Body flame retardant plastic wood composite material and preparation method thereof

A technology for wood-plastic composite materials and flame-retardant fabrics, applied in the field of flame-retardant materials, can solve the problems of the decline of flame-retardant performance, easy decomposition and loss of wood-plastic composite materials, and achieve the realization of body flame retardant and long-lasting flame retardant and flame retardant. Excellent performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

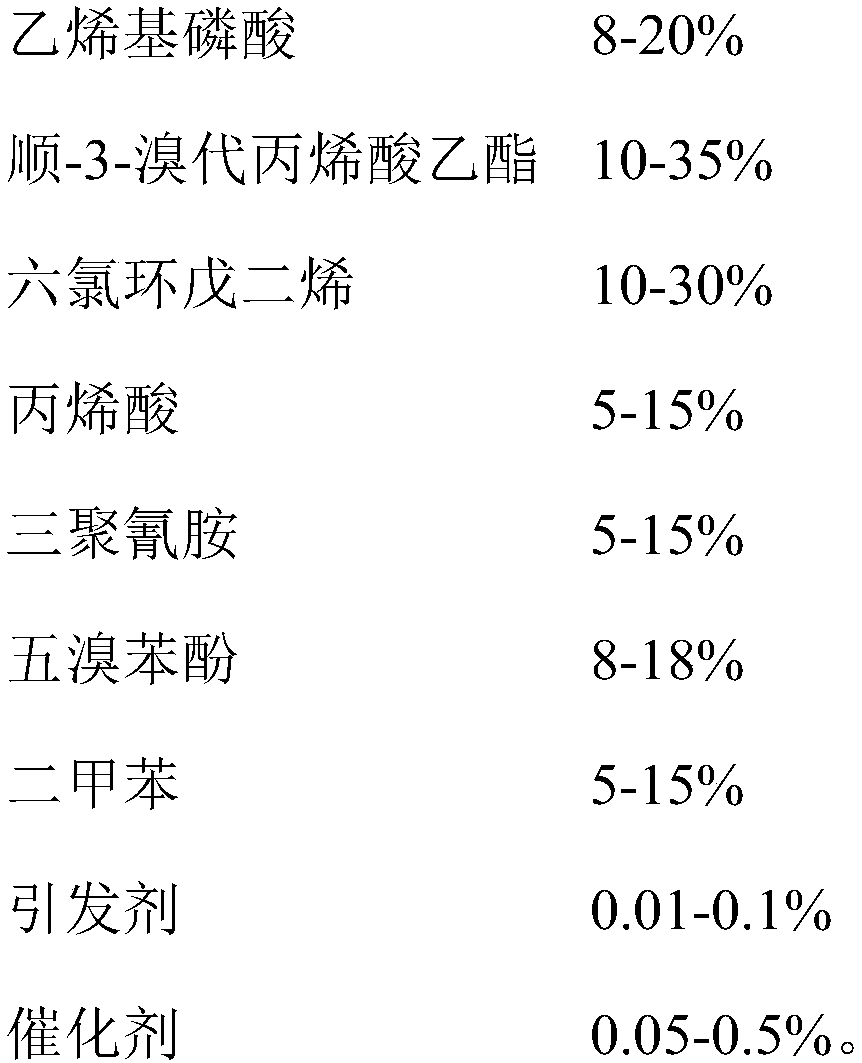

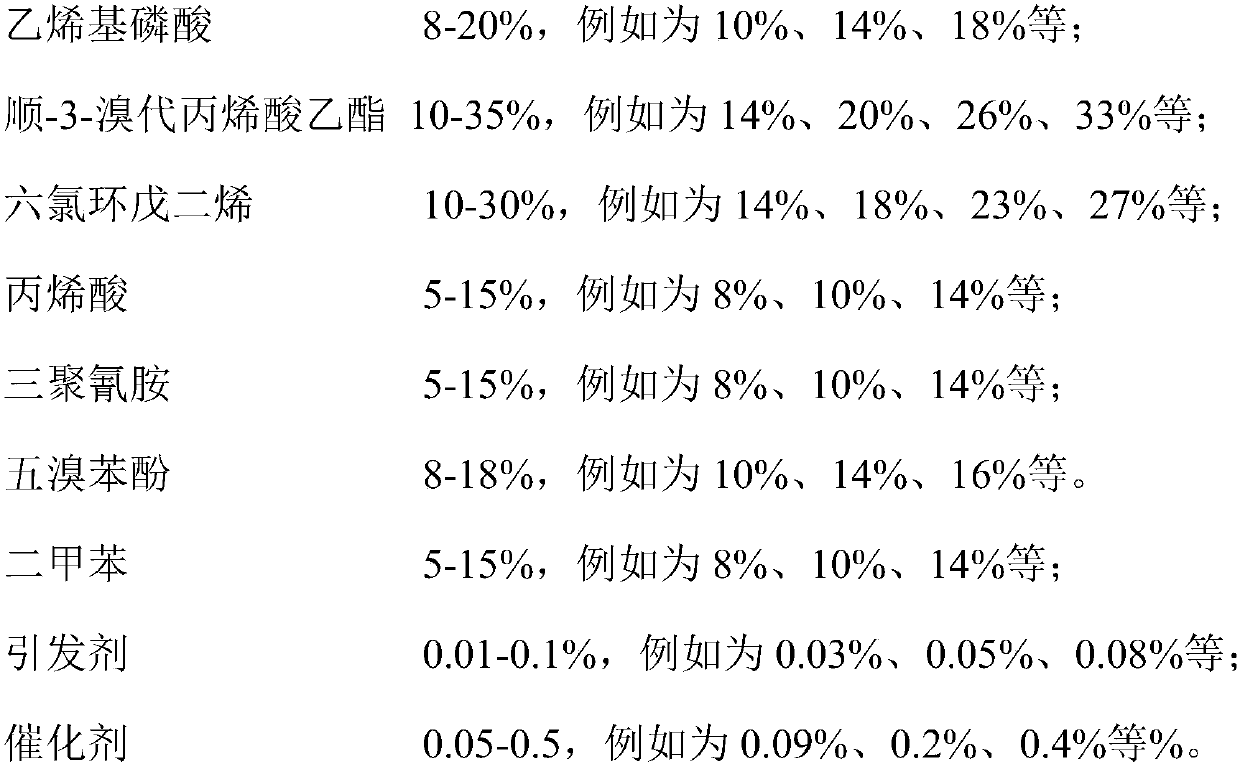

[0038] A body flame-retardant plastic-wood composite material, the body flame-retardant fabric is composed of raw materials in terms of mass fraction:

[0039] Vinyl Phosphate 8%;

[0040] cis-3-ethyl bromoacrylate 30%;

[0041] Hexachlorocyclopentadiene 10%;

[0042] Acrylic acid 14.49%;

[0043] Melamine 15%;

[0044] Pentabromophenol 17%;

[0045] Xylene 5%;

[0046] Initiator 0.01%;

[0047] Catalyst 0.5%.

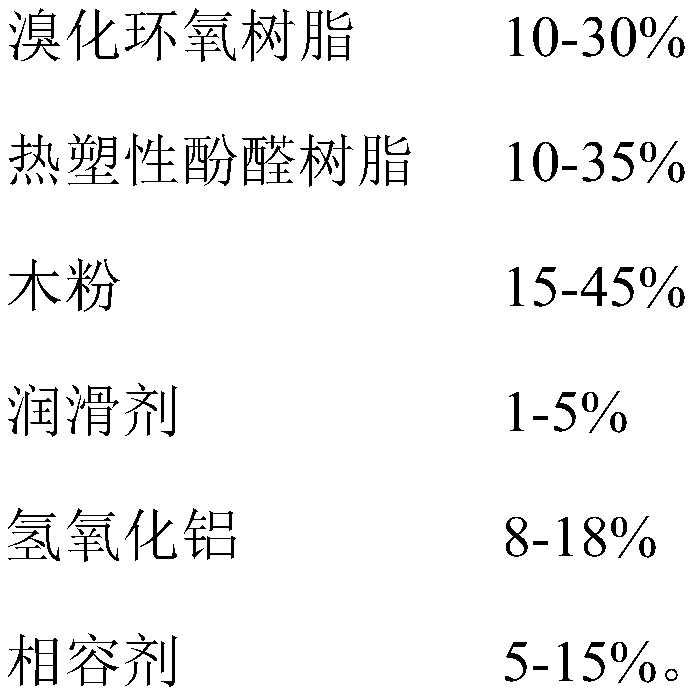

[0048] The raw material composition of the core material is as follows according to the mass fraction:

[0049]

[0050]

[0051] The preparation method comprises the following steps:

[0052] A. Fully mix the raw materials of the flame retardant core material according to the formula at 130-150°C, and discharge them into the cold mix, cool down to 70°C and discharge to make a special premix;

[0053] B. Add the core material special premix and body flame retardant fabric materials into the parallel twin-screw extruder to extrude and granulate separately...

Embodiment 2

[0056] A body flame-retardant plastic-wood composite material, the body flame-retardant fabric is composed of raw materials in terms of mass fraction:

[0057] Vinyl Phosphate 20%;

[0058] Cis-3-Ethyl Bromoacrylate 10%;

[0059] Hexachlorocyclopentadiene 29.85%;

[0060] Acrylic 12%;

[0061] Melamine 5%;

[0062] Pentabromophenol 8%;

[0063] Xylene 15%;

[0064] Initiator 0.1%;

[0065] Catalyst 0.05%.

[0066] The raw material composition of the core material is as follows according to the mass fraction:

[0067]

[0068] The preparation method is the same as in Example 1.

Embodiment 3

[0070] A body flame-retardant plastic-wood composite material, the body flame-retardant fabric is composed of raw materials in terms of mass fraction:

[0071] Vinyl Phosphate 20%;

[0072] cis-3-ethyl bromoacrylate 15%;

[0073] Hexachlorocyclopentadiene 17%;

[0074] Acrylic 11%;

[0075] Melamine 11%;

[0076] Pentabromophenol 15.7%;

[0077] Xylene 10%;

[0078] Initiator 0.05%;

[0079] Catalyst 0.25%.

[0080] The raw material composition of the core material is as follows according to the mass fraction:

[0081]

[0082]

[0083] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com