Transparent nylon material and preparation method thereof

A nylon and transparent technology, applied in the field of polymer material nylon synthesis, can solve the problems of increased production cost, low tolerance and harsh processing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

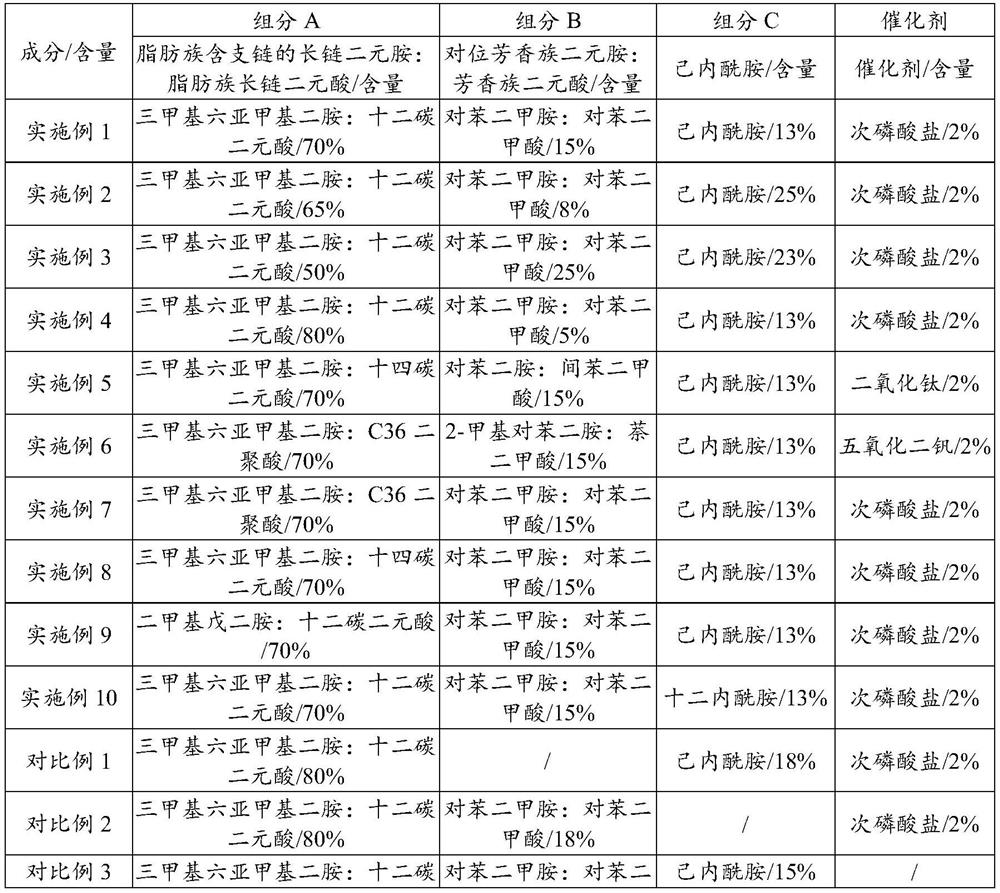

Embodiment 1

[0023] A kind of transparent nylon material, preparation raw material comprises the following components by mass percentage:

[0024] 70% Component A: obtained by reacting aliphatic branched long-chain diamine with a molar ratio of 1:1 and aliphatic long-chain dibasic acid, wherein the aliphatic branched long-chain diamine is trimethyl Hexamethylenediamine, the aliphatic long-chain dibasic acid is dodecane dibasic acid;

[0025] 15% Component B: para-position aromatic dibasic amine and aromatic dibasic acid with a molar ratio of 1:1, wherein the para-position aromatic dibasic amine is p-xylylenediamine, and the aromatic dibasic acid is p-phenylene dicarboxylic acid;

[0026] 13% Component C: Caprolactam;

[0027] 2% catalyst: hypophosphite.

[0028] The preparation method of transparent nylon material comprises the following steps:

[0029] (1) Add component A, component B, component C and the catalyst into the liquid mixing tank, raise the temperature to 120-160°C under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com