Dissimilar materials double-layer superpacket center thread and manufacturing method thereof

A double-layer composite and production method technology, applied in the direction of yarn, spinning machine, continuous winding spinning machine, etc., can solve the problems of poor coating effect, low strength and toughness, and inability to produce, and achieve high Performance and use value, high strength and toughness, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

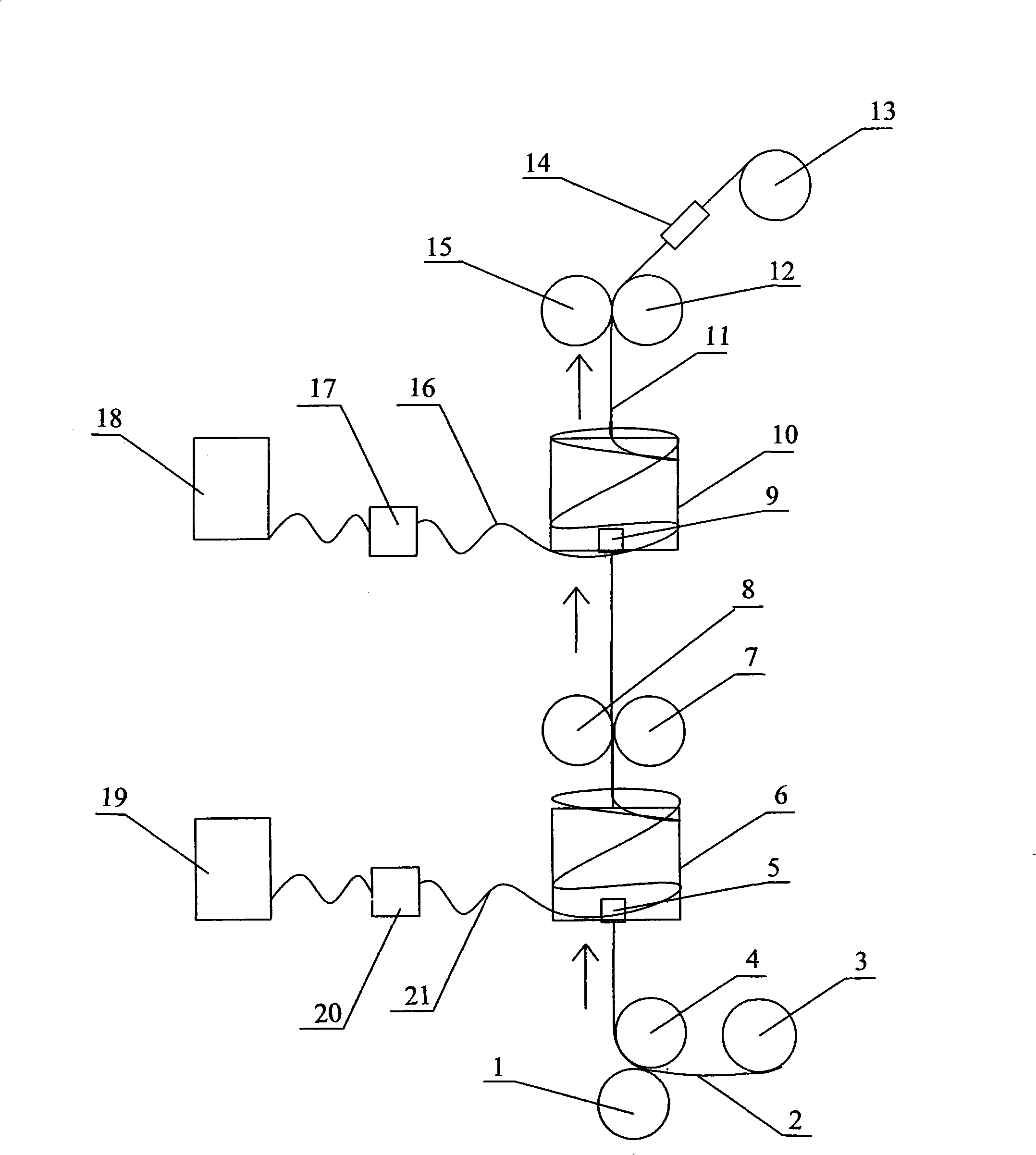

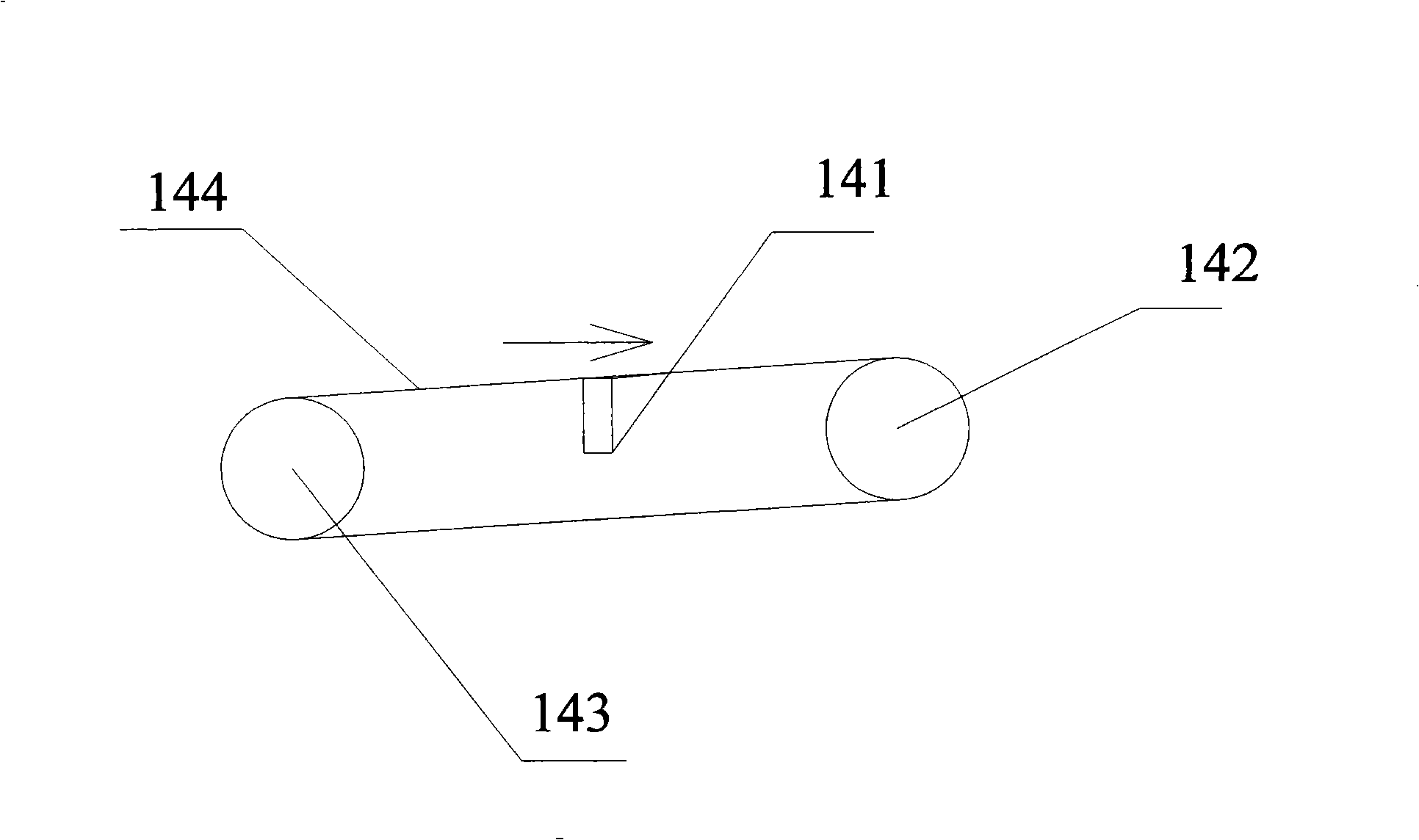

[0028] The different-material double-layer composite core-spun yarn and its preparation method referred to in this embodiment, see figure 1 and figure 2 shown. The equipment in the figure includes: roller 1, core yarn 2, core yarn spindle 3, roller 4, frequency conversion control device 5, ring spindle device 6, middle roller 7, middle roller 8, frequency conversion control device 9, ring spindle device 10, Core-spun gray fabric 11, back roller 12, winding spindle 13, automatic tension compensation device 14, back roller 15, upper layer covering material 16, tension controller 17, upper layer covering thread spindle 18, lower layer covering thread spindle 19, a tension controller 20, and a lower cladding material 21.

[0029] The different-material double-layer composite core-spun yarn referred to in this embodiment consists of upper and lower layers of outer fiber covering material layers of different materials and a chemical fiber filament core yarn in the middle. The lo...

Embodiment 2

[0042]The different-material double-layer composite core-spun yarn and its preparation method referred to in this embodiment, see figure 1 and figure 2 shown. The equipment in the figure includes: roller 1, core yarn 2, core yarn spindle 3, roller 4, frequency conversion control device 5, ring spindle device 6, middle roller 7, middle roller 8, frequency conversion control device 9, ring spindle device 10, Core-spun gray fabric 11, back roller 12, winding spindle 13, automatic tension compensation device 14, back roller 15, upper layer covering material 16, tension controller 17, upper layer covering thread spindle 18, lower layer covering thread spindle 19, a tension controller 20, and a lower cladding material 21.

[0043] The different-material double-layer composite core-spun yarn referred to in this embodiment consists of upper and lower layers of outer fiber covering material layers of different materials and a chemical fiber filament core yarn in the middle. The low...

Embodiment 3

[0056] The different-material double-layer composite core-spun yarn and its preparation method referred to in this embodiment, see figure 1 and figure 2 shown. The equipment in the figure includes: roller 1, core yarn 2, core yarn spindle 3, roller 4, frequency conversion control device 5, ring spindle device 6, middle roller 7, middle roller 8, frequency conversion control device 9, ring spindle device 10, Core-spun gray fabric 11, back roller 12, winding spindle 13, automatic tension compensation device 14, back roller 15, upper layer covering material 16, tension controller 17, upper layer covering thread spindle 18, lower layer covering thread spindle 19, a tension controller 20, and a lower cladding material 21.

[0057] The different-material double-layer composite core-spun yarn referred to in this embodiment consists of upper and lower layers of outer fiber covering material layers of different materials and a chemical fiber filament core yarn in the middle. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com