Special flexing-resistant material for protecting sleeve pipe for communication cable and preparation method of special flexing-resistant material

A technology for communication cables and sheath tubes, which is applied in the field of special materials for flexure-resistant communication cable sheath tubes and its preparation. It can solve the problems of affecting optical fiber transmission, easy cracking, and poor flex resistance. Wide temperature range and high flex resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

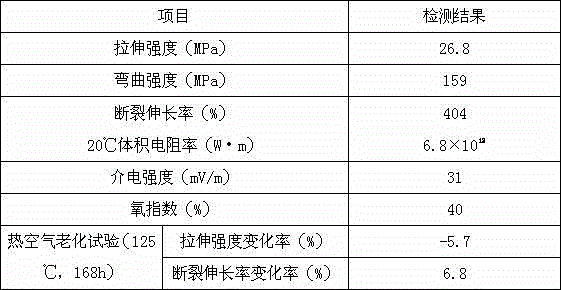

Image

Examples

Embodiment

[0012] A special material for flexure-resistant communication cable sheath, made of the following materials (kg): polyethylene terephthalate 64, α-methylstyrene-acrylonitrile-styrene ternary copolymer Compound 48, nano halloysite 21, calcium laurate 3, triisodecyl trimellitate 16, β-diketone 2.5, thermoplastic polyurethane elastomer 25, stannous stearate 3.5, activated clay 16, colloidal pentoxide Antimony 13, Dipropylene glycol dibenzoate 14, Corundum powder 12, N, N-p-phenylenediamine (2-hydroxy) dibenzyl tetraethyl phosphonate 2.5, hydroxyaluminum chloride 5, zinc benzoate 2.5. Bis(hexachlorocyclopentadiene) cyclooctane 4, 2,2`-methylene bis(4-methyl-6-tert-butylphenol) 1.5, auxiliary 5;

[0013] The preparation method of the auxiliary agent is as follows: a. Take the following parts by weight of raw materials: calcium zirconate 10, methylene bis(2,4-di-tert-butylphenoxy) aluminum phosphate 3, titanium oxalate 2.5, rectorite 8, 3,5-di-tert-butyl-4-hydroxybenzoic acid methyl e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com