Deformation control method for difficult-to-deform high-elongation aluminum alloy

A high elongation and deformation control technology, applied in the forging field of aluminum alloy forgings, can solve the problems of low qualification rate, abnormal material texture, mechanical properties that do not meet the requirements of design and use, and achieve the effect of sufficient deformation and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

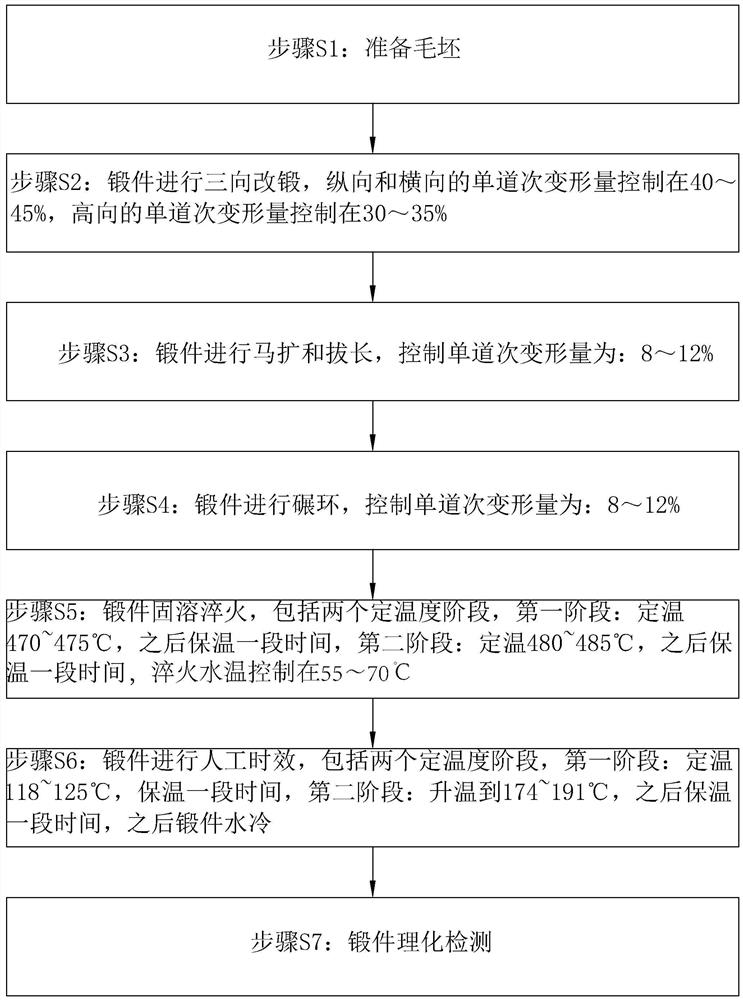

[0027] Step S1: Prepare a blank, the size of which is Φ800mm×1600mm.

[0028] Step S2: The forging is re-forged in three directions. The deformation of each fire in the longitudinal and transverse directions is controlled at 40-45%, and the deformation of each fire in the high direction is controlled at 30-35%. After the re-forging, the forging is punched. : Φ1230mm×Φ380mm×700mm.

[0029] Step S3: Carry out expansion and elongation of the forging, the size of the forging is Φ1400mm×Φ1085mm×1220mm, and the deformation amount of each fire is controlled to be 8-12%.

[0030] Step S4: Carry out ring grinding on the forging, and carry out ring rolling for multiple fires, the size of the forging is Φ2205mm×Φ2021mm×1220mm, and the deformation amount of each fire is controlled to be 8-12%. In this embodiment, the first firing ring: the instantaneous size of the forging is Φ1500mm×Φ1213mm×1220mm, and the deformation is 10.87%; the second firing ring: the instantaneous size of the forg...

Embodiment 2

[0036] The steps different from Embodiment 1 are:

[0037] Step S5: The forging is subjected to solution quenching. It includes two stages of constant temperature, the first stage: constant temperature of 472°C, followed by heat preservation for 2 hours, the second stage: constant temperature of 483°C, and then heat preservation for 4.5 hours. The quenching water temperature is controlled at 60°C.

[0038] Step S6: Artificial aging of the forgings, including two stages of constant temperature, the first stage: constant temperature of 121°C, holding for 7 hours, the second stage: raising the temperature to 185°C, and then holding for 9 hours, after which the forgings are immediately taken out of the furnace and cooled with water at a temperature of 35°C.

Embodiment 3

[0040] The steps different from Embodiment 1 are:

[0041] Step S5: The forging is subjected to solution quenching. It includes two stages of constant temperature, the first stage: constant temperature of 475°C, followed by 3 hours of heat preservation, the second stage: constant temperature of 485°C, and then heat preservation of 5 hours. The quenching water temperature is controlled at 70°C.

[0042] Step S6: Artificial aging of the forgings, including two stages of constant temperature, the first stage: constant temperature of 125°C, holding for 8 hours, the second stage: raising the temperature to 191°C, and then holding for 10 hours, after which the forgings are immediately taken out of the furnace and cooled with water at a temperature of 40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com