Fire-resistant and fireproof cable and full-horizontal semi-porcelain production technology

A fire-resistant cable and fire-resistant technology, which is applied in the manufacture of insulated cables, cables/conductors, and insulation of conductors/cables, etc., can solve the problems of large floor space and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

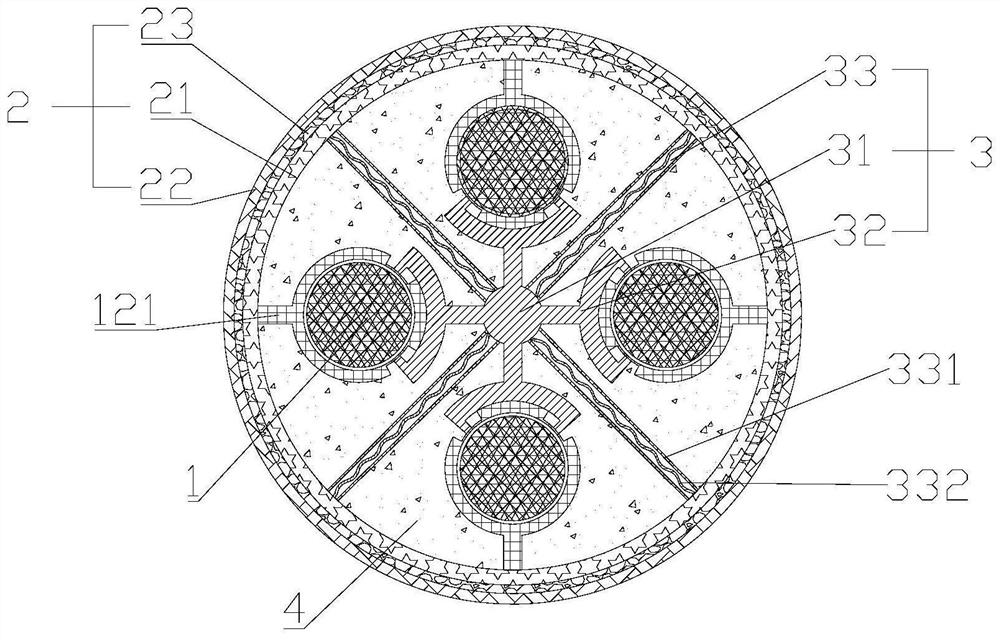

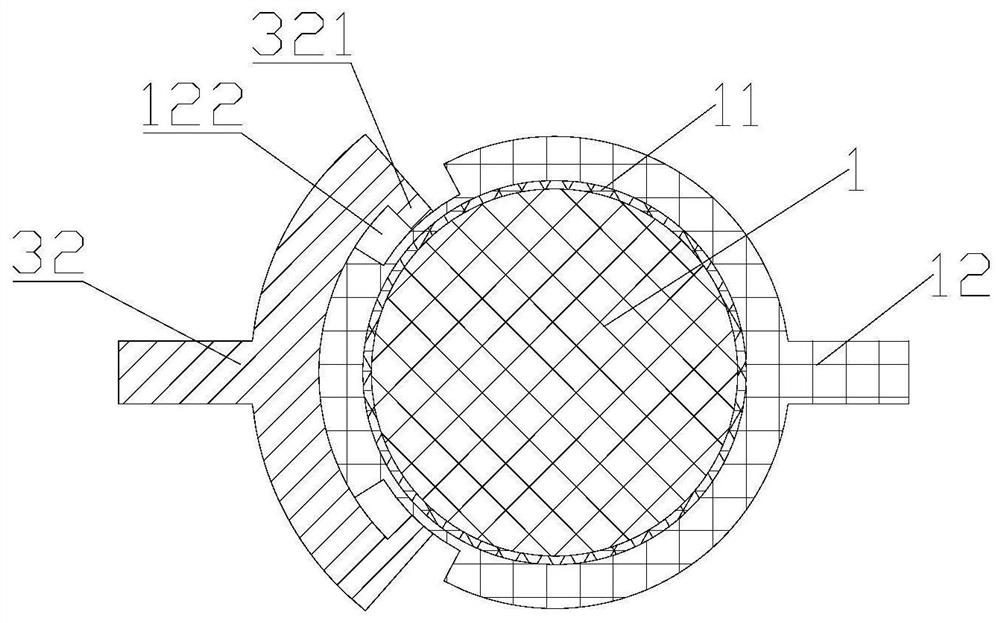

[0029] Such as figure 1 and figure 2 As shown, a fire-resistant and fire-resistant cable includes a copper core 1, a protective sheath 2 and a support frame 3. The copper core 1 is made of copper tape, the outer wall of the copper core 1 is wound with a semiconductor tape, and the support frame 3 is arranged in the protective sheath 2. , the copper core 1 is set on the supporting frame 3, and the copper core 1 is covered with an insulating shielding layer 11 and a rubber protective layer 12 in sequence from the inside to the outside. The thickness of the insulating shielding layer 11 is set to 0.4mm, and the supporting frame 3 includes a central rod 31. The connection part 32 and the skeleton 33, the connection part 32 is arranged between the central rod 31 and the rubber protection layer 12, the connection part 32 is connected with the rubber protection layer 12, the skeleton 33 is arranged between the connection parts 32, and the skeleton 33 connects the central rod 31 Con...

Embodiment 2

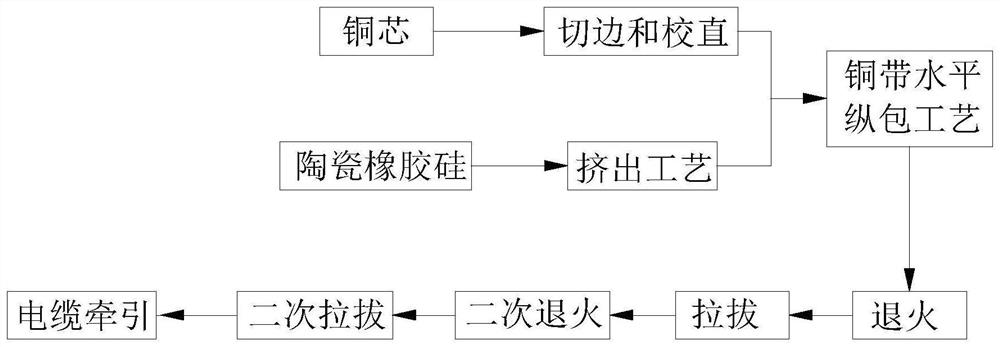

[0035] Such as image 3 Shown, a kind of all-horizontal semi-porcelain production process that is used to produce fire-resistant and fireproof electricity in embodiment 1,

[0036] Step 1: Trim and straighten the copper core 1, and then wrap the semiconductor tape on the outer wall of the copper core 1. At the same time, through the extrusion process, the ceramic silicon rubber, the extrusion speed of the ceramic silicon rubber extrusion process, and the copper tape and Copper core 1 moves at the same speed, 18 m / min;

[0037] Step 2: Connect the copper core 1 through the copper strip horizontal longitudinal wrapping process, and wrap the ceramic silicone rubber on the outside of the rubber protective layer 12. The copper strip horizontal longitudinal wrapping process adopts the argon arc welding method, and the welding temperature is 350°C. The eccentricity meter is used to detect the eccentricity problem in the horizontal longitudinal wrapping process in real time in the pr...

Embodiment 3

[0043] Such as Figure 1-Figure 3 As shown, a fire-resistant and fire-resistant cable includes a copper core 1, a protective sheath 2 and a support frame 3. The copper core 1 is made of copper tape, the outer wall of the copper core 1 is wound with a semiconductor tape, and the support frame 3 is arranged in the protective sheath 2. , the copper core 1 is set on the supporting frame 3, and the copper core 1 is covered with an insulating shielding layer 11 and a rubber protective layer 12 in sequence from the inside to the outside. The thickness of the insulating shielding layer 11 is set to 0.4mm, and the supporting frame 3 includes a central rod 31. The connection part 32 and the skeleton 33, the connection part 32 is arranged between the central rod 31 and the rubber protection layer 12, the connection part 32 is connected with the rubber protection layer 12, the skeleton 33 is arranged between the connection parts 32, and the skeleton 33 connects the central rod 31 Connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com