Silicon material sorting system based on machine vision

A technology of machine vision and sorting system, applied in sorting and other directions, can solve the problems of low efficiency of manual sorting work, unfavorable silicon material sorting work, and increased missed detection rate, so as to reduce the probability of missed detection, reduce absorption, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

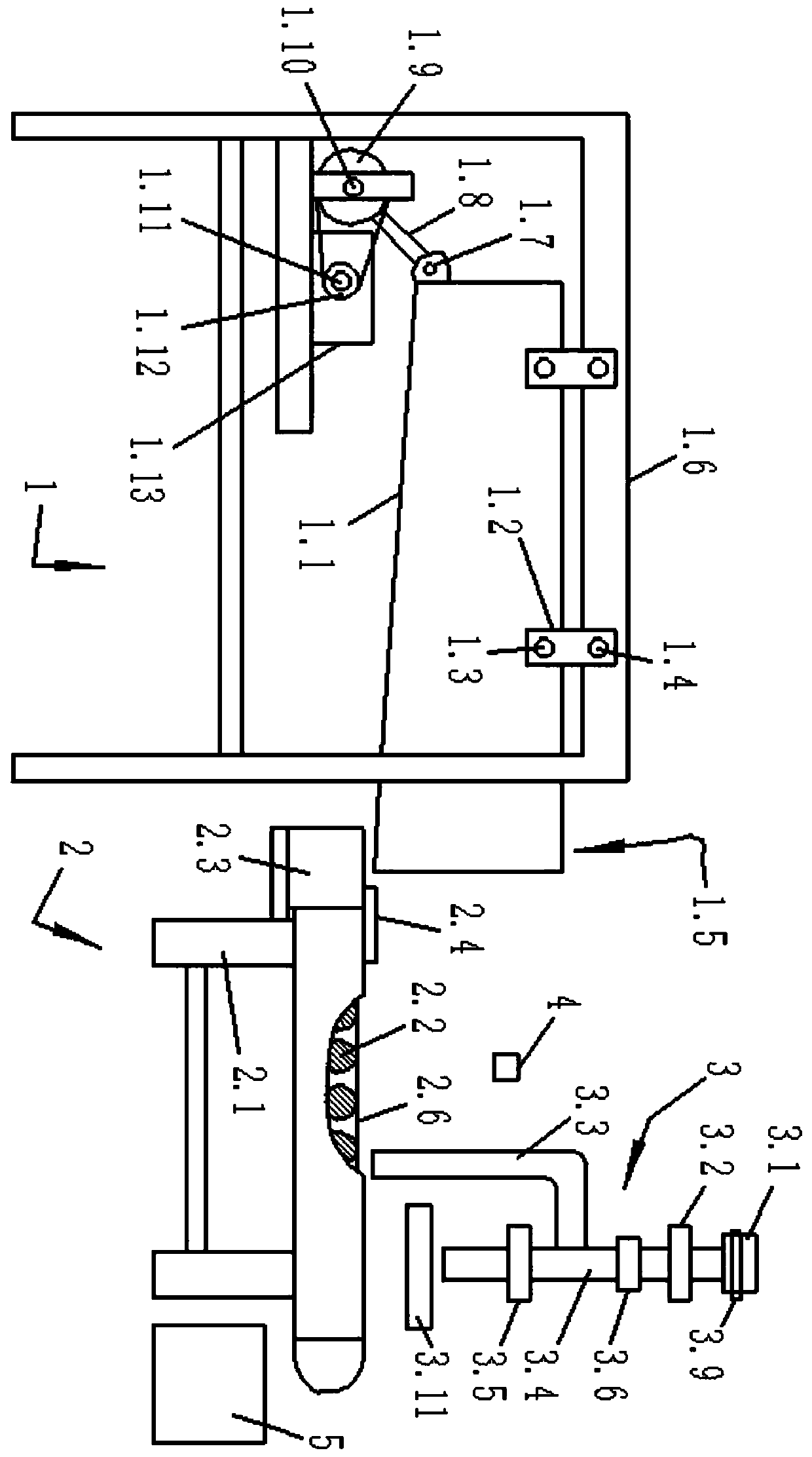

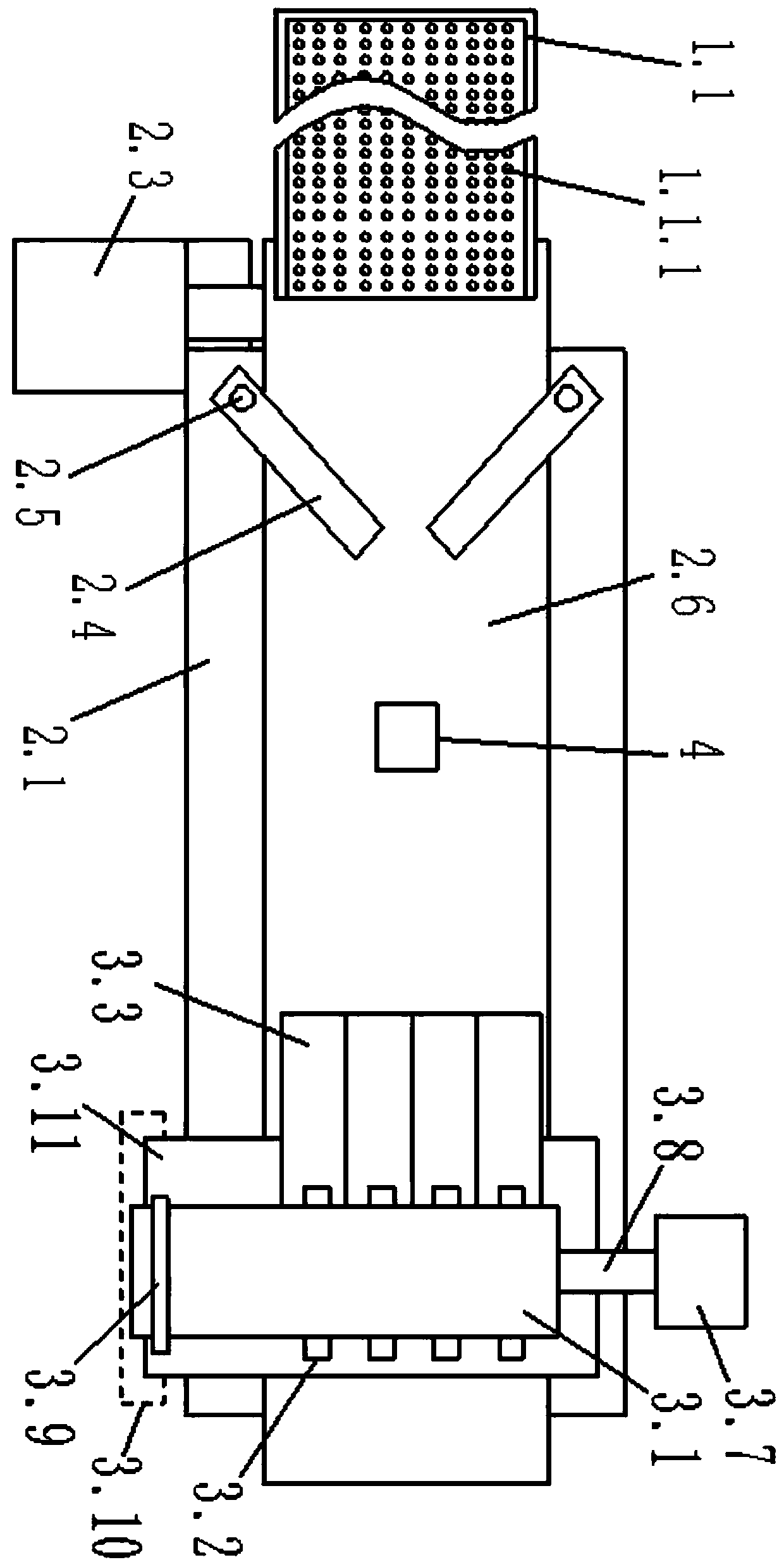

[0054] figure 1 with Figure 3-Figure 5 It is a schematic structural diagram of a silicon material sorting system based on machine vision according to an embodiment of the present invention.

[0055] see figure 1 with Figure 3-5 As shown, the silicon material sorting system based on machine vision includes a first conveying device 2, a control system, and a feeding device 1 for paving and loading materials. The feeding device 1 is used in cooperation with the conveying start end of the first conveying device 2 for feeding materials to the conveying start end of the first conveying device 2 . The first conveying device 2 is equipped with a first machine vision image acquisition device 4 for real-time acquisition of the RGB images of the silicon material to be sorted conveyed by the first conveying device 2, and a first machine vision image acquisition device 4 for sucking the first conveying device 2 The first abnormal material sorting device 3 for the abnormal material am...

Embodiment 2

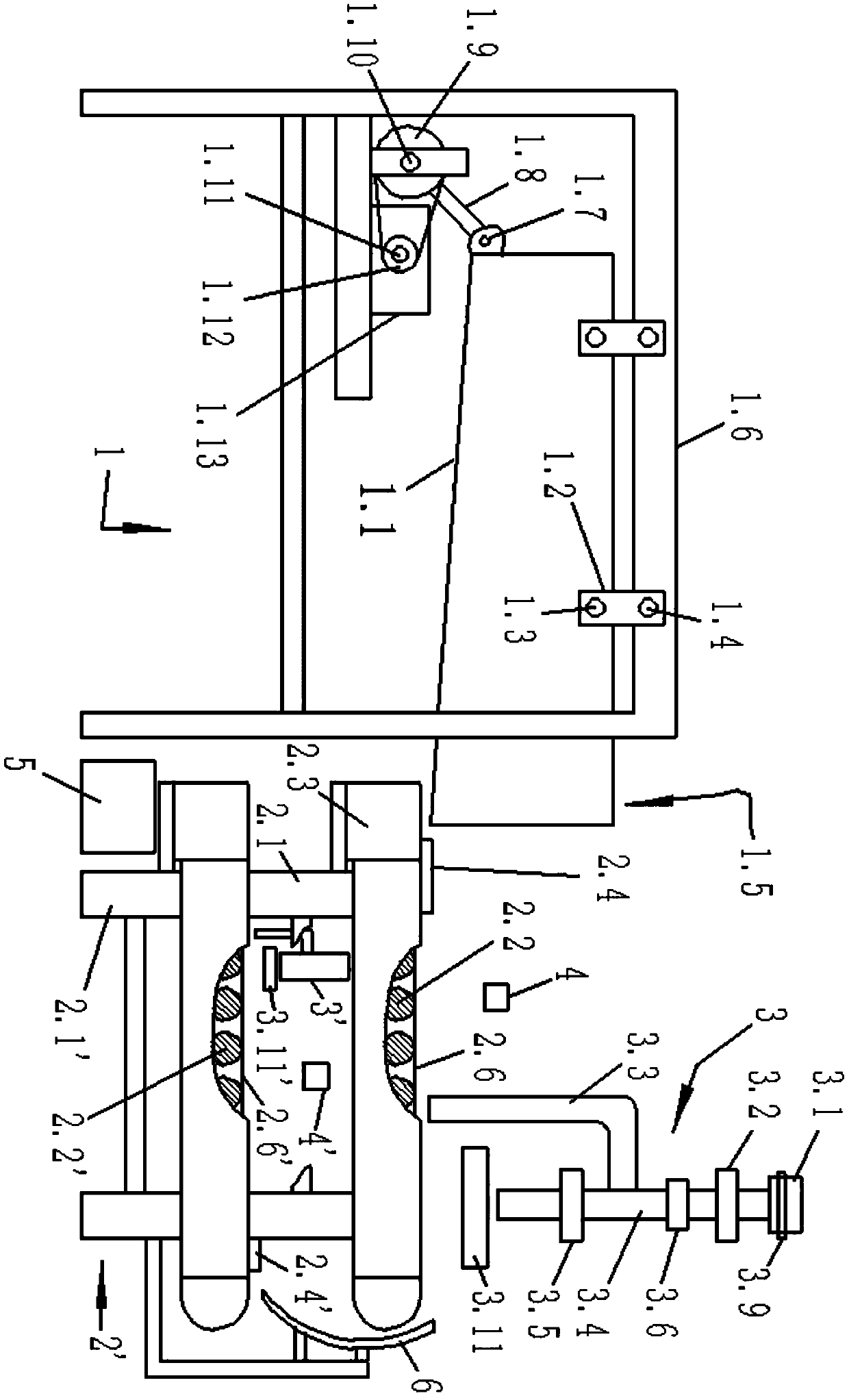

[0081] Figure 2-Figure 4 with Image 6 It is another embodiment of the machine vision-based silicon material sorting system of the present invention.

[0082] see Figure 2-Figure 4 with Image 6 , compared with the silicon material sorting system based on machine vision described in Embodiment 1, the silicon material sorting system based on machine vision described in this embodiment is different in that: the The silicon material sorting system based on machine vision also includes a second conveying device 2' arranged below the first conveying device 2, and an arc-shaped reversing plate used in conjunction with the second conveying device 2' and the first conveying device 2 6. Described second conveying device 2 ' also adopts belt conveyor. The second conveying device 2' is equipped with a second machine vision image acquisition device 4' and a second abnormal material sorting device 3'. The second machine vision image acquisition device 4' is used to collect in real ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com