Lubricating oil with modified additive and preparation method of lubricating oil

A lubricating oil and additive technology, which is applied in the field of lubricating oil with modified additives and its preparation, can solve the problems of increasing the anti-friction performance of lubricating oil, poor lubricating effect of lubricating oil, and reducing contact area, etc., so as to improve engine oil Viscosity-temperature properties, good load-bearing and anti-wear and anti-friction capabilities, and the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

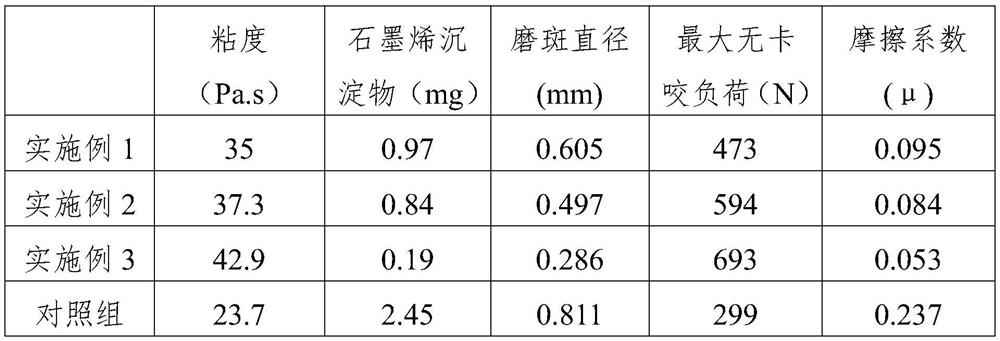

Embodiment 1

[0027] The invention provides a lubricating oil with modified additives. The raw materials used (in parts by weight) include 73-85 parts of base oil, 8-15 parts of compounding agent, 3-5 parts of viscous agent, pour point depressant 1-3 parts, 1-3 parts of antifoaming agent and 1-3 parts of tackifier, the auxiliary materials used (by weight) include 15-20 parts of ethanedithiol, 17-25 parts of hexachlorocyclopentadiene 10-15 parts of potassium peroxodisulfate, 7-10 parts of phosphorus pentoxide, 1200-1500 parts of water, 0.25-2 parts of graphene, 13-18 parts of potassium permanganate and 12-13 parts of hydrogen peroxide.

[0028]And specifically in the present embodiment: the raw materials used (by weight) include 73 parts of base oil, 8 parts of compounding agent, 3 parts of viscous agent, 1 part of pour point depressant, 1 part of antifoaming agent and tackifier 1 part, the auxiliary materials used (by weight) include 15 parts of ethanedithiol, 17 parts of hexachlorocyclopen...

Embodiment 2

[0037] The invention provides a lubricating oil with modified additives. The raw materials used (in parts by weight) include 73-85 parts of base oil, 8-15 parts of compounding agent, 3-5 parts of viscous agent, pour point depressant 1-3 parts, 1-3 parts of antifoaming agent and 1-3 parts of tackifier, the auxiliary materials used (by weight) include 15-20 parts of ethanedithiol, 17-25 parts of hexachlorocyclopentadiene 10-15 parts of potassium peroxodisulfate, 7-10 parts of phosphorus pentoxide, 1200-1500 parts of water, 0.25-2 parts of graphene, 13-18 parts of potassium permanganate and 12-13 parts of hydrogen peroxide.

[0038] And specifically in the present embodiment: the raw materials used (by weight) include 78 parts of base oil, 11 parts of compounding agent, 4 parts of viscous agent, 2 parts of pour point depressant, 2 parts of antifoaming agent and tackifier 2 parts, the auxiliary materials used (by weight) include 17 parts of ethanedithiol, 21 parts of hexachlorocyc...

Embodiment 3

[0047] The invention provides a lubricating oil with modified additives. The raw materials used (in parts by weight) include 73-85 parts of base oil, 8-15 parts of compounding agent, 3-5 parts of viscous agent, pour point depressant 1-3 parts, 1-3 parts of antifoaming agent and 1-3 parts of tackifier, the auxiliary materials used (by weight) include 15-20 parts of ethanedithiol, 17-25 parts of hexachlorocyclopentadiene 10-15 parts of potassium peroxodisulfate, 7-10 parts of phosphorus pentoxide, 1200-1500 parts of water, 0.25-2 parts of graphene, 13-18 parts of potassium permanganate and 12-13 parts of hydrogen peroxide.

[0048] And specifically in the present embodiment: the raw materials used (by weight) include 85 parts of base oil, 15 parts of compounding agent, 5 parts of viscous agent, 3 parts of pour point depressant, 3 parts of antifoaming agent and tackifier 3 parts, the auxiliary materials used (by weight) include 20 parts of ethanedithiol, 25 parts of hexachlorocyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com