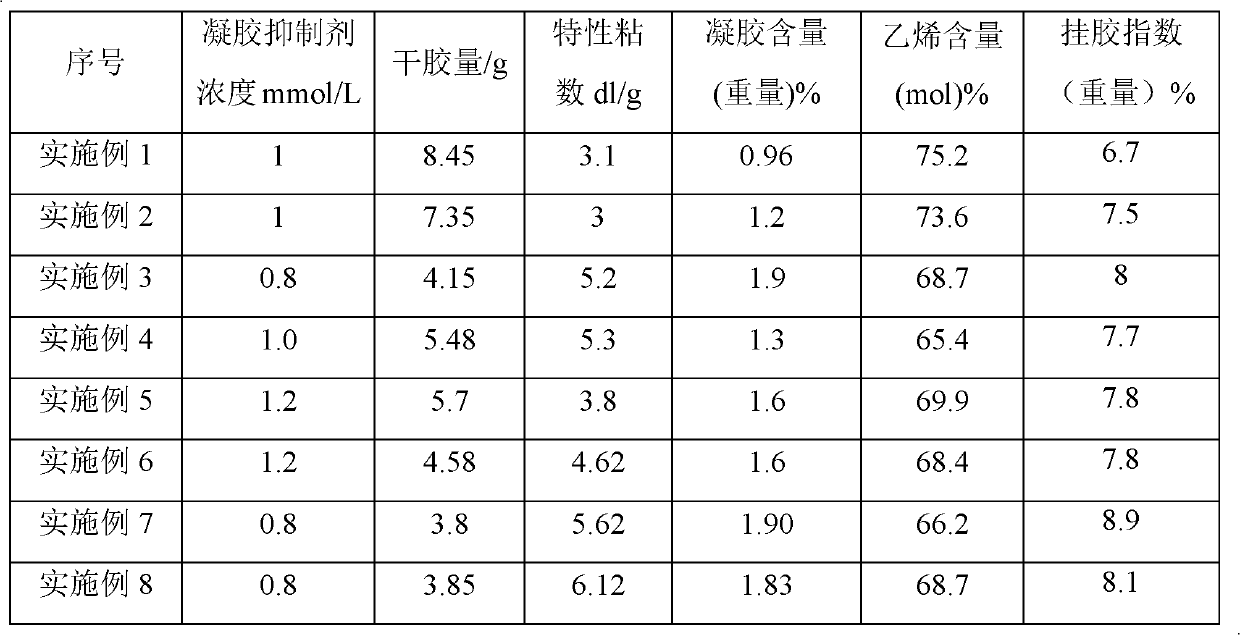

The invention discloses an ethylene-alpha olefin copolymer and a preparation method thereof. The method comprises the following step of: enabling ethylene and alpha olefin to be in contact with a catalyst under the condition of olefin solution polymerization in the presence of a solvent and a gel inhibitor to obtain the ethylene-alpha olefin copolymer, wherein the catalyst contains an organic aluminum and vanadium compound, and the gel inhibitor is selected from one or more of 1,1,2,3,3,3-hexachloro-1-propene, hexachlorocyclopentadiene, aryl sulfonyl halide, halogenated fatty acid ester with at least two halogen atoms and aryl halide with at least three halogen atoms. By using the method provided by the invention, gel generated in the copolymerization process can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Injection machine lubricating oil

ActiveCN106085562AImprove wear resistanceImprove corrosion resistanceLubricant compositionMethyl carbamatePhenyl Ethers

The invention relates to injection machine lubricating oil. The injection machine lubricating oil comprises the following raw materials in parts by weight: 85-95 parts of mineral base oil, 15-25 parts of polyoxyethylene nonyl phenyl ether, 3-5 parts of hexachlorocyclopentadiene, 3-5 parts of dithioglycol, 5-10 parts of alkylated diphenylamine, 10-15 parts of graphene, 5-10 parts of modified zircon powder, 1-3 parts of methyl carbamate and 2-4 parts of benzimidazole. The lubricating oil has good abrasion resistance, rust resistance, heat stability, anti-foaming property, good seal compatibility, and high cleanliness, and can satisfy the requirement of an injection machine hydraulic system on lubricating oil. The lubricating oil has strong adhesive force so that oil is not easy to lose rapidly, the preparation method has the advantages of simpleness, convenient industrial production, and low cost.

Owner:NINGBO RUNBEI WANLING LUBRICANT

Paint good in sun-screening and heat-insulating performances

InactiveCN104927448AGood sun protection and heat insulationImprove anti-corrosion performanceCoatingsPolymer scienceCarbon fibers

A paint good in sun-screening and heat-insulating performances is made from, by weight, 3 to 4 parts of citric acid, 6 to 9 parts of aluminum nitride, 1 to 4 parts of m-xylylenediamine, 2 to 4 parts of phthalic anhydride, 1 to 2 parts of vinyl triamine, 3 to 5 parts of asbestos, 1 to 2 parts of hexachlorocyclopentadiene, 20 to 35 parts of E-51 epoxy resin, 2 to 4 parts of calcium stearate, 3 to 5 parts of nano carbon fiber, 2 to 4 parts of catechol, 3 to 5 parts of hexamethylphosphorotriamide, 8 to 14 parts of chlorinated paraffin, 2 to 5 parts of fireproof additive, 12 to 16 parts of titanium white, 10 to 16 parts of nano-zirconia, 1 to 3 parts of acrylate, 3 to 5 parts of polypropylene carbonate, and 2 to 4 parts of titanium dioxide. The paint is good in corrosion resistance, water resistance, high temperature tolerance and sun-screening performance, allows a coating to be tough and highly adhesive, is ideal in heat-insulating effect and is energy saving and environment friendly.

Owner:QINGDAO JINGSHITONG PRECISION MACHINERY MFG

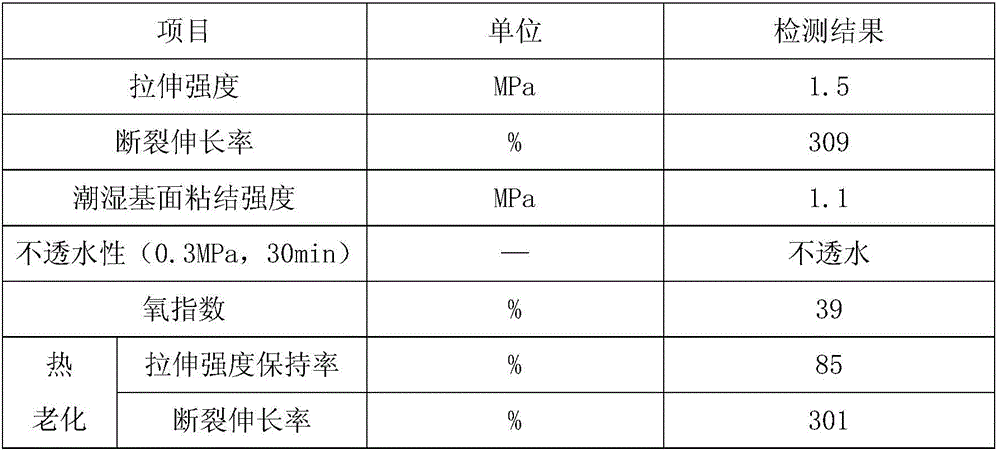

Flame-retardant two-component polychloroprene copolymer cement-based waterproof coating and preparation method thereof

InactiveCN106085018AHigh mechanical strengthEfficient flame retardant effectFireproof paintsChloropene polymer coatingsSlagALUMINUM PHOSPHATE

The invention discloses a flame-retardant two-component polychloroprene copolymer cement-based waterproof coating and a preparation method thereof. The coating is prepared from a liquid material A and a powdery material B in a mass ratio of 1: (1-1.5). The liquid material A is prepared from polychloroprene latex, hexachlorocyclopentadiene, dibromotoluene glycidol ether, tributoxyethyl phosphate, sodium dioctyl sulfosuccinate, beta-cyclodextrin, etc.; and the powdery material B is prepared from composite Portland cement, perlite tailings, aluminum phosphate, hydrated magnesium silicate micropowder, sillimanite, yellow phosphorus slag, etc. The two-component EVA copolymer cement-based waterproof coating prepared in the invention has high-efficiency flame retardation effect and an oxygen index of 35% or above; and the two-component EVA copolymer cement-based waterproof coating has the advantages of high mechanical strength, good weatherability, good corrosion resistance, high binding power, excellent impermeability, etc., and is extensively applicable to waterproof exterior walls of high-rise buildings, waterproof roofs, waterproof basements and anticorrosive pools.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

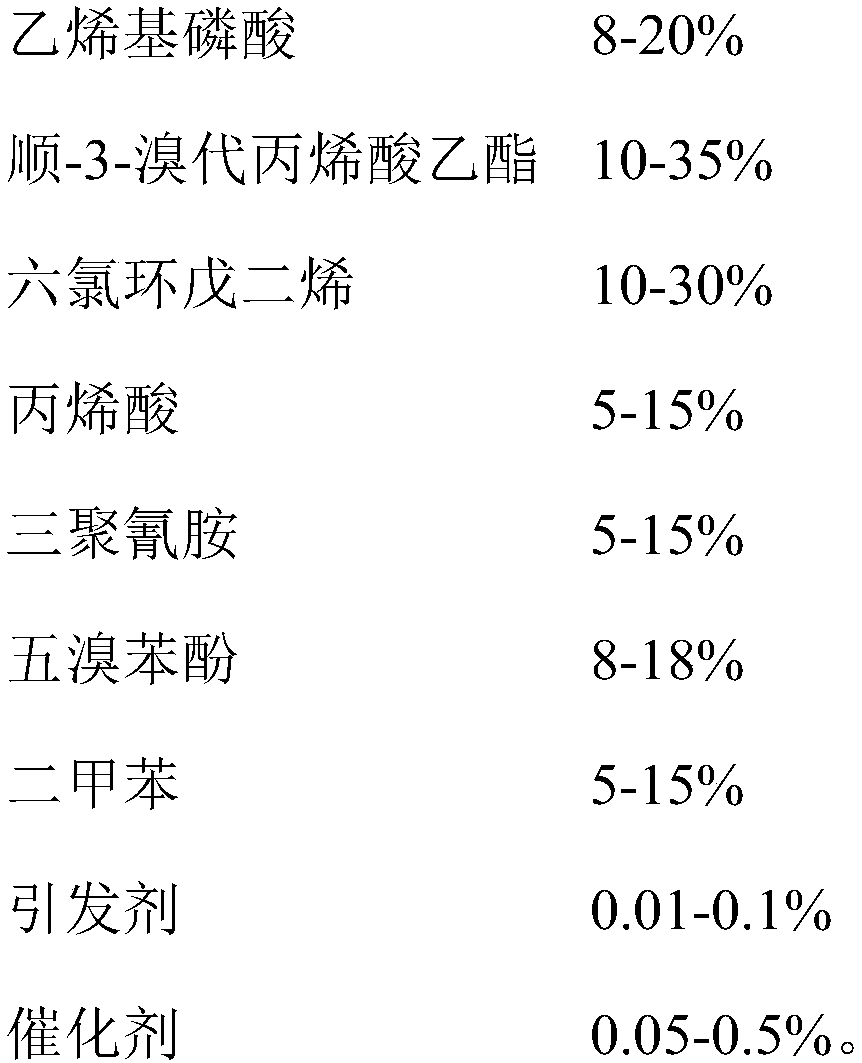

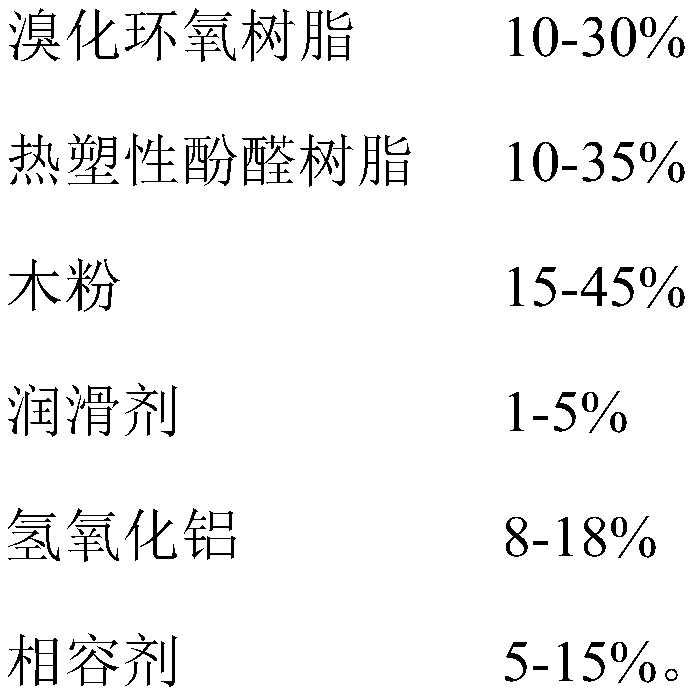

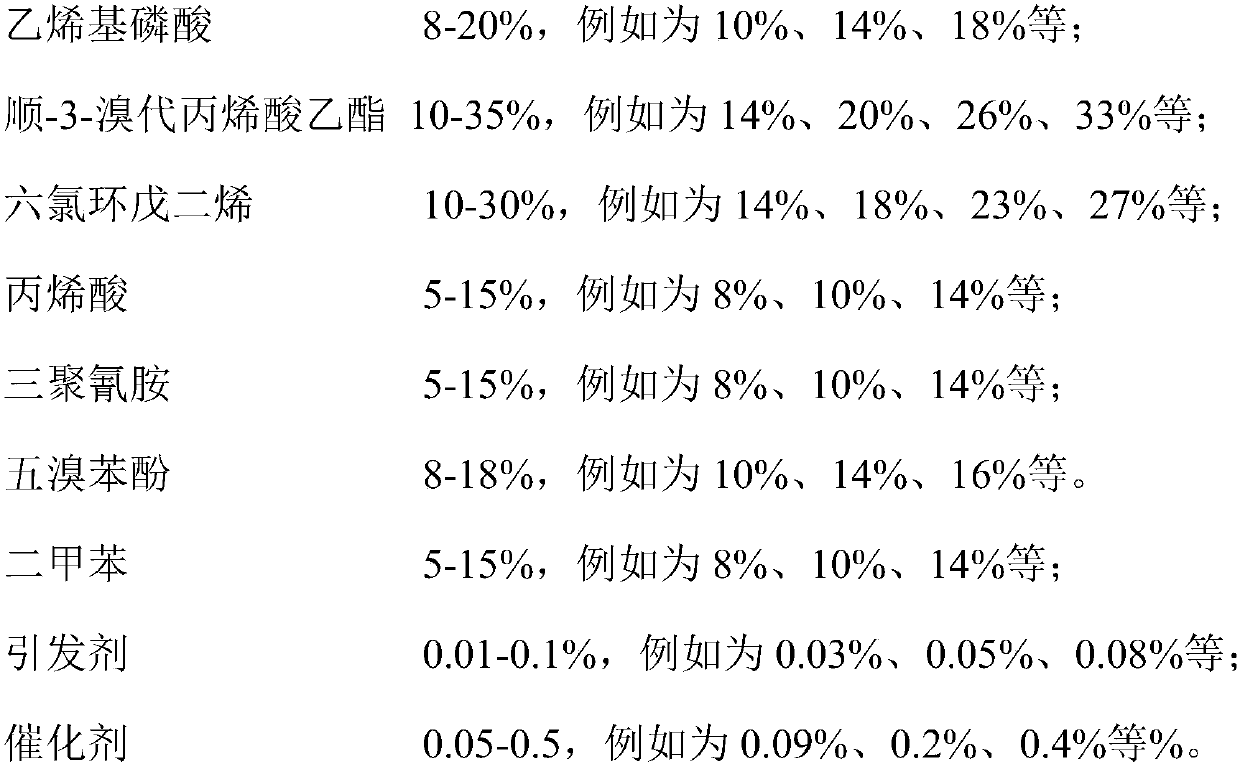

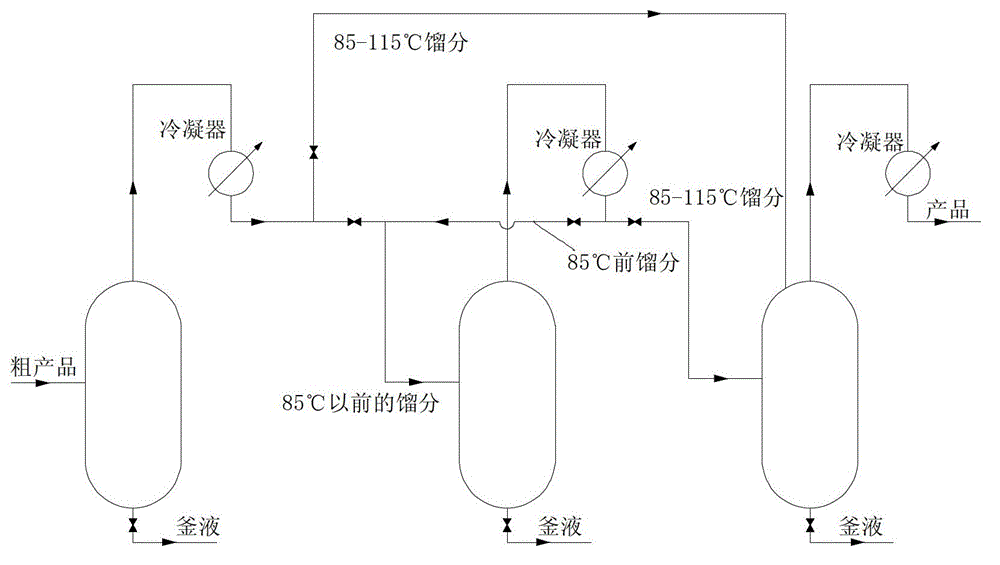

Body flame retardant plastic wood composite material and preparation method thereof

The invention relates to a body flame retardant plastic wood composite material and a preparation method thereof. the composite material is prepared from a body flame retardant fabric and a core material, wherein the body flame retardant fabric is mainly prepared from vinyl phosphate, cis-3-ethyl bromoacrylate, hexachlorocyclopentadiene, acrylic acid, melamine and pentabromophenol as major raw materials; the body flame retardant core material can be mainly prepared from brominated epoxy resin, thermoplastic phenolic resin, wood flour, lubricating agents, aluminum hydroxide and compatilizers asraw materials. The plastic wood composite material has durable flame retardant performance.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD

Weather-proof anti-aging high-thermal-stability insoluble sulfur and production method thereof

InactiveCN104671215AIncrease contentGood weather resistanceSulfur preparation/purificationDispersityQuenching

The invention discloses weather-proof anti-aging high-thermal-stability insoluble sulfur, which is characterized by being prepared from the following raw materials in parts by weight: 100 parts of sulfur powder, 0.5-1.2 parts of white carbon black, 0.2-0.4 part of urea, 0.1-0.3 part of magnesium carbonate, 4-7 parts of attapulgite, 1-2 parts of nanotitanium dioxide, 0.03-0.07 part of accelerant CZ, 2-3 parts of dioctyl phthalate, 6-9 parts of hexachlorocyclopentadiene, 2-4 parts of p-tolyl isocyanate, 0.3-0.5 part of anti-aging agent 2246, and a proper amount of water. According to the method, the energy consumption is low, and static electricity of the product can be eliminated and the content of insoluble sulfur can be increased by adding modified white carbon black serving as an antistatic agent during preparation through a low-temperature liquid method; by taking 0.1% of pentaerythritol water solution as a cold quenching liquid, the cost is low, and the effect is obvious; and by adding nanotitanium dioxide, the weather-proof property of rubber finished products can be enhanced and the dispersity of insoluble sulfur can be improved; and according to the prepared insoluble sulfur, the conversion rate is high, the heat resistance and natural degradation capabilities are also good.

Owner:SHANGHAI JINGHAI ANHUI CHEM

Strong wear-resistance rubber sealing material for detector as well as preparation method of strong wear-resistance rubber sealing material

The invention provides a strong wear-resistance rubber sealing material for a detector as well as a preparation method of the strong wear-resistance rubber sealing material, and relates to the technical field of detector production. The rubber sealing material is prepared from the following raw materials in parts by weight: 40 to 50 parts of ethylene propylene diene monomer, 15 to 20 parts of isoprene rubber, 10 to 15 parts of acrylic ester rubber, 6 to 10 parts of tripolybutenone sulfide, 1 to 2 parts of neopentyl glycol dioleate sulfide, 0.8 to 1.2 parts of coupling agent, 5 to 7 parts of dibenzyl disulfide, 2 to 4 parts of sulfide terpene, 4 to 6 parts of hexachlorocyclopentadiene, 6 to 8 parts of potassium triborate, 2 to 4 parts of nickelous-nickelic oxide, 4 to 6 parts of calcium fluoride, 2 to 3 parts of silicon carbon fiber, 2 to 4 parts of vulcanizing agent and 2 to 4 parts of dispersing agent. According to the strong wear-resistance rubber sealing material for the detector aswell as the preparation method thereof, the defects in the prior art are overcome; the wear resistance and the cracking resistance of the rubber sealing material can be effectively improved; influence on the normal use of the detector caused by the fact that the rubber sealing material is worn, even is cracked under the action of an external force is avoided; and the rubber sealing material has excellent overall performance and high wear resistance and is suitable for popularizing.

Owner:ANHUI SHENGLONG ELECTRIC

High-temperature-resistant high-fire-resistant polyimide film and preparation method thereof

InactiveCN106009667AImprove high temperature resistanceGood chemical resistanceColemaniteN-phenylmaleimide

The invention discloses a high-temperature resistant and highly flame-retardant polyimide film and a preparation method thereof, which is prepared from the following raw materials in parts by weight: o-phenylenediamine 50-55, pyromellitic anhydride 105-115, N, N-dimethylacetamide 25-30, furfural resin 28-34, nano-silicon nitride 8-14, colemanite 5-10, tris(2-chloropropyl) phosphate 13-17, dioxygen trioxide Antimony 6‑9, Hexachlorocyclopentadiene 10‑15, Aluminum Hypophosphite 7‑11, Melamine Formaldehyde Resin 12‑18, N‑Phenylmaleimide 3‑6, Dimethylbiphenyl Diisocyanate 2 ‑5, ammonium chloride 1‑2, p-hydroxybenzenesulfonic acid 1‑2. Inorganic raw materials such as colemanite added in the present invention cooperate with organic raw materials such as furfural resin to act as heat-resistant modifiers in polyimide films, which can improve the high temperature resistance, chemical resistance and impact resistance of materials The added inorganic raw materials such as aluminum hypophosphite and organic raw materials such as hexachlorocyclopentadiene cooperate with each other, and are used as flame retardant modifiers in polyimide films, so that the prepared materials have high flame retardancy and Self-extinguishing.

Owner:刘禾青

Special flexing-resistant material for protecting sleeve pipe for communication cable and preparation method of special flexing-resistant material

InactiveCN104448725AImprove bending strengthGood flexibilityInsulated cablesInsulated conductorsHalloysitePhosphate

The invention discloses a special flexing-resistant material for a protecting sleeve pipe for a communication cable and a preparation method of the special flexing-resistant material. The special flexing-resistant material is prepared from the following raw materials in parts by weight: 49 to 73 parts of polyethylene glycol terephthalate, 32 to 54 parts of alpha-methyl styrene-acrylonitrile-styrene terpolymer, 17 to 23 parts of nano-sized halloysite, 2 to 4 parts of calcium laurate, 14 to 19 parts of tri-isodecyl trimellitate, 2 to 3 parts of beta-diketone, 23 to 37 parts of thermoplastic polyurethane elastomer, 3 to 4 parts of stannous stearate, 14 to 21 parts of activated clay, 12 to 15 parts of colloidal antimony pentoxide, 9 to 17 parts of dipropylene glycol dibenzoate, 10 to 15 parts of alundum powder, 2 to 3 parts of N, N-p-phenylenediamine (2-hydroxy) dibenzyl tetraethyl phosphate, 4 to 7 parts of aluminum chlorohydrate, 2 to 3 parts of zinc benzoate, 3 to 5 parts of dechlorane plus, 1 to 2 parts of 2, 2`-methylenebis(6-tert-butyl-4-methylphenol), and 4 to 6 parts of adjuvant. The material is high in flexural strength, high in flexibility, and wide in applicable scope.

Owner:安徽电信器材贸易工业有限责任公司

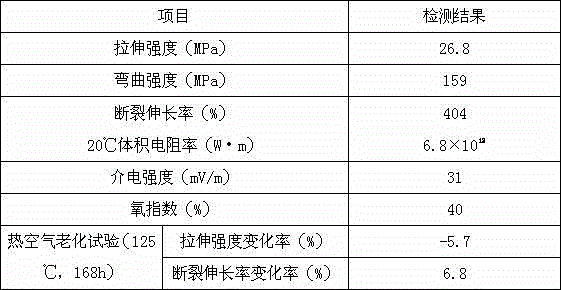

Method for purifying hexachlorocyclopentadiene

InactiveCN102942442ASimple and fast operationReduce energy consumptionHalogenated hydrocarbon preparationDistillationProcess engineering

The invention discloses a method for purifying hexachlorocyclopentadiene. The method for purifying the hexachlorocyclopentadiene includes the steps: firstly, distilling crude hexachlorocyclopentadiene under reduced pressure and collecting front cut fractions and rear cut fractions of two temperature sections; secondly, continuing constant-temperature stirring of the front cut fractions for 2-8 hours, performing reduced pressure distillation and mixing the front cut fractions with the rear cut fractions; and thirdly, continuing constant-temperature stirring for 2-8 hours and performing reduced pressure distillation to obtain the high-purity hexachlorocyclopentadiene. The method has excellent effects in application, the purity of the hexachlorocyclopentadiene can reach 99%, the yield can reach more than 93%, needed equipment is simple, energy consumption is low, the process is easily controlled, and the method is suitable for industrial application.

Owner:SICHUAN UNIV

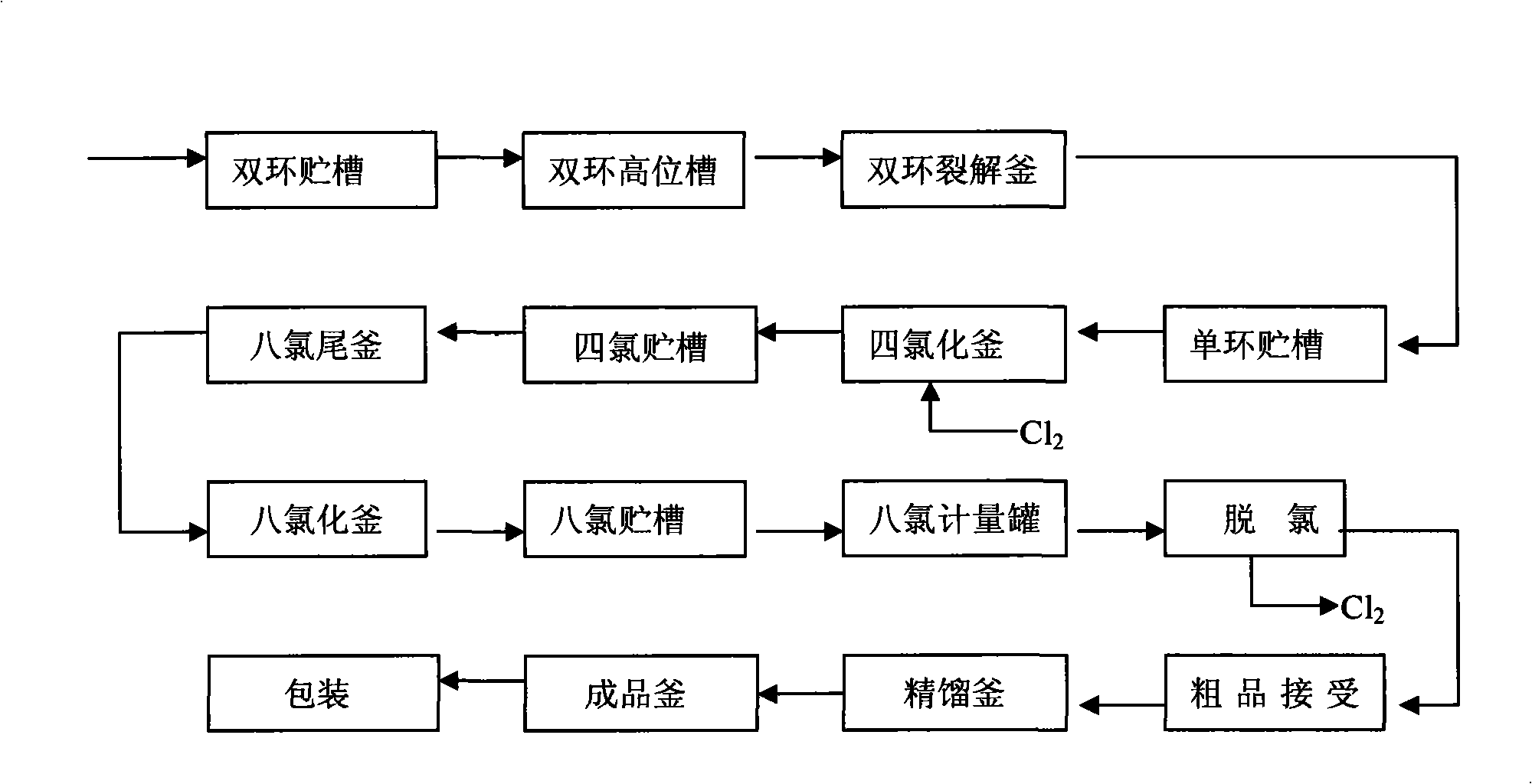

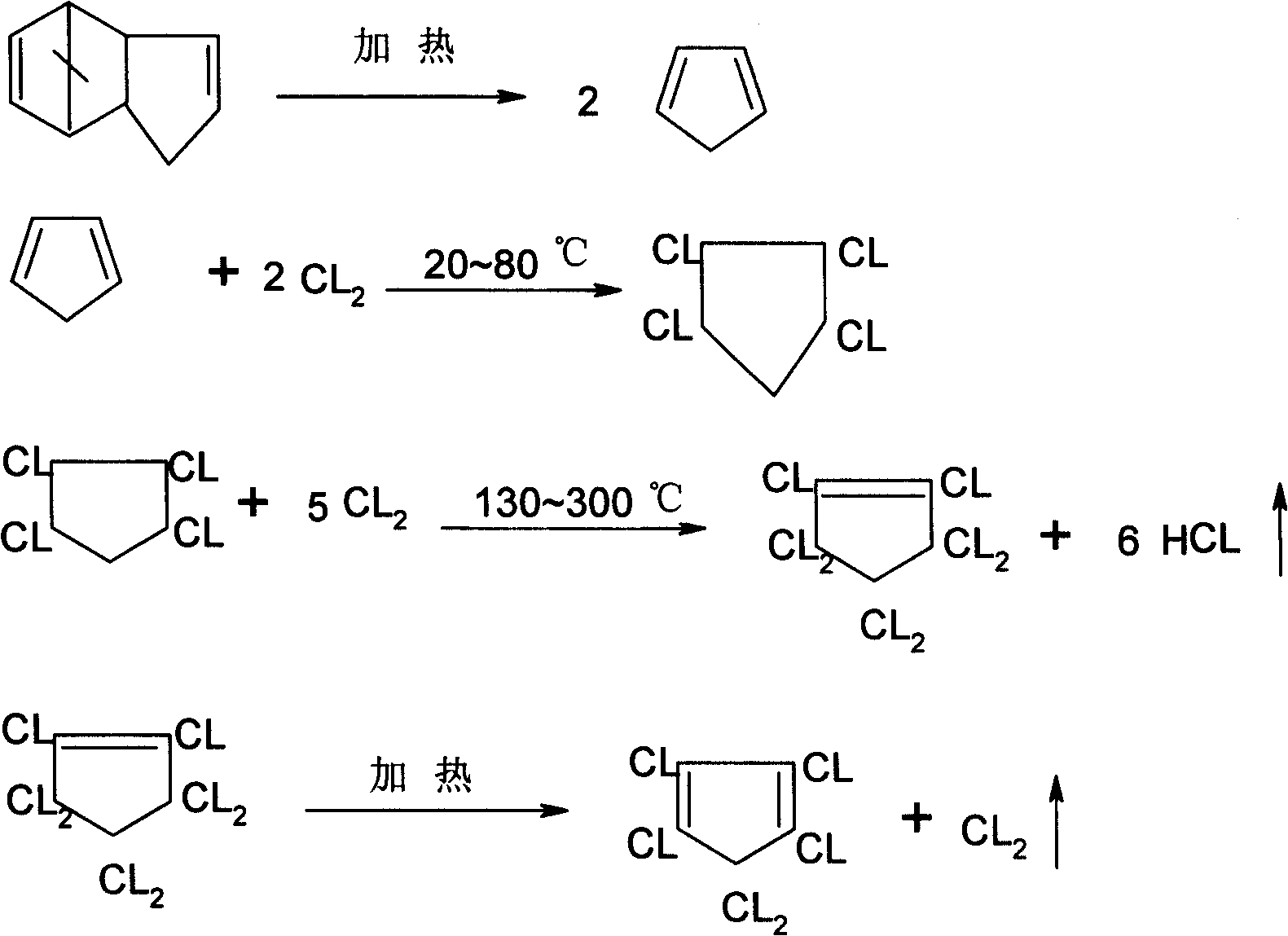

Method for preparing perchlorinated cyclopentadienyl

ActiveCN101318878ASimple processLow costPreparation by dehalogenationPreparation by halogen additionHexachlorocyclopentadieneUtilization rate

The invention discloses a method for preparing hexachlorocyclopentadiene. The method comprises the following steps of: using dicyclopentadiene as a raw material and carrying out pyrolysis, two-step chlorination, dechlorination, rectification, and deacidification to obtain a product with a purity of more than 98 percent, wherein the chlorination is a serial multi-step reaction which is capable of making an effective use of chlorine and improving the utilization rate of the chlorine. With the use of dicyclopentadiene, the overall yield of the invention can reach more than 90 percent.

Owner:JIANGSU ANPON ELECTROCHEM

Lubricating oil with modified additive and preparation method of lubricating oil

InactiveCN113025413AHigh viscosityReduce the effect of viscosityLubricant compositionLubricationTackifier

The invention discloses lubricating oil with a modified additive and a preparation method of the lubricating oil, and particularly relates to the technical field of lubricating oil preparation, and the lubricating oil is prepared from the following raw materials in parts by weight: 73-85 parts of base oil, 8-15 parts of a complexing agent, 3-5 parts of a viscous agent, 1-3 parts of a pour point depressant, 1-3 parts of an anti-foaming agent and 1-3 parts of a tackifier. Employed auxiliary materials (in parts by weight) comprises 15 to 20 parts of dithioglycol and 17 to 25 parts of hexachlorocyclopentadiene. The anti-foaming agent and the tackifier are mixed with the base oil, so that the viscosity of the lubricating oil can be increased, the influence of temperature change on the viscosity of engine oil is reduced, the viscosity-temperature property of the engine oil is improved, the contact area of an oil product and air is reduced, and the oil product is prevented from being oxidized and deteriorated. Through the preparation of the oxidation liquid, the graphene is subjected to two times of oxidation treatment, and thus the graphene material can be directly applied to the field of lubrication. The lubricating oil has good bearing capacity and anti-wear and anti-friction capacity, the anti-friction performance of the lubricating oil is effectively improved, and the loss of an engine is reduced.

Owner:苏州润纳斯纳米科技有限公司

Preparation method of chlorendic anhydride

ActiveCN103087014AAvoid it happening againProper liquidityOrganic chemistryPolyesterReaction temperature

The invention discloses a preparation method of chlorendic anhydride. The chlorendic anhydride is prepared through a reaction of maleic anhydride and hexachlorocyclopentadiene. According to the invention, maleic anhydride is added into hexachlorocyclopentadiene, wherein a molecular ratio of maleic anhydride to hexachlorocyclopentadiene is (1-1.05):(1-1.05). A diluting agent should be added before or during the reaction. The reaction temperature is 150-180 DEG C, and a reaction time is 2-5h. According to the invention, maleic anhydride is added into hexachlorocyclopentadiene, and a reaction is carried for 2-5h under a temperature of 150-180 DEG C, such that high-quality chlorendic anhydride is successfully produced, and a yield reaches 96%. The chlorendic anhydride can be directly used in polyester production. The method has the advantages such as easy-to-obtain raw materials, short reaction time, simple operation, low investment, and high yield.

Owner:JIANGSU ANPON ELECTROCHEM

Potent anti-cracking cable plug material and preparation method thereof

The invention provides a potent anti-cracking cable plug material and a preparation method thereof and relates to the technical field of cable production. The cable plug material is prepared from thefollowing raw materials in parts by weight: 45-55 parts of high density polyethylene, 15-20 parts of chloroprene rubber, 6-8 parts of phenyl-beta-naphthylamine, 3-5 parts of N,N-diphenyl p-phenylenediamine, 3-5 parts of N-phenyl N'-isopropyl p-phenylenediamine, 5-7 parts of bis(3-triethoxysilylpropyl)tetrasulfide, 3-5 parts of hexachlorocyclopentadiene, 2-3 parts of polyvinyl butyral, 3-4 parts ofsodium sulfomolybdate and 2-3 parts of titanium carbide. By adopting the material, defects of the prior art are overcome, the anti-cracking performance of the plug material can be effectively improved, the danger that a plug is cracked when being pulled and electric leakage and electric shock are caused can be avoided, the toughness, the strength and the wearing resistance of the plug can be alsoeffectively improved, and the plug material is excellent in overall property, good in anti-cracking property, high in security and applicable to popularization.

Owner:涌纬集团股份有限公司

Lubricating oil for injection molding machine joints

ActiveCN106010755BImprove wear resistanceImprove corrosion resistanceAdditivesMethyl carbamateInjection molding machine

The invention relates to an injection molding machine joint lubricating oil, which is prepared from the following raw materials by weight: 85-95 parts of mineral base oil, 15-25 parts of nonylphenol polyoxyethylene ether, and 3-5 parts of hexachlorocyclopentadiene 3-5 parts of ethanedithiol, 5-10 parts of propolis extract, 5-10 parts of seaweed extract, 10-15 parts of graphene, 5-10 parts of modified zircon powder, 1-1 methyl carbamate 3 parts and 2-4 parts of benzimidazole. The lubricating oil of the present invention has good anti-wear properties, corrosion resistance, thermal stability, anti-foaming properties, good sealing adaptability, high cleanliness, and can meet the requirements of the hydraulic system of the injection molding machine for lubricating oil. The lubricating oil itself has strong adhesion so that the oil is not easily lost quickly. The preparation method of the invention is simple, convenient for industrial production and low in cost.

Owner:NINGBO RUNBEI WANLING LUBRICANT

Preparation method of chlorendic anhydride

ActiveCN103087014BAvoid it happening againProper liquidityOrganic chemistryPolyesterReaction temperature

The invention discloses a preparation method of chlorendic anhydride. The chlorendic anhydride is prepared through a reaction of maleic anhydride and hexachlorocyclopentadiene. According to the invention, maleic anhydride is added into hexachlorocyclopentadiene, wherein a molecular ratio of maleic anhydride to hexachlorocyclopentadiene is (1-1.05):(1-1.05). A diluting agent should be added before or during the reaction. The reaction temperature is 150-180 DEG C, and a reaction time is 2-5h. According to the invention, maleic anhydride is added into hexachlorocyclopentadiene, and a reaction is carried for 2-5h under a temperature of 150-180 DEG C, such that high-quality chlorendic anhydride is successfully produced, and a yield reaches 96%. The chlorendic anhydride can be directly used in polyester production. The method has the advantages such as easy-to-obtain raw materials, short reaction time, simple operation, low investment, and high yield.

Owner:JIANGSU ANPON ELECTROCHEM

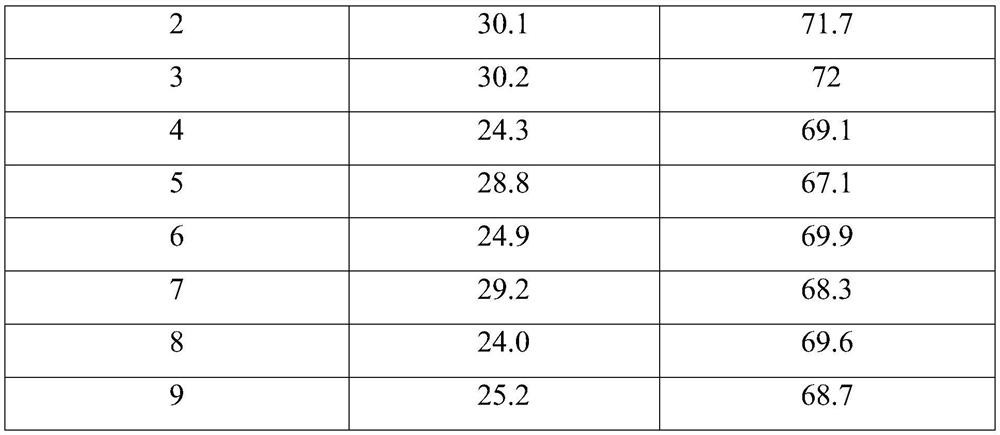

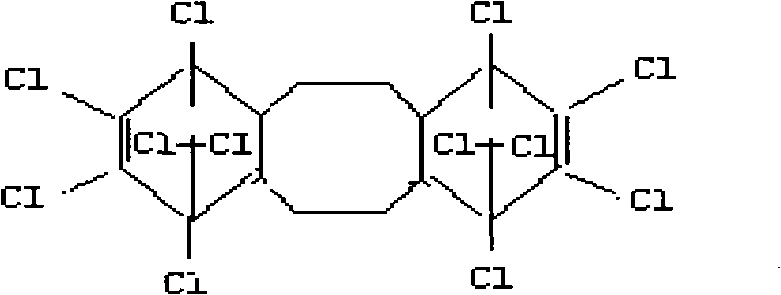

Method for preparing high-quality DRCP

ActiveCN101891585AEasy to recycleImprove qualityHalogenated hydrocarbon preparationHexachlorocyclopentadieneSolvent

The invention discloses a method for preparing high-quality DRCP, which is characterized in that hexachlorocyclopentadiene and cyclooctadiene are insulated and react for 3-10h in a solvent under 140-180 DEG C, wherein the molar ratio of hexachlorocyclopentadiene to cyclooctadiene is 2.0-2.5:1; the solvent is single and is alkane or halohydrocarbon; and the mass of the solvent is 30-60% of the total mass of hexachlorocyclopentadiene and cyclooctadiene. The method is simple and practicable and easy for industrialization, and the single solvent is convenient for recycling the subsequent solvent, thus reducing the load of subsequent processing. The high-quality DRCP obtained by the method of the invention has chromaticity being more than 98 and yield up to 98.5%.

Owner:JIANGSU ANPON ELECTROCHEM

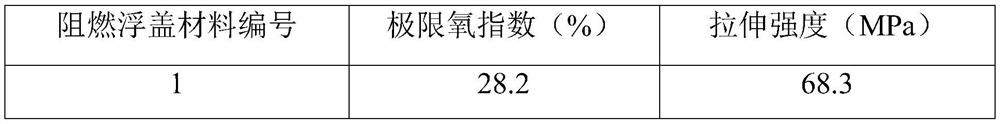

Composition for flame-retardant floating cover, flame-retardant floating cover material and preparation method of flame-retardant floating cover material

The invention relates to the field of fire fighting, in particular to a composition for a flame-retardant floating cover, a flame-retardant floating cover material and a preparation method of the flame-retardant floating cover material. The composition for the flame-retardant floating cover contains polyamide and a flame retardant, the flame retardant comprises a first component and a second component, the first component is selected from expanded graphite, and the second component is selected from at least one of bis (hexachlorocyclopentadiene) cyclooctane, decabromodiphenyl ethane, brominated polystyrene, antimony trioxide, aluminum hydroxide and magnesium hydroxide; the weight ratio of the first component to the second component is 1: (0.1-5). The composition for the flame-retardant floating cover can play a role in reducing the volatilization rate of the liquid level of an oil product, the composition is thrown in when a fire accident occurs, the flame intensity can be reduced, and the purpose of rapidly extinguishing fire is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high-quality DRCP

The invention discloses a method for preparing high-quality DRCP, which is characterized in that hexachlorocyclopentadiene and cyclooctadiene are insulated and react for 3-10h in a solvent under 140-180 DEG C, wherein the molar ratio of hexachlorocyclopentadiene to cyclooctadiene is 2.0-2.5:1; the solvent is single and is alkane or halohydrocarbon; and the mass of the solvent is 30-60% of the total mass of hexachlorocyclopentadiene and cyclooctadiene. The method is simple and practicable and easy for industrialization, and the single solvent is convenient for recycling the subsequent solvent,thus reducing the load of subsequent processing. The high-quality DRCP obtained by the method of the invention has chromaticity being more than 98 and yield up to 98.5%.

Owner:JIANGSU ANPON ELECTROCHEM

Novel low-temperature resistant lubricant formulation

The invention provides a novel low-temperature resistant lubricant formulation. Raw materials in the formulation include, by weight, 5%-15% of base oil, 1%-5% of lubricant additive, 1%-10% of graphite, 5%-15% of bentonite, 3%-9% coupling agent, 2%-3% of nonylphenol polyoxyethylene ether, 1%-5% of hexachlorocyclopentadiene, 11%-19% of ethanedithiol, 5%-7% of propolis extract, and 3%-5% of seaweed extract. Novel low-temperature resistant lubricant prepared by the formulation has strong low temperature resistance.

Owner:徐州易高中泰新能源有限公司

Lubricating oil for injection molding machine

ActiveCN106085562BImprove wear resistanceImprove corrosion resistanceLubricant compositionMethyl carbamateInjection molding machine

The invention relates to an injection molding machine lubricating oil, which is prepared from the following raw materials by weight: 85-95 parts of mineral base oil, 15-25 parts of nonylphenol polyoxyethylene ether, and 3-5 parts of hexachlorocyclopentadiene , 3-5 parts of ethanedithiol, 5-10 parts of alkylated diphenylamine, 10-15 parts of graphene, 5-10 parts of modified zircon powder, 1-3 parts of methyl carbamate and 2 parts of benzimidazole -4 parts. The lubricating oil of the present invention has good anti-wear properties, corrosion resistance, thermal stability, anti-foaming properties, good sealing adaptability, high cleanliness, and can meet the requirements of the hydraulic system of the injection molding machine for lubricating oil. The lubricating oil itself has strong adhesion so that the oil is not easily lost quickly. The preparation method of the invention is simple, convenient for industrial production and low in cost.

Owner:NINGBO RUNBEI WANLING LUBRICANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com