High-temperature resistant polyphosphazene microsphere and preparation method thereof

A technology of polyphosphazene and high temperature resistance, which is applied in the field of high temperature resistant polyphosphazene microspheres and its preparation, can solve the problems of single polyphosphazene microspheres and unsatisfactory thermal properties, and achieve simple and easy process and good thermal stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 0.06 g (0.18 mmol) of hexachlorocyclotriphosphazene, 0.04 g (0.36 mmol) of phloroglucinol to a 100 mL flask, add 50 mL of acetonitrile to dissolve, and add 2 mL (1.44 mmol) when the temperature of the water bath reaches 30°C. Mol) triethylamine, reacted in an ultrasonic (190W) constant temperature water bath for 3h. After the reaction, the solid was separated by centrifugation. The crude product was washed three times with ethanol, then washed three times with deionized water, and finally dried in a vacuum oven for 24h. Get cross-linked polyphosphazene microspheres.

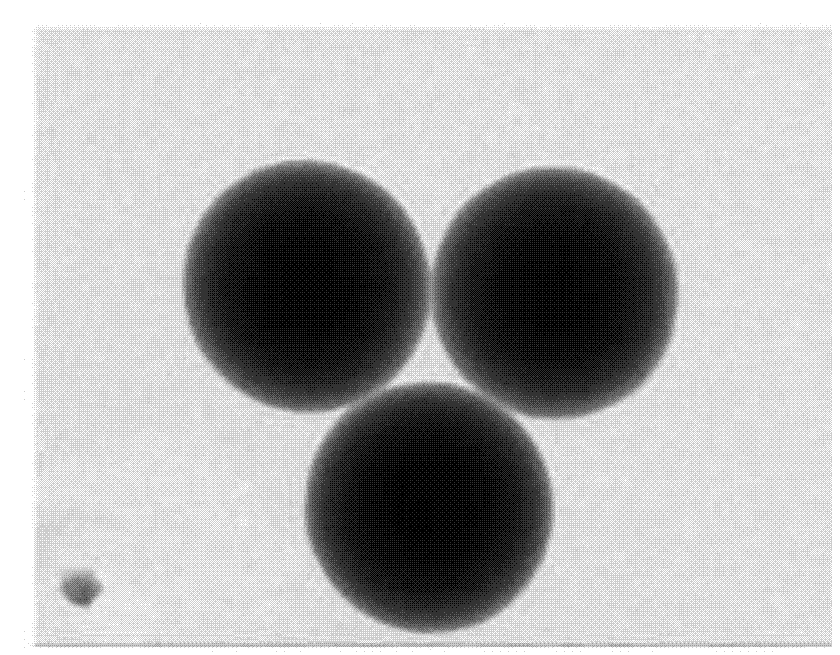

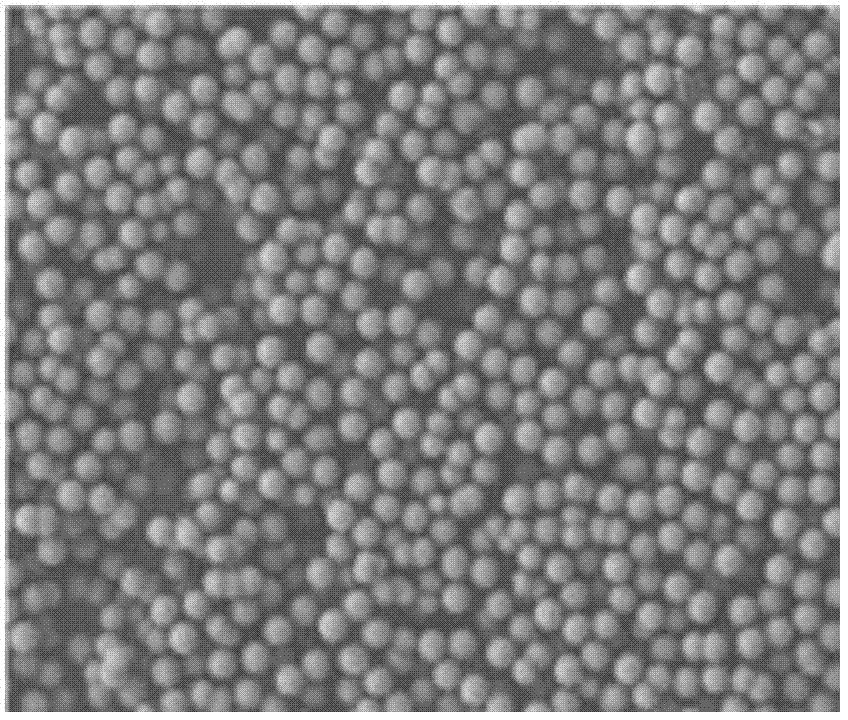

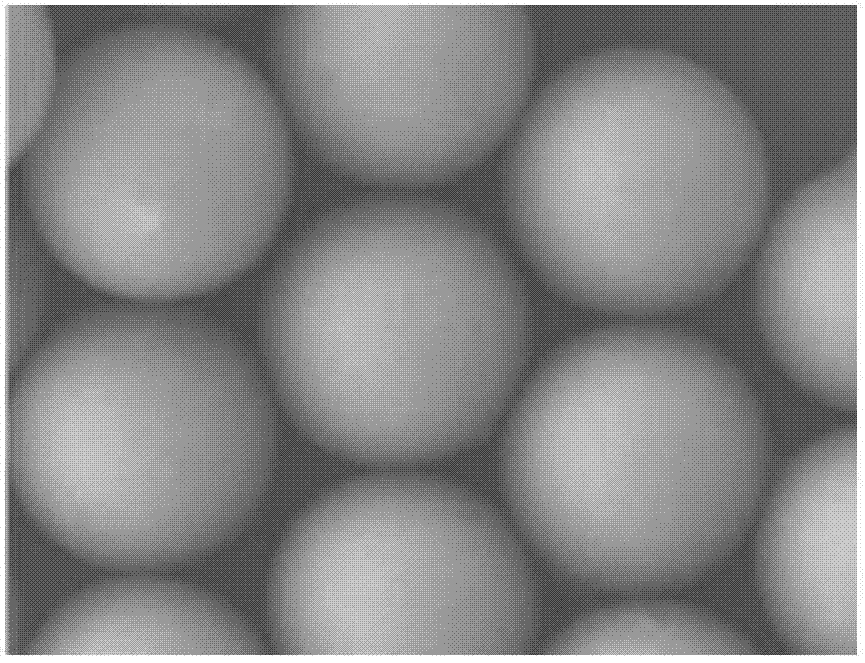

[0025] figure 1 Is the transmission electron micrograph of the crosslinked polyphosphazene microspheres, figure 2 Is a scanning electron micrograph of cross-linked polyphosphazene microspheres, image 3 It is a field emission scanning electron microscope photo of cross-linked polyphosphazene microspheres. It can be seen from the photo that the diameter of the microspheres is about 800 nm, and the surface ...

Embodiment 2

[0029] Using the equipment and preparation process described in Example 1, hexachlorocyclotriphosphazene was 0.06 g (0.18 mmol) and phloroglucinol was 0.06 g (0.54 mmol). The crude product was washed three times with ethanol, and then used Washed with deionized water three times, and finally dried in a vacuum oven for 24 hours to obtain cross-linked polyphosphazene microspheres. The analysis of the experimental results showed that the diameter of the microspheres was about 800nm, and the surface of the microspheres was flat and solid, and the structure was a cross-linked condensation structure of hexachlorocyclotriphosphazene and phloroglucinol.

Embodiment 3

[0031] Using the equipment and preparation process described in Example 1, the ultrasonic power used was 190W, the temperature of the constant temperature water bath was 30℃, and the reaction time was 1min, 10min, 30min, 1h, 2h, 3h, and some samples were taken out, and the samples were subjected to ethanol and deionization. Sample preparation after washing with water several times. The analysis of SEM experiment results showed that the diameter of the microspheres was 800nm-900nm, the surface of the microspheres was flat and solid, and the structure was a cross-linked condensation structure of hexachlorocyclotriphosphazene and phloroglucinol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com