Ethylene-alpha olefin copolymer and preparation method thereof

A technology of alpha olefin and copolymer, applied in the field of ethylene-alpha olefin copolymer and its preparation, can solve problems such as gel phenomenon, achieve the effects of good fluidity, easy availability of raw materials, and reduction of gel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

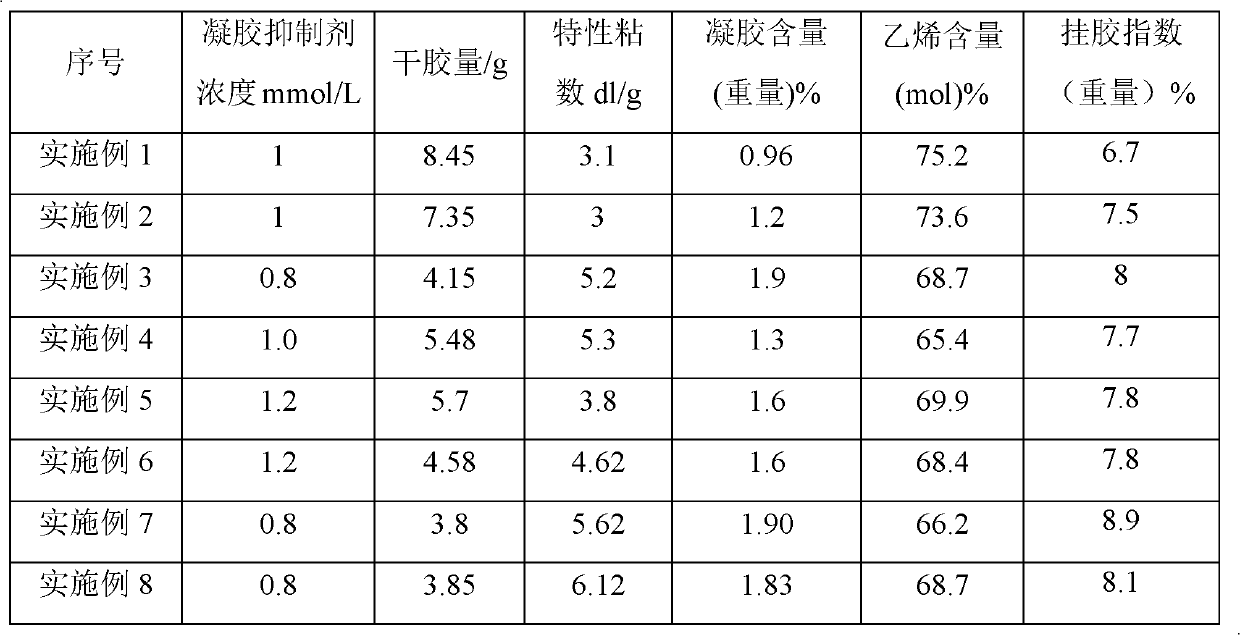

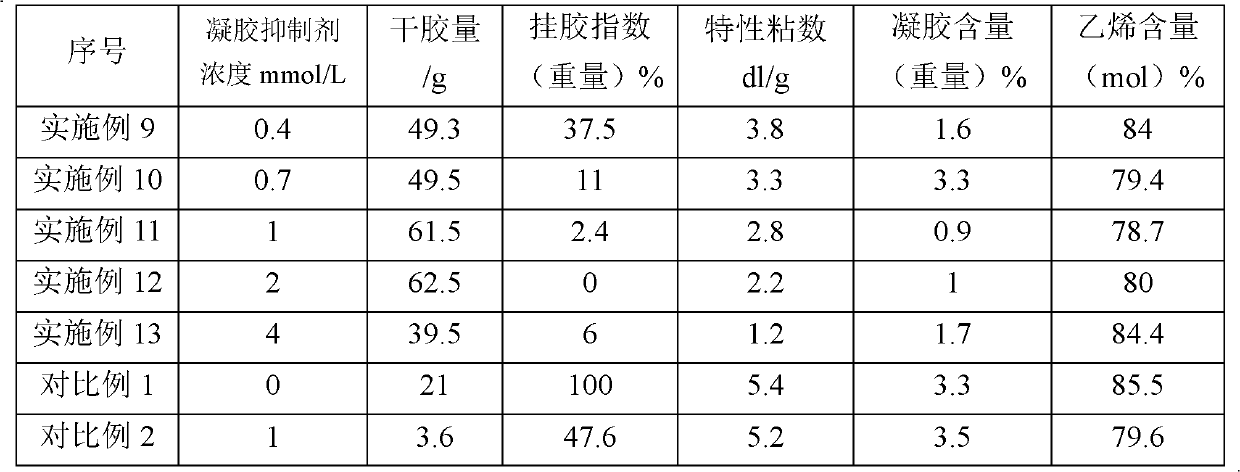

Examples

preparation example Construction

[0012] According to the preparation method of ethylene-alpha olefin copolymer of the present invention, the method comprises: under the condition of olefin solution copolymerization, in the presence of a solvent and a gel inhibitor, contacting ethylene and alpha olefin with a catalyst to obtain ethylene-alpha olefin copolymerization The catalyst contains organoaluminum and vanadium compounds, wherein the gel inhibitor is selected from the group consisting of perchloropropene, hexachlorobutadiene, hexachlorocyclopentadiene, arylsulfonyl halides, and halogen atoms with at least 2 One or more of halogenated fatty acid esters and aromatic halogenated hydrocarbons with at least 3 halogen atoms.

[0013] In the present invention, the term "dry glue amount" refers to the weight of ethylene-alpha olefin polymer; "insoluble matter" refers to the dry glue that exists in the polymer solution and is insoluble in the polymer solution; The polymer attached to the wall of the polymerization ...

Embodiment 1

[0047] Replace the pre-dried 0.5L polymerization kettle equipped with stirring paddle and jacket with nitrogen and raw material monomer respectively, add 200mL dry hexane solvent into the polymerization kettle, and then dry the The mixed gas of ethylene, propylene and hydrogen is pre-saturated at 20°C and 0.5 MPa pressure for 20 minutes, and the cocatalyst sesquiethylaluminum chloride 0.8mmol, vanadyl trichloride 0.04mmol and ethyl trichloroacetate 0.2mmol are added, and the polymerization kettle The jacket was circulated with cold water, the reaction temperature was controlled to keep constant at 20° C., the reaction pressure was 0.5 MPa, and the flow rate of the mixed monomer was guaranteed to be 2 standard liters / minute. After polymerization reaction 30 minutes, stop conveying ethylene, propylene, hydrogen, stop stirring, remove ethylene, propylene, add ethanol 10ml to terminate polymerization reaction, add the hexane solution that is the antioxidant Irganox 1520 of 0.2wt% b...

Embodiment 2

[0049] Other conditions were the same as in Example 1, except that the type and amount of the gel inhibitor used during polymerization were changed to: 0.2 mmol of n-butyl trichloroacetate. After reacting for 30 minutes, the amount of dry glue and the gel condition of the measured sample are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com