Patents

Literature

48 results about "Abnormal material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dissimilar materials double-layer superpacket center thread and manufacturing method thereof

InactiveCN101328637AGuaranteed wrapping tensionFeel comfortableContinuous wound-up machinesYarnYarnFiber

The invention discloses an abnormal material dual-layer composite clad yarn, which comprises an upper fiber-wrapped clad material layer, a lower fiber-wrapped clad material layer and a clad yarn layer which is positioned in the middle, wherein, the clad yarn layer adopts chemical fiber filament clad yarns and fiber-wrapped clad materials with different materials to be compositely processed into a dual-layer composite clad yarn. The invention also discloses a method for manufacturing the dual-layer composite clad yarn. The dual-layer composite clad yarn has the characteristics of comfortable hand feeling, large strength and toughness of chemical fiber filaments of the sandwich layer, burliness and durability, and high performance and use value.

Owner:鲁建国

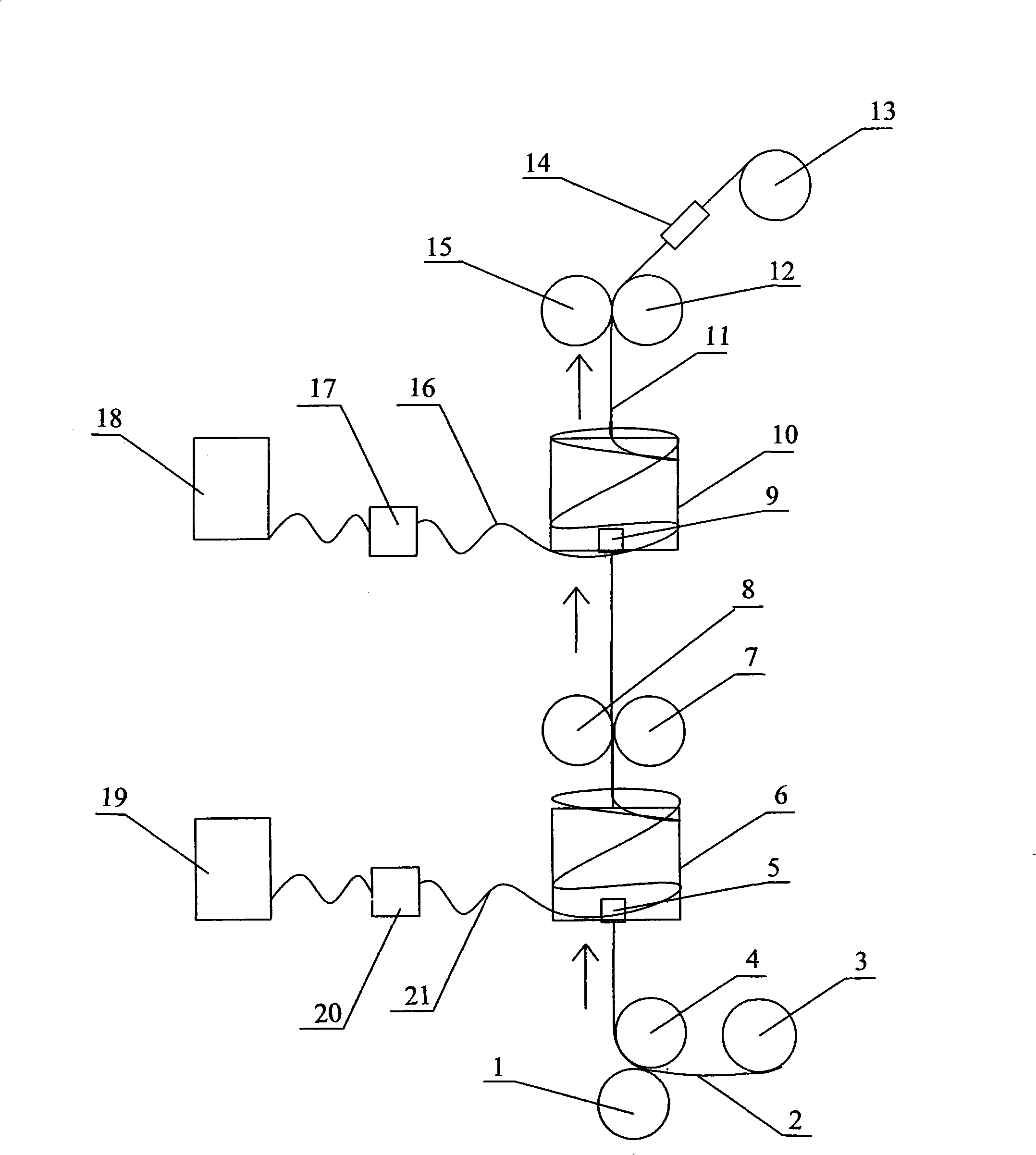

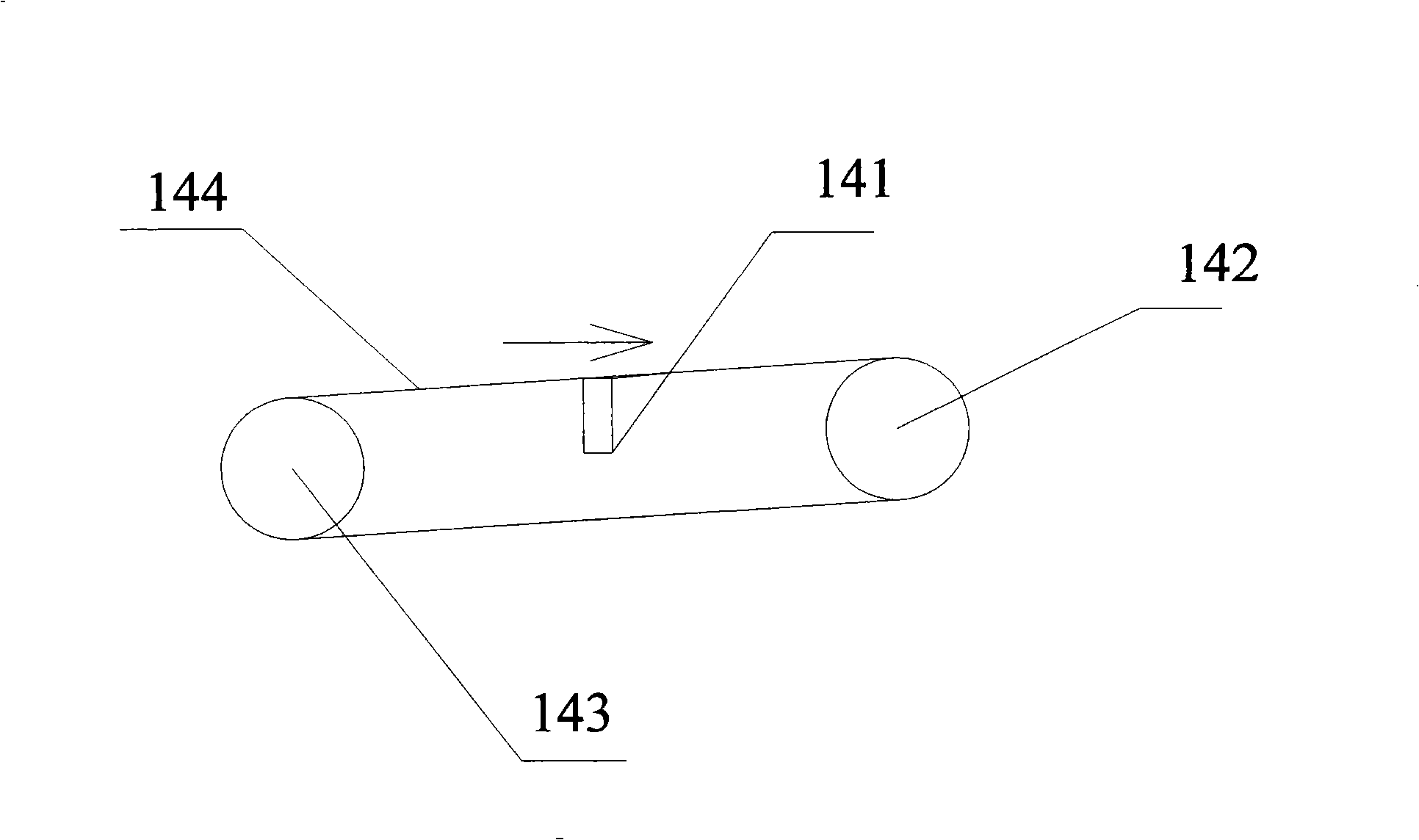

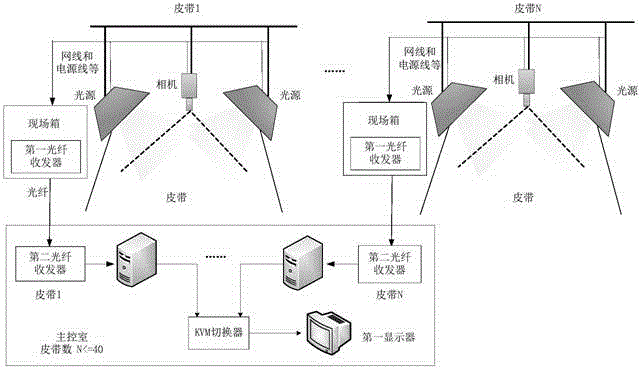

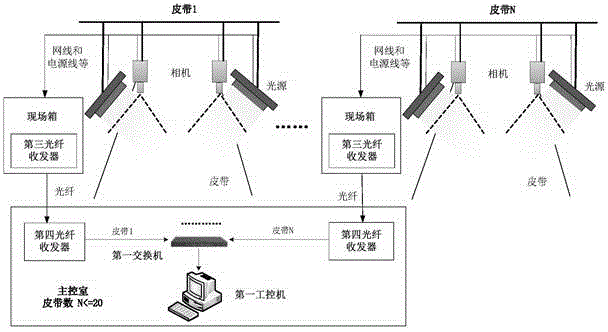

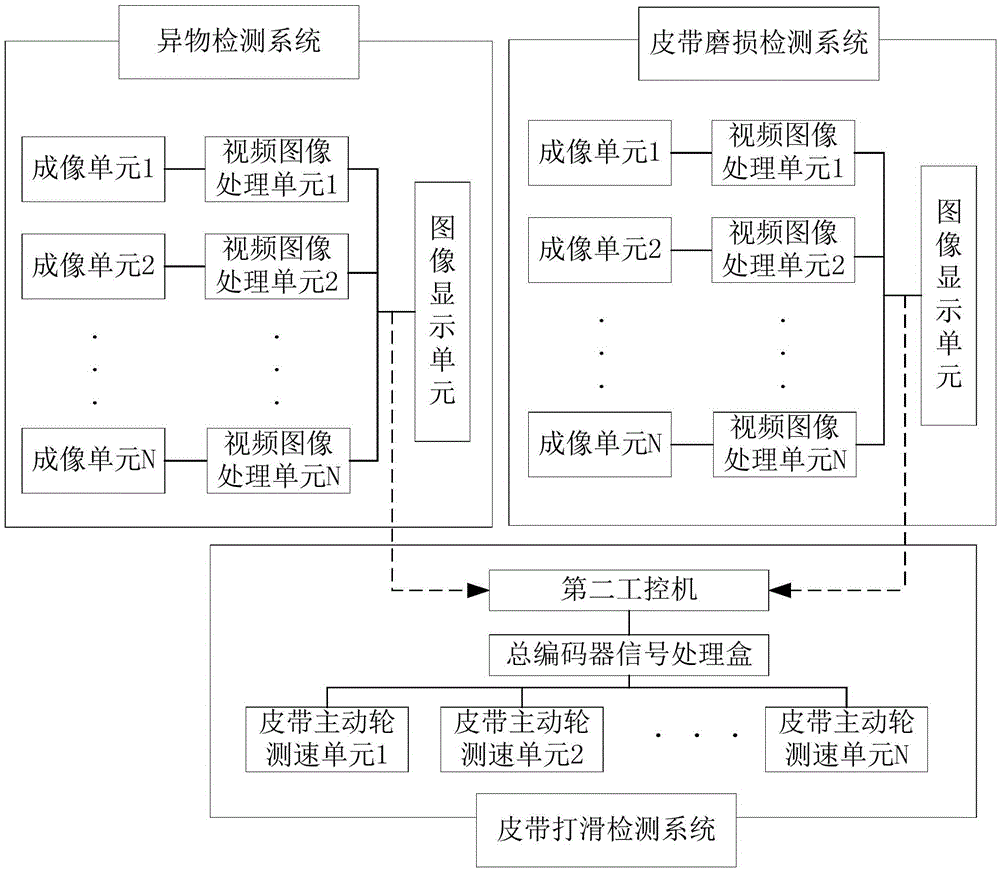

Belt group abnormal state automatic touring detection system and detection method thereof

ActiveCN105491349AReal-time monitoring of running statusAvoid major production accidentsControl devices for conveyorsClosed circuit television systemsForeign matterVideo monitoring

The invention discloses a belt group abnormal state automatic touring detection system and a detection method thereof. The system includes a foreign matter detection system, a belt wearing detection system, and a belt slipping detection system that can be selected and combined at will. The system effectively combines machine vision and belt velocity measurement equipment, and adopts non-contact video monitoring technology in a touring detection manner to monitor the running states of all of the belts in a belt group in real time. The system automatically detects abnormal materials on the belt, belt edge wearing, and belt slipping, and automatically sends an alarm when abnormity occurs to prompt relative working personnel to perform timely maintenance. The system can timely find out the abnormal hidden troubles of the belt group, and provides detailed and reliable data and image data for preventive maintenance and belt group accidents, thereby occurring great production accidents and reducing economic loss.

Owner:天津市三特电子有限公司

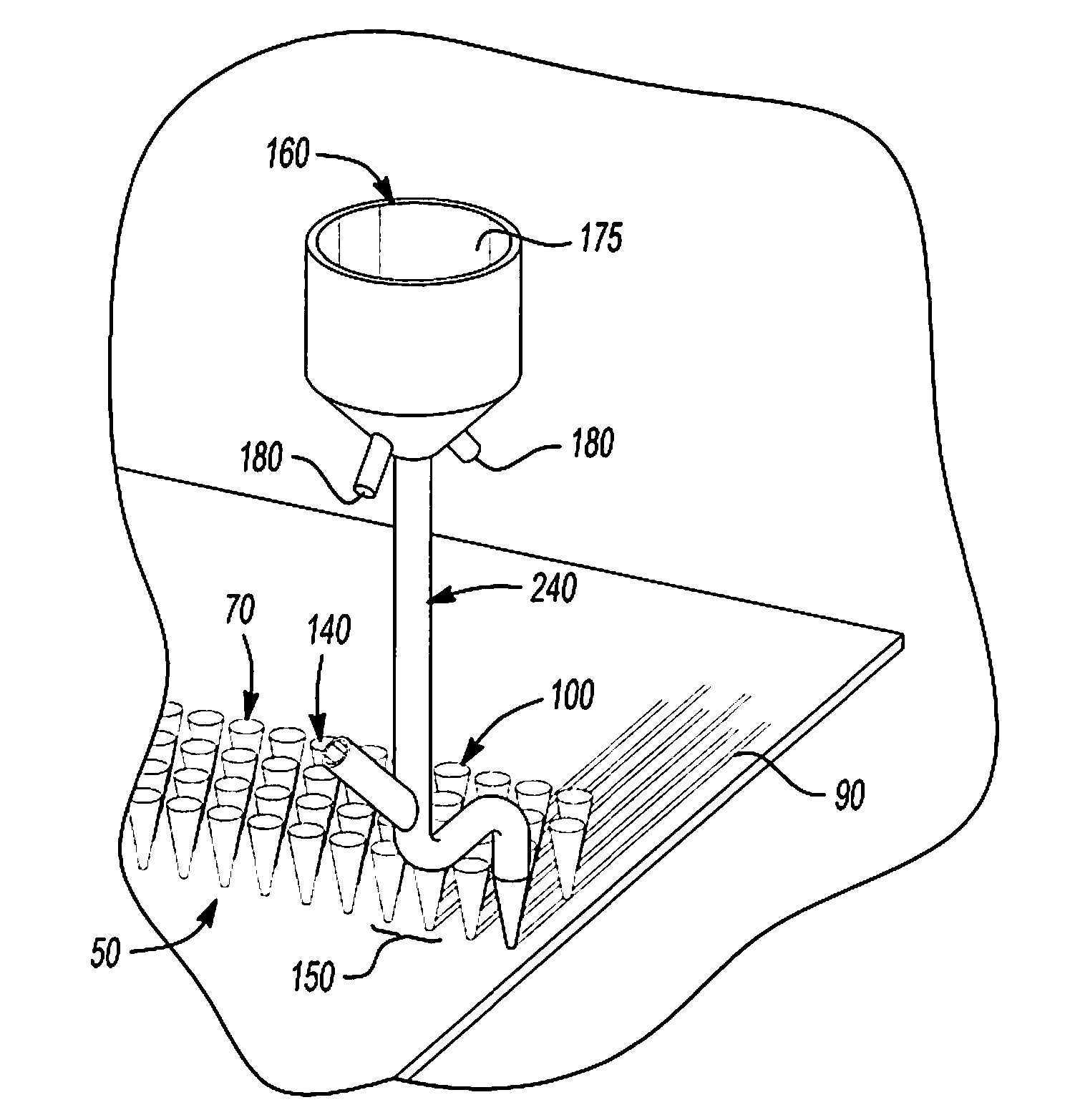

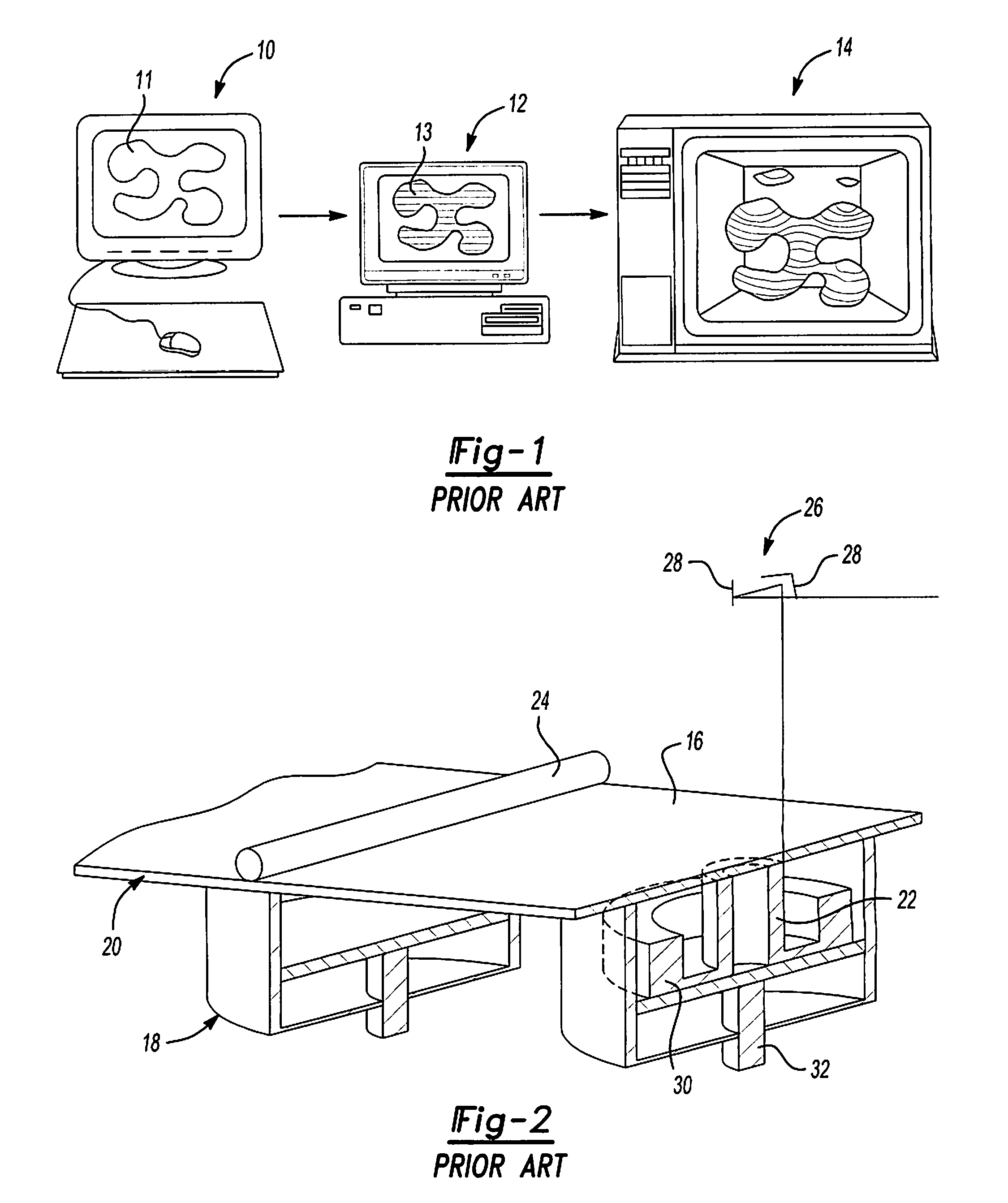

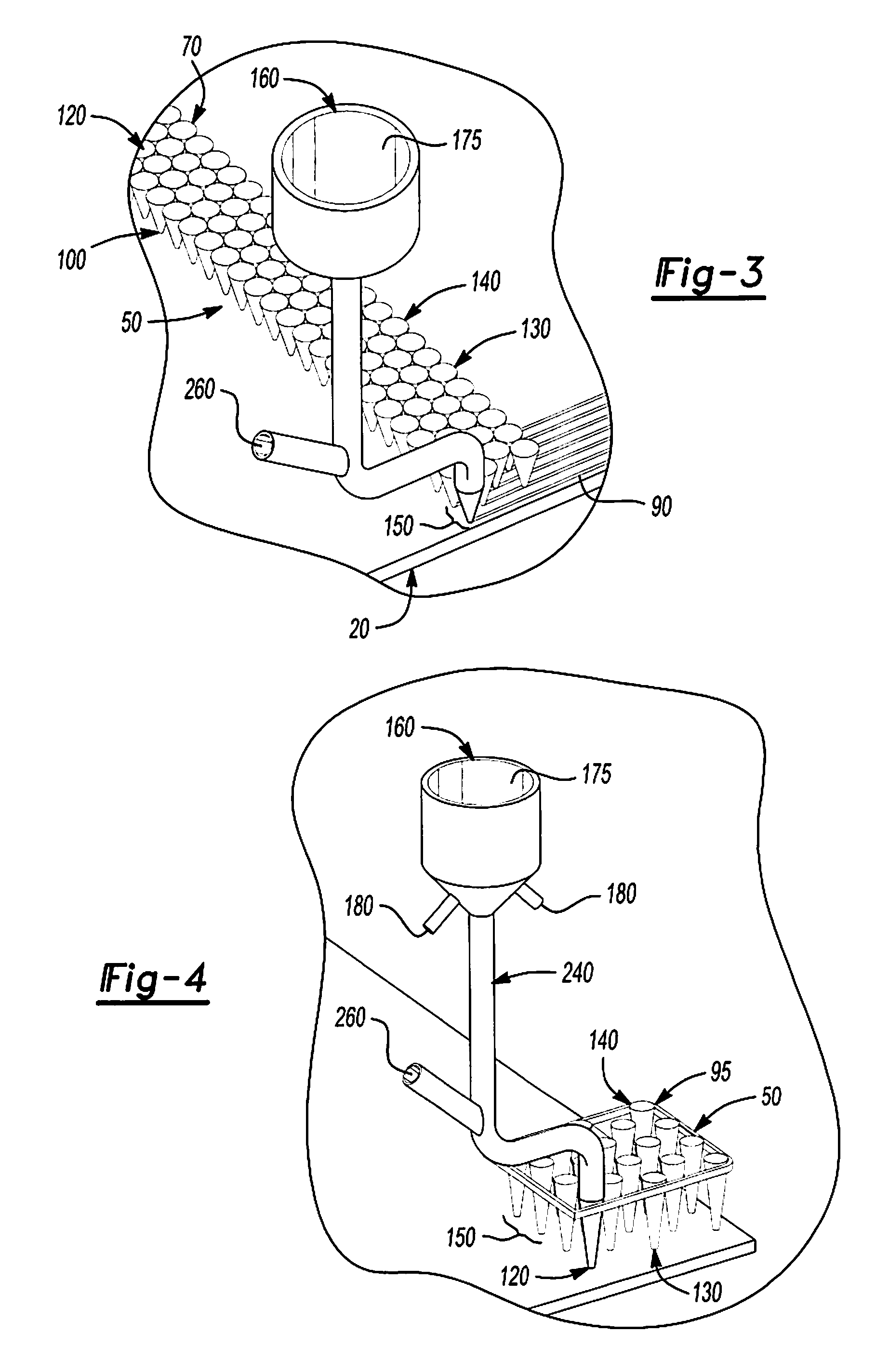

Solid freeform fabrication of structurally engineered multifunctional devices

ActiveUS7509240B2Additive manufacturing apparatusAnalogue computers for heat flowSelective laser sinteringSpray nozzle

A selective laser sintering technique and system are provided for producing a heterogeneous product. The selective laser sintering technique and system is generally comprised of generating a computer model of the product and processing the model to obtain numerous cross-sectional representations of the model. The cross-sectional representations are manufactured layer by layer to create the product. Specifically, numerous different powders having a variety of properties are placed within nozzles positioned above a deposition bed using a hopper. Using the computer model as a guide, the different powders are placed at different positions on the deposition bed to form each layer of the device. The deposited powders are consolidated, micromachined, and milled using one or more lasers to create the product. Using this selective laser sintering technique a wide variety of heterogenous products may be produced, such as the following: 1) bio-implants, 2) small scale energy production, storage and conversion devices, 3) devices that exploit anomalous material behavior, and 4) nanocomposites.

Owner:RGT UNIV OF MICHIGAN

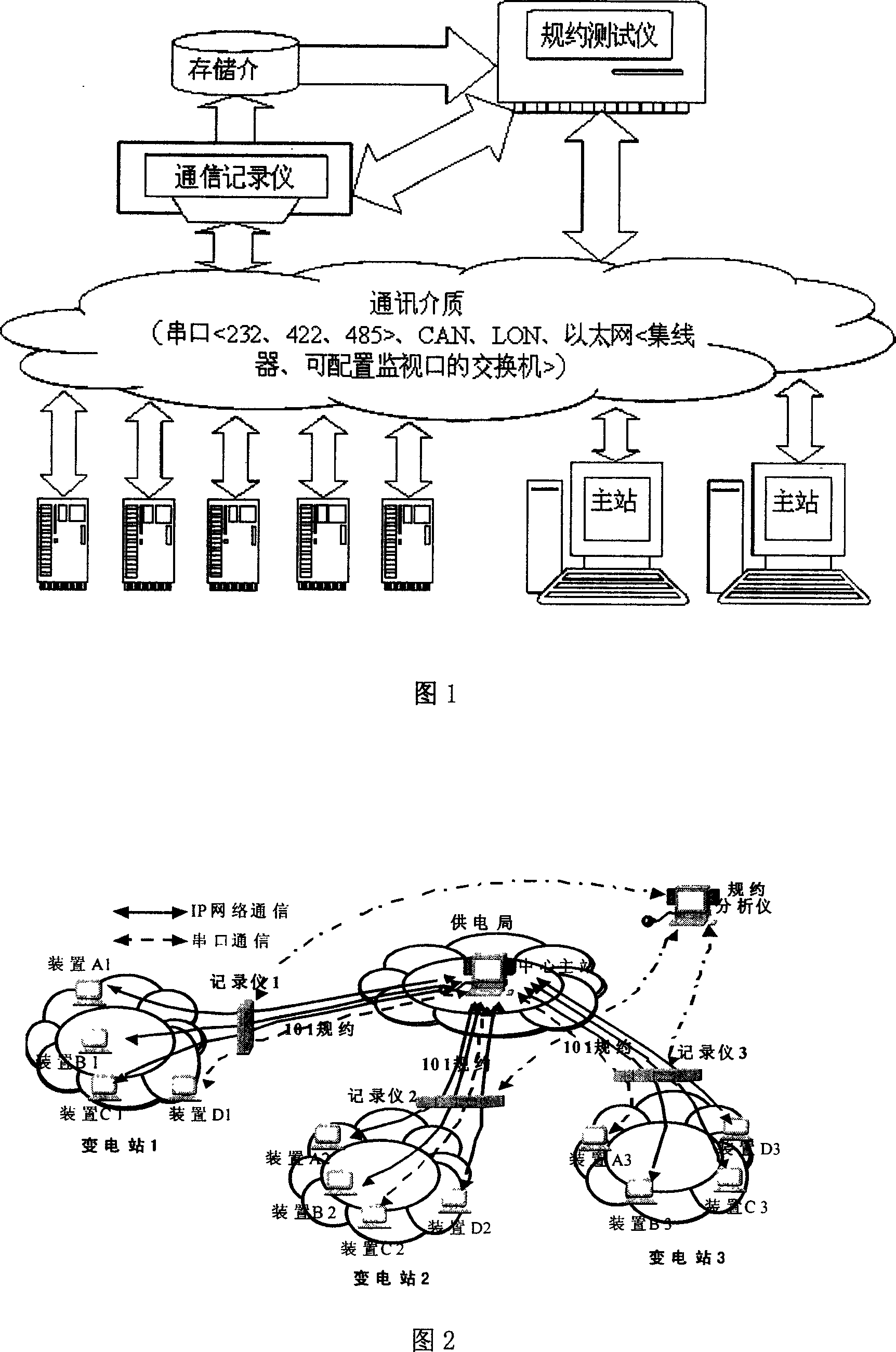

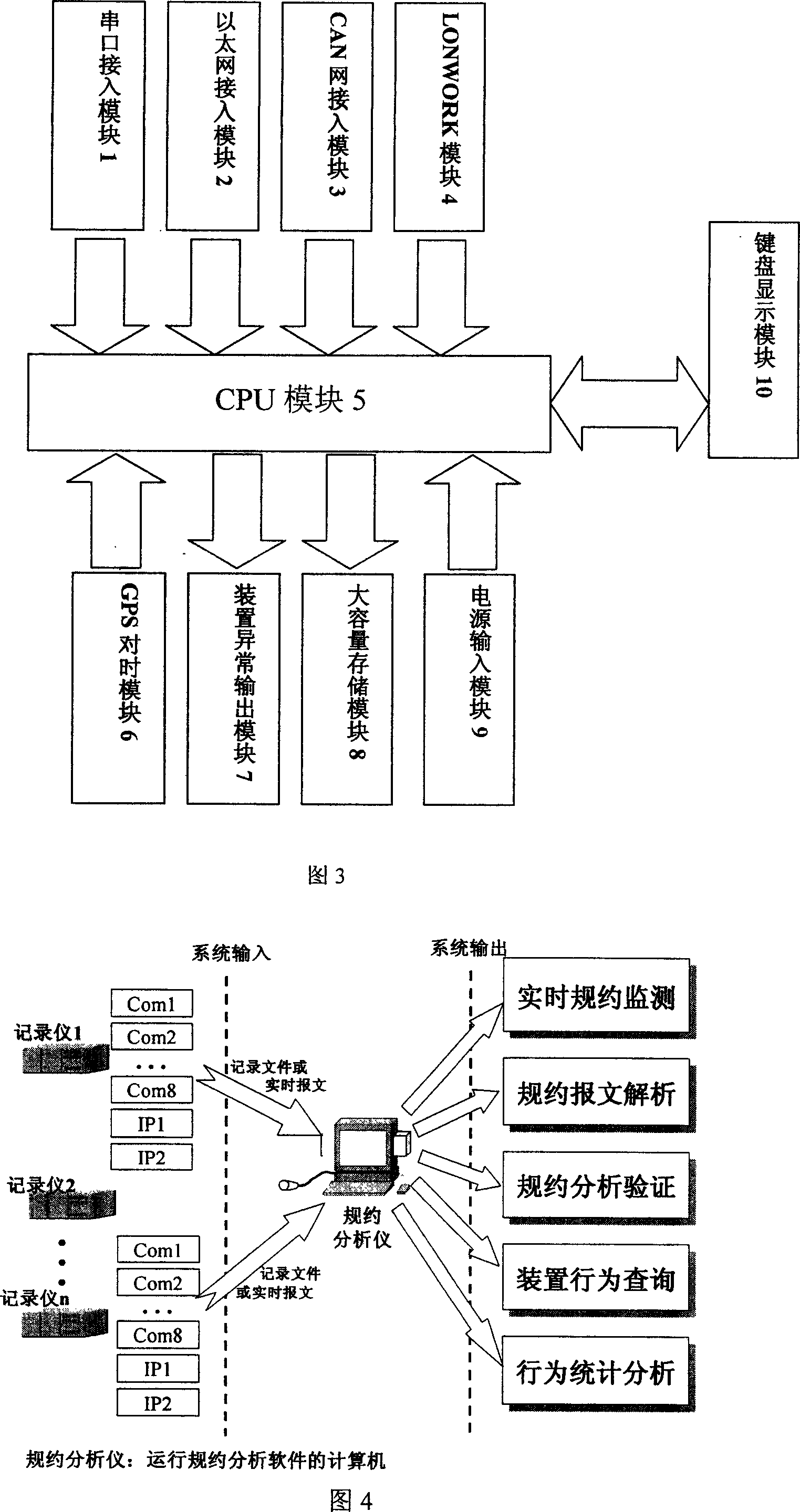

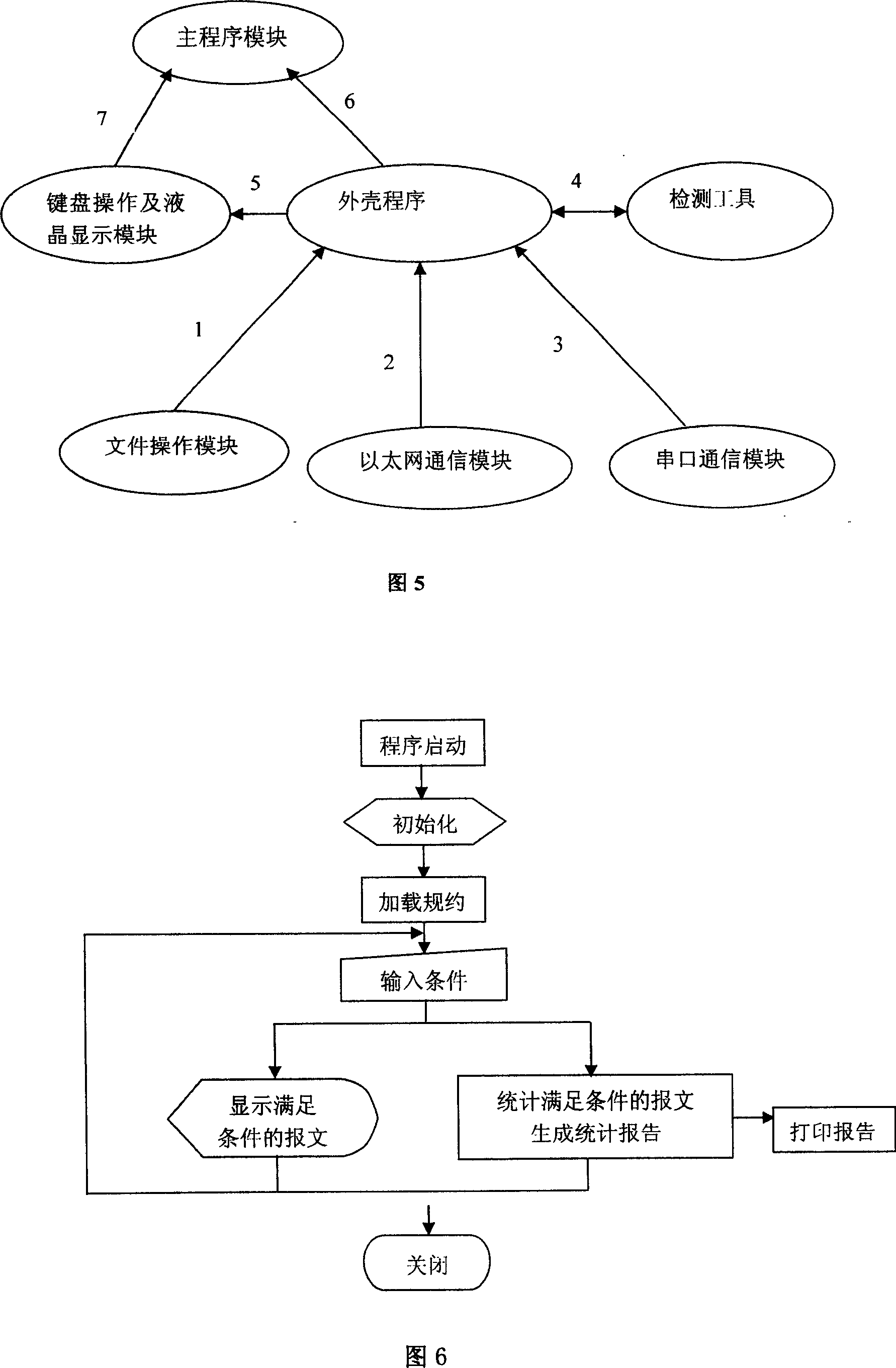

Communication protocol record analysis apparatus and its analysis method

ActiveCN1972287AConvenient communication debuggingReliable dataData switching by path configurationMass storageDistributed structure

This invention relates to communication rules record and analysis device and its method, which records all abnormal materials for each situation during whole process and provides record analysis device and method for back data analysis. This invention device is one distribution structure, which comprises each communication point recorder and one analysis management machine connected by single high speed Ethernet, wherein, series interface module, Ethernet interface module, CAN interface module, LONMORK module, GPS module output end are separately connected to CPU module input end.

Owner:NICE SYST CONTROL

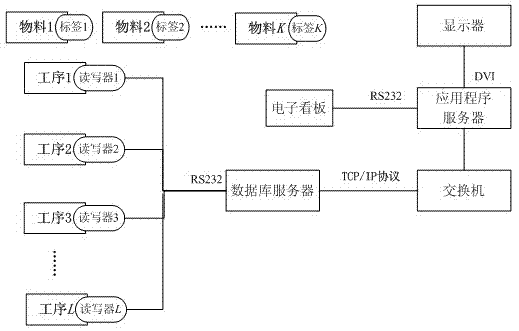

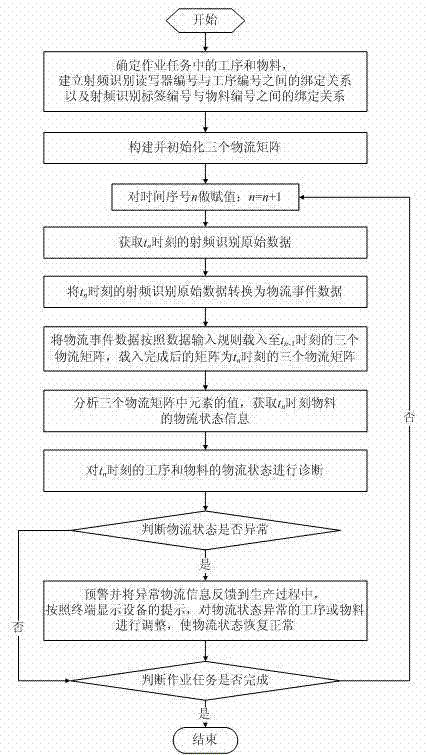

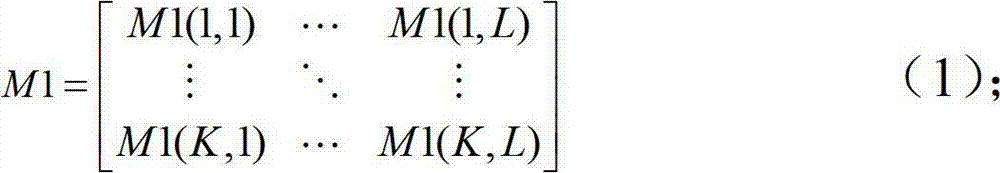

Method for acquisition, analysis processing and feedback of logistics data in production process

InactiveCN102855389AReduce hardware acquisition costsEfficient storageSpecial data processing applicationsLogistics managementEvent data

The invention discloses a method for acquisition, analysis processing and feedback of logistics data in a production process. The method includes establishing binding relations between radio frequency identification reader numbers and process numbers and between tag numbers and material numbers; constructing and initializing three logistics matrixes; obtaining radio frequency identification initial data; converting the radio frequency identification initial data into logistics event data and then loading the data into the three logistics matrixes according to a data input rule; analyzing element values in the three logistics matrixes to obtain logistics state information; diagnosing logistics states of processes and materials; adjusting processes and materials which have abnormal material states according to prompts; and determining whether a job task is completed or not, and finishing if the job task is completed. According to the method, hardware acquisition costs of enterprises are saved, efficient storage and reading for mass logistics data are achieved, real-time comprehensive understanding of logistics state information and timely adjustment for abnormal conditions are facilitated, and the workshop logistics monitoring level of the enterprises is improved effectively.

Owner:ZHEJIANG UNIV

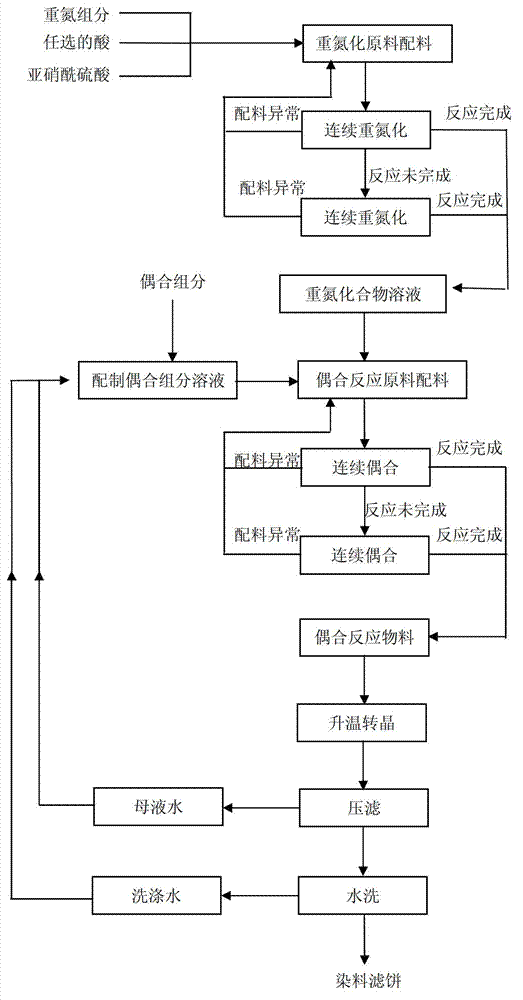

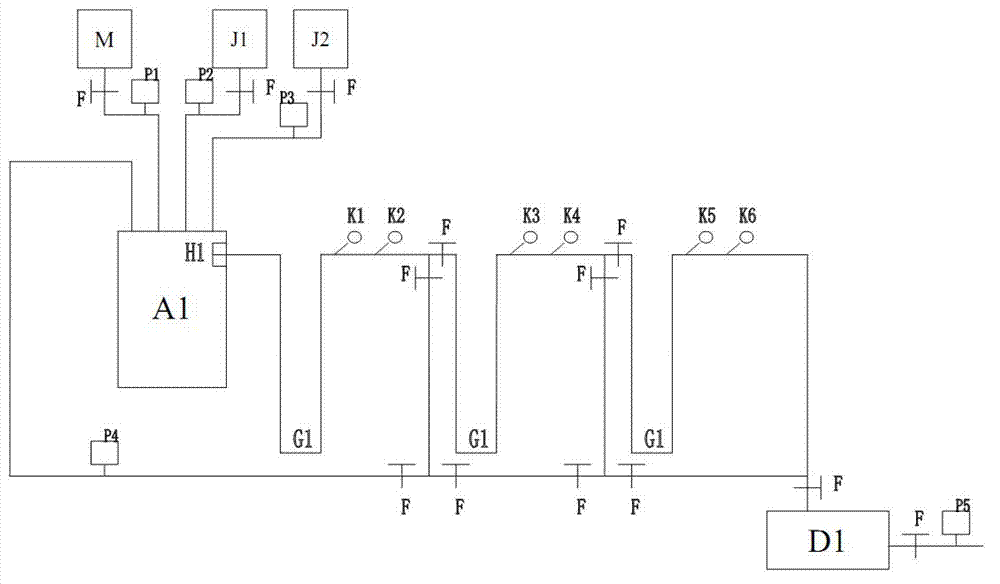

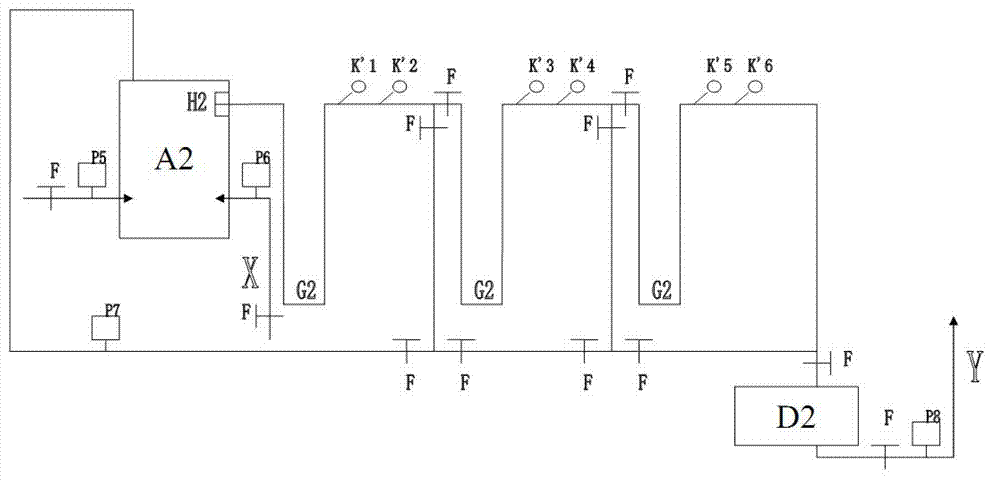

Method and device for automatic-control continuous production of dye

ActiveCN103160145ARealize low pollution and low consumptionAchieve economyMonoazo dyesAutomatic controlProcess engineering

The invention discloses a method and a device for automatic-control continuous production of dye. The method comprises that raw materials are metered, are continuously fed into a tubular reactor and undergo a reaction and the products are discharged continuously. The device is characterized in that a reactor is provided with multiple reaction state detection devices; through multipoint automatic control, the reaction liquid obtained by the reaction is timely transferred to a next process; and abnormal materials in blending are timely pumped back to a blending kettle and then are re-blended. The method and the device realize accurate and automatic-control continuous production of dye, guarantee stable product quality, shorten production time, improve production efficiency, reduce a production cost, reduce three wastes, realize pollution and energy consumption reduction, and realize recycling economy and clean production.

Owner:ZHEJIANG DIBANG CHEM

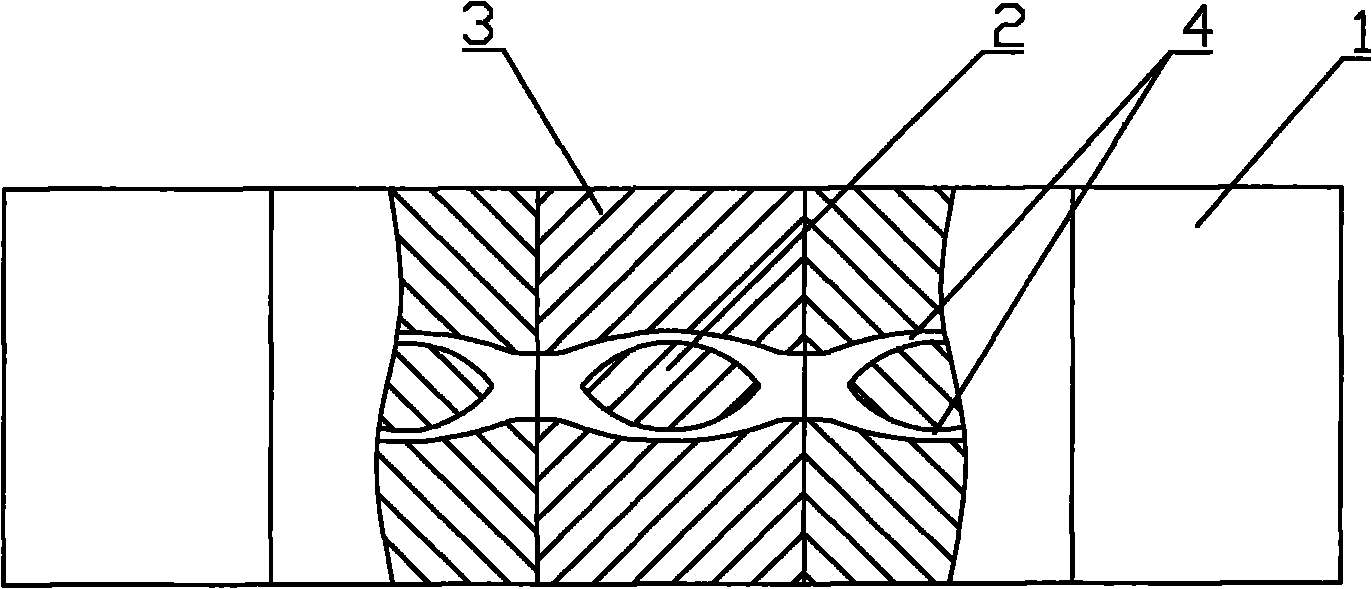

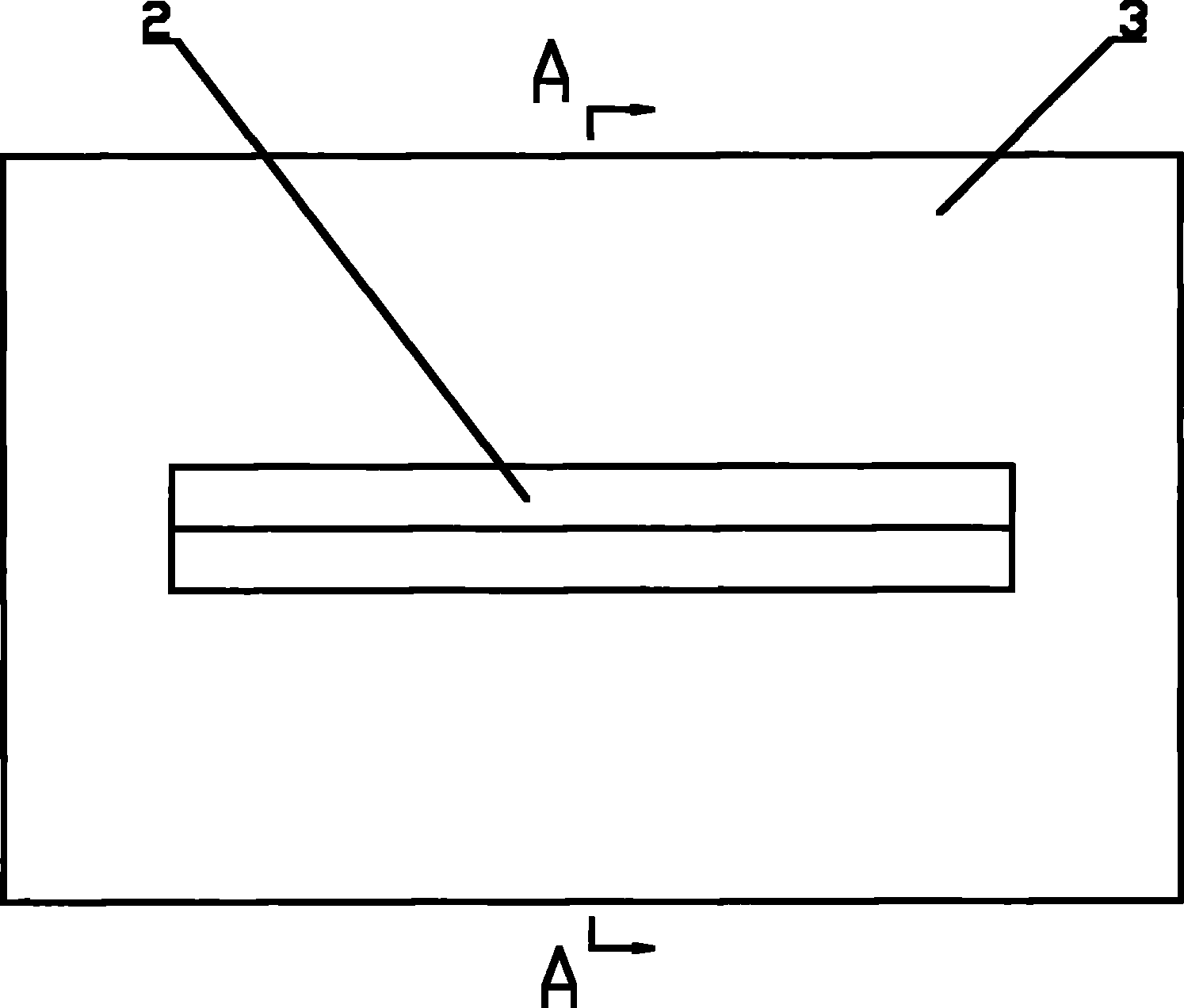

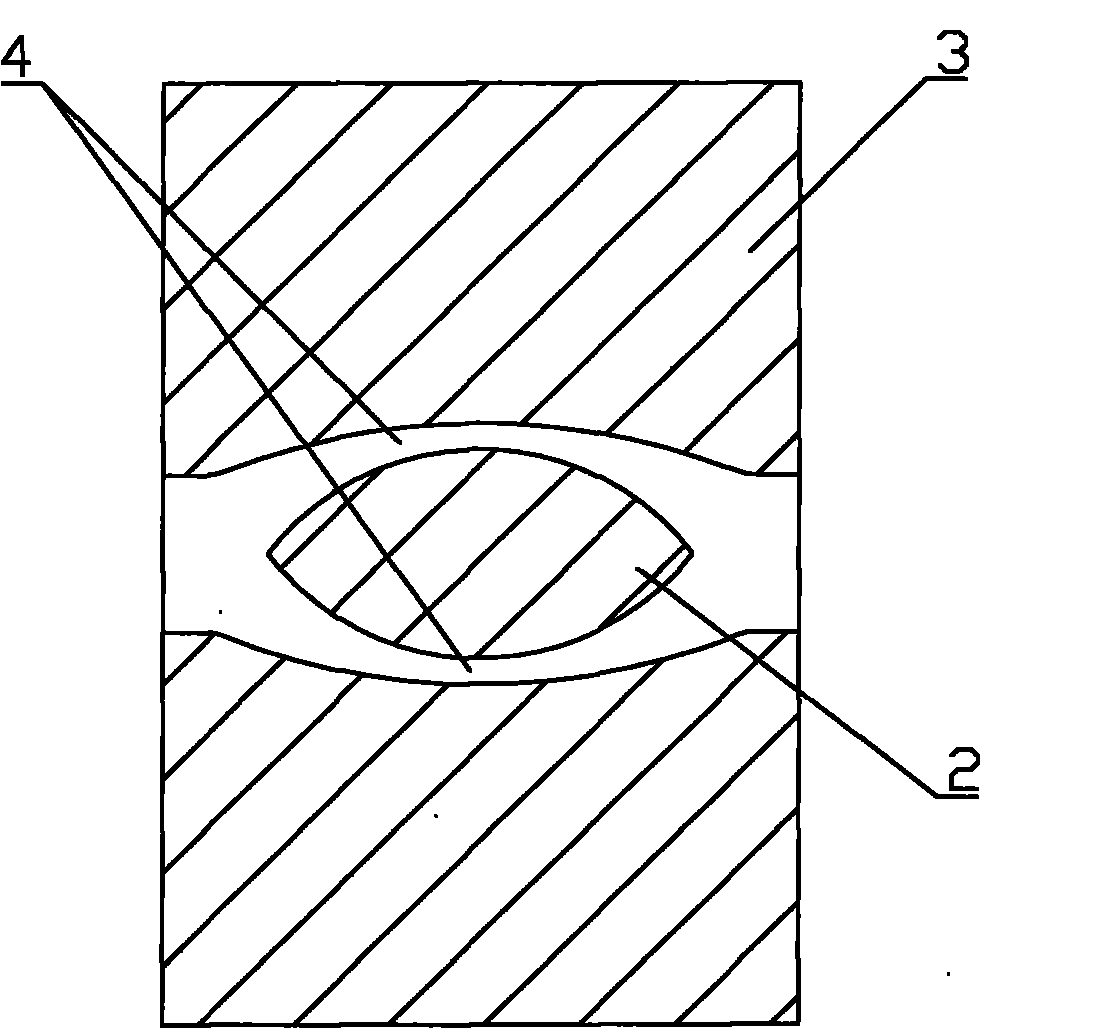

Extrusion neck ring mold and method for preparing materials with high orientation degree distribution of filling materials

The invention discloses an extrusion neck ring mold for preparing materials with high orientation degree distribution of filling materials, which comprises at least two orientation devices, wherein the orientation devices are mutually connected, the orientation devices comprise modules and cases, the modules are arranged in the cases, and two orientation flow passages with two merged ends and the separated middle part are formed between the modules and the inner walls of the cases. The extrusion neck ring mold has the advantages of simple structure, easy manufacture, low cost, convenient dismounting and installation and the like. In addition, the extrusion neck ring mold consists of a plurality of modules of the orientation devices, the orientation degree of the filling materials can be regulated and controlled through increasing or decreasing the number of the orientation devices, and at the same time, the orientation degree of the filling materials can also be regulated and controlled through regulating the radian of the orientation flow passages. The invention also discloses a method for preparing the materials with high orientation degree distribution of the filling materials on the basis of the extrusion neck ring mold. High molecular composite films, plate materials, sheet materials, abnormal materials and the like with high orientation degree distribution of the filling materials can be prepared through the steps of drying, mixing, pelleting, drying, extruding and forming, and the application range is wide.

Owner:SOUTHWEST UNIVERSITY

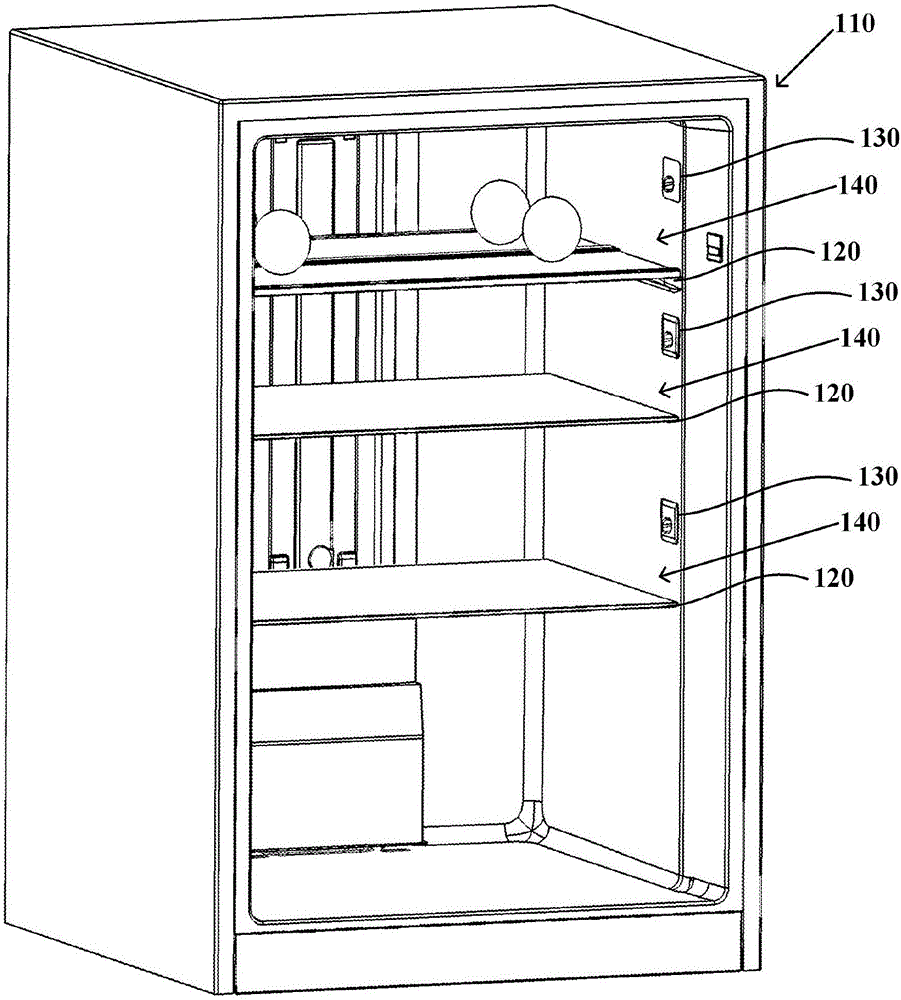

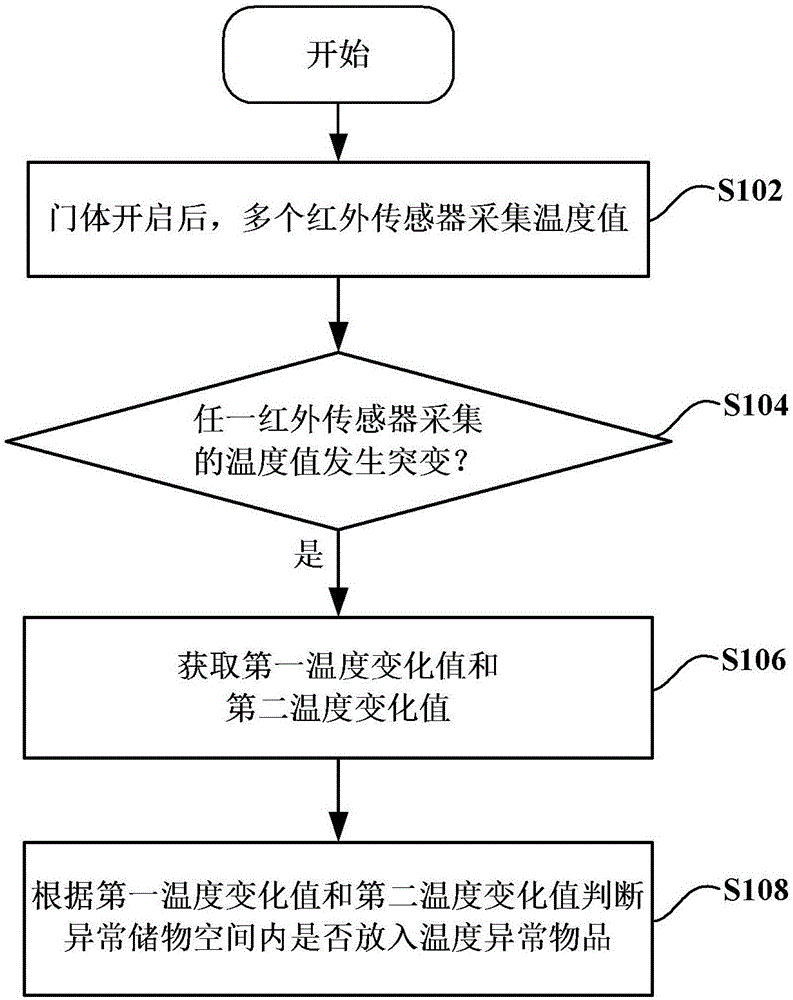

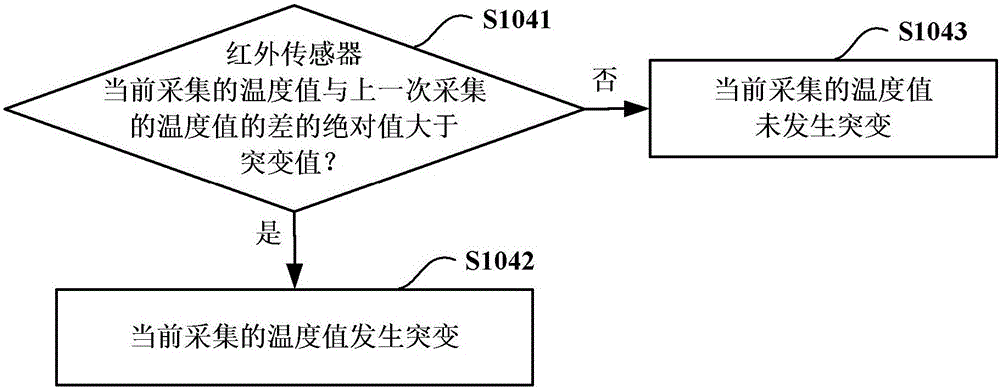

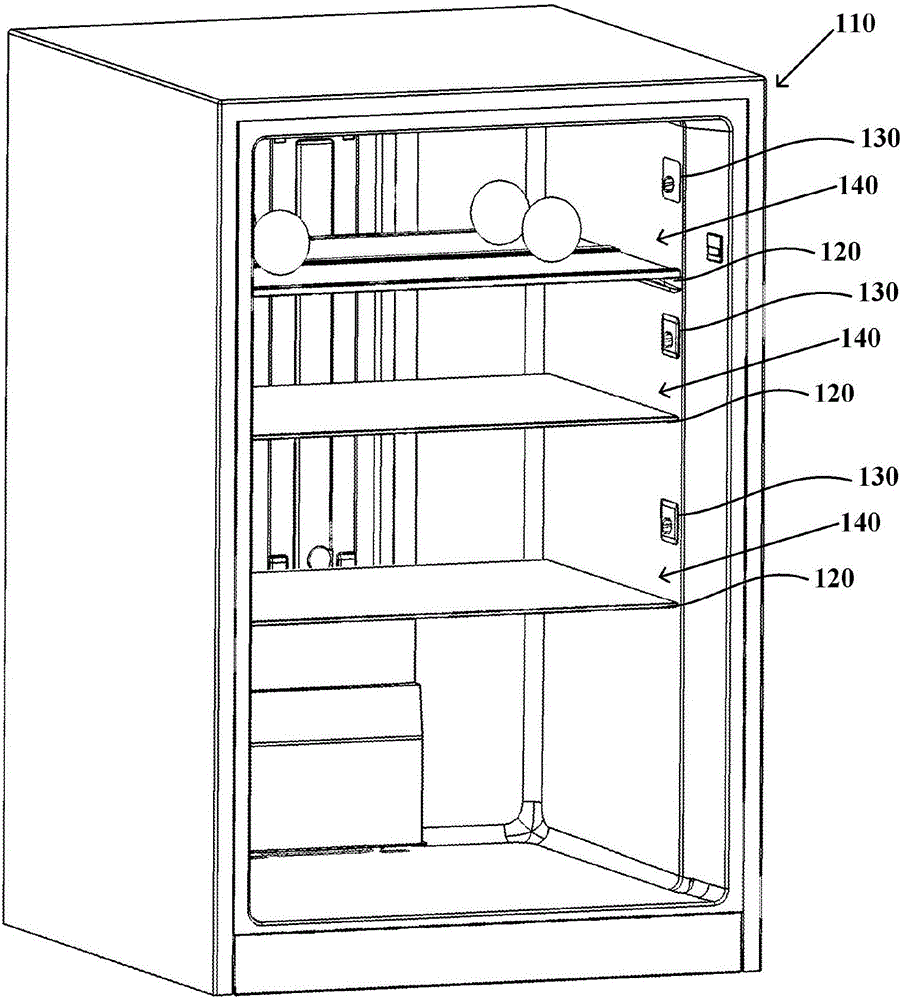

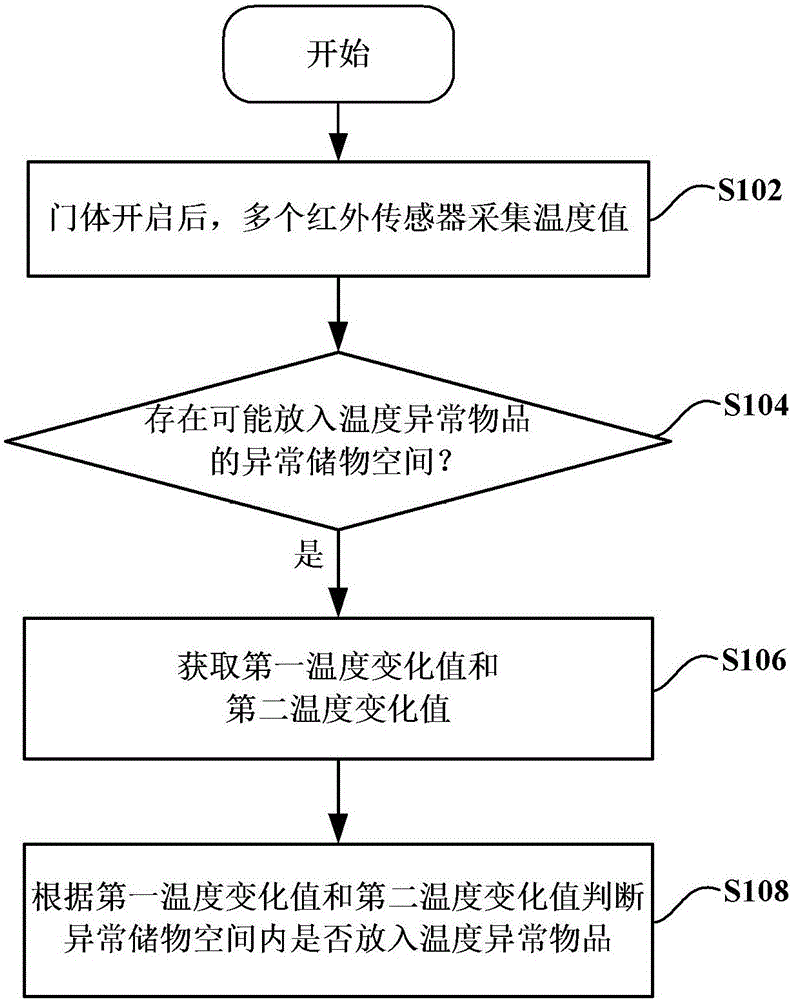

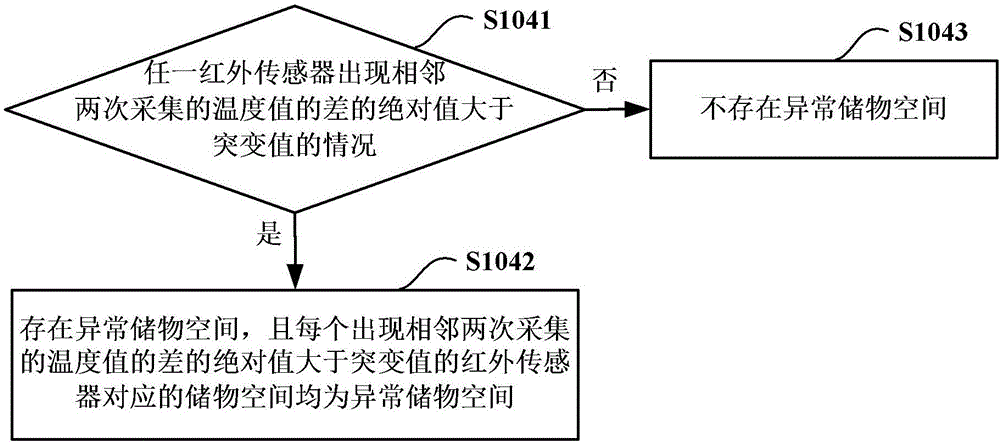

Method for detecting whether temperature abnormal materials are placed in refrigerator or not

ActiveCN106766650AAdverse effects avoided or reducedEasy to storeLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

The invention provides a method for detecting whether temperature abnormal materials are placed in a refrigerator or not. The refrigerator comprises a refrigerator body internally divided into a plurality of storage spaces, a door body arranged at the front of the refrigerator body and a plurality of infrared sensors for sensing temperatures of the multiple storage spaces correspondingly. The method includes the steps that after the door body is opened, the multiple infrared sensors are controlled to collect temperature values; whether an temperature value collected by any one of the infrared sensors generates sudden change or not is judged; if yes, a first temperature change value obtained before and after the temperature abnormal materials are possibly placed into the abnormal storage space corresponding to the infrared sensor and a second temperature change value caused by heat exchange between the outer environment and the abnormal storage space before and after the temperature abnormal materials are possibly placed into the abnormal storage space are obtained; and whether the temperature abnormal materials are placed into the abnormal storage space or not is judged according to the first temperature change value and the second temperature change value. By means of the method, whether excessively hot food is placed into a certain storage space or not can be judged relatively accurately.

Owner:HAIER SMART HOME CO LTD

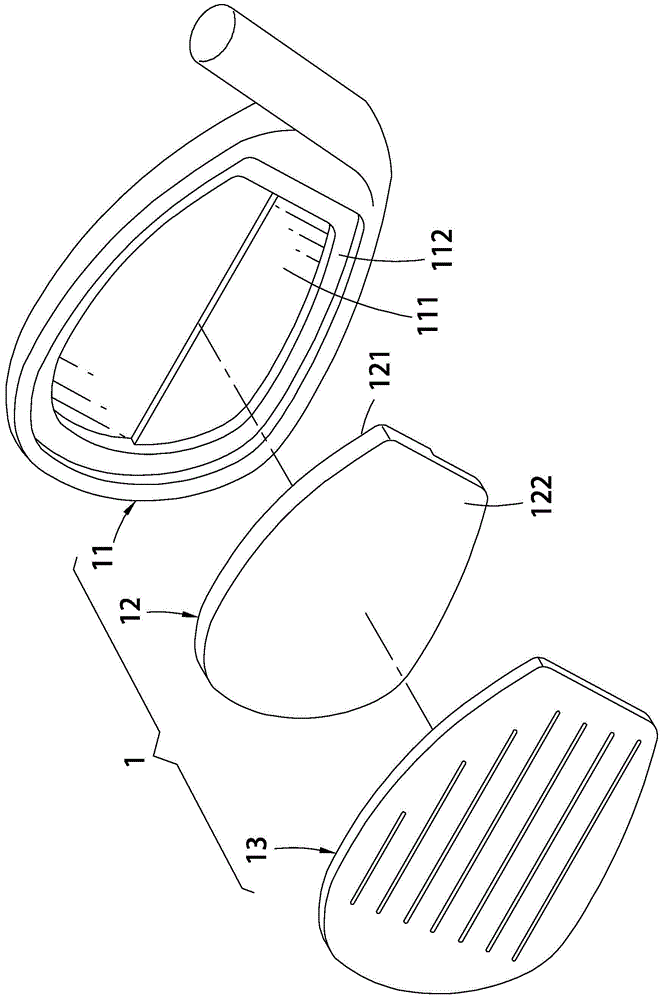

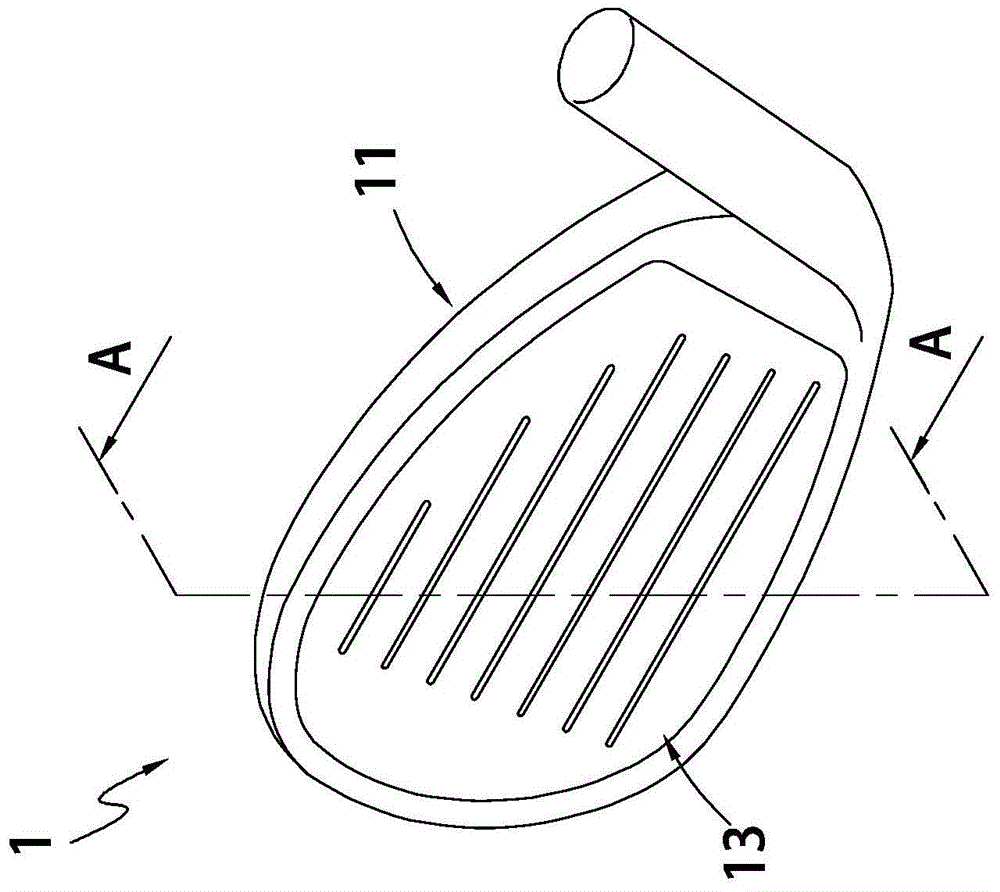

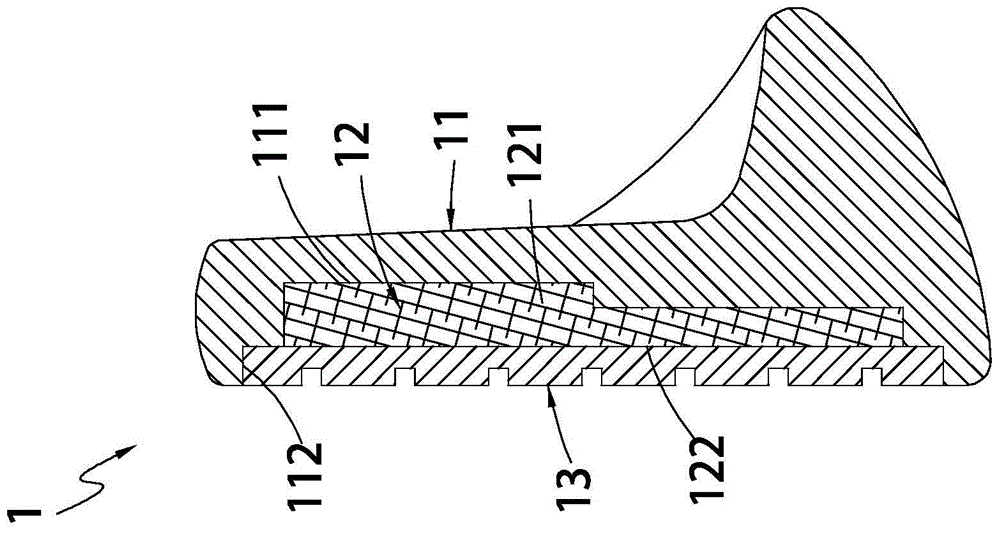

Golf iron head composite structure

ActiveCN105833490AImprove deep and low center of gravityDesigning for Improved Performance at High Moments of InertiaGolf clubsRacket sportsCompound structureGravity center

A composite structure of a golf iron club head, which includes a club head main body, a hitting panel, and a backboard. The main body of the club head is a hollow frame, and the striking panel and the back plate of different materials are respectively provided as sleeves so that the three are combined into one. The hollow frame is used to increase the volume of the back plate of different materials, A performance design with a deep low center of gravity and a high moment of inertia that can simultaneously improve the golf iron head's high degree of freedom.

Owner:JETOX SPORTING GOODS (DONGGUAN) CO LTD

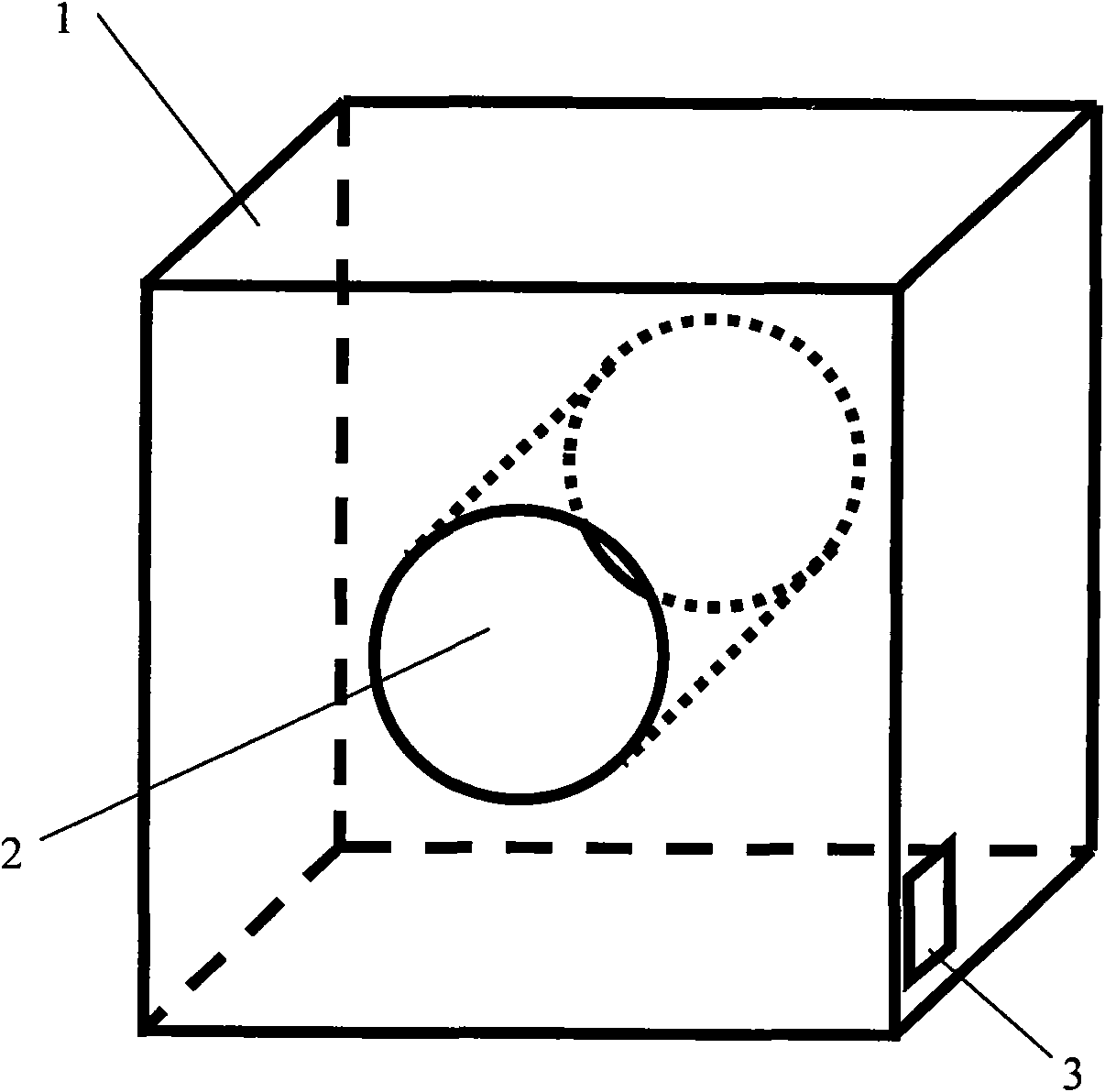

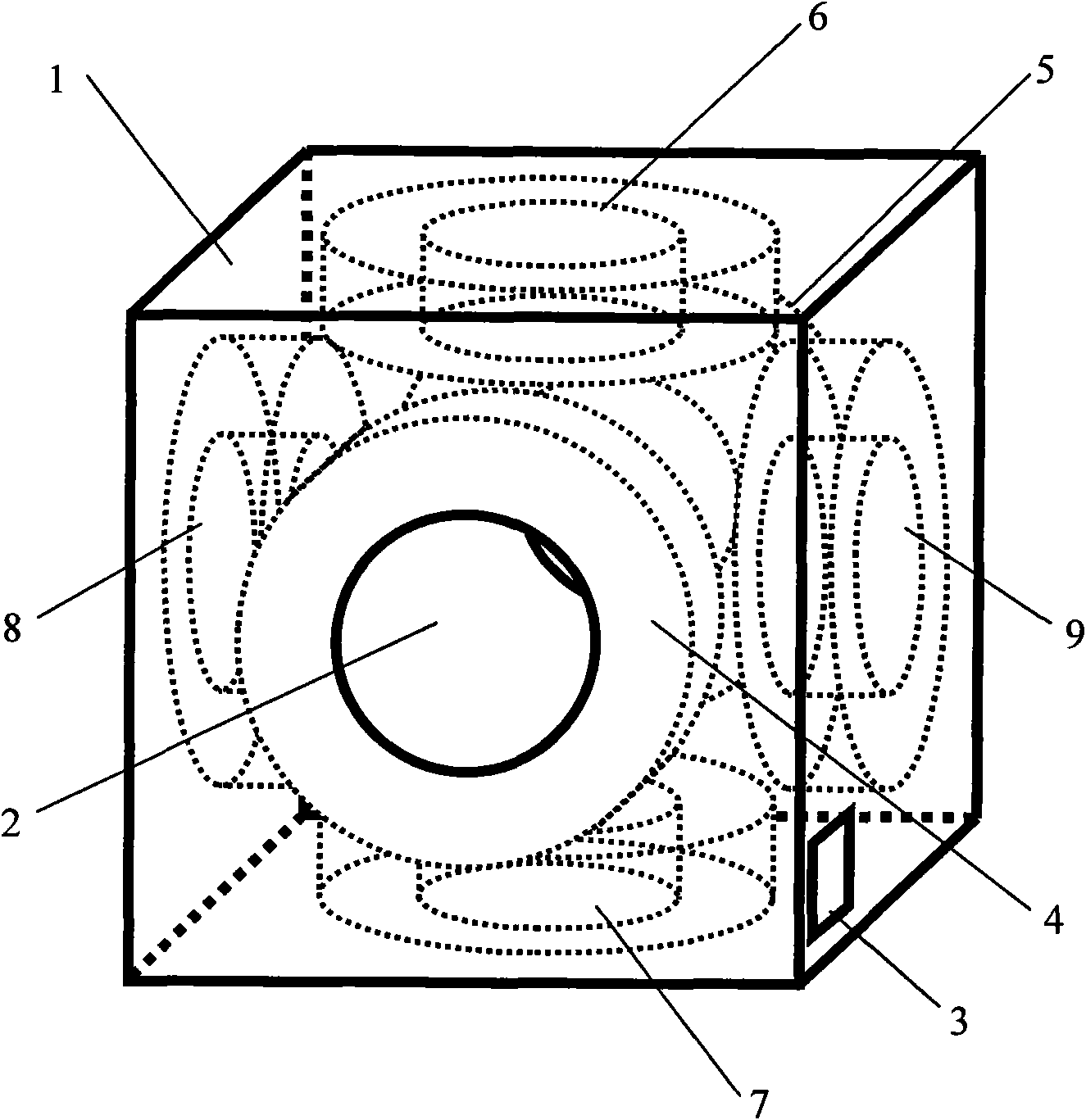

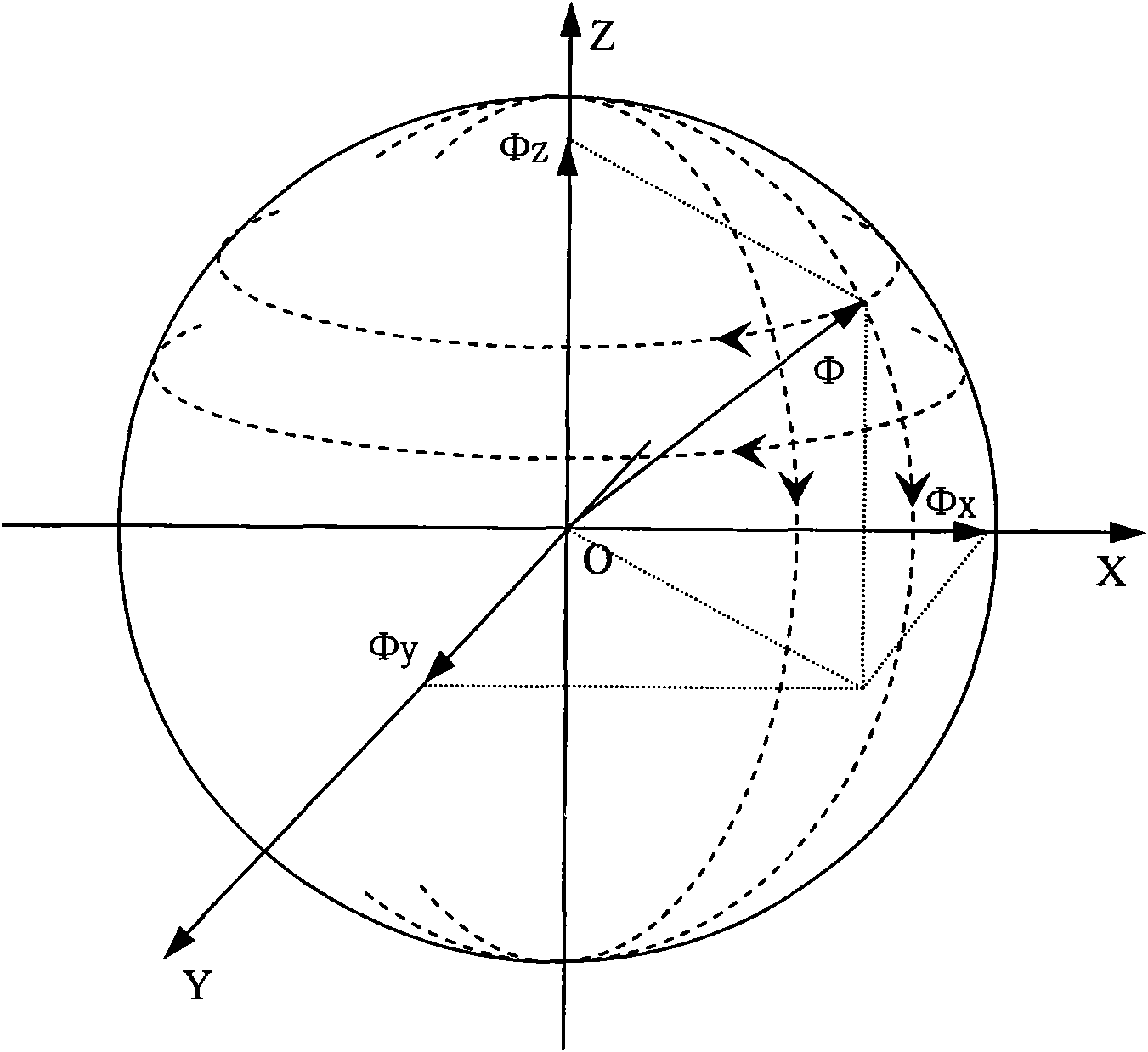

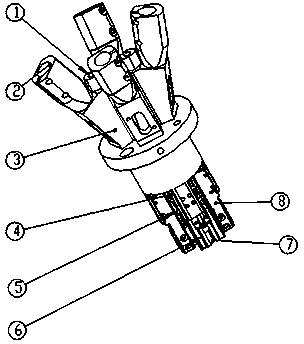

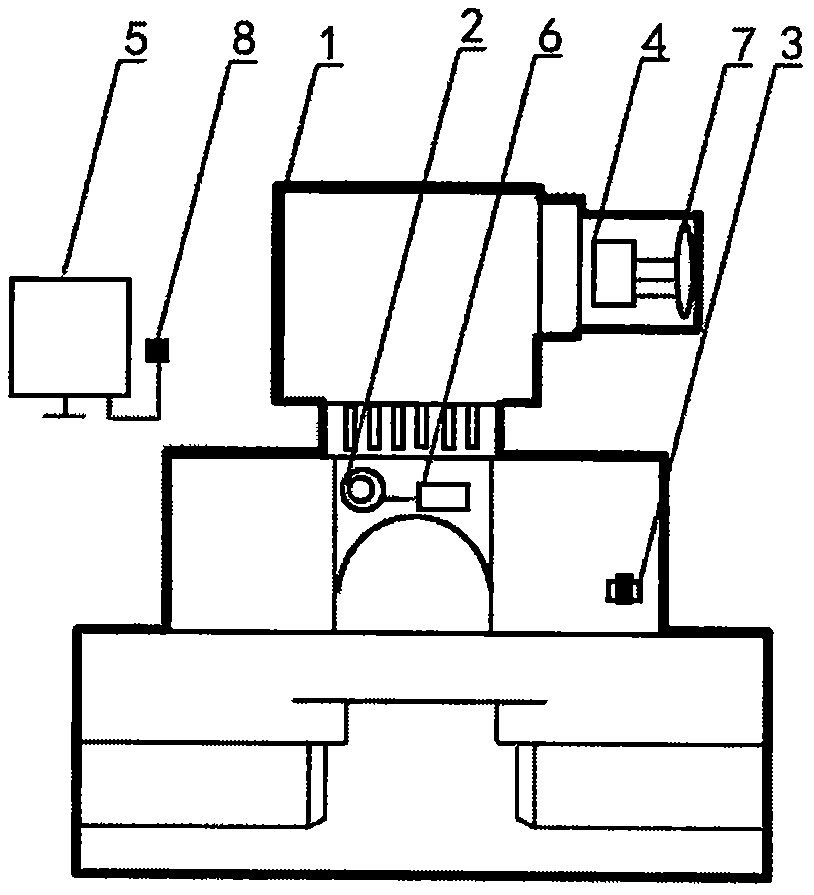

Three-dimensional electromagnetic probe and gyromagnetic detection method

InactiveCN101661018AOvercoming detectionOvercome functionMaterial magnetic variablesAdditive ingredientMetallic materials

The invention relates to a three-dimensional electromagnetic probe and gromagnetic detection method for metal material nondestructive detection and evaluation. The electromagnetic probe comprises a probe body 1, a probe hole 2, a connection port 3, a front detection coil 4, a rear detection coil 5, an upper detection coil 6, a lower detection coil 7, a left detection coil 8 and a right detection coil 9. The probe is characterized in that each detection coil comprises a pair of magnet exciting coils and a pair of detection coils, exciting current of each coil is reasonably adjusted, thus providing a constant spatial rotating magnetic field for gyromagnetic detection. The result obtained by gromagnetic can generate an analog similar to the detected work piece by three-dimensional data visualization, abnormal material quality can be shown by obvious evagination or sinking on the analog, material quality uniformity and abnormal tissue in the interior of metal material can be obviously reflected, thus being helpful for detection personnel to rapidly evaluate the quality of the detected work piece. The invention not only can be used for detection and evaluation of ingredient, mechanic performance and tissue uniformity but also can detect and early warn of tissue abnormality such as crack by non-uniformity of material quality distribution.

Owner:帅立国

Method for detecting whether temperature abnormal materials are placed in refrigerator or not

ActiveCN106766646AAdverse effects avoided or reducedEasy to storeDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

The invention provides a method for detecting whether temperature abnormal materials are placed in a refrigerator or not. The refrigerator comprises a refrigerator body internally divided into a plurality of storage spaces, a door body arranged at the front of the refrigerator body and a plurality of infrared sensors for sensing temperatures of the multiple storage spaces correspondingly. The method includes the steps that after the door body is opened, the multiple infrared sensors are controlled to collect temperature values; whether temperature abnormal materials are possibly placed into an abnormal storage space in the multiple storage spaces or not is judged; if it is judged that the abnormal storage space exists, a first temperature change value obtained before and after the temperature abnormal materials are possibly placed into the abnormal storage space and a second temperature change value caused by heat exchange between the outer environment and the abnormal storage space before and after the temperature abnormal materials are possibly placed into the abnormal storage space are obtained; and whether the temperature abnormal materials are placed into the abnormal storage space or not is judged according to the first temperature change value and the second temperature change value. By means of the method, whether excessively hot food is placed into a certain storage space or not can be judged relatively accurately.

Owner:HAIER SMART HOME CO LTD

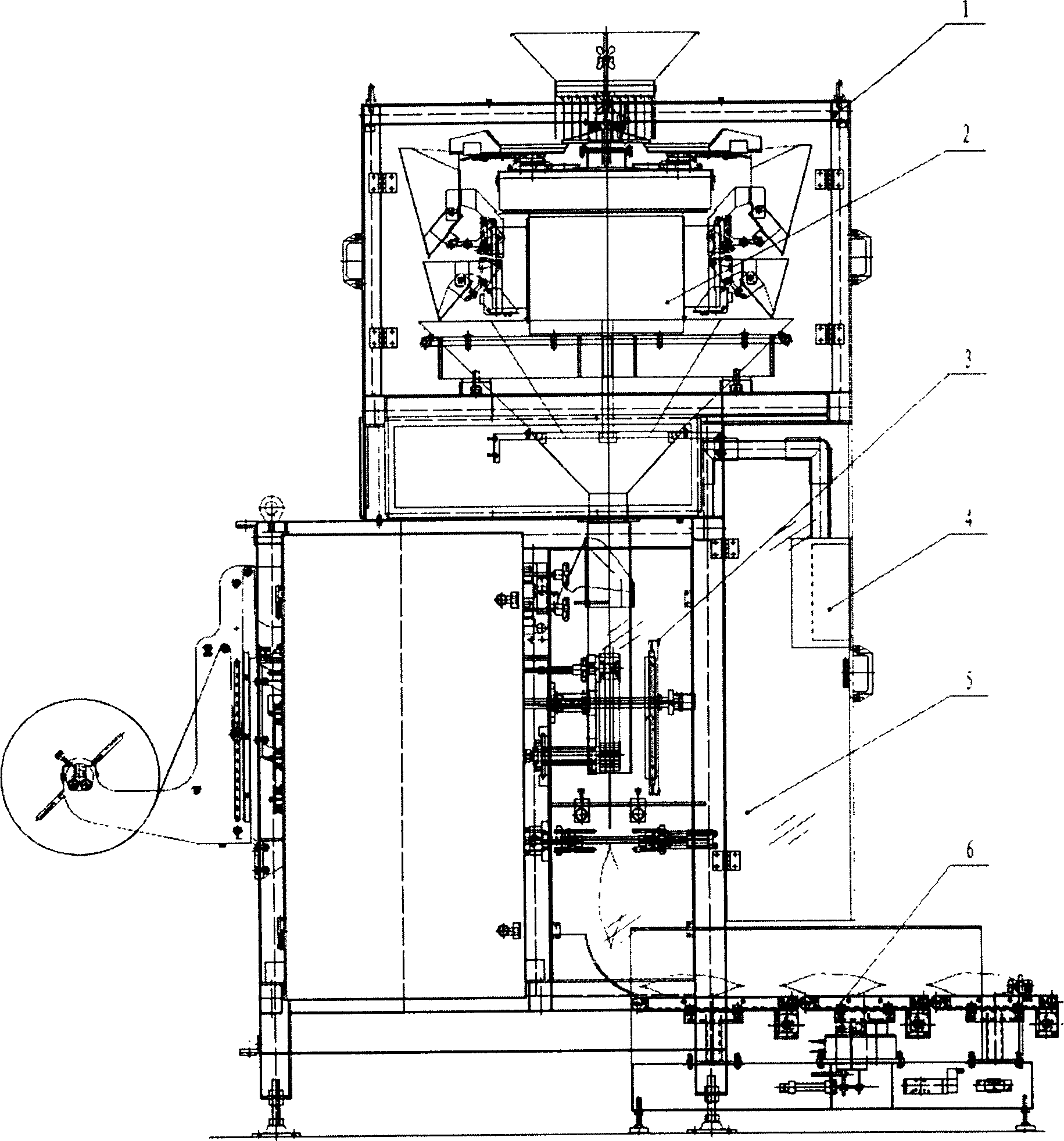

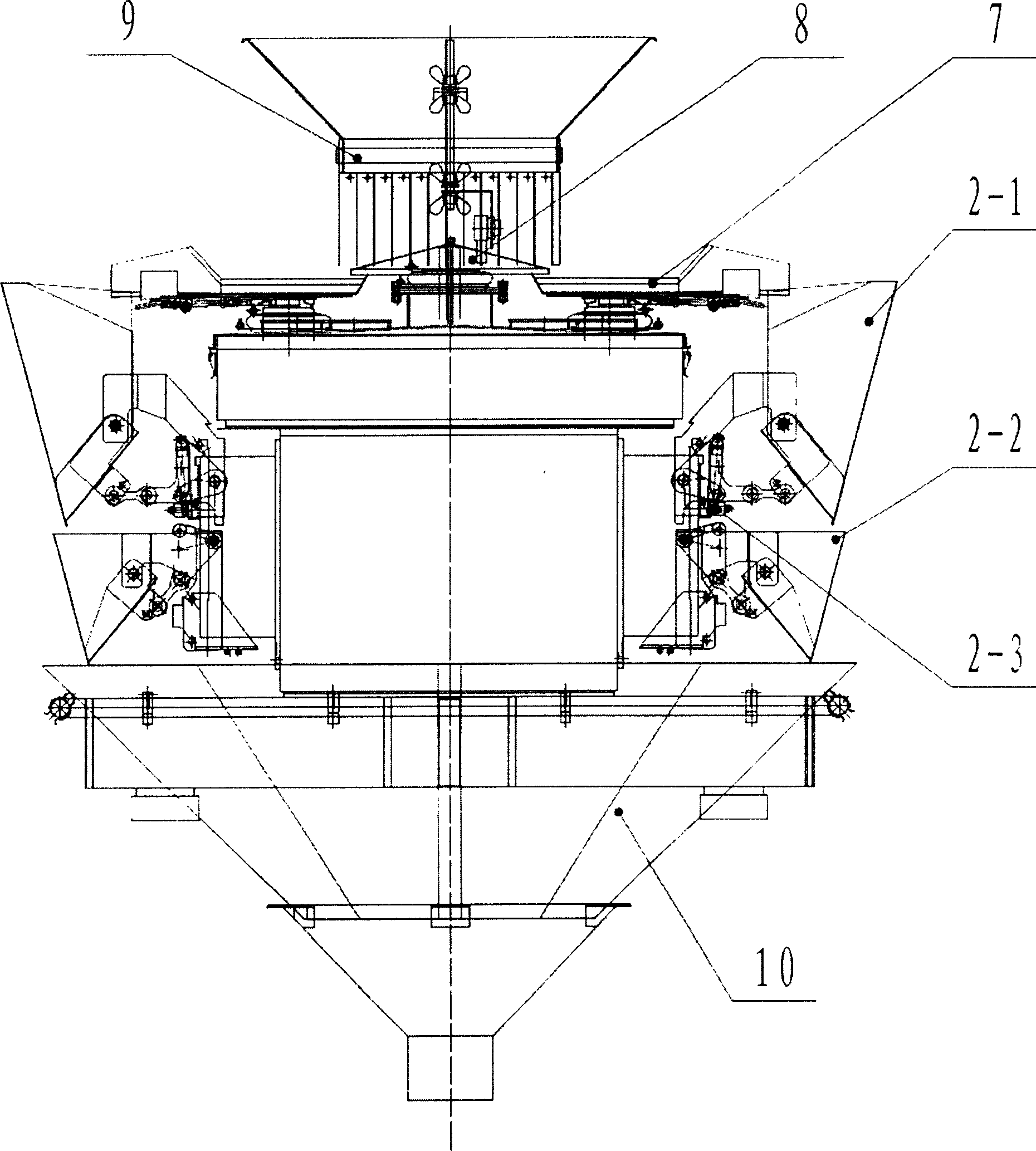

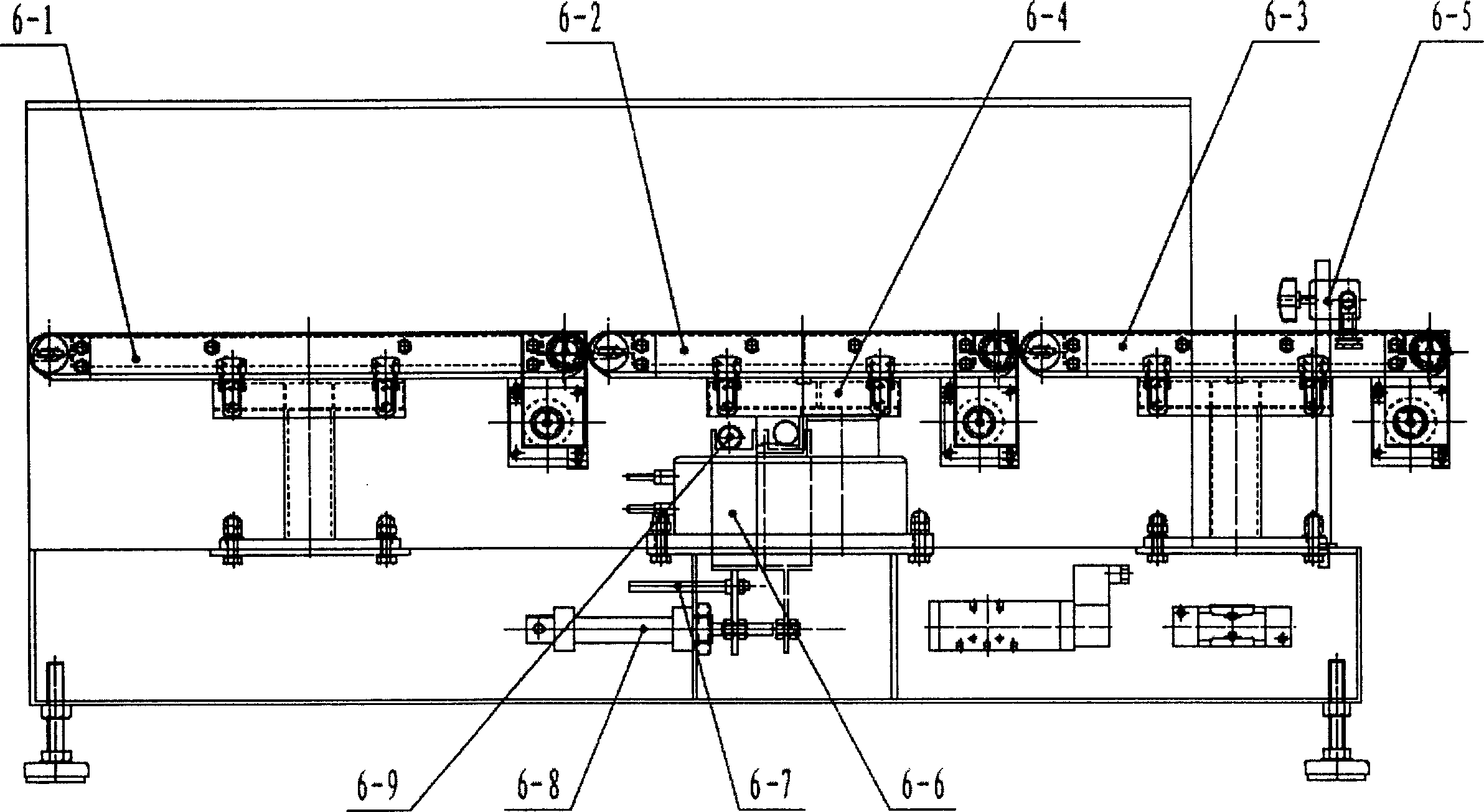

Full-automatic vertical quantitative package machine

InactiveCN1827478AReduce the overall heightSmall form factorWrappingPackaging automatic controlControl systemElectric machinery

The invention relates to a full-automatic upright quantitative packing device, which can apply the weighting, packing, transmitting and detecting on particle, sheet and abnormal materials. The invention combines the weighting device, the packing device and the weight detecting device; the feeding hopper of weighting device and the weighting hopper only have one motor for switching the material gate; the whole system uses PLC and computer as controller with one apparatus control system; the weight detecting device, according to preset weight value, detects the real packed weight and feeds back the result to said weighting device for dynamic adjustment, to make packed weight reach preset weight value; the weight detecting device first automatically adjusts itself after starting the system, then online adjusts each weighting hopper of weighting device to improve the weighting accuracy, to complete the automatic weighting, packing, weight detection and adjustment. The invention has tight structure, small size, less occupied area, easy operation, lower cost and wider application.

Owner:SAIMO ELECTRIC

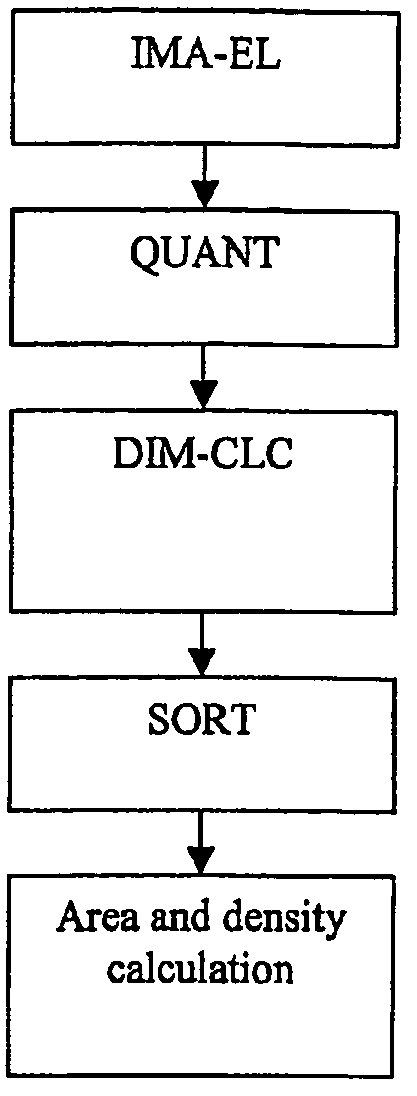

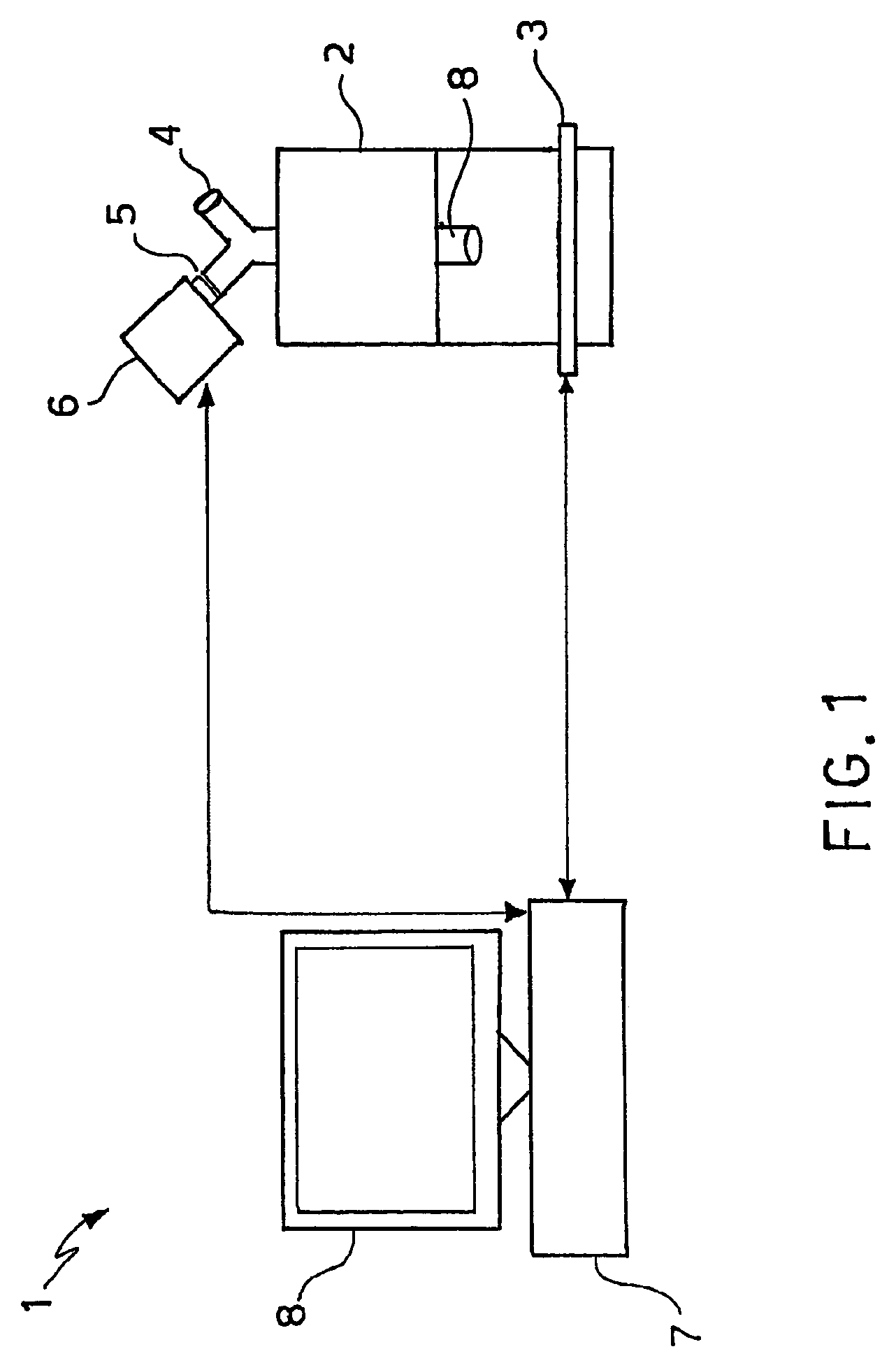

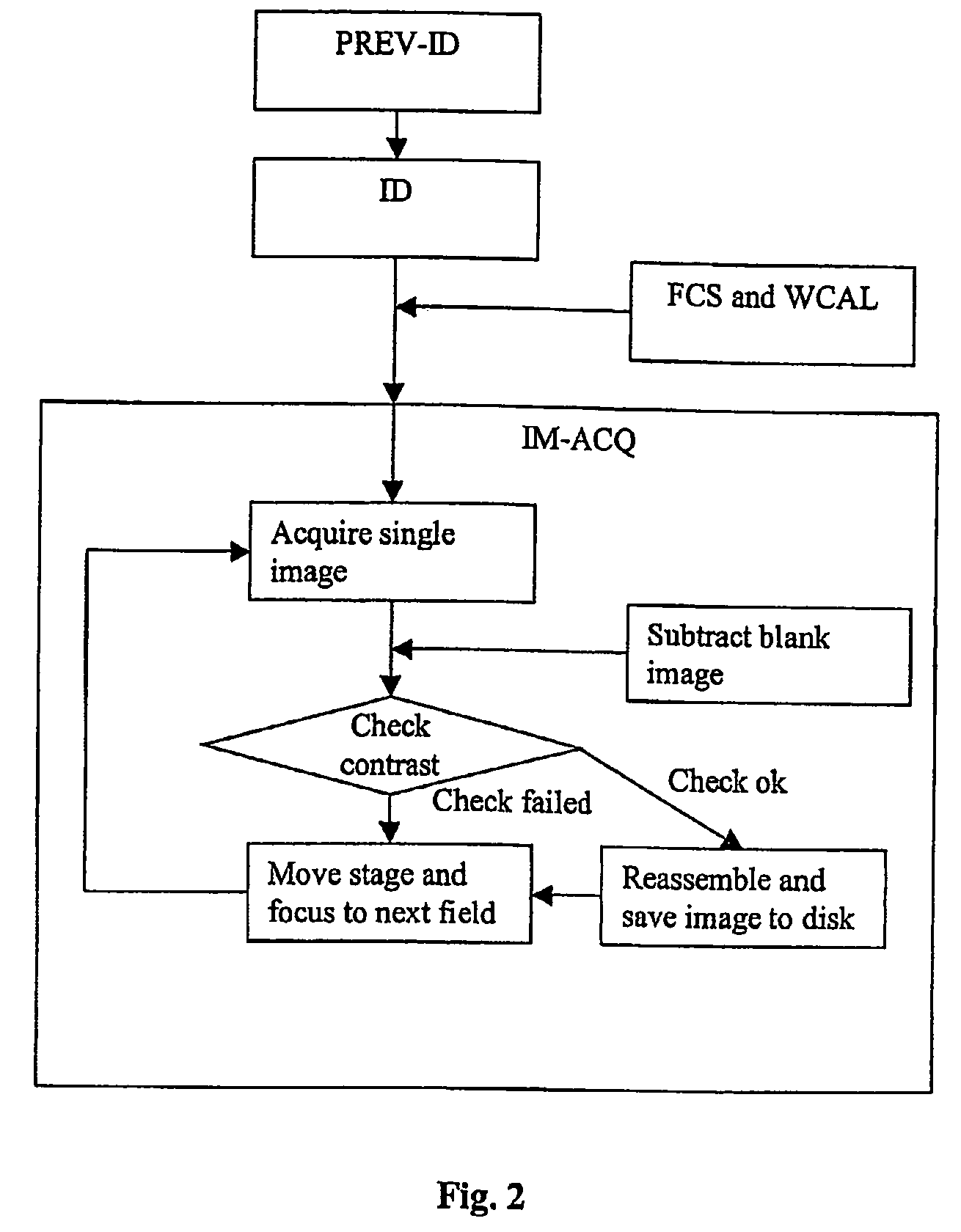

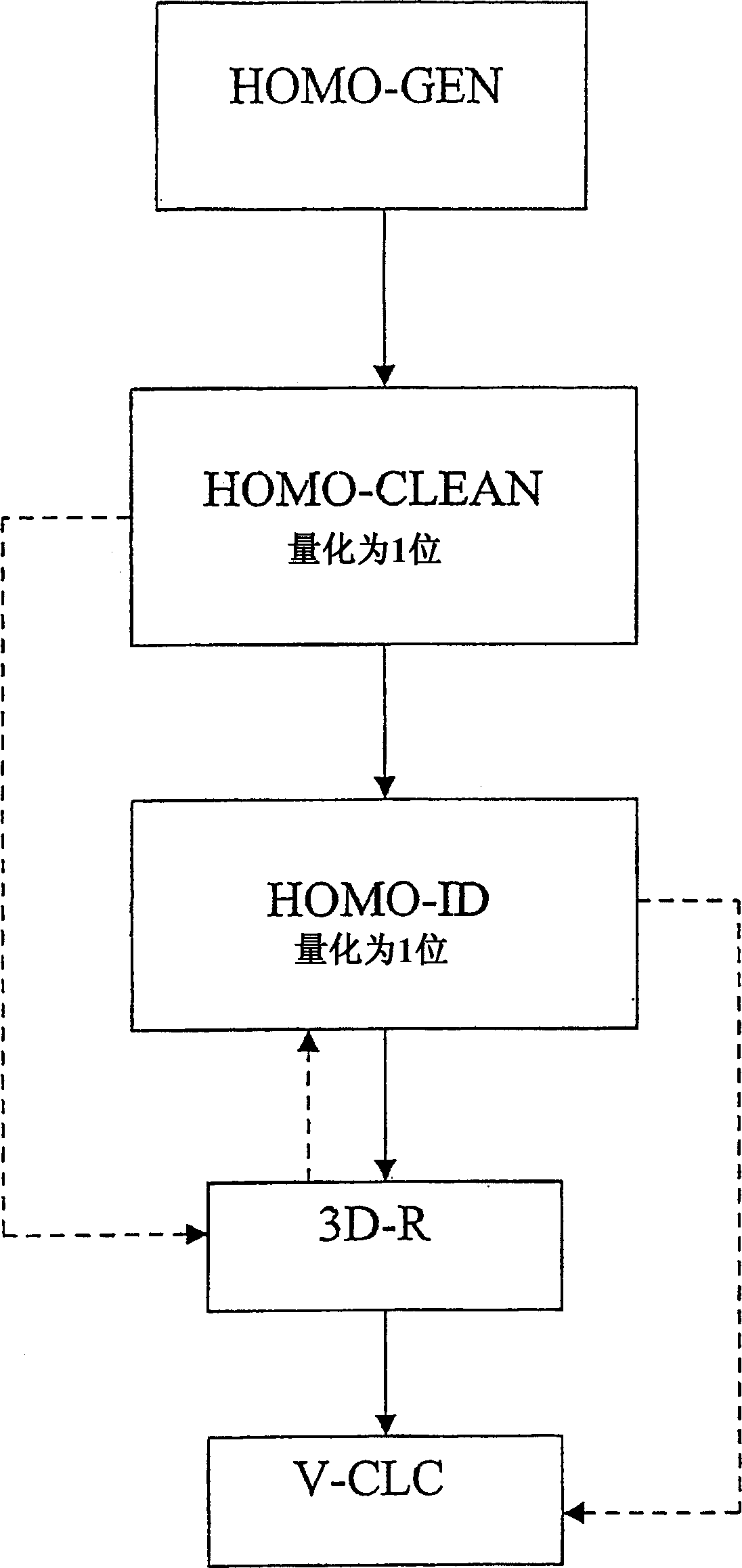

Method and apparatus for analyzing biological tissue specimens

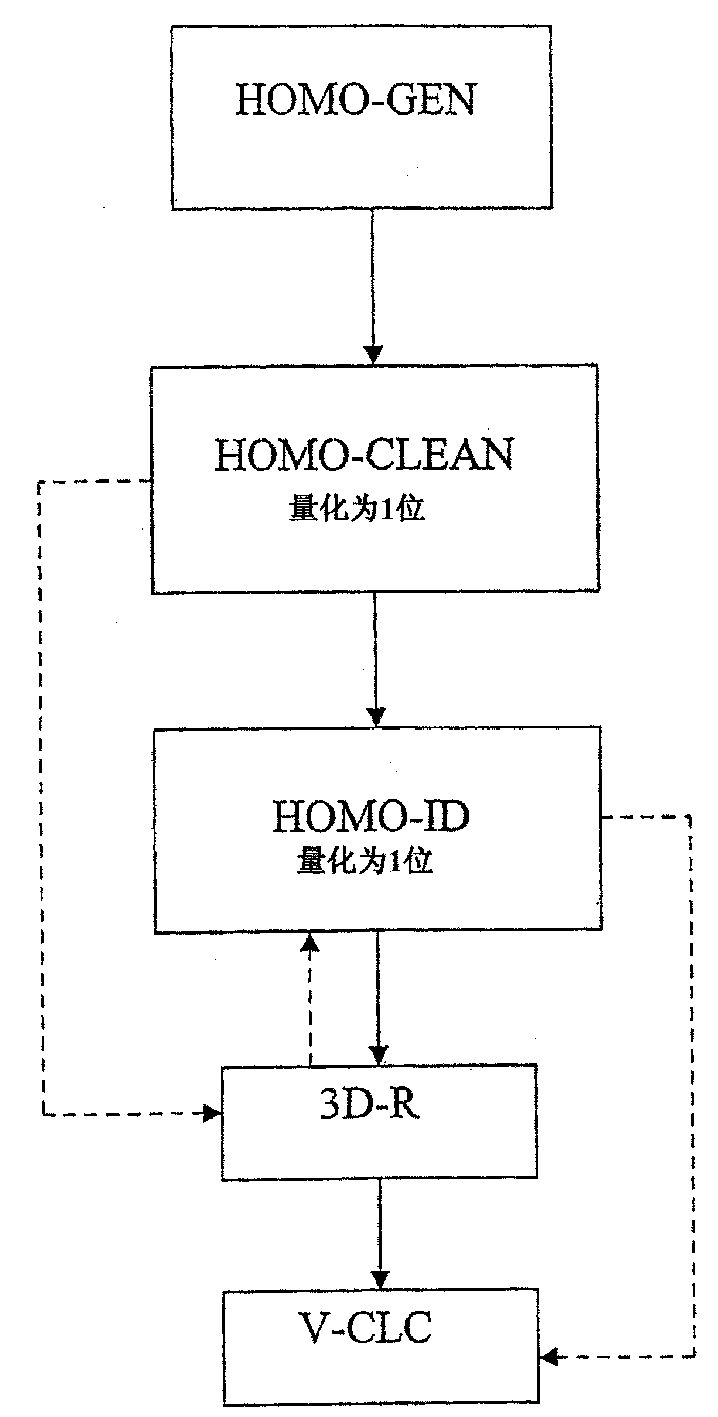

The present invention relates to a method and an apparatus for processing images of irregularly shaped objects, such as biological specimens, in particular of human or animal origin, or images thereof. The metric quantification of a biological body part or tissue or of an abnormal material spot or aggregate contained therein is also performed by means of the invention method. In particular, the present invention relates to a method for processing images of irregularly shaped objects, comprising a stage of acquisition of a digital image of said object, a stage of image elaboration (IMAEL) for quantifying said digital image to 1 bit and a stage of metrical processing of said 1-bit quantized image, wherein said stage of metrical processing comprises: —) a stage of object's metrical quantification (QUANT) for determining Euclidean perimeter P and / or area A of said object; —) a stage of dimensional calculation (DIM-CLC) for calculating a fractal-corrected perimeter Pf and / or area Af of said object.

Owner:HUMANITAS MIRASOLE S P S +1

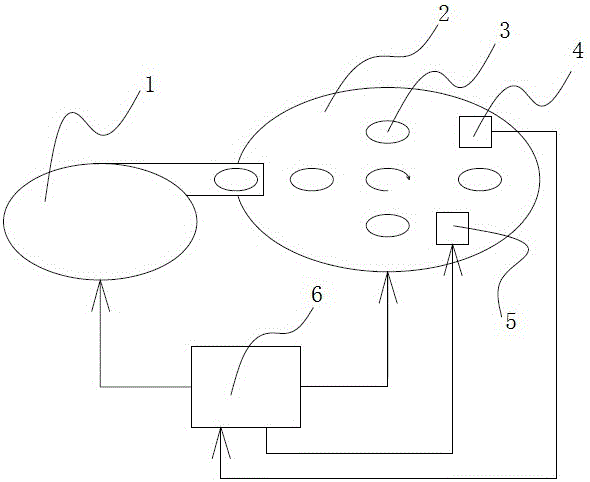

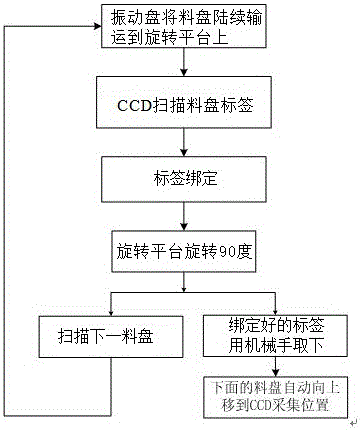

Multi-material-disc label collecting and binding system and control method thereof

InactiveCN106778424AAuto scanEasy to traceCo-operative working arrangementsJigging conveyorsMulti materialEngineering

The invention discloses a multi-material-disc label collecting and binding system and a control method thereof. The multi-material-disc label collecting and binding system comprises a vibrating disc and a rotating platform. A discharging opening in the vibrating disc is joined to the rotating platform, material discs are successively transported on the rotating platform, a CCD scanner for scanning material-disc labels and a mechanical arm for taking out the material discs are arranged on the rotating platform, the CCD scanner is connected to a controller in an output mode, and the controller binds scanned material-disc-label information and a new-set unique identification label. A warning device is also connected on the controller, and if scanned materials of the material discs are required materials or overdue abnormal materials, warning and reminding are carried out through the warning device. According to the multi-material-disc label collecting and binding system and the control method thereof, the structure is simple, operating is convenient, automatic feeding and automatic discharging are achieved, automatic scanning of material information is achieved, the working efficiency is improved, the material information is easy to trace.

Owner:ZHEJIANG SIPING INTELLIGENT TECH CO LTD

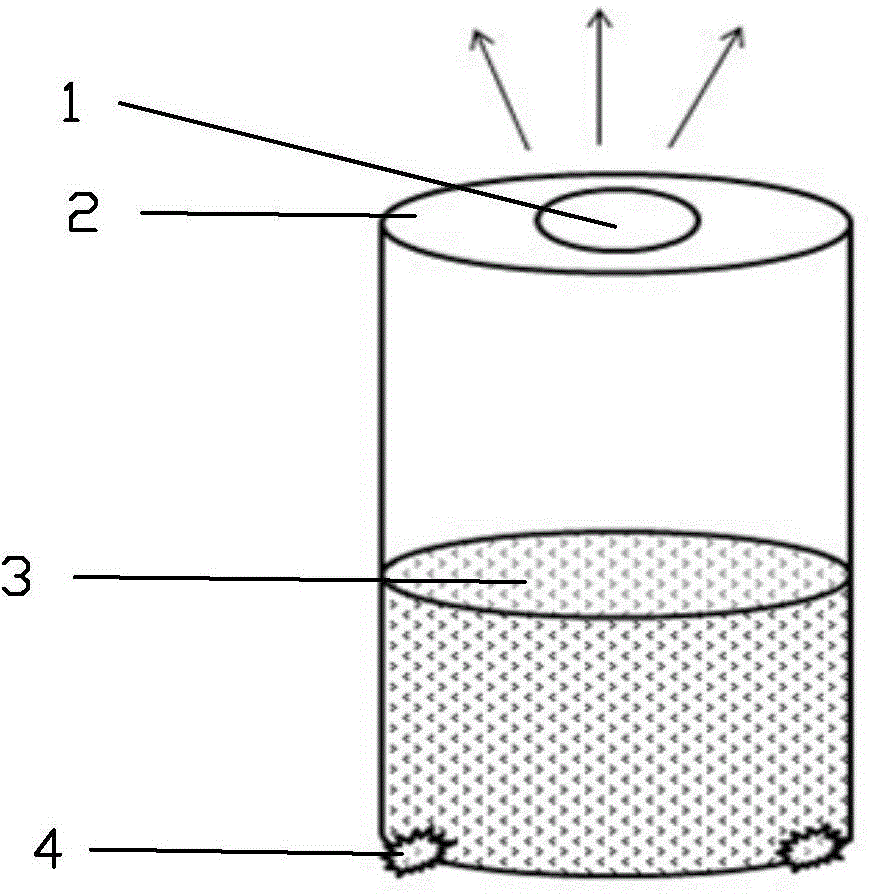

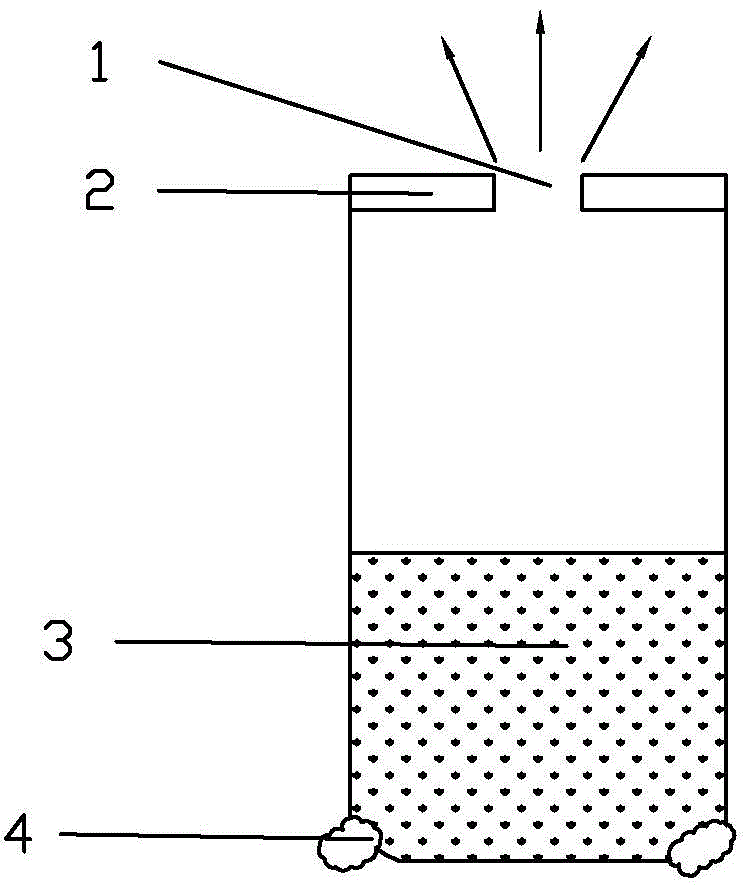

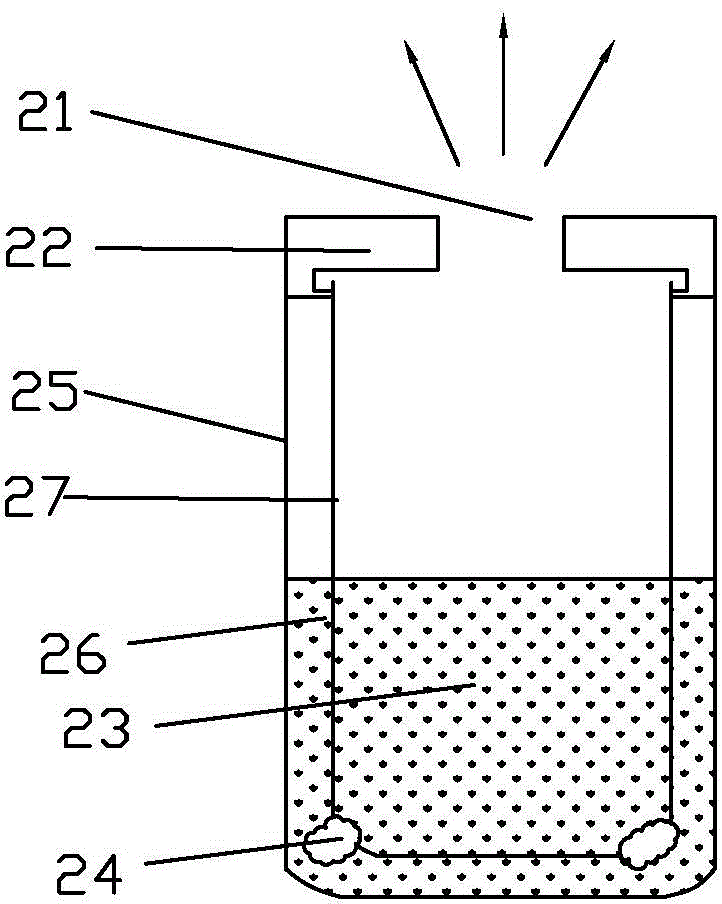

Heating container for preventing leakage of high-temperature metal material and manufacturing method thereof

InactiveCN104018121AManufacturing Method ImprovementsLow costVacuum evaporation coatingSputtering coatingProduction scheduleEvaporation

The invention relates to a heating container for preventing leakage of a high-temperature metal material and a manufacturing method thereof. The heating container comprises an internal heating container for containing a metal material, an external heating container for accepting the heating of a heating device, and an upper cover with an air hole for escaping of the metal material after evaporation, wherein the internal heating container is completely contained in the external heating container, and is fixed at a position relative to the external heating container; a gap is formed between the side wall of the internal heating container and the side wall of the external heating container; the upper cover is fixed above the internal heating container and the external heating container, and is used for covering openings of the internal heating container and the external heating container. The invention also provides the manufacturing method of the heating container. By adopting the heating container disclosed by the invention, the problems of abnormal material loss and production schedule interruption caused by cracks of the heating container generated in daily use can be solved; the continuous and stable operation cycle of the heating device can be effectively prolonged, and the product quality can be ensured.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

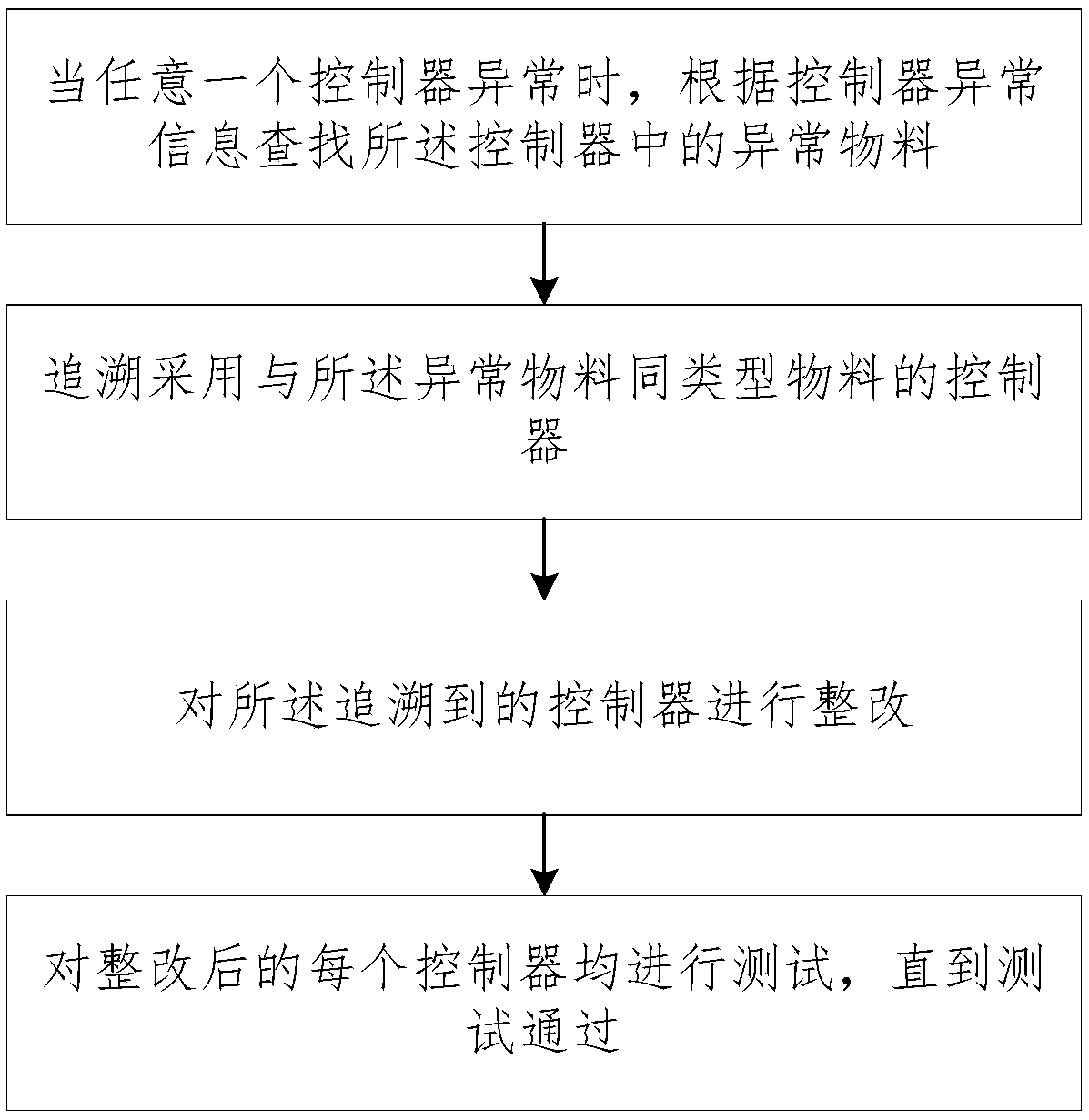

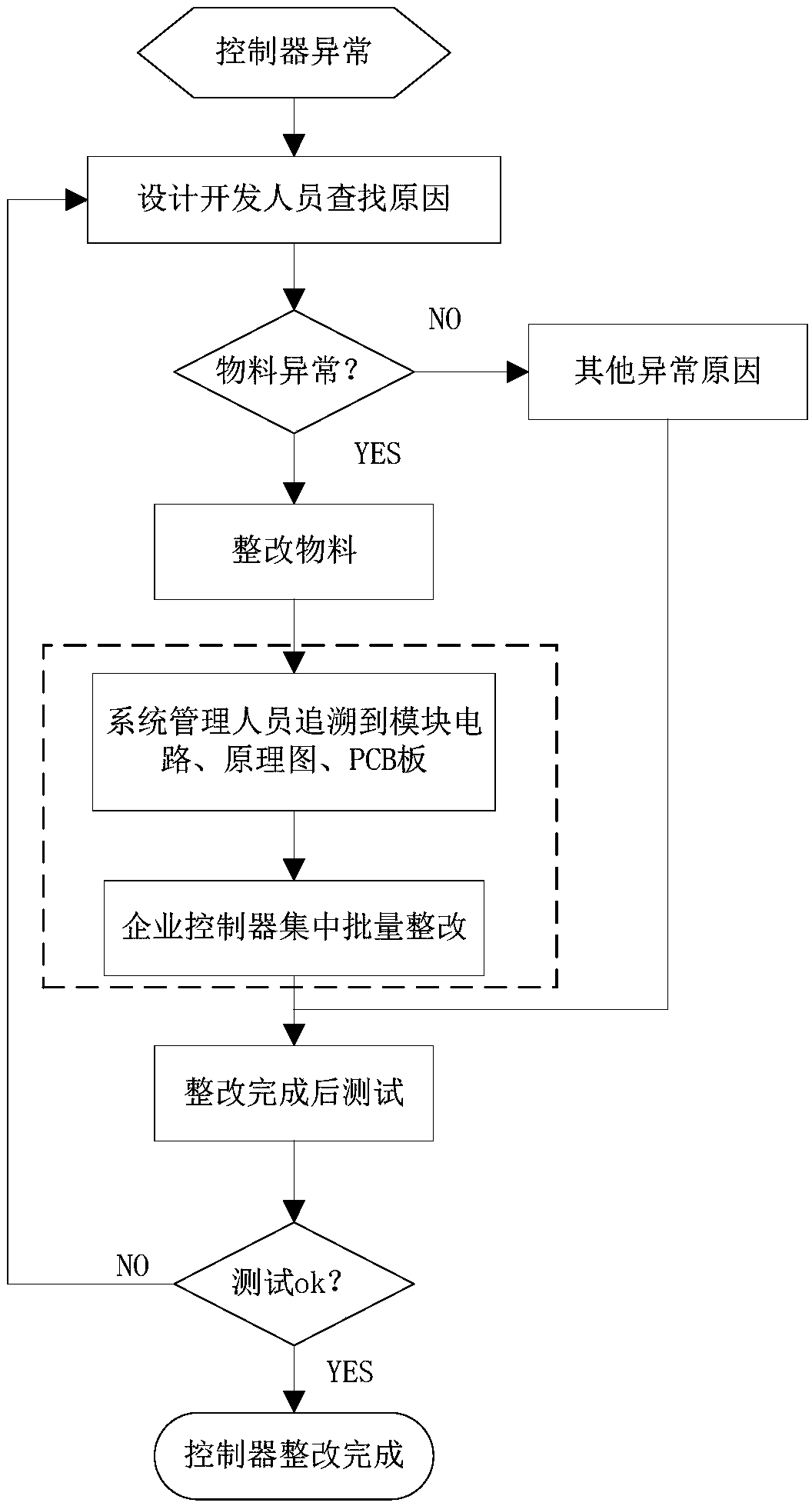

Intelligent tracing management method and system of controller

InactiveCN108693867AConvenient for centralized processingRealize batch rectificationElectric testing/monitoringData informationControl theory

The invention relates to an intelligent tracing management method and system of a controller. The method comprises: when any controller becomes abnormal, an abnormal material in the controller is searched based on the abnormal information of the controller; controllers employing materials with the same types as the abnormal material are tracked back; the traced controllers are rectified; and all rectified controllers are tested until testing is done successfully. According to the invention, the abnormal material in the controller is traced and thus all controllers using the same materials arefound out to carry out rectification in batches, so that the enterprise is able to deal with abnormal controller data information in a centralized manner and thus the product quality is improved.

Owner:GREE ELECTRIC APPLIANCES INC

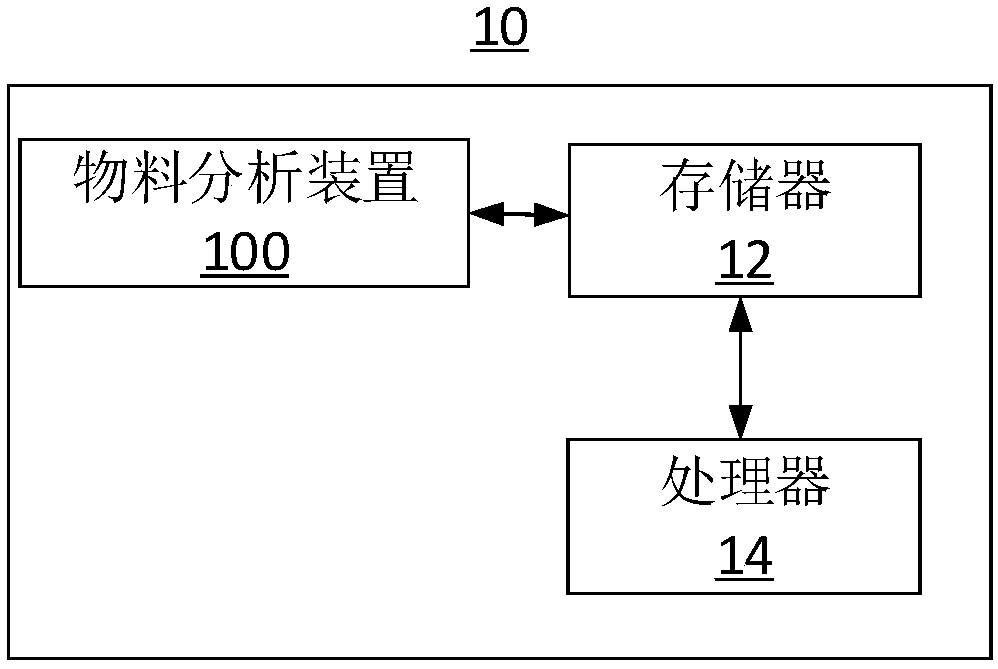

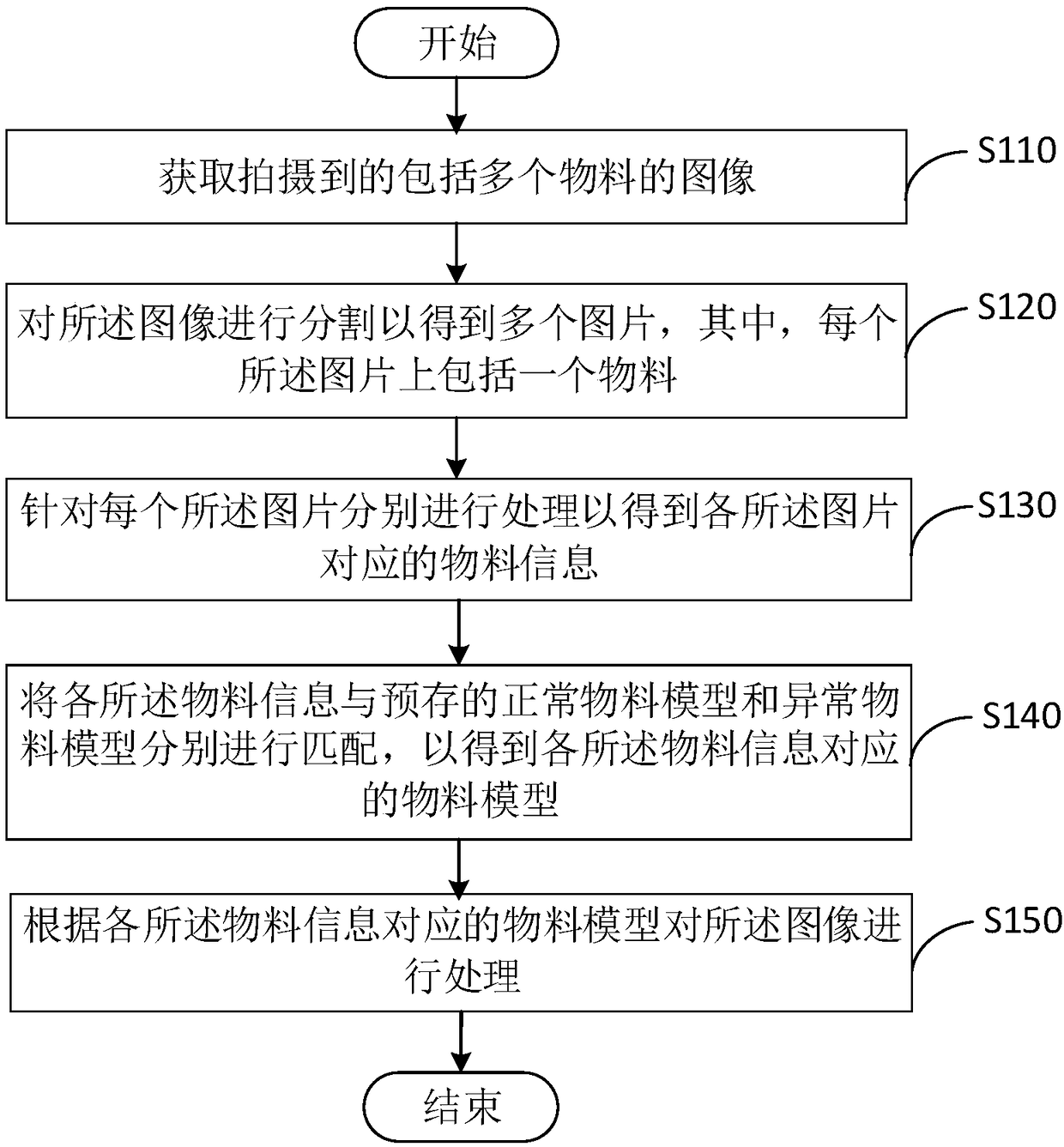

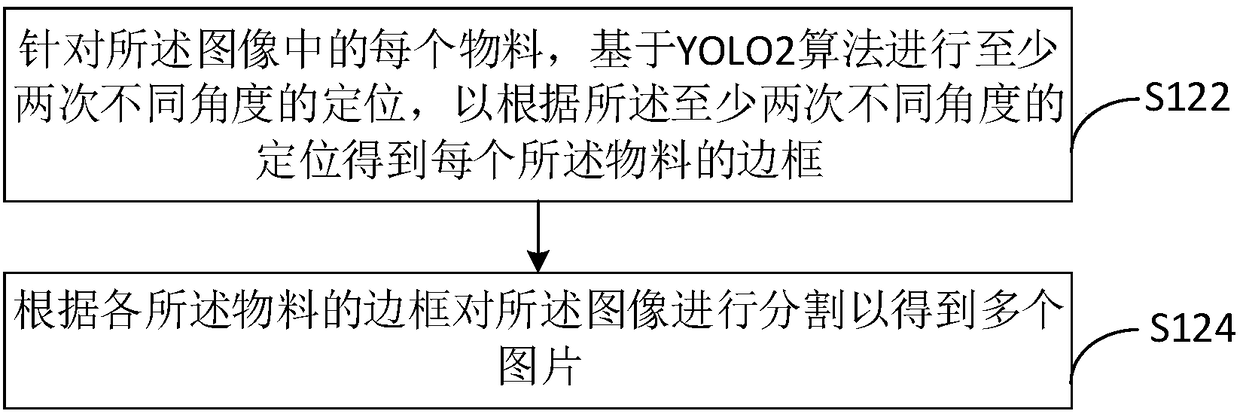

Material analysis method and device

InactiveCN108198168ARealize analysisRealize authenticationImage enhancementInvestigation of vegetal materialComputer visionAnalysis method

Embodiments of the invention relate to the technical field of sample classification, and in particular to a material analysis method and device. The method comprises the following steps of: obtaininga shot image comprising a plurality of materials; segmenting the image to obtain a plurality of pictures, wherein each picture comprises a material; respectively processing the pictures to obtain material information corresponding to the pictures; respectively matching the material information with pre-stored normal material models and abnormal material models so as to obtain material models corresponding to the material information; and processing the image according to the material models corresponding to the material models. Through the method, materials in images can be rapidly analyzed and identified.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

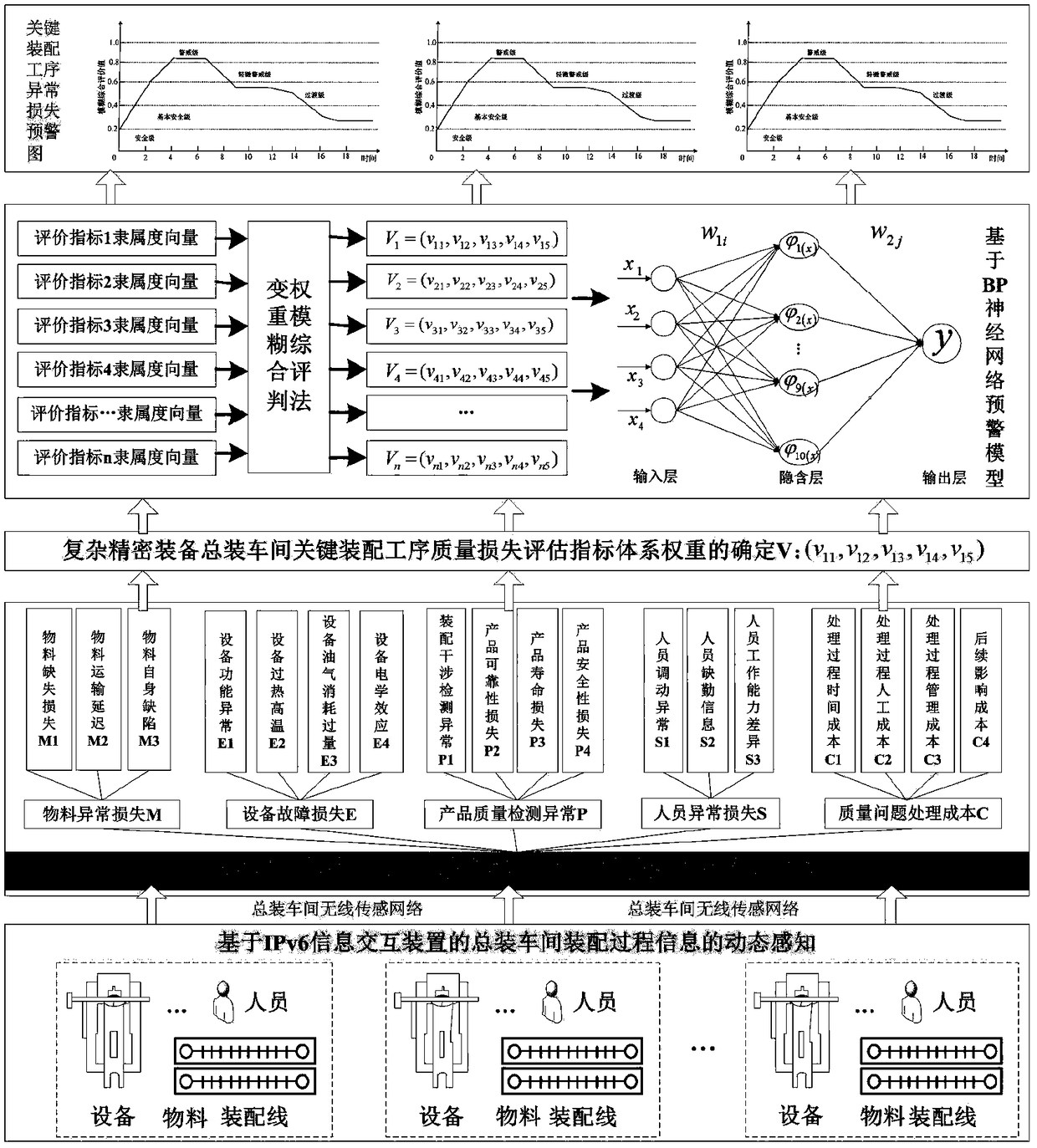

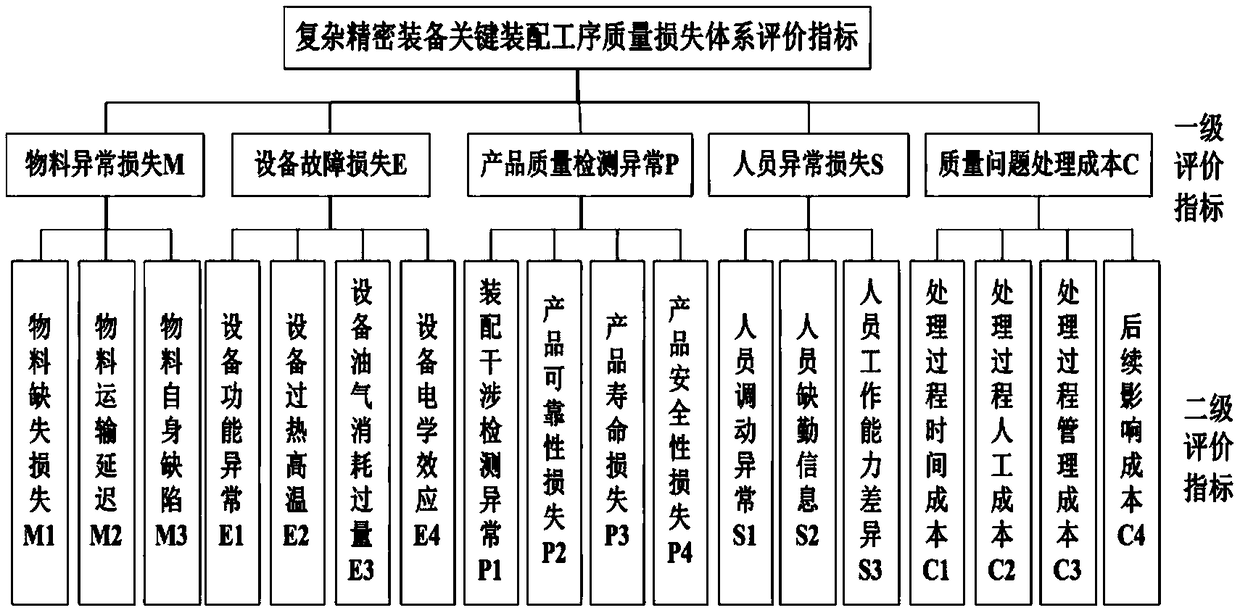

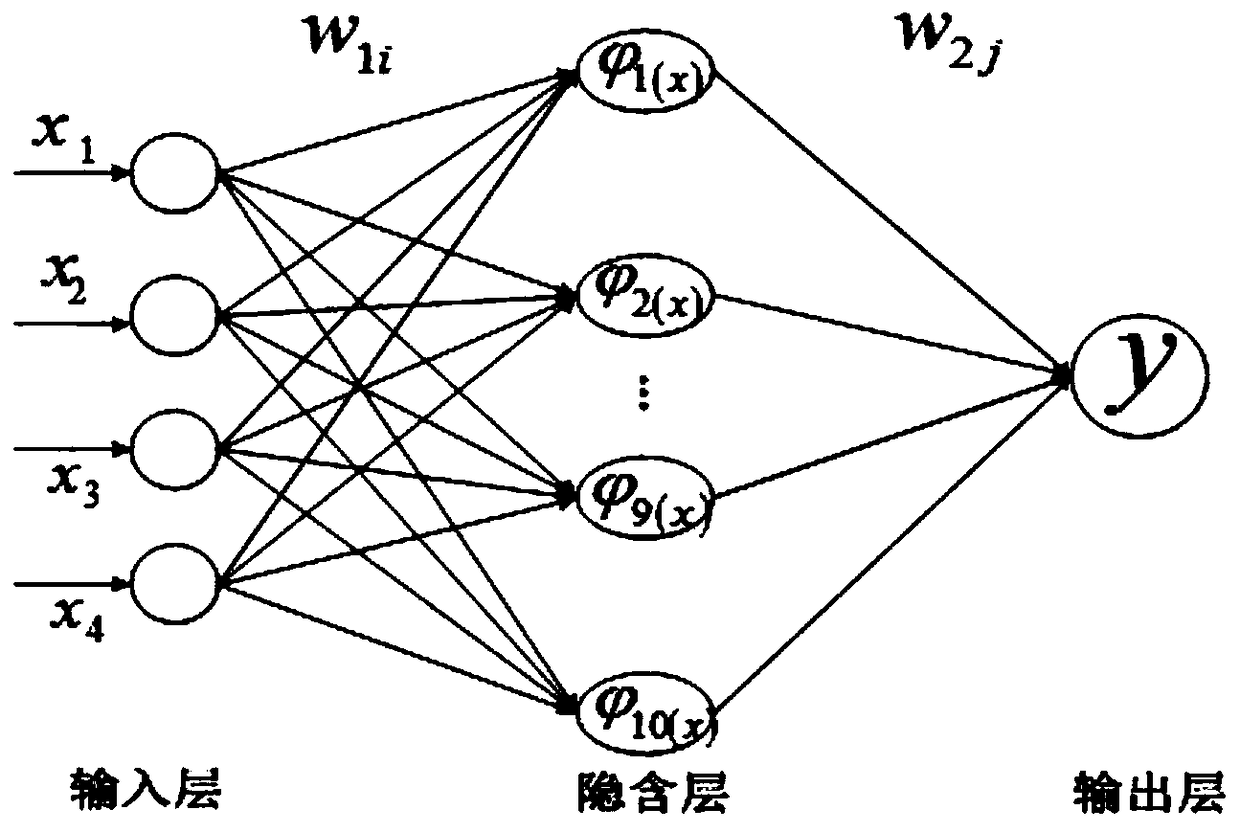

A method for quality loss assessment and early warning of key assembly process in complex precision equipment assembly workshop

The invention discloses a quality loss assessment and early warning method for key assembly process of a complex precision equipment assembly workshop, belonging to the field of intelligent manufacturing technology. This method establishes a set of key assembly process quality loss evaluation index system, which includes five dimensions: abnormal material loss M, equipment failure loss E, abnormalproduct quality detection P, abnormal personnel loss S, quality problem handling cost C, etc. On this basis, a fuzzy comprehensive evaluation method based on variable weights is adopted to evaluate the quality loss of key assembly processes in complex precision equipment assembly workshop, and a BP neural network quality loss early warning model is established, which provides support for the effective control of quality loss of key assembly processes. The invention aims at effectively evaluating and early warning the quality loss of the key assembly process in the complex precision equipmentgeneral assembly workshop, and providing decision support for preventing and controlling the quality abnormal problems of the key assembly process in advance.

Owner:CHONGQING TIEMA IND GRP +3

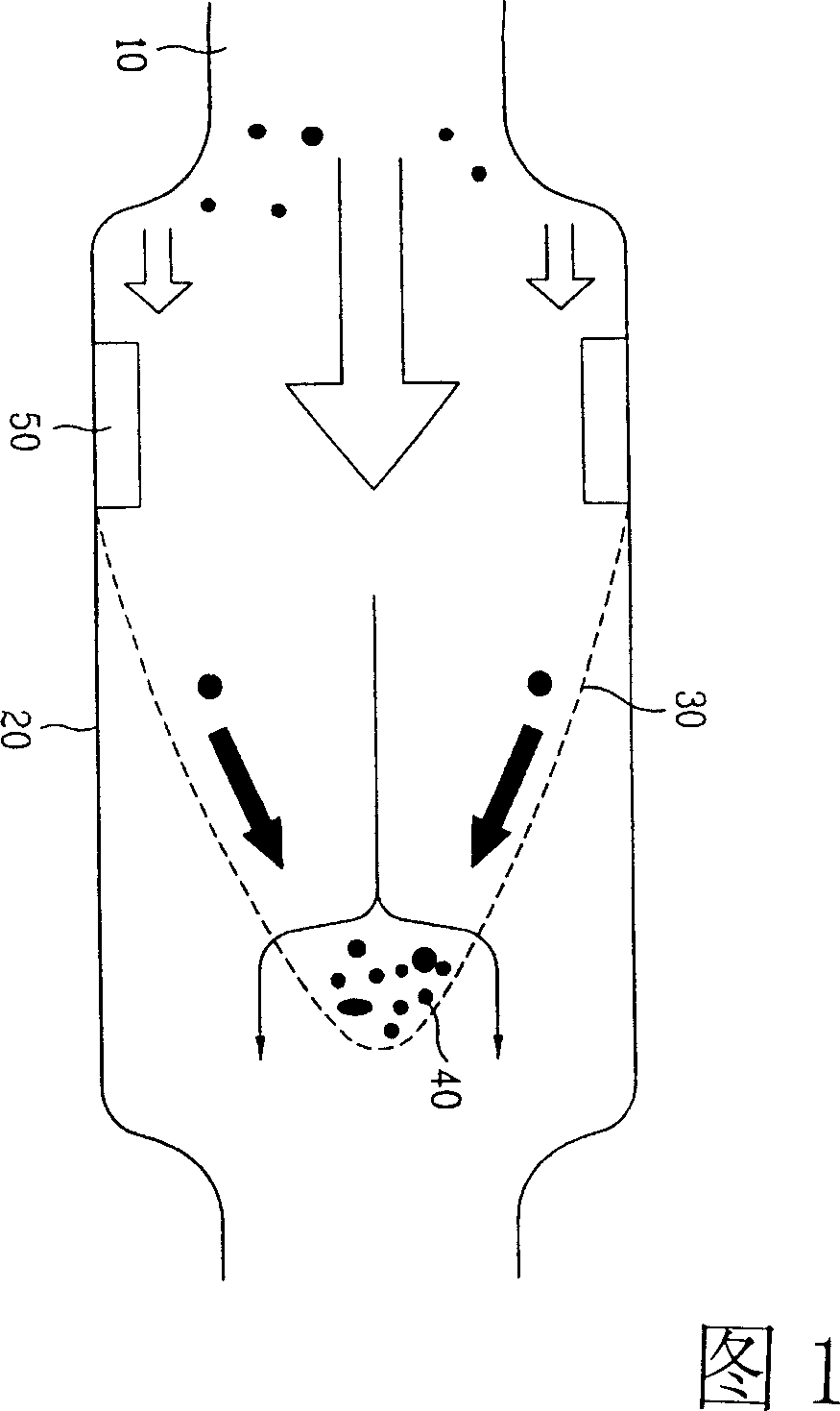

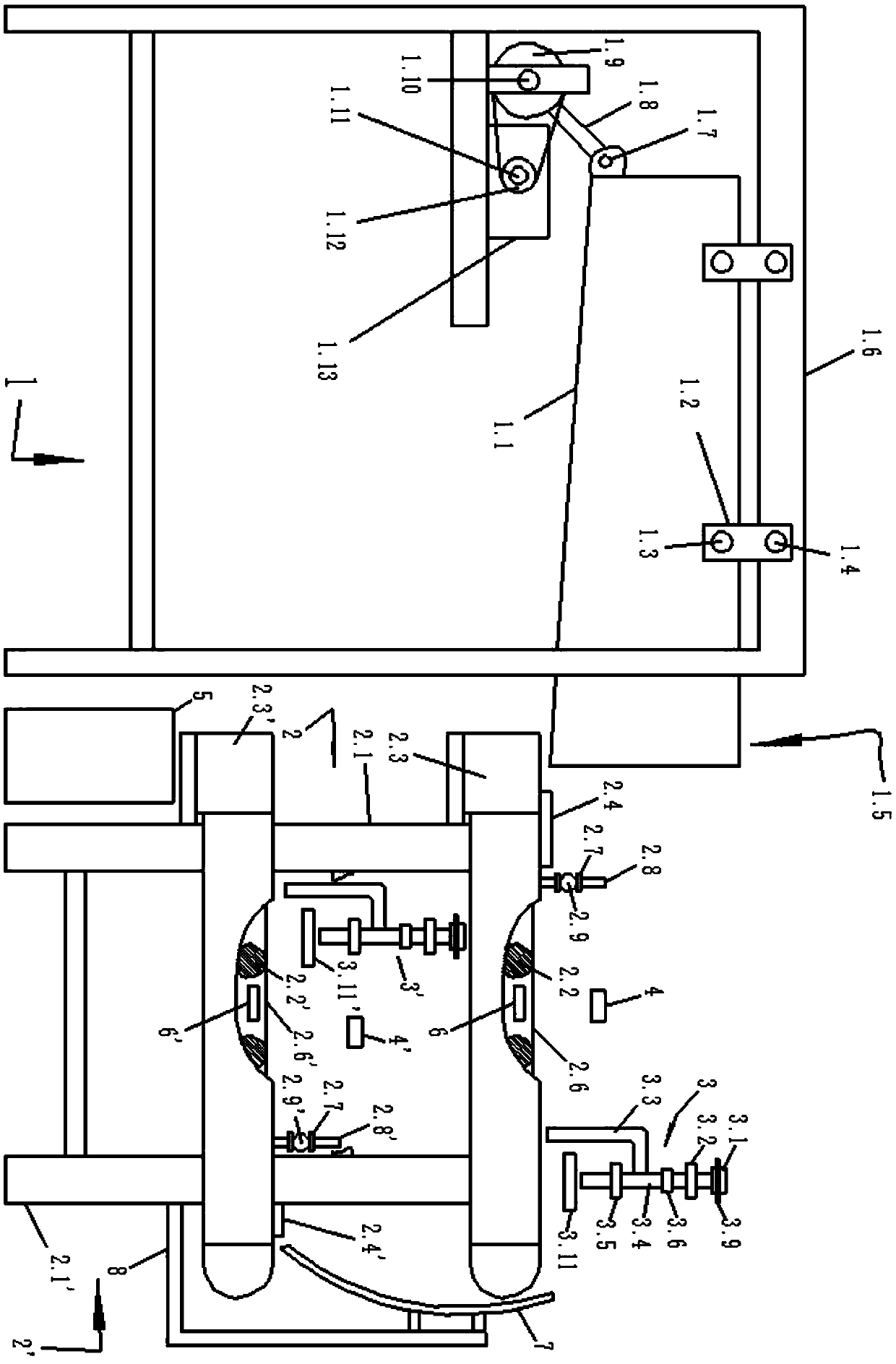

Silicon material sorting system based on machine vision

ActiveCN109909184AAvoid overlappingReduce the chance of missed detectionSortingMachine visionControl system

The invention provides a silicon material sorting system based on machine vision. The silicon material sorting system comprises a first conveying device, a control system and a feeding device for leveling and feeding; and the first conveying device is provided with a first machine vision image acquisition device for real-time acquisition of RGB images of to-be-sorted silicon materials conveyed bythe first conveying device, and a first abnormal material sorting device for absorbing abnormal materials in the to-be-sorted silicon materials conveyed on the first conveying device are arranged on the first conveying device. The silicon material sorting system further comprises a second conveying device and an arc-shaped reversing plate for being used in fit with the second conveying device andthe first conveying device; and a second machine vision image acquisition device and a second abnormal material sorting device which are successively distributed in the conveying direction of the second conveying device are arranged on the second conveying device. The silicon material sorting system based on machine vision is used for improving the efficiency of silicon material sorting and decreasing the probability of leak detection of silicon material sorting.

Owner:山东九思新材料科技有限责任公司

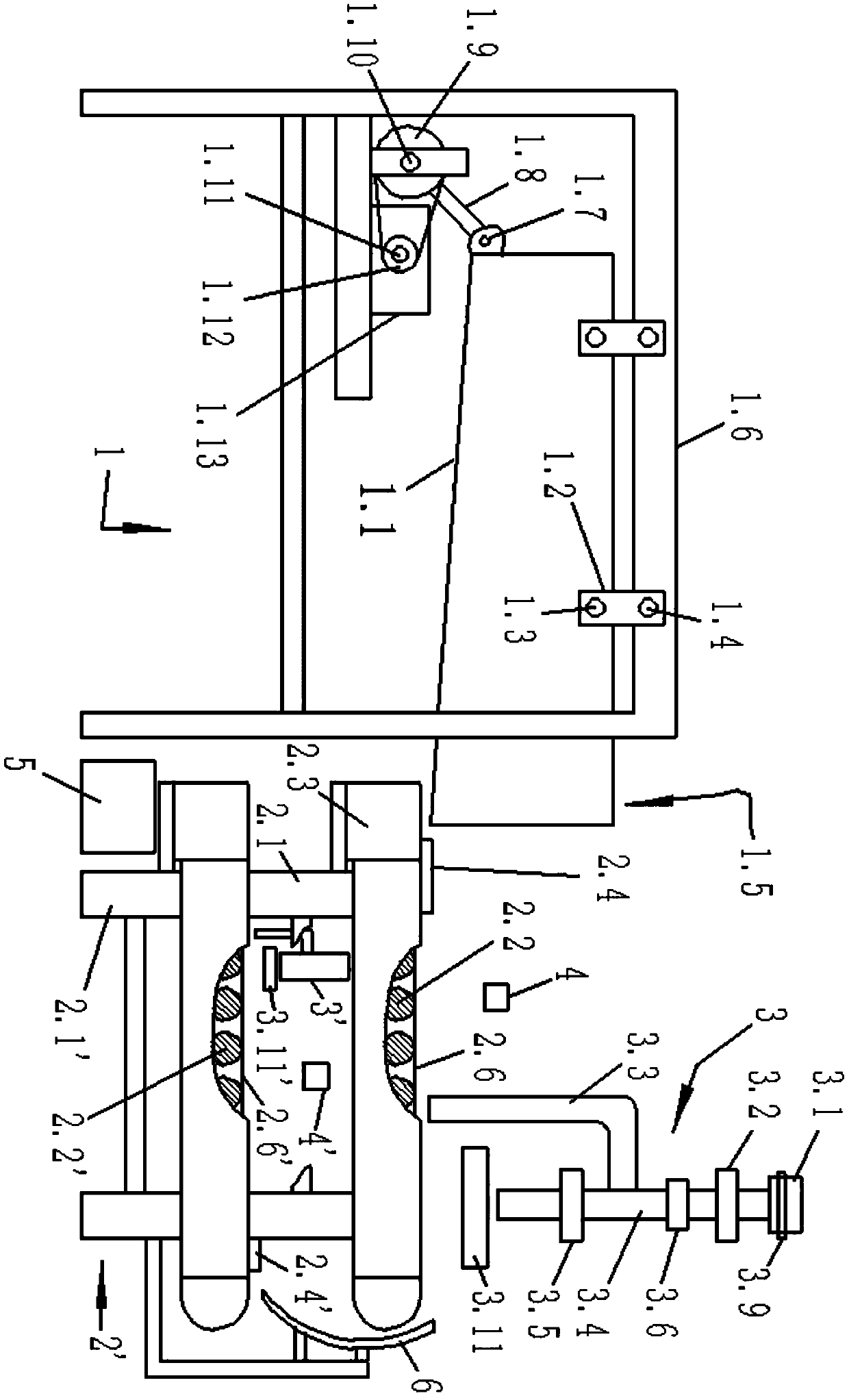

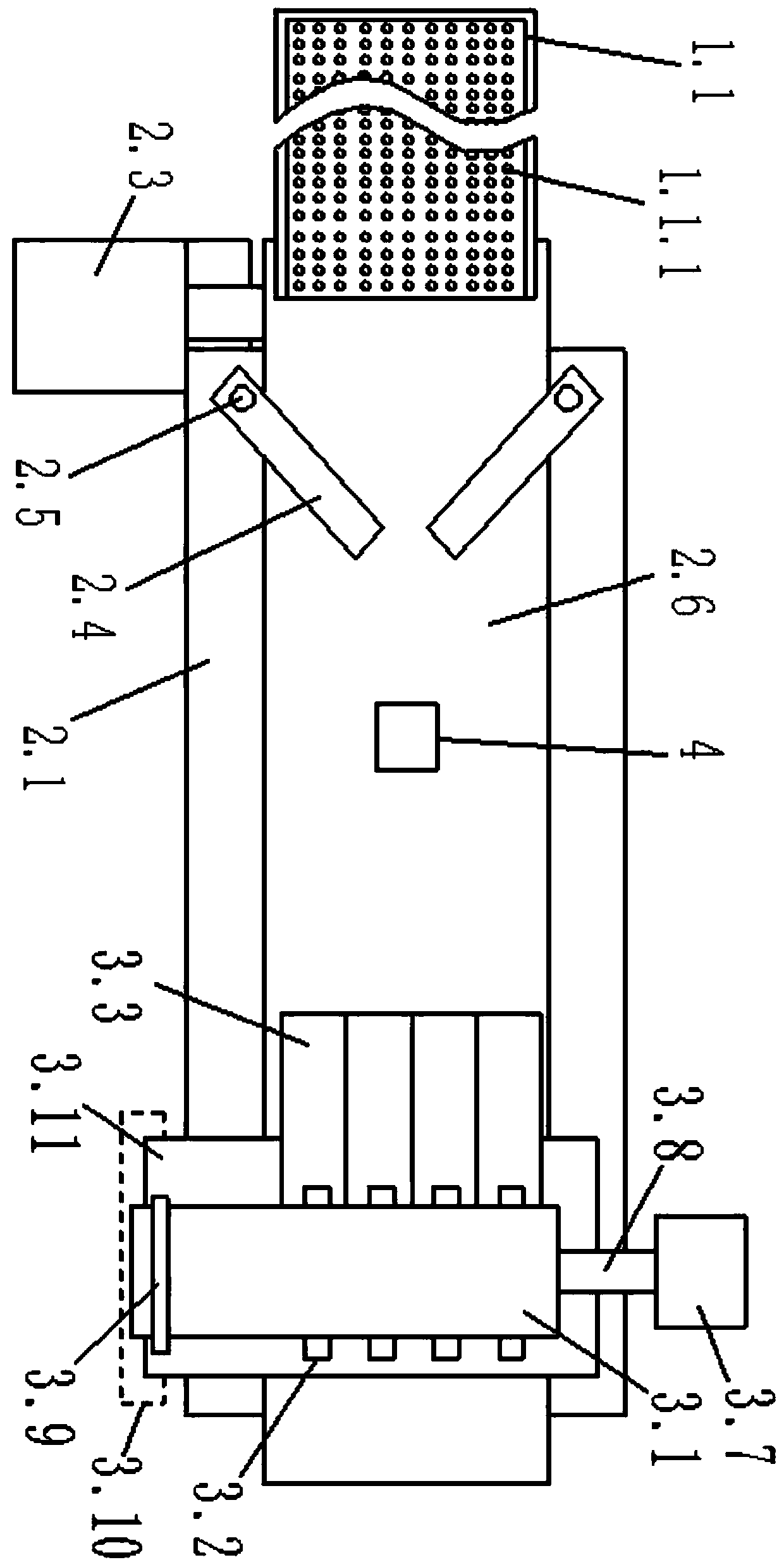

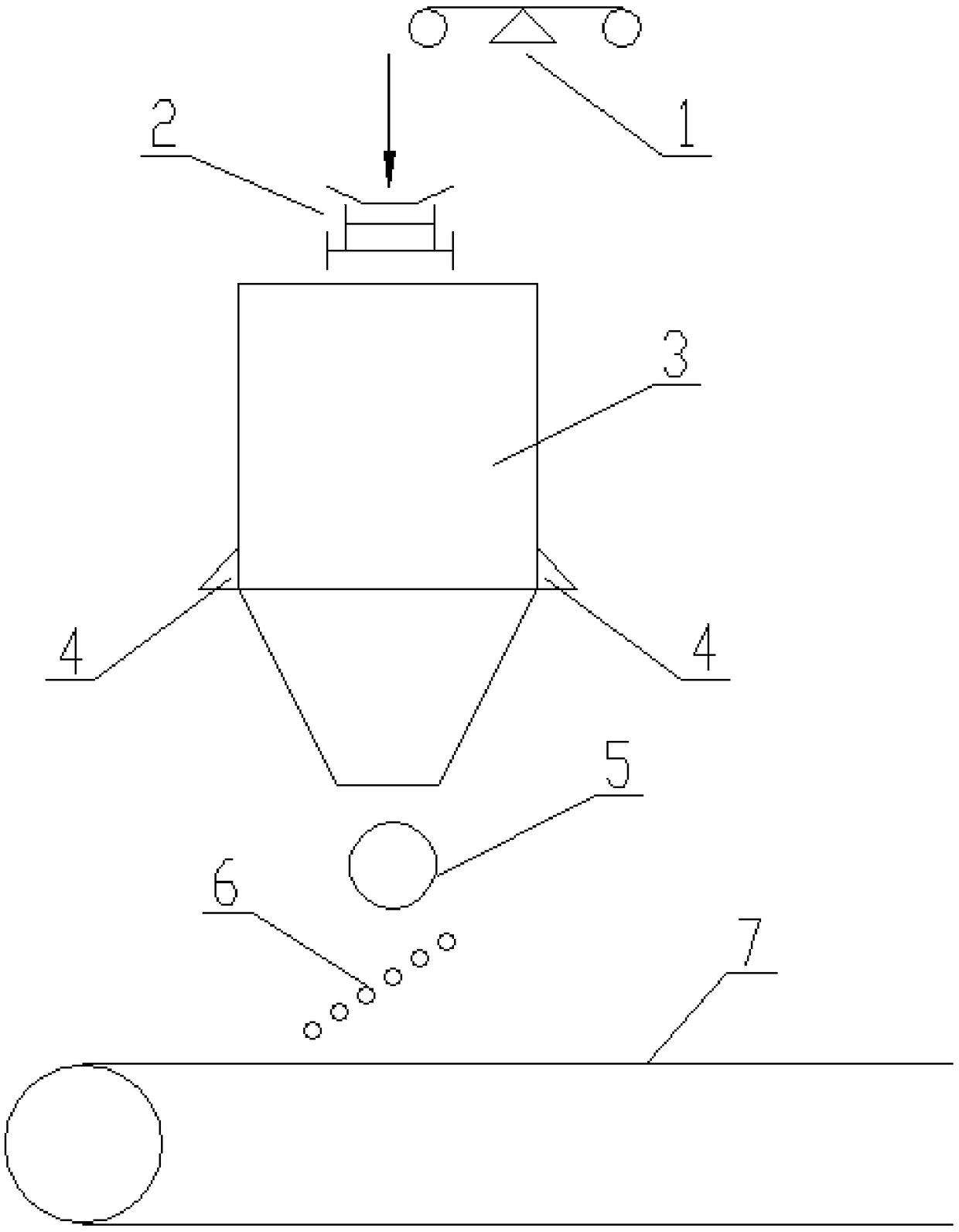

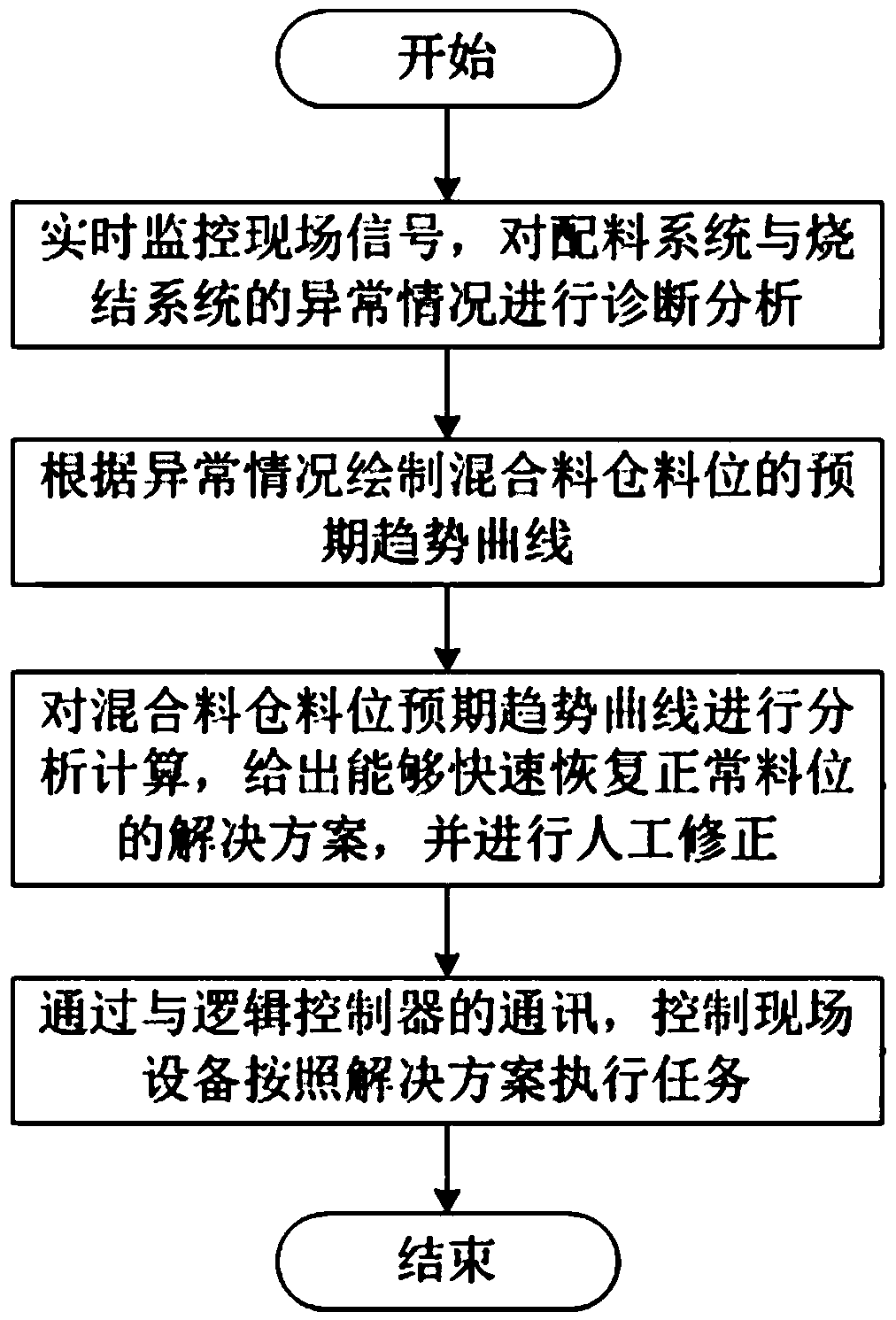

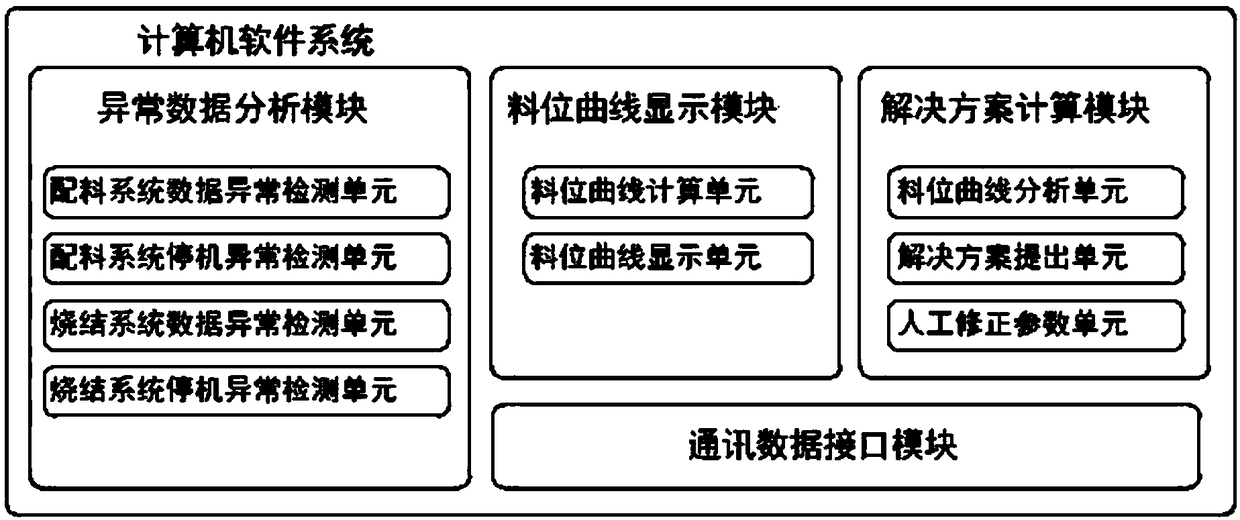

System and method for controlling material level of sintering mixing material bin

PendingCN109186272ARealize intelligent controlShorten adjustment timeControl devices for furnacesEngineeringTime control

The invention belongs to the technical field of industrial computer real-time control, in particular to a system and method for controlling a material level of a sintering mixing material bin. The system is characterized by comprising a real-time monitoring mechanism, a signal acquisition and analysis mechanism and a control execution mechanism, wherein the real-time monitoring mechanism comprisesa charging belt weigher positioned above the mixing material bin, bin weighing sensors arranged on the mixing material bin, a round roller feeder positioned below the mixing material bin, and a converter detection speed feedback device arranged on a sintering machine; the signal acquisition and analysis mechanism comprises a computer analysis system; and the control execution mechanism comprisesa logic controller. The system and method for controlling the material level of the sintering mixing material bin can diagnose and analyze on-site abnormal conditions according to on-site signals, draw an expected trend curve of the material level of the mixing material bin, and give a solution for restoring the normal material level, thereby realizing the intelligent control of the material levelof the mixing material bin, shortening the time for adjusting the abnormal material level, increasing the sinter output and increasing the production profit of a whole plant.

Owner:中冶北方(大连)工程技术有限公司

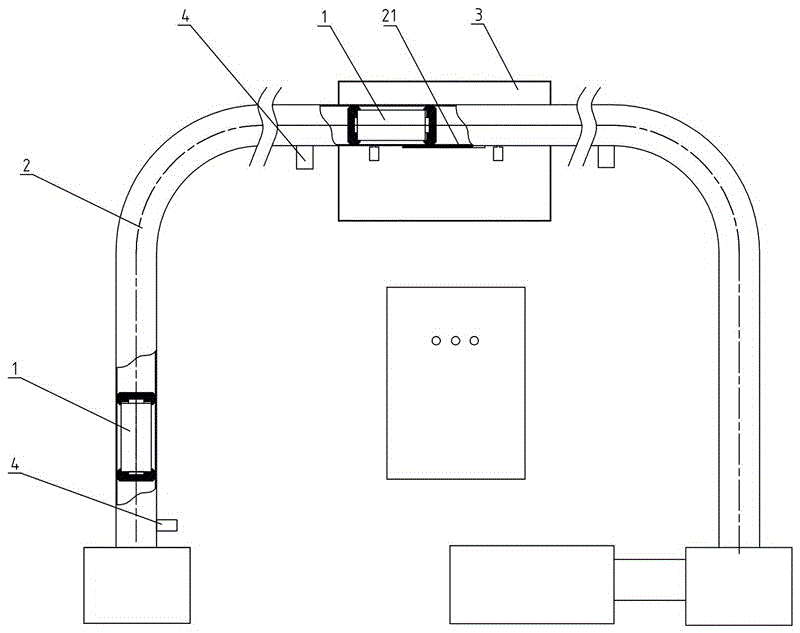

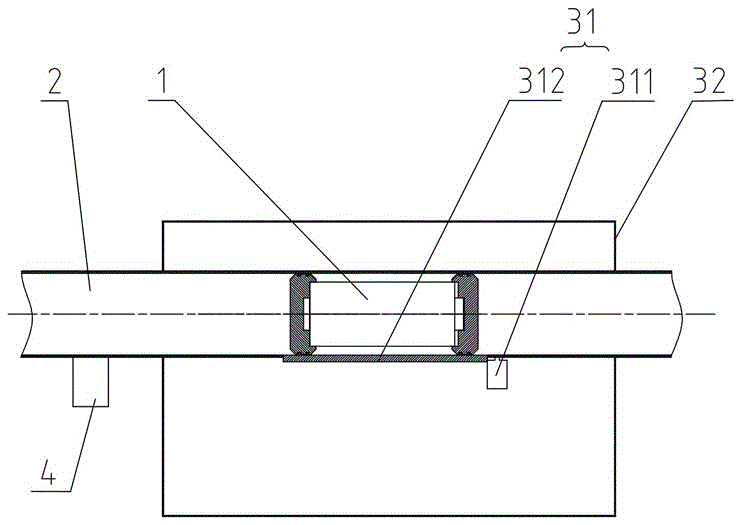

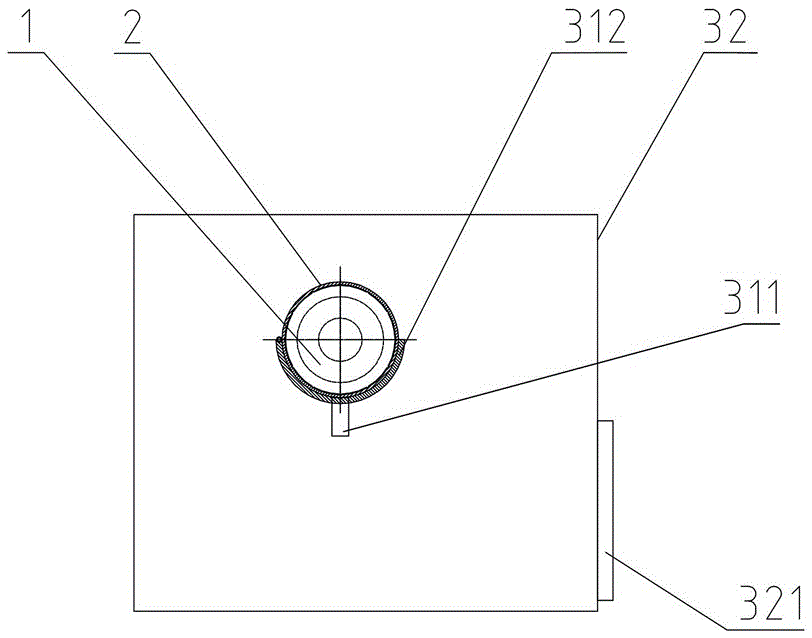

Multi-shaft filature locking nozzle clamping jaw mechanism

InactiveCN103878575ANo offsetMisalignment exception does not occurMetal working apparatusScrew positionSpring force

The invention discloses a multi-shaft filature locking nozzle clamping jaw mechanism which comprises screwdriver inlets (1), screw inlets (2), a fixed seat (3), an external force spring (4), a guiding shaft (5), a screw positioning piece (6), a screw sample (7) and a sliding piece (8). The multi-shaft filature locking nozzle clamping jaw mechanism is characterized in that the screw inlets (2) are connected beside the screwdriver inlets (1), the lower ends of the screw inlets (2) are connected with the fixed seat (3), the lower end of the fixed seat (3) is connected with the external force spring (4), the lower end of the external force spring (4) is connected with the guiding shaft (5), the lower end of the guiding shaft (5) is connected with the screw positioning piece (6), the screw positioning piece (6) is provided with the screw sample (7), and the right end of the external force spring (4) is connected with the sliding piece (8). According to the multi-shaft filature locking nozzle clamping jaw mechanism, a dispersing mechanism is positioned towards the center through the guiding shaft and spring force so as to be correctly positioned, and it is guaranteed that excursion and dislocation abnormity cannot happen in the screw locking process. The multi-shaft filature locking nozzle clamping jaw mechanism has the advantages of being simple in structure, easy to adjust, more stable in the working process, capable of completely removing abnormal material clamping and material overturning and saving a large amount of time and labor cost, lower in manufacturing cost and the like.

Owner:KUNSHAN LITE AUTOMATION EQUIP

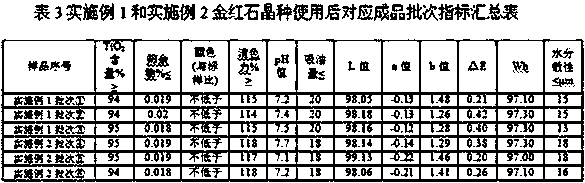

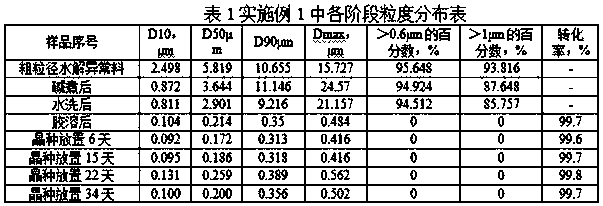

Process for reparation of rutile seed crystals from coarse-granularity hydrolysis abnormal material

InactiveCN109970099AImprove conversion rateExtended storage timeTitanatesTitanium dioxideGranularityHydrolysis

The invention relates to a process for preparation of rutile seed crystals from a coarse-granularity hydrolysis abnormal material. The process includes the following steps that a metatitanic acid hanging film as a coarse-granularity hydrolysis abnormal material is washed, beaten to 300-350 g / L and pre-heated, alkaline liquor is pre-heated according to the alkali-to-titanium ratio of (1.5-1.8):1, metatitanic acid is added for curing after pre-heating, water is added for dilution, alkaline liquor is cooled to be 70 DEG C, and a titanate is obtained; the hanging film is washed to obtain titanateslurry, hydrochloric acid is added to make the pH value become 2.8-3.1, the temperature rises to 60 DEG C, and the pH is adjusted to be 2.8-3.1 with hydrochloric acid; hydrochloric acid is added again, heating is performed until boiling occurs, the boiling state is maintained, water is added to be 95-105 g / L, and then the rutile seed crystals are obtained. The method is simple, the cost is low, the rutile conversion rate is high, the seed crystal storage time is long, when the seed crystals are used for preparation of titanium dioxide, the obtained titanium dioxide is small in particle size, the conversion rate is high, and the color index and the lightening power are significantly improved.

Owner:JINAN YUXING CHEM

Rapid maintenance device for pneumatic conveying of material and material pneumatic conveying system

Owner:HUNAN SUNDY SCI & TECH DEV

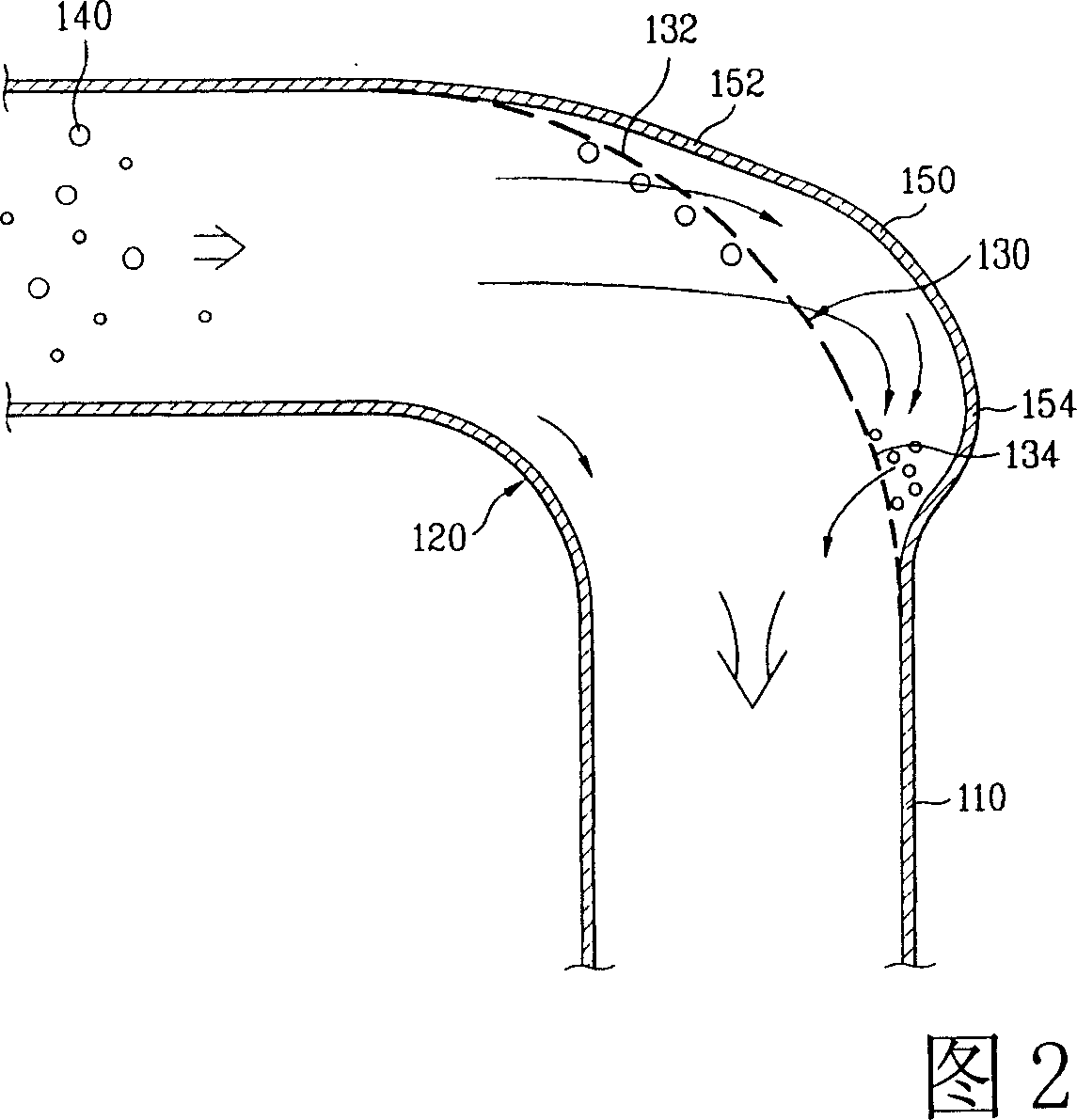

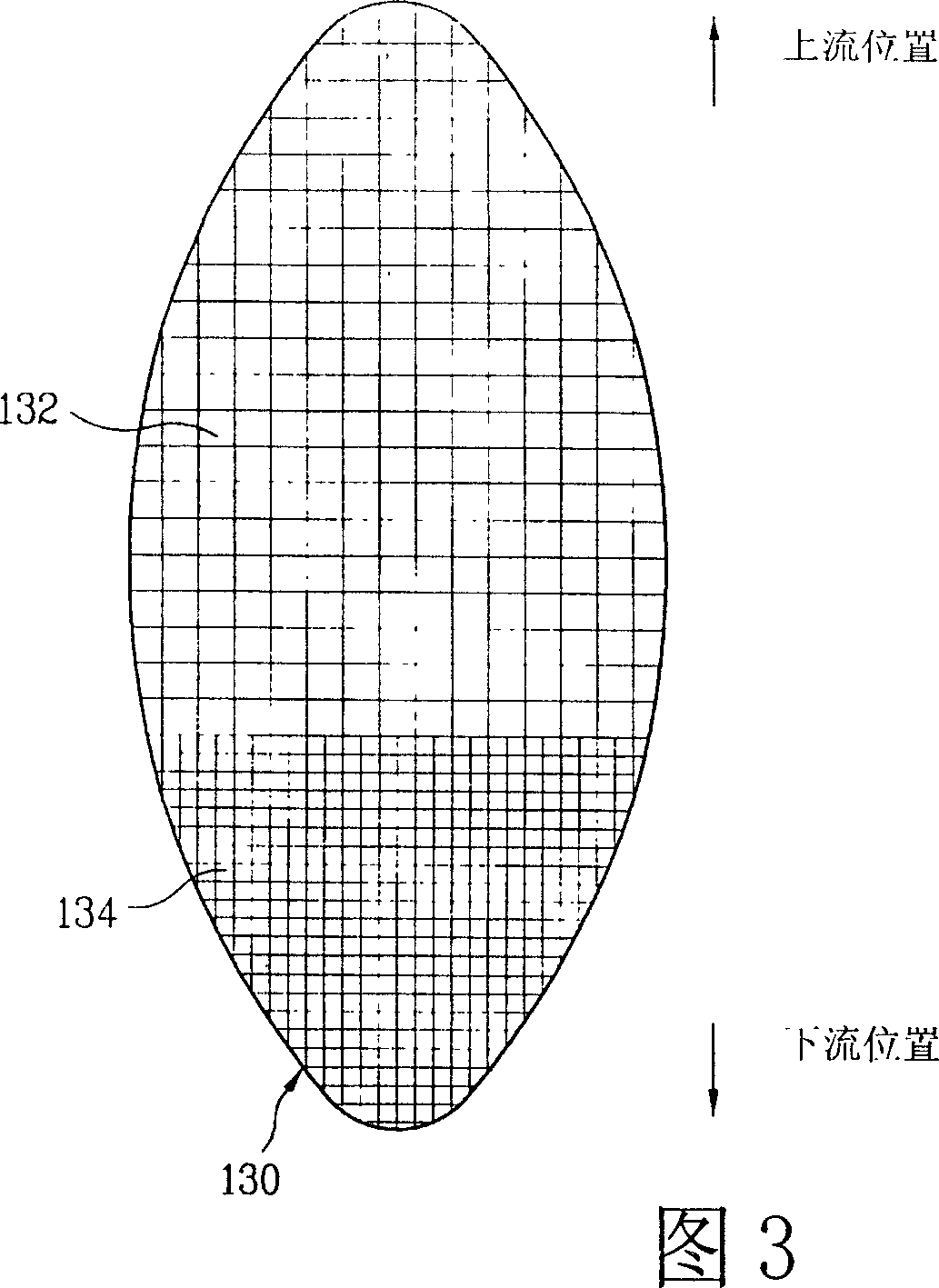

Freon filter in air conditioner

InactiveCN1967100AFlow cross-sectional area does not decreaseDoes not increase flow resistanceRefrigeration componentsFreonCurved Tube

It relates to a Freon filtering device of an air conditioner. It mainly comprises the curved tube formed by the bending of the flow channel, and abnormal material filtering net on the outside wall of the curved channel. It features in the smaller diameter of the down flow net holes than that of the up flow net holes. It will not reduce flowing cross section of running Freon when abnormal material accumulated on the filtering net, without increasing flowing resistance of the Freon.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

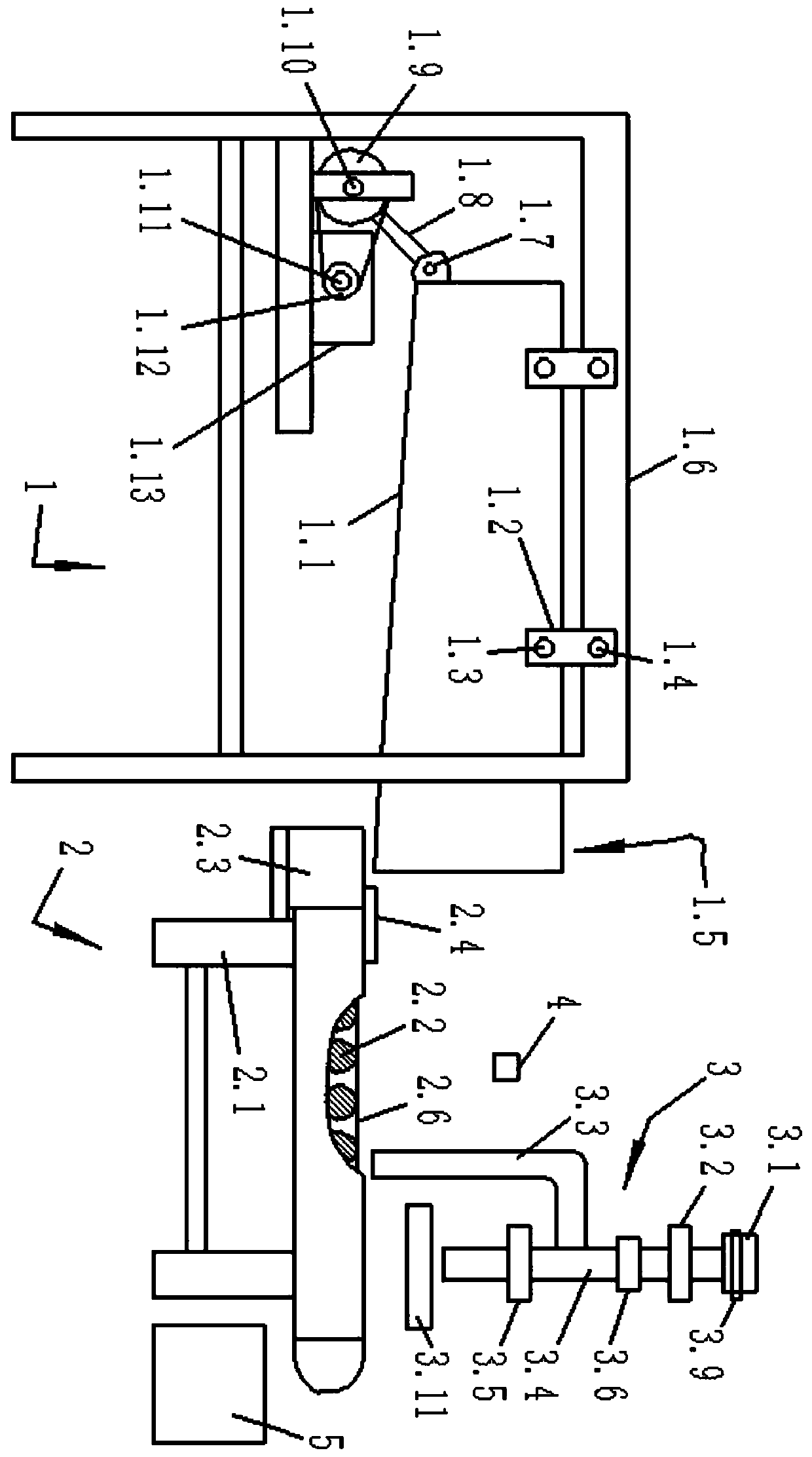

Exhaust and mould-closing control device for abnormal material intake of hollow extrusion blower

The control device for abnormal exhaust and mold closing of hollow extrusion blowing machine includes a body (1), on which a gas sensing module (2), a noise sensing module (3), a pressure sensing module (4), a management Module (5), during operation, the gas sensing module (2) senses the gas content, the noise sensing module (3) senses the decibel value inside the fuselage, the pressure sensing module (4) senses the force value, and the management module (5) processes the comprehensive Information; a timing module (6) is set on the gas sensing module (2) to set the change of gas within a certain period of time in the fuselage; a display module (7) is set on the pressure sensing module (4) to display the sensed pressure in real time Numerical value; a prompting module (8) is set on the management module (5); the prompting module (8) sends prompts in the form of sound or LED display; by controlling the exhaust and mold closing conditions, it is avoided to affect the operation effect.

Owner:XINCHANG CHENGTAN DADONG MACHINERY FACTORY

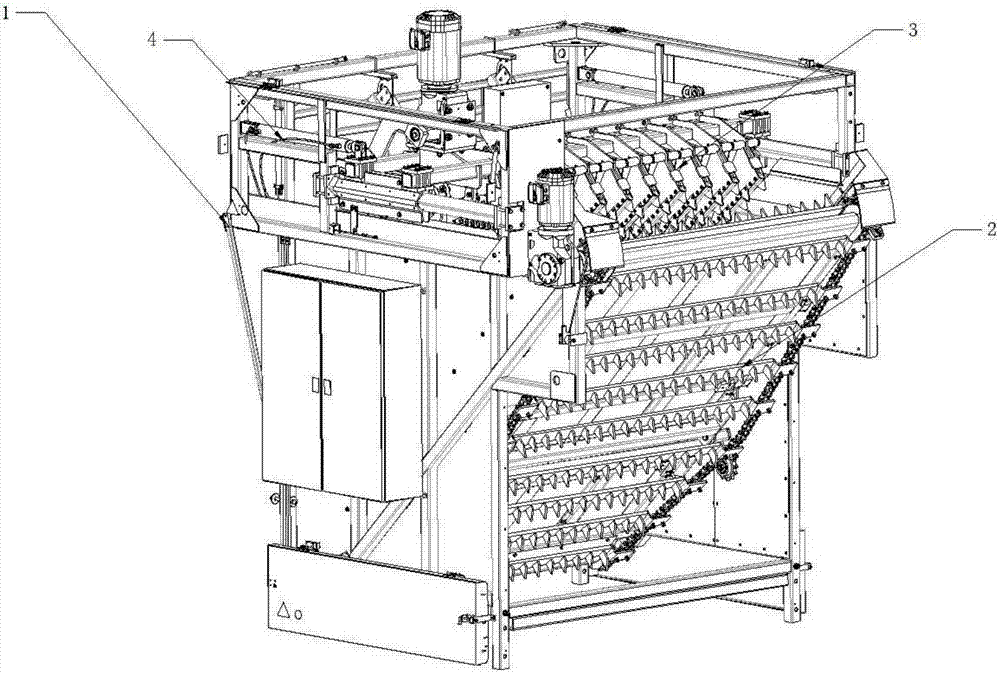

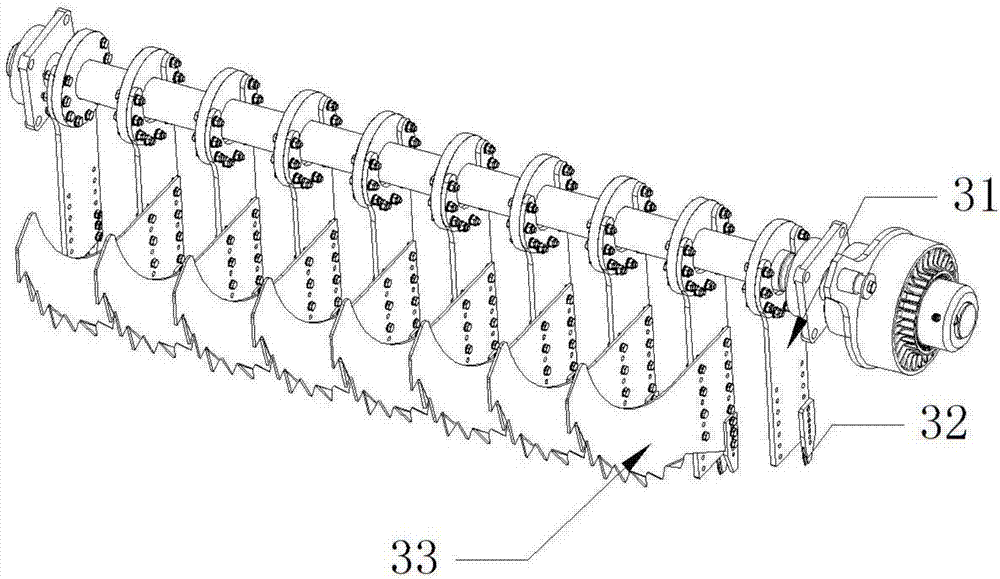

Household garbage flying shear bag breaking and material uniform-distribution equipment

The invention relates to household garbage flying shear bag breaking and material uniform-distribution equipment. The household garbage flying shear bag breaking and material uniform-distribution equipment comprises a rack, an auxiliary chain-type conveyor assembly, a bag breaking cutter assembly, a cutter space adjusting assembly, a sensing device and a controller. The auxiliary chain-type conveyor assembly is arranged on the rack, the bag breaking cutter assembly is arranged above an auxiliary chain-type conveyor, the cutter space adjusting assembly is arranged on one side of the bag breaking cutter assembly and connected with the bag breaking cutter assembly, the sensing device is arranged on the other side of the bag breaking cutter assembly and connected with the bag breaking cutter assembly, and the controller is arranged on the rack and is in signal connection with the cutter space adjusting assembly and the sensing device. According to the household garbage flying shear bag breaking and material uniform-distribution equipment, bag breaking intervals can be controlled; abnormal materials can be avoided, and thus the equipment is protected and stopping is avoided; winding ofsoft and long materials such as cloth strips in household garbage is effectively prevented, bag breaking and material uniform-distribution can be achieved while household garbage is conveyed, and sorting efficiency of subsequent sorting equipment is improved.

Owner:SUZHOU JONO RECYCLING RESOURCES EQUIP

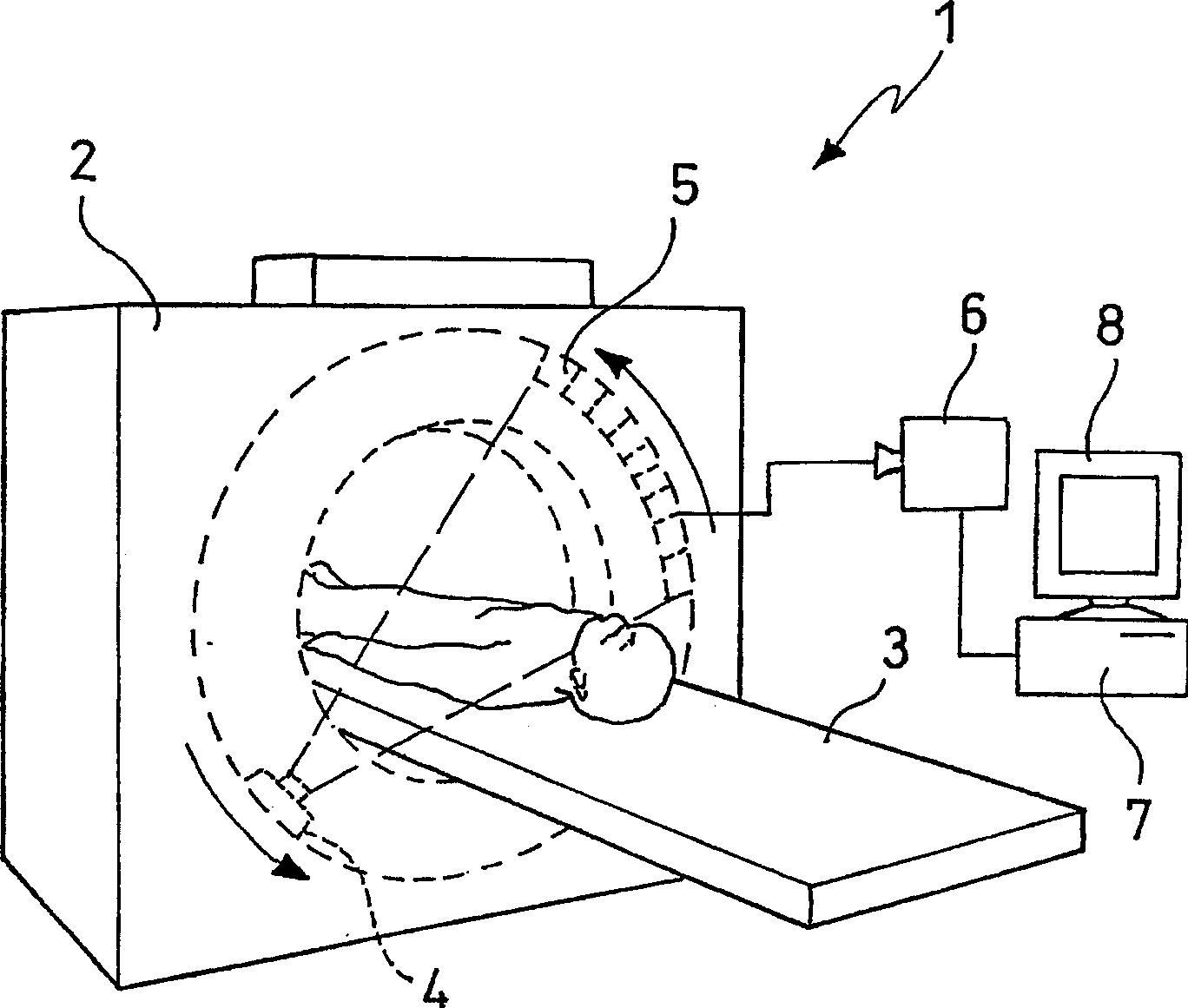

Method and apparatus for analyzing biological tissue images

InactiveCN1742293AImprove Visual AnalyticsImage enhancementImage analysisBiological bodyComputer science

The present invention relates to a method and an apparatus for processing images of biological tissues, in particular of human or animal origin. The metric quantification of a biological body part or tissue or of an abnormal material spot or aggregate contained therein is also performed. The invention is applied in particular to the Computed Axial Tomography technique. In particular, the present invention comprises the following steps: la) dividing the image into boxes of different size iteratively; (2a) calculating for each quadrant at each division scale the relative dispersion (RD) obtained as the Standard Deviation divided by the mean value of the pixels, in order to associate to each quadrant a set of values of RD; (3a) generating a homogeneity map as a grey scale image, each point's brightness being given by the mean of the set of values of RD for each quadrant, wherein the image's regions having higher brightness correspond to homogeneous regions.

Owner:HUMANITAS MIRASOLE SPA

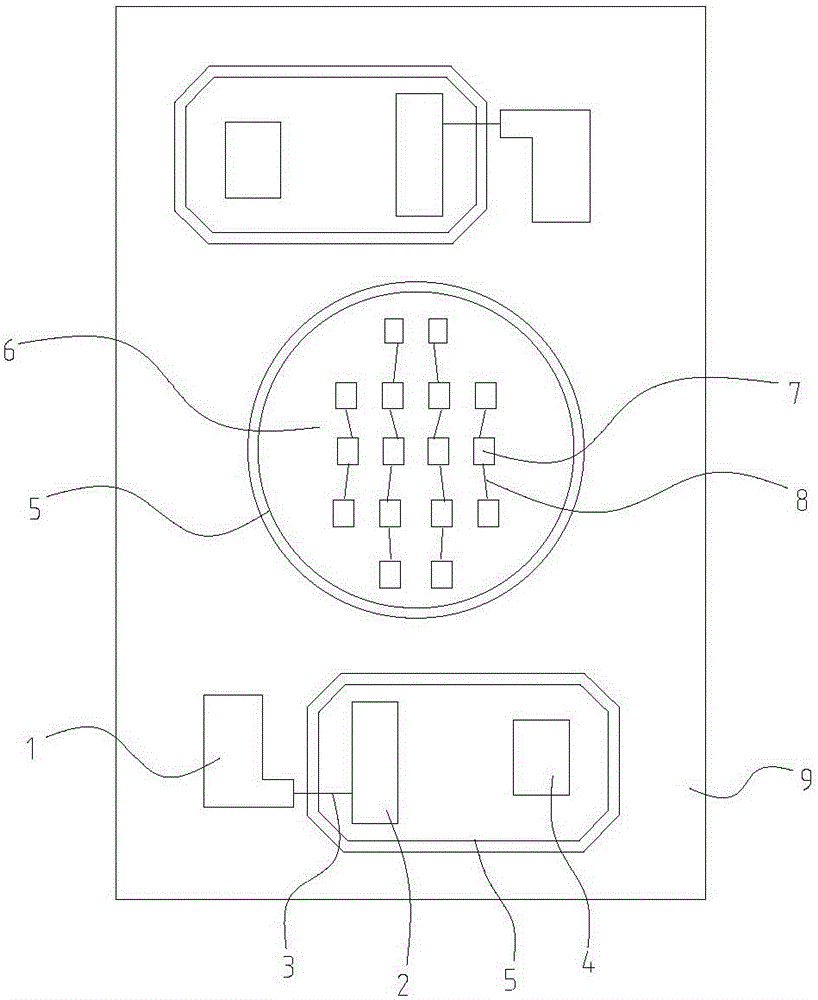

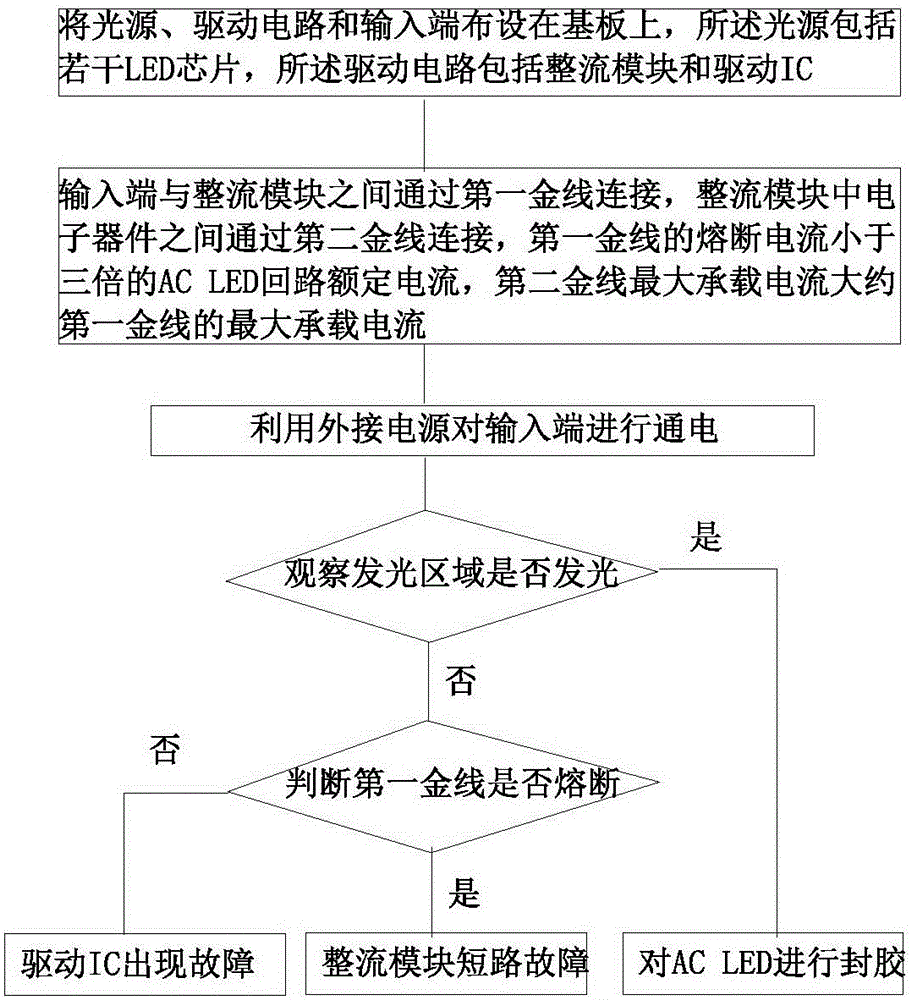

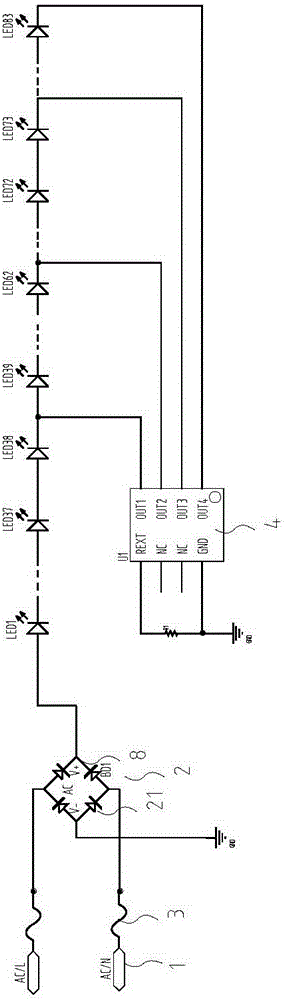

AC LED manufacturing method

InactiveCN106066004AAvoid burning phenomenonConductiveSemiconductor/solid-state device testing/measurementElectric circuit arrangementsPower flowComputer module

An AC LED manufacturing method includes the following steps: (1) a light source, a drive circuit and an input end are arranged on a substrate; (2) the input end and a rectification module are connected through a first gold wire, electronic devices in the rectification module are connected through second gold wires, the fusing current of the first gold wire is smaller than the triple rated current of an AC LED loop, and the maximum bearing current of the second gold wires is larger than the maximum bearing current of the first gold wire; (3) the input end is powered on through an external power source, whether a light-emitting area emits light or not is observed, if not, whether the first gold wire is fused or not is judged, if the first gold wire is fused, it is judged that the short-circuit problem happens to the rectification module, and if the first gold wire is not fused, it is judged that a drive IC breaks down; and when the light-emitting area emits light normally, adhesive sealing is performed on an AC LED, if a short circuit happens to the input end when the circuit is tested, the circuit current is fast increased, the first gold wire is fused, the phenomenon that the rear end of the substrate is burnt down is avoided, and solid welding can be performed on an abnormal material again.

Owner:HONGLI ZHIHUI GRP CO LTD

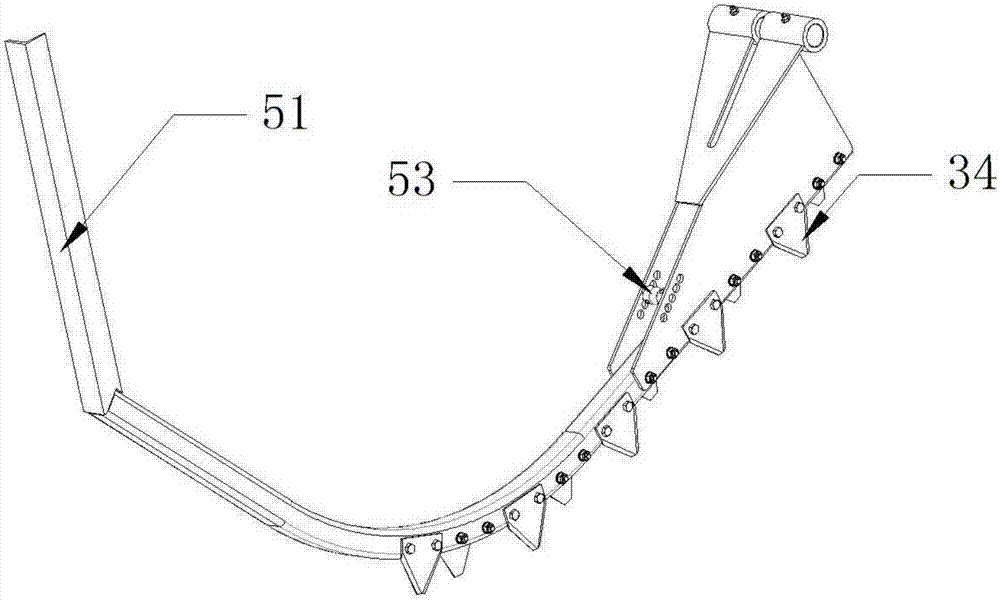

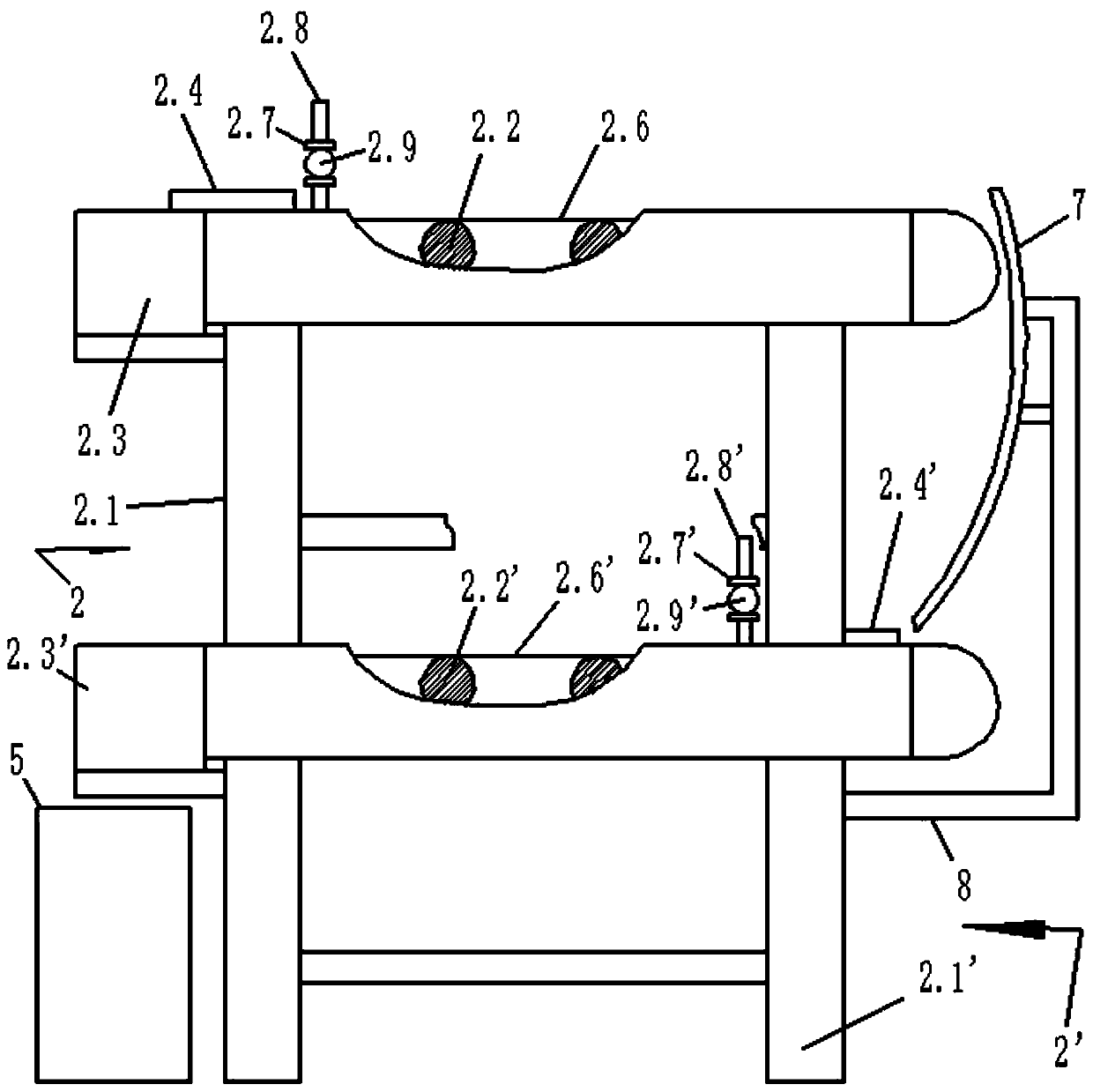

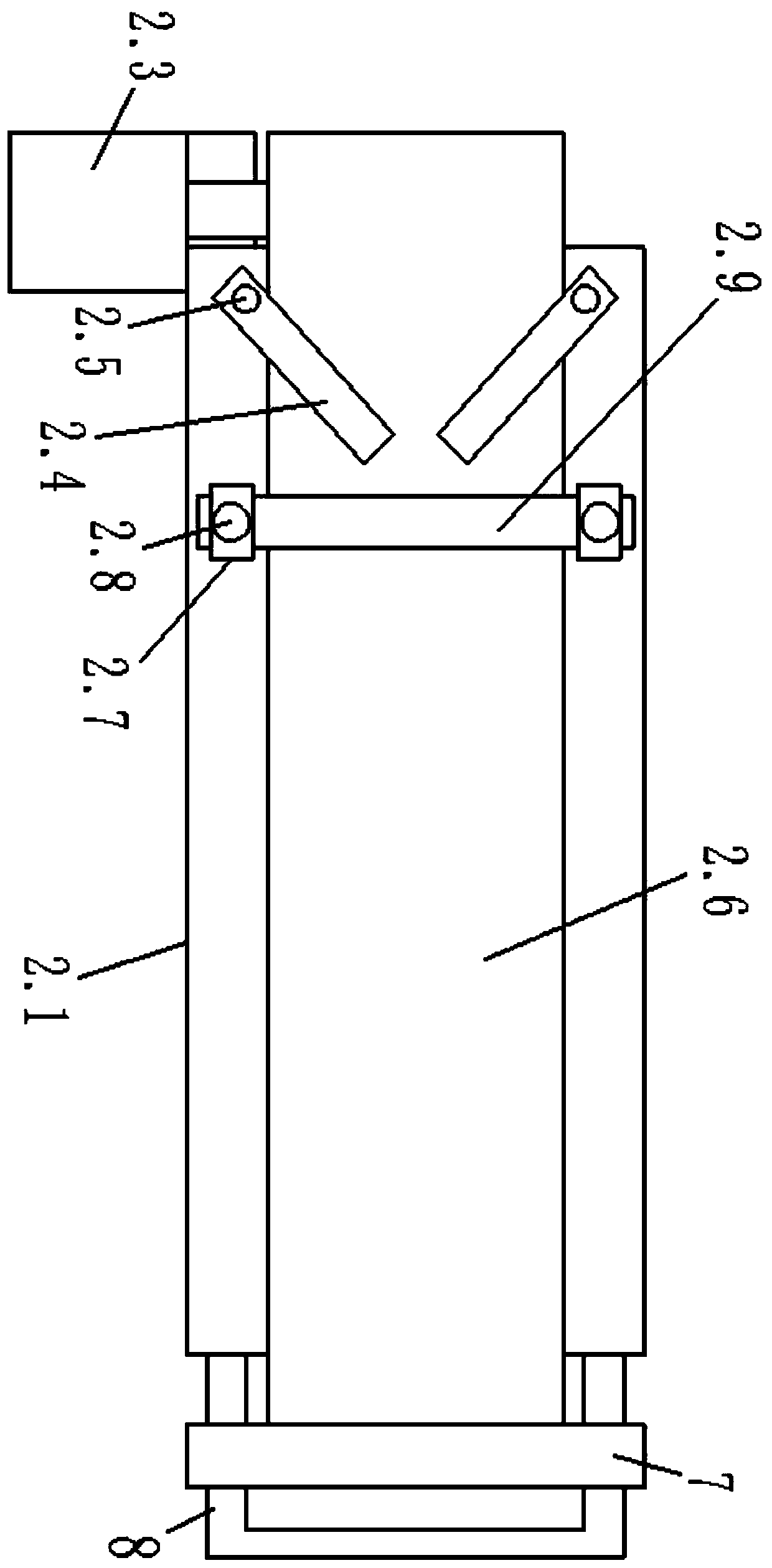

Belt conveying device and automatic silicone material sorting system

ActiveCN109894377AReduce missed detection rateAchieve automatic sortingFinal product manufactureSortingMachine visionEngineering

The invention provides a belt conveying device which comprises a first belt conveyor, a second belt conveyor and an arc-shaped reversing plate; the arc-shaped reversing plate is used for being used incoordination with a conveying tail end of the first belt conveyor and a transporting initial end of the belt conveyor belt; the arc-shaped reversing plate is positioned on the same side of the firstbelt conveyor and the second belt conveyor; the first belt conveyor performs conveying to an inner arc surface of the arc-shaped reversing plate; and the transporting direction of the second belt conveyor is opposite to that of the first belt conveyor. Magnetic rods are separately arranged on the first belt conveyor and the second belt conveyor. The invention further provides an automatic siliconematerial sorting system which comprises a belt conveying device, silicone material heavily-doping detecting devices, a machine vision image acquisition device and automatic sorting mechanisms. The belt conveying device and the automatic silicone material sorting system are used for realizing automatic sorting of abnormal materials in a to-be-sorted silicone material, heavily-doped silicone materials and metal wires, the silicone material sorting efficiency is improved, and the omission ratio of silicone material sorting is reduced.

Owner:山东九思新材料科技有限责任公司

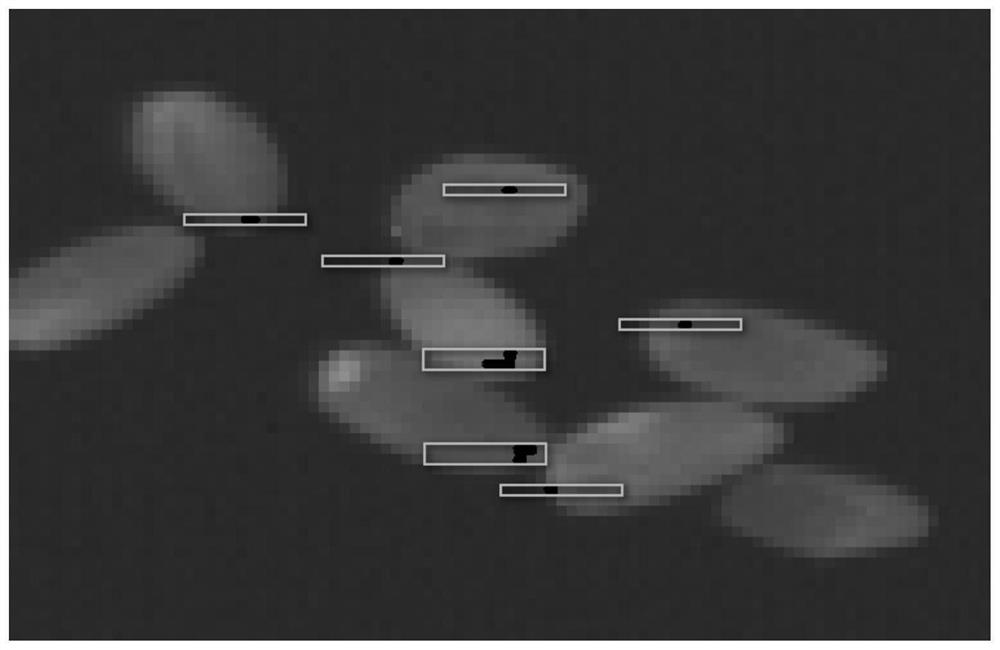

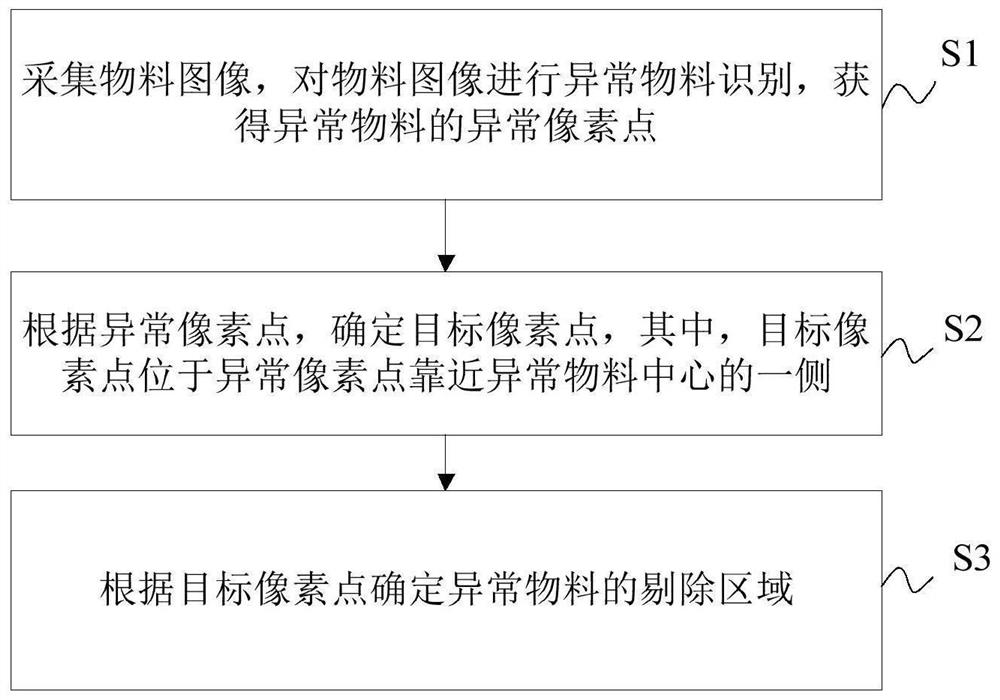

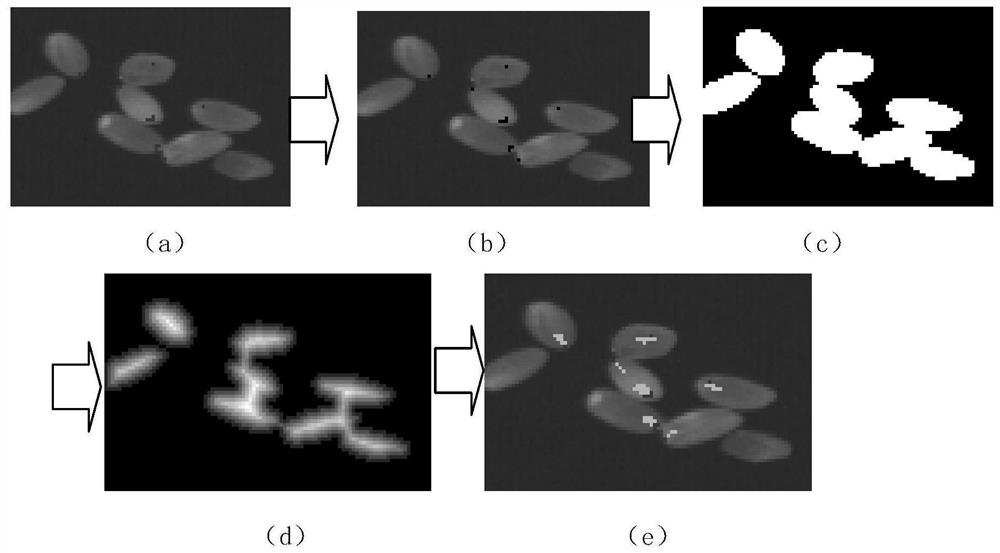

Determination method and device for abnormal material removal area and material sorting method and equipment

The invention discloses a determination method and device for an abnormal material removal area and a material sorting method and equipment. The method comprises the steps: collecting a material image, and performing abnormal material recognition on the material image to obtain abnormal pixel points of an abnormal material; according to the abnormal pixel points, determining target pixel points, wherein the target pixel points are located on the sides, close to the center of the abnormal material, of the abnormal pixel points; and determining a removal area of the abnormal material according to the target pixel points. According to the determination method for the abnormal material removal area, the removal area of the abnormal material is determined according to the target pixel points of the abnormal material, the removal area can be closer to the center of the abnormal material, the abnormal material is removed according to the removal area, the removal is more accurate and effective, and the removal rate of abnormal materials is effectively improved.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com