Lubricating oil for joints of injection molding machine

A lubricating oil and machine joint technology, applied in the field of lubricating oil, can solve problems such as inability to use centralized lubrication, unsuitable pumping, high production costs, etc., and achieve the effects of not easy to lose quickly, low cost, and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

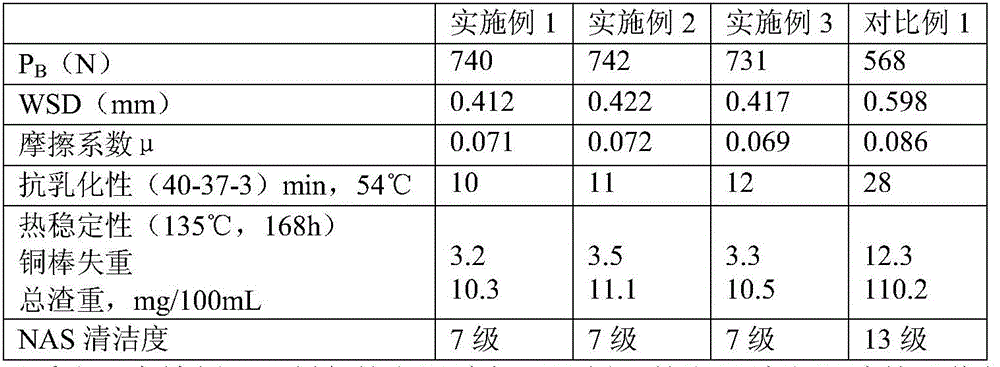

Examples

Embodiment 1

[0024] An injection molding machine joint lubricating oil, prepared from the following raw materials in parts by weight: 85 parts of mineral base oil, 15 parts of nonylphenol polyoxyethylene ether, 3 parts of hexachlorocyclopentadiene, 3 parts of ethanedithiol, 5 parts of propolis extract, 5 parts of seaweed extract, 10 parts of graphene, 5 parts of modified zircon powder, 1 part of methyl carbamate and 2 parts of benzimidazole.

[0025] The preparation method of modified nano-zircon powder is: adding stearic acid into dichloromethane, then adding tetradecyl trimethyl ammonium chloride, cetyl mercaptan and 3-mercaptopropyl triethoxy base silane to prepare a modified solution; then crush the zircon into 20-40 μm and add it to the modified solution, heat it in a water bath at 85°C for 5 hours at an ultrasonic frequency of 60KHz, take it out after cooling, and calcinate it at 650°C for 2 hours, and then grind it into Nano powder obtains modified nano zircon powder; The solid-liqu...

Embodiment 2

[0030] An injection molding machine joint lubricating oil, prepared from the following raw materials in parts by weight: 90 parts of mineral base oil, 20 parts of nonylphenol polyoxyethylene ether, 4 parts of hexachlorocyclopentadiene, 4 parts of ethanedithiol, 7 parts of propolis extract, 8 parts of seaweed extract, 12 parts of graphene, 7 parts of modified zircon powder, 2 parts of methyl carbamate and 3 parts of benzimidazole.

[0031] The preparation method of modified nano-zircon powder is: adding stearic acid into dichloromethane, then adding tetradecyl trimethyl ammonium chloride, cetyl mercaptan and 3-mercaptopropyl triethoxy base silane to prepare a modified solution; then crush the zircon into 20-40 μm and add it to the modified solution, heat it in a water bath at 90°C for 7h at an ultrasonic frequency of 70KHz, take it out after cooling, and calcinate at 680°C for 2.5h, then grind Become nanometer powder and obtain modified nanometer zircon powder; The solid-liquid...

Embodiment 3

[0036] An injection molding machine joint lubricating oil, prepared from the following raw materials in parts by weight: 95 parts of mineral base oil, 25 parts of nonylphenol polyoxyethylene ether, 5 parts of hexachlorocyclopentadiene, 5 parts of ethanedithiol, 10 parts of propolis extract, 10 parts of seaweed extract, 15 parts of graphene, 10 parts of modified zircon powder, 3 parts of methyl carbamate and 4 parts of benzimidazole.

[0037] The preparation method of modified nano-zircon powder is: adding stearic acid into dichloromethane, then adding tetradecyl trimethyl ammonium chloride, cetyl mercaptan and 3-mercaptopropyl triethoxy base silane to obtain a modified solution; then crush the zircon into 20-40 μm and add it to the modified solution, heat it in a water bath at 95°C for 10h at an ultrasonic frequency of 90KHz, take it out after cooling, dry it and calcinate it at 700°C for 3h, and then grind it into Nano powder obtains modified nano zircon powder; The solid-liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com