Anti-backfire multi-nozzle burner and waste gas treatment method

A burner and anti-backfire technology, which is applied in the direction of combustion methods, burners, gas fuel burners, etc., can solve the problems of complex exhaust gas components, imperfect combustion technology and combustion applicability, and achieve increased heat transfer area, Ensure safety and increase the effect of fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

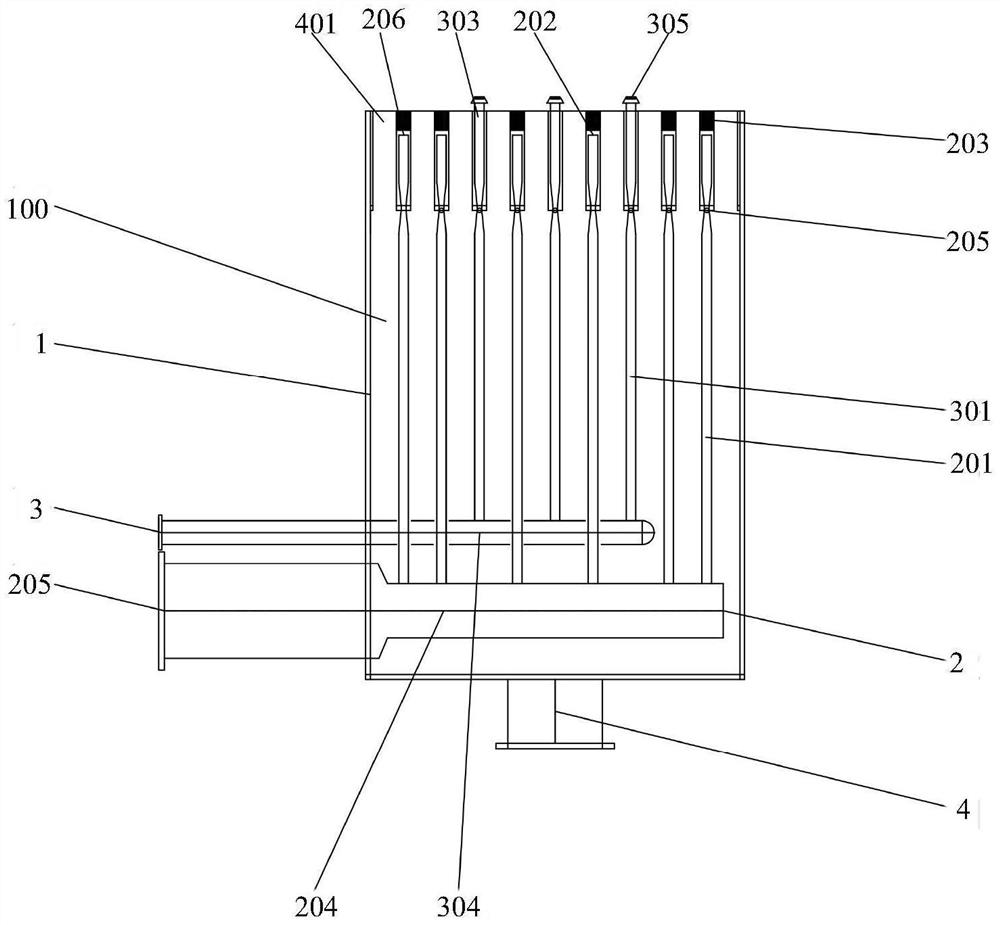

[0026] Example 1: as figure 1 As shown, an anti-backlash multi-burner burner of the present invention, the medium of the burner of the present invention is fuel gas, waste gas, and air, and the burner is a combination of three kinds of medium combustion and combustion-supporting. The burner includes a burner main body 1, the burner main body 1 includes a heat exchange cavity 100, and the bottom of the burner main body 1 is provided with a first pipe 2 for introducing exhaust gas and a second pipe 3 for introducing fuel gas and for supporting combustion. The third duct 4 into which the wind enters, in this embodiment, the third duct 4 has a cylindrical structure, and the top of the burner main body 1 is provided with a combustion-supporting air outlet 401 for sending out the combustion-supporting air. The pipeline materials of the present invention are divided into various materials, wherein the materials of fuel gas and exhaust gas are stainless steel and ultra-high temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com