Patents

Literature

49results about How to "Reduce the chance of missed detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for detection of hangover

InactiveCN101231696AAccurate judgmentReduce the chance of missed detectionImage analysisCharacter and pattern recognitionTarget analysisComputer science

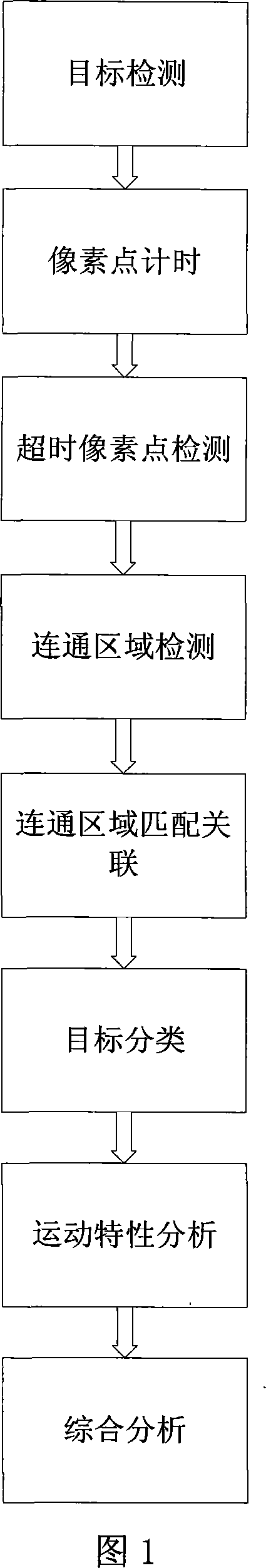

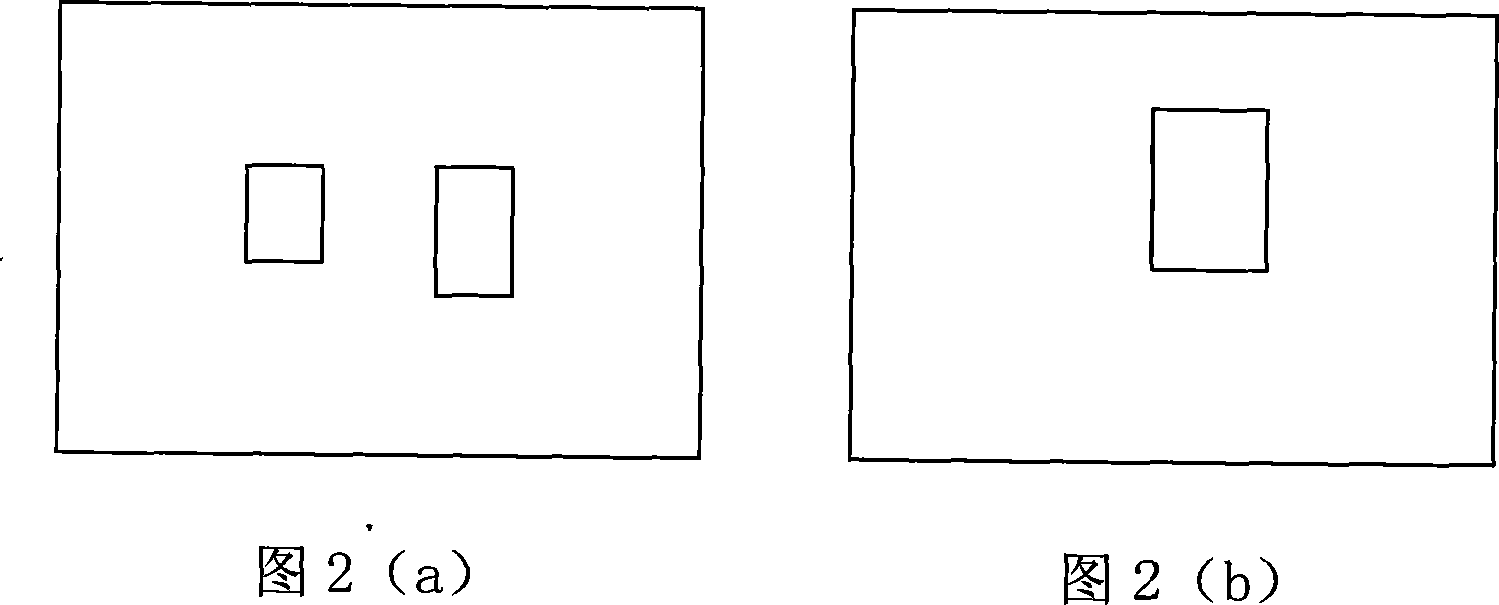

The invention discloses a residue detection method, which comprises the following steps that: foreground images which are different to a background are detected, foreground pixel points are determined, and then the foreground pixel points are characterized; the persistent state that the foreground pixel points are characterized is timed, and the timed pixel points which achieve a pre-set value are extracted; a connected region formed by the extracted pixel points is detected, and is determined to be a target to be analyzed; the motion characteristics of the target is analyzed to determine whether the targets to be analyzed are the residue. The invention also discloses a residue detecting system, which comprises a target detection device, a timing treatment device, a connected region detection device and a target analysis device, wherein, the timing treatment device times the pixel points, and extracts the pixel points, the characterization state persistent time of which achieve the pre-set value, the connected region detection device detects the connected region which is formed by the extracted pixel points, so as to determine the connected region of the targets to be analyzed, and the target analysis device is used to determine whether the targets to be analyzed are the residue. The invention can precisely extract the effective pixel points of the targets, thereby precisely judging whether the detected targets are the residue.

Owner:ANKE SMART CITY TECH PRC

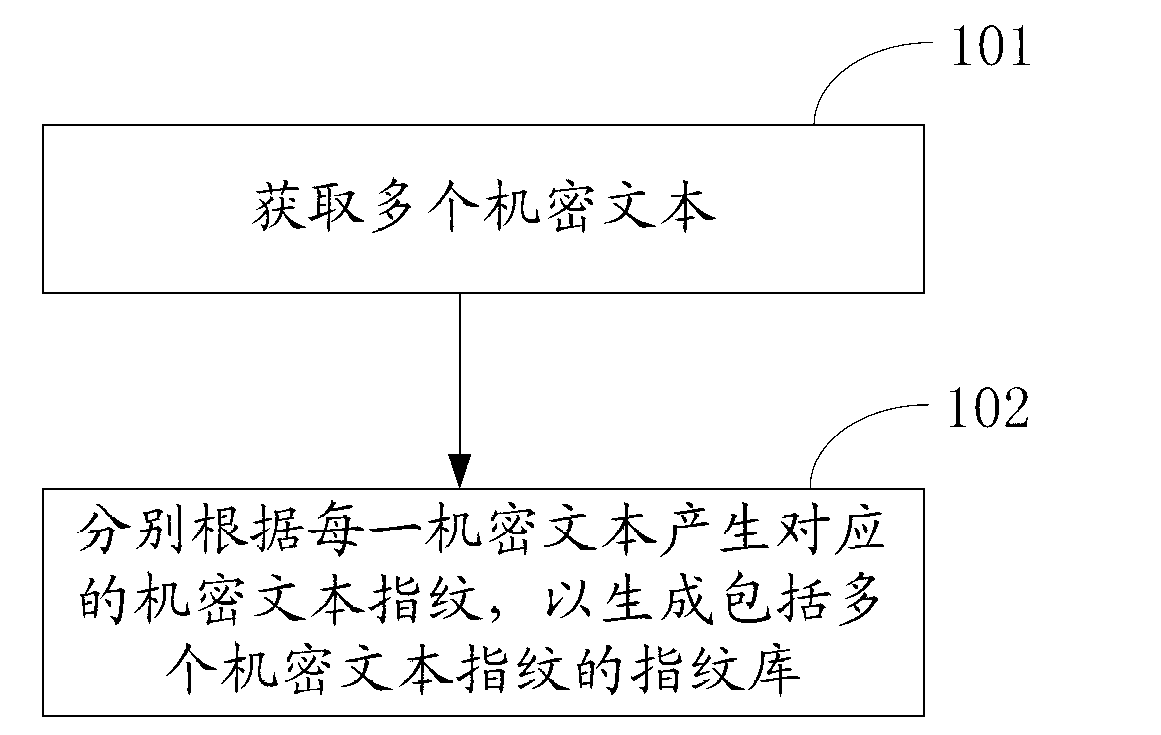

Method and device of generating fingerprint database and method and device of fingerprint matching of text to be tested

InactiveCN103164698AUniform coverageImprove accuracyCharacter and pattern recognitionData miningDatabase

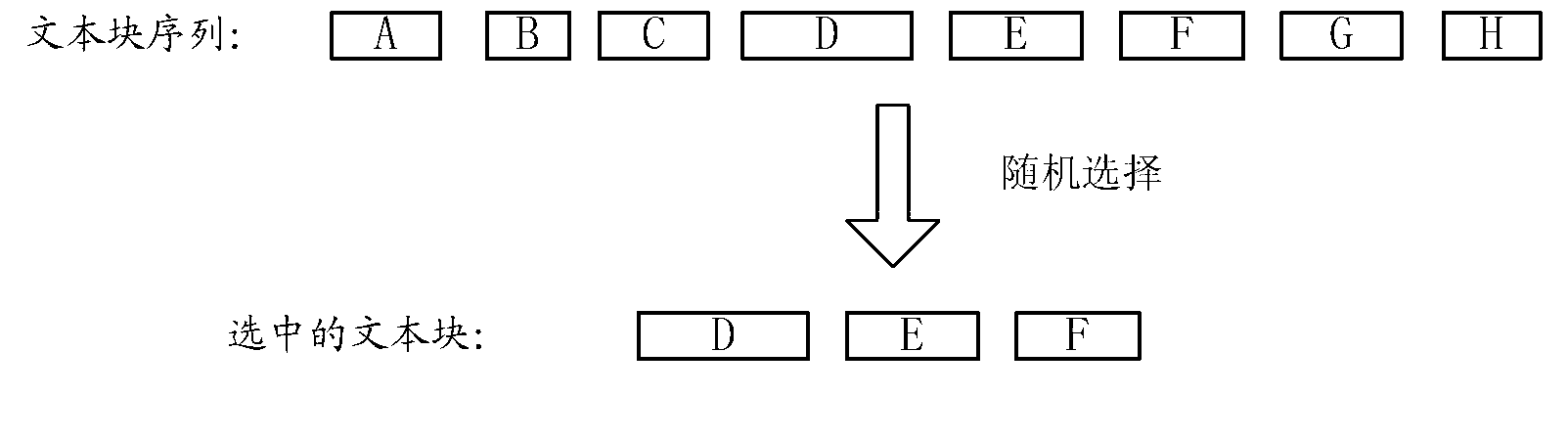

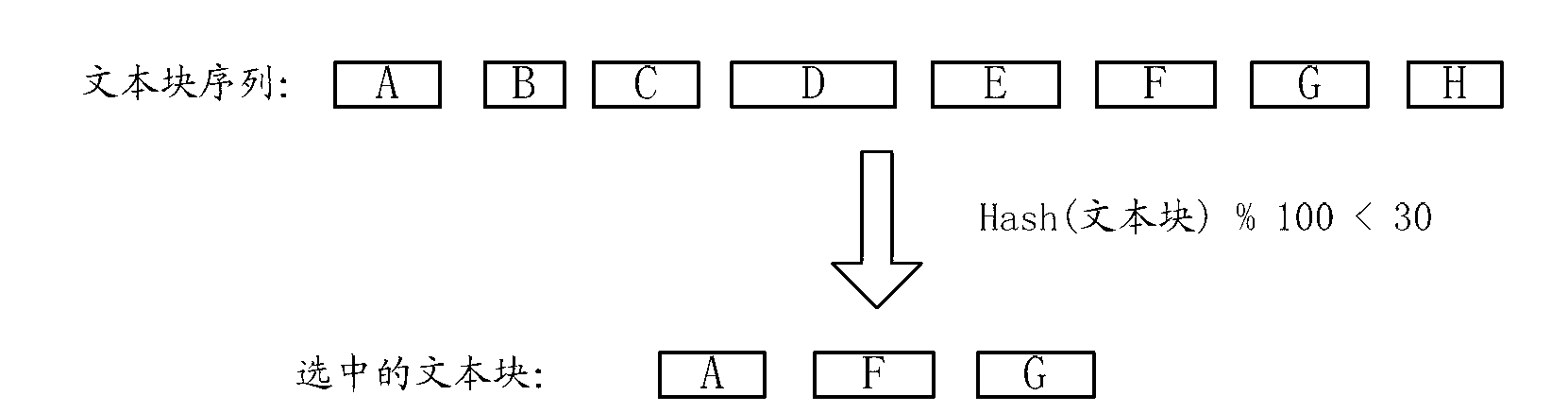

The invention discloses a method and a device of generating fingerprint database and a method and a device of fingerprint matching of texts to be tested. The method of generating fingerprint database includes: obtaining a plurality of confidential texts; and generating corresponding fingerprint of the confidential text according to each of the confidential texts respectively. According to the technical scheme provided by the invention, the certainty of the fingerprint of the selected confidential text can be guaranteed and the position of the selected confidential text block can be ensured to cover the whole first sequence evenly, so that the detection rate of the confidential text block can be guaranteed on a high level.

Owner:航天神洁(宁夏)科技发展有限公司

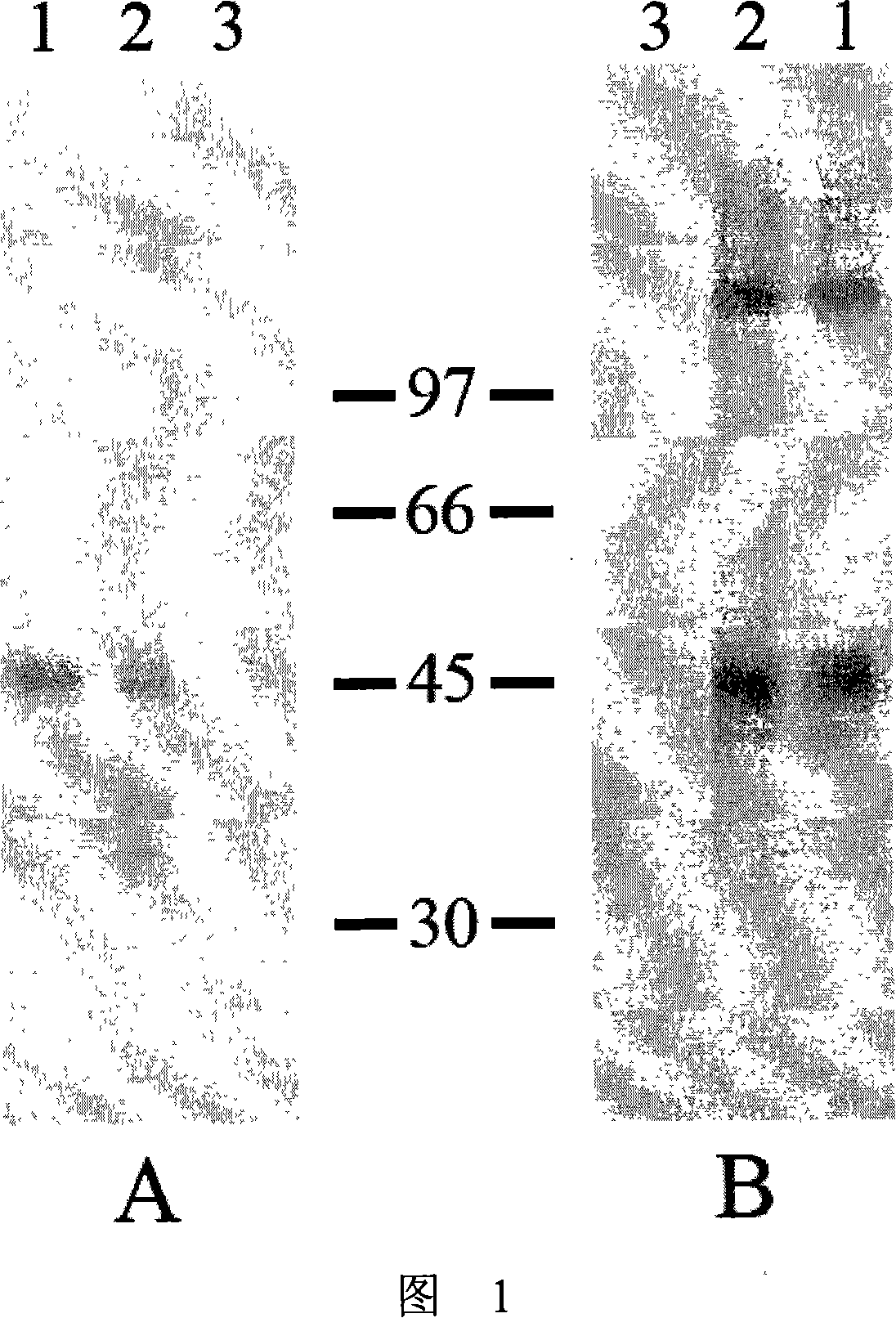

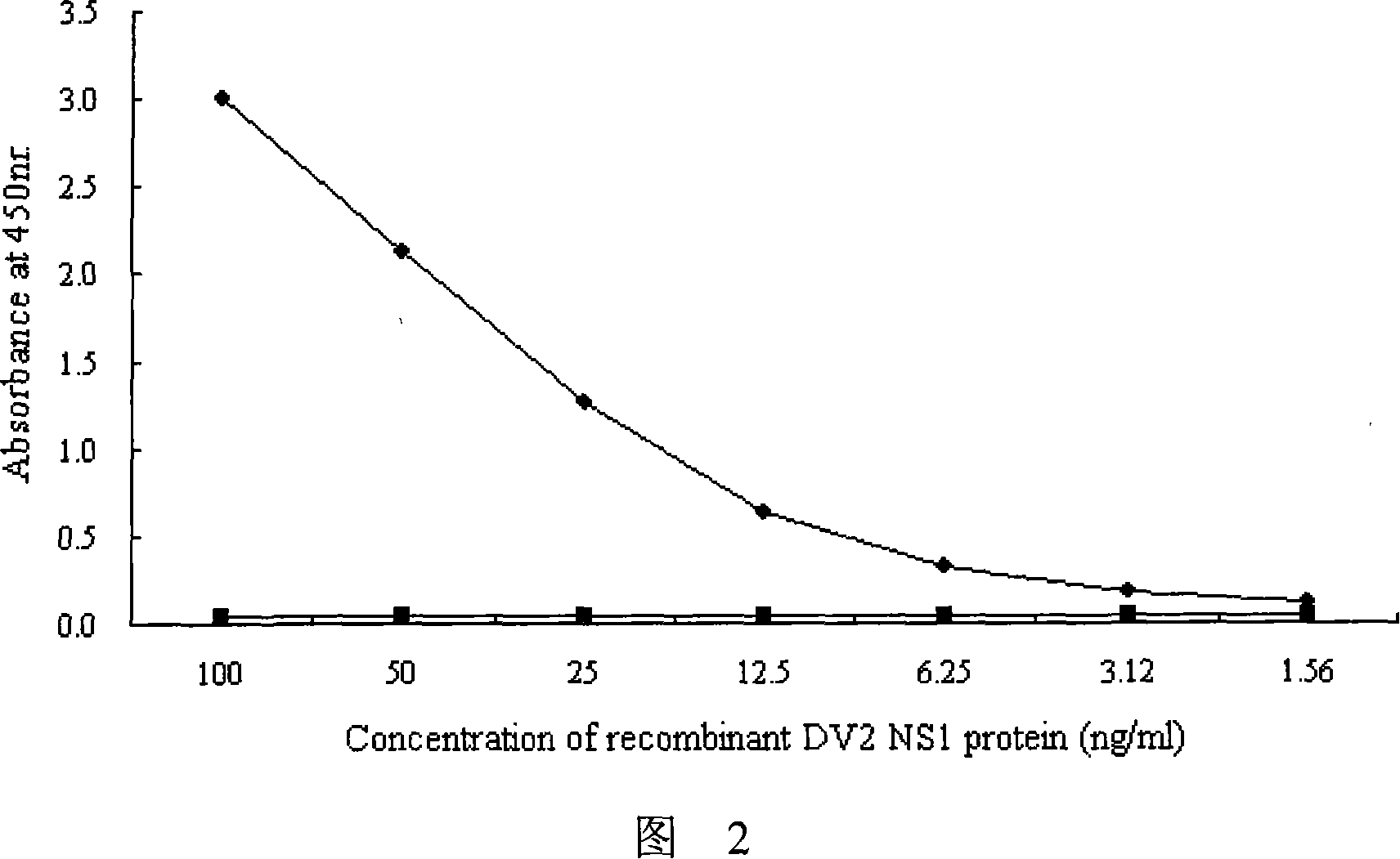

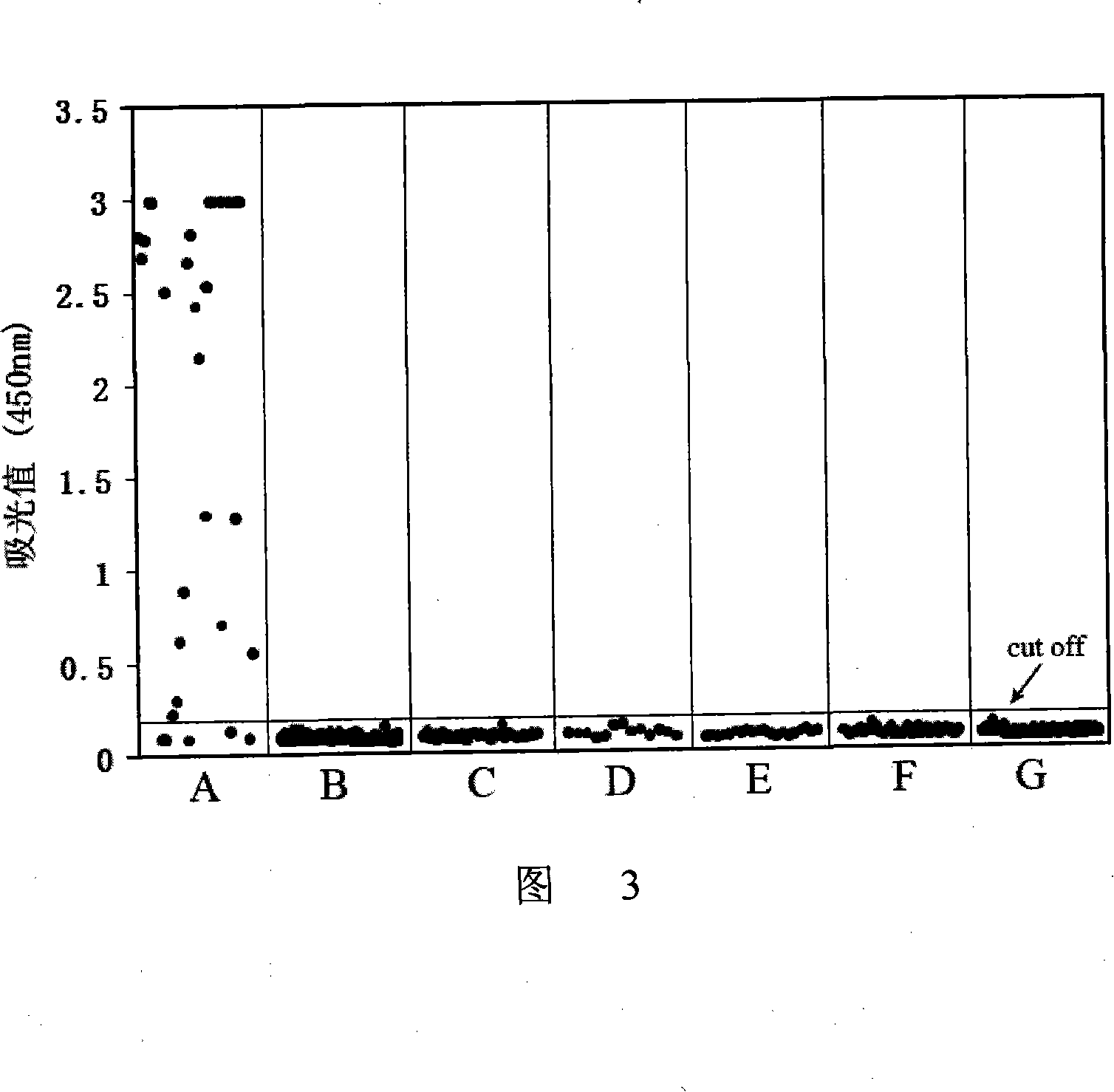

Immunologic diagnosis kit for detecting type II dengue virus NS1 antigen

ActiveCN101226196AAccurate detectionQuick checkMaterial analysisAgainst vector-borne diseasesSerotypeElisa test

The invention provides an immunity diagnosis test kit for detecting II-type dengue virus antigen, which comprises a porous reaction plate covering monoclonal antibody DV2-M6, a sample treatment liquid, a monoclonal antibody DV2-M15 marked with a label, a positive contrast, a negative contrast, a concentration washing liquid, a develop liquid and a termination liquid, wherein the monoclonal antibodies DV2-M6 and DV2-M14 of the test kit can be specifically combined with NS1 protein of II-type dengue virus, without cross reaction with other three kinds of serotype dengue viruses NS1 and respectively combined with different antigen points of NS1, while the check sensitivity of NS1 protein of II-type dengue virus can reach 3ng / ml and the check sensitivity of culture supernatant of II-type dengue virus infection cell is 8 power of Pan-E dengue early elisa test kit, thereby improving the sensitivity of clinical serum sample check.

Owner:SOUTHERN MEDICAL UNIVERSITY

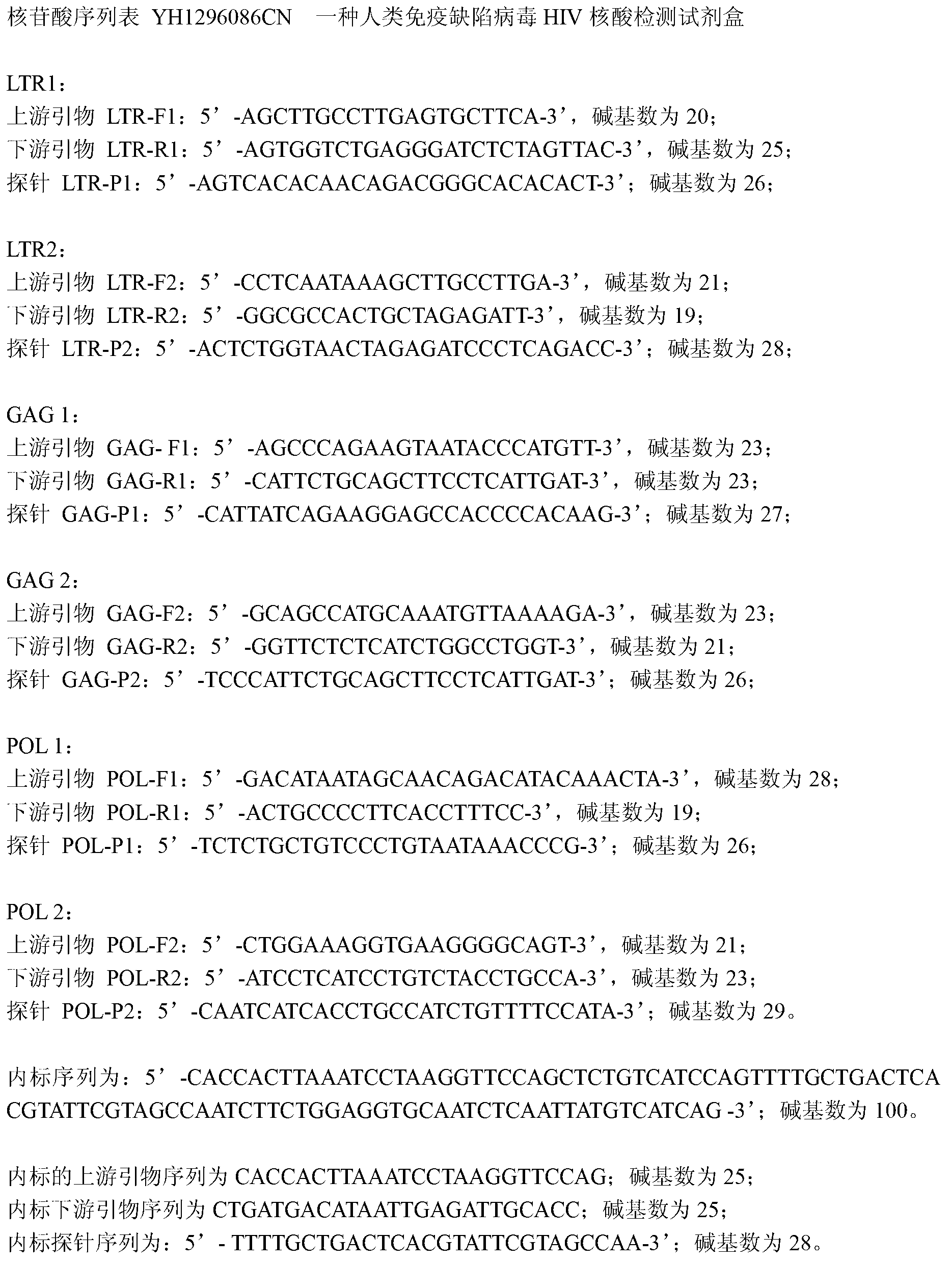

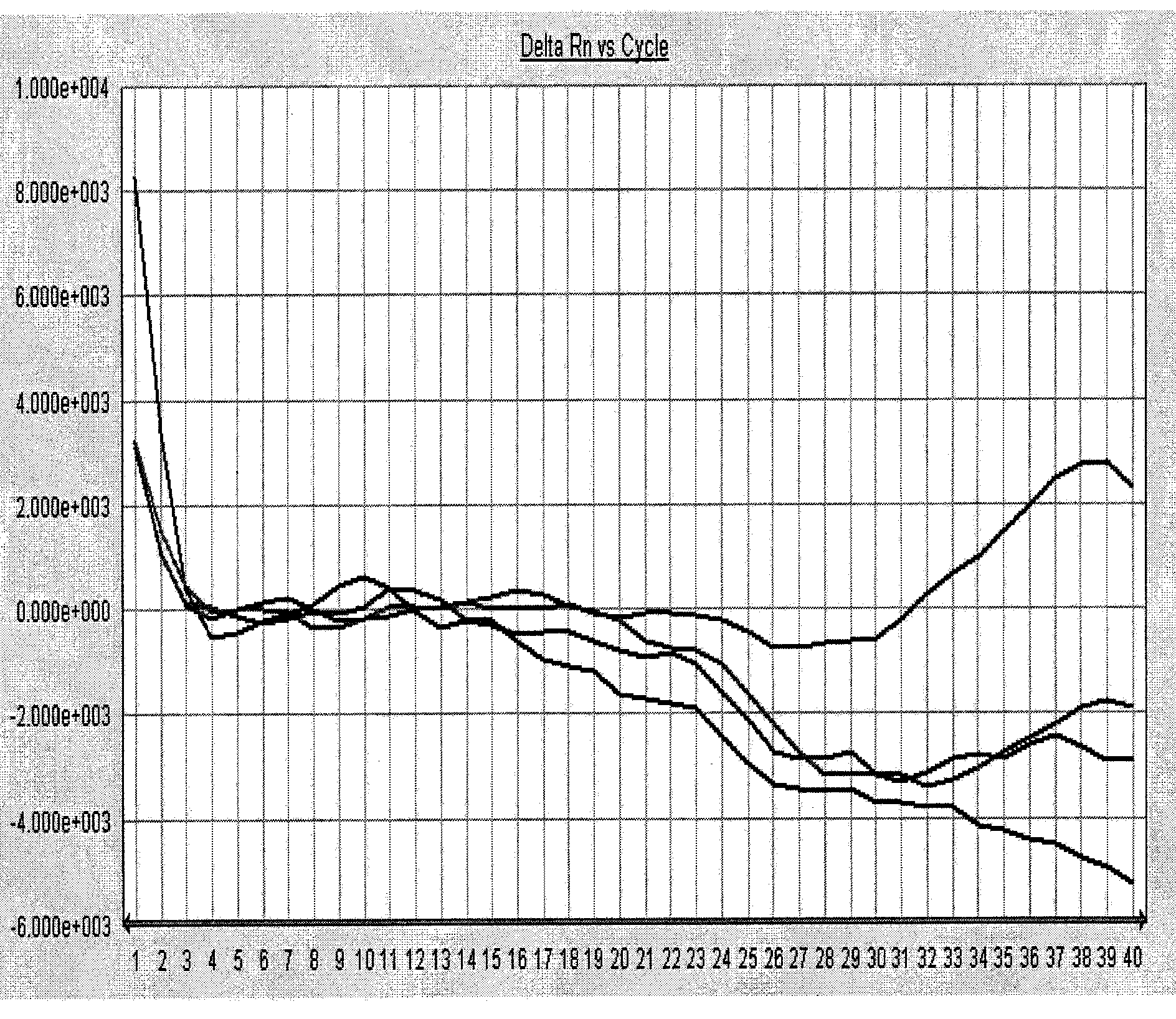

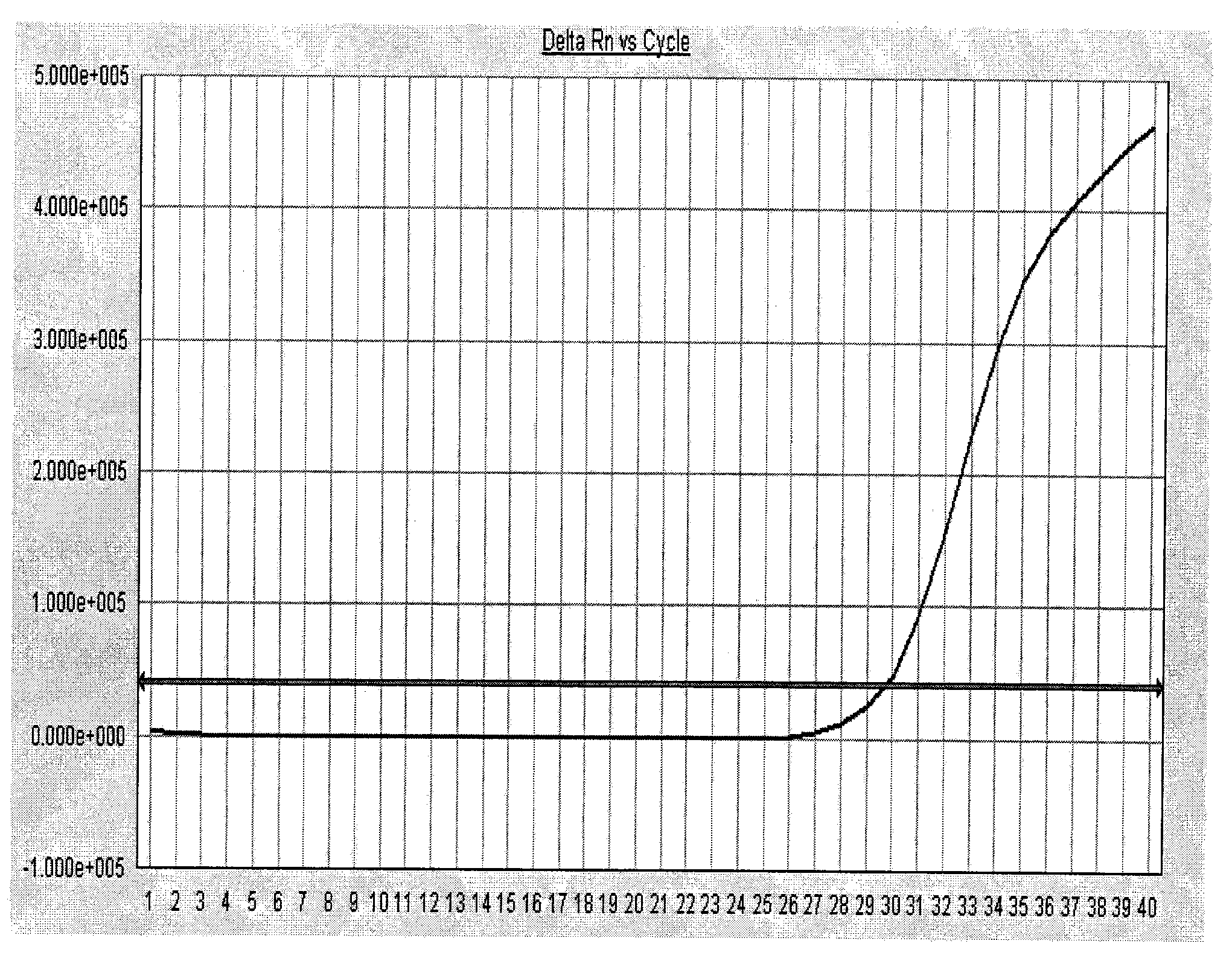

Human immunodeficiency virus (HIV) nucleic acid detection kit

ActiveCN103074446AReduce the chance of missed detectionIncrease coverageMicrobiological testing/measurementMicroorganism based processesNucleic acid detectionHuman immunodeficiency

The invention provides a human immunodeficiency virus (HIV) nucleic acid detection kit. The kit comprises at least two sets of primer probes which are respectively from different conservative regions. Preferably, the conservative regions comprise the relative conservation regions of HIV gene, i.e. GAG, POL and LTR regions. According to the invention, the two sets of designed and combined primer probe preparation reaction systems from two different regions jointly detect HIV-1RNA to identify the existence of positive reaction, effectively lower the probability of detection miss, can more comprehensively cover all subtypes, including all the subtypes of M, N and O groups of HIV-1, and further improve detection sensitivity and quantification accuracy, wherein the detection sensitivity can reach 50 IU / ml, and the linear range of the quantification is 50-1.0*108 IU / ml. The human immunodeficiency virus (HIV) nucleic acid detection kit provided by the invention further comprises a set of primer probe sequence, which is selected from any one of six sets of sequences including LTR1, LTR2, GAG1, GAG2, POL1 and POL2.

Owner:SANSURE BIOTECH INC

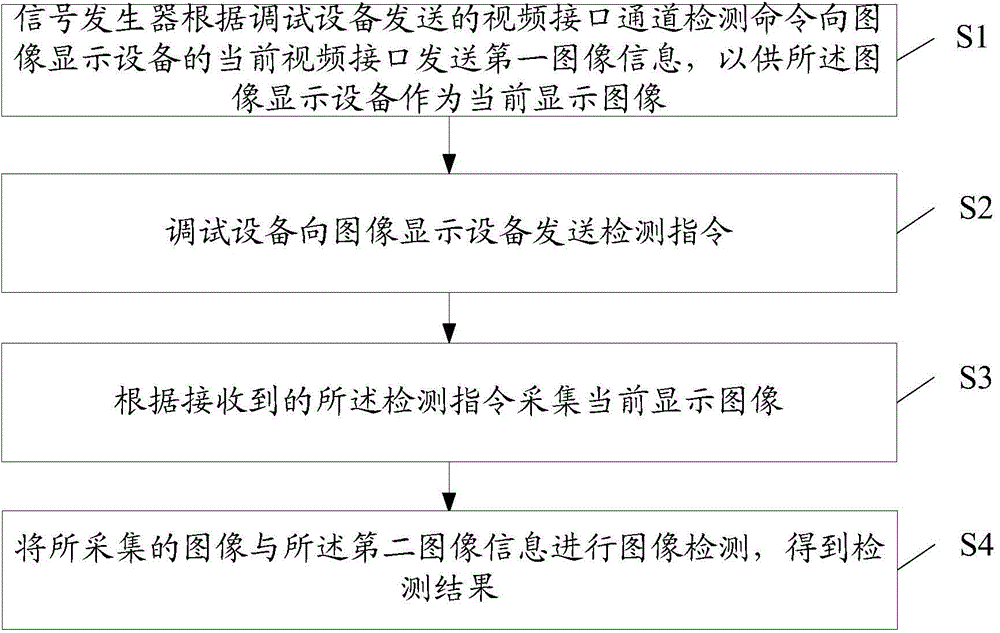

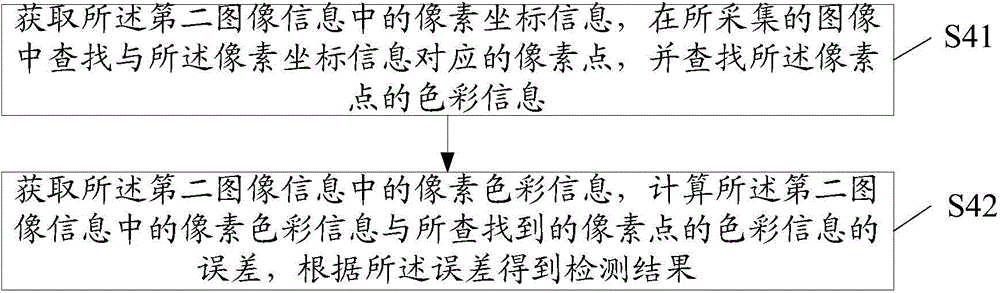

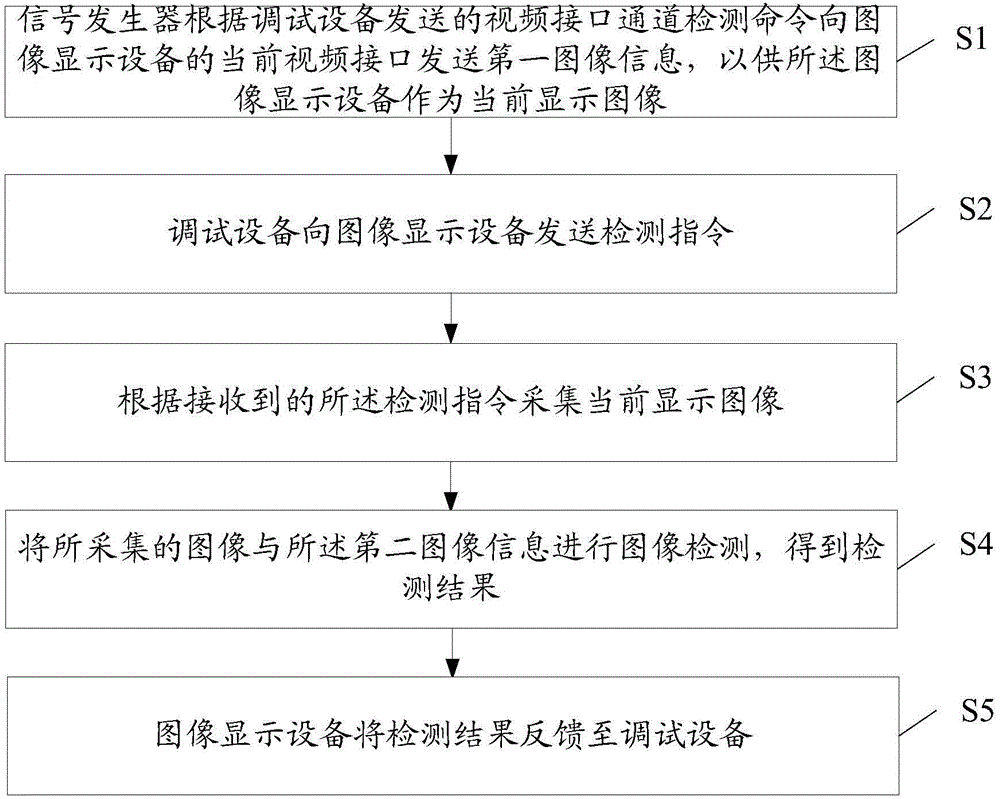

Method and system for video interface channel detection

ActiveCN105704481AImprove detection efficiencyFully automatedTelevision systemsComputer graphics (images)Image detection

The invention discloses a method and a system for video interface channel detection. The method for video interface channel detection includes following steps: a signal generator sends first image information to a current video interface of an image display device according to a video interface channel detection command sent by a debugging device so that the first image information is regarded as the current displayed image of the image display device; the debugging device sends a detection instruction to the image display device, wherein the detection instruction includes second image information corresponding to the first image information and an instruction for starting the detection; the image display device acquires the current displayed image according to the received detection instruction; and the image display device conducts image detection of the acquired images and the second image information and obtains a detection result. According to the method and the system, the efficiency for video interface channel detection of the image display device can be improved, and detection automation is realized.

Owner:SHENZHEN TCL NEW-TECH CO LTD

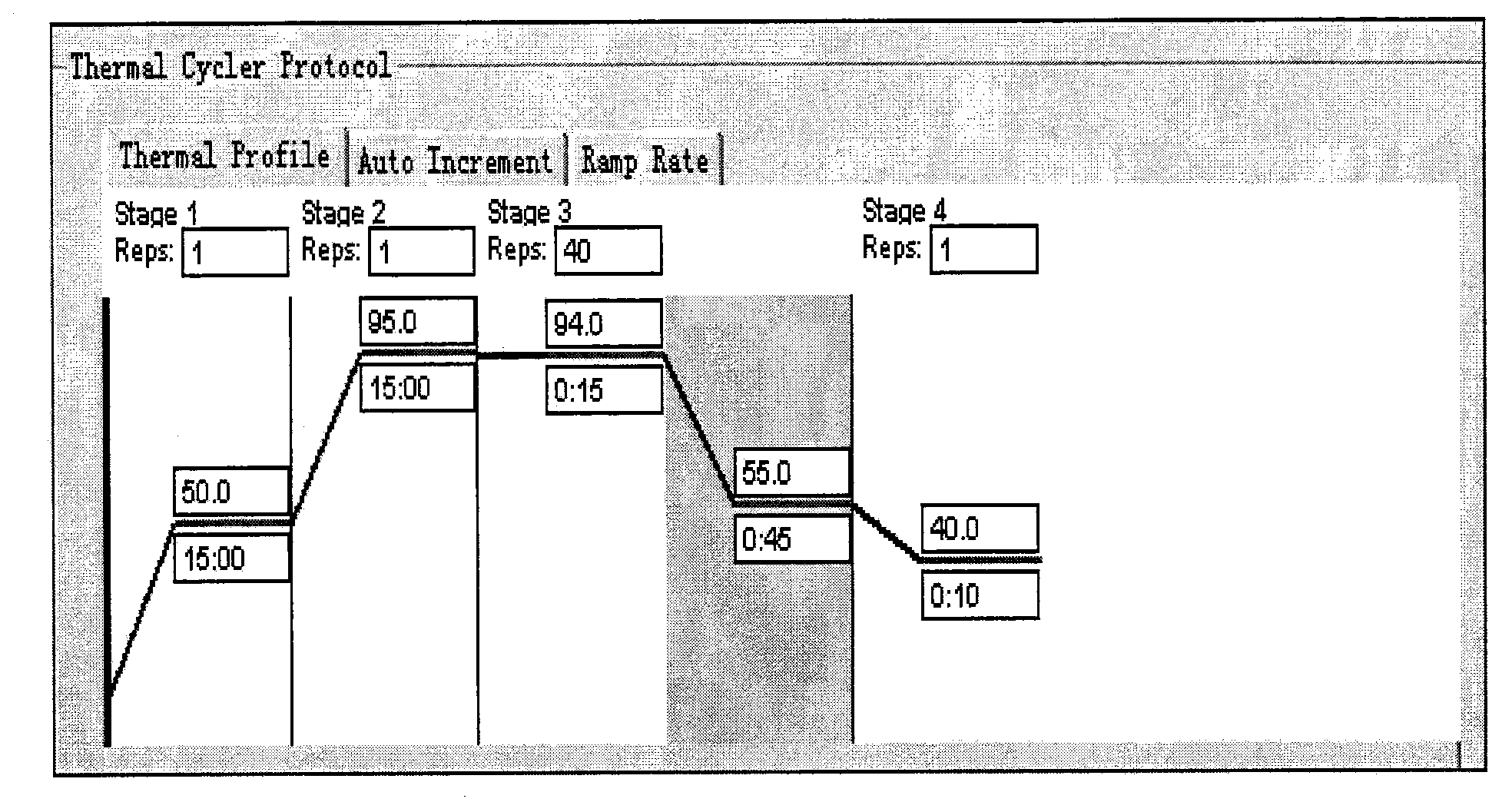

Reagent kit for distinguishing and detecting dengue virus/yellow fever virus/west nile virus/chikungunya virus

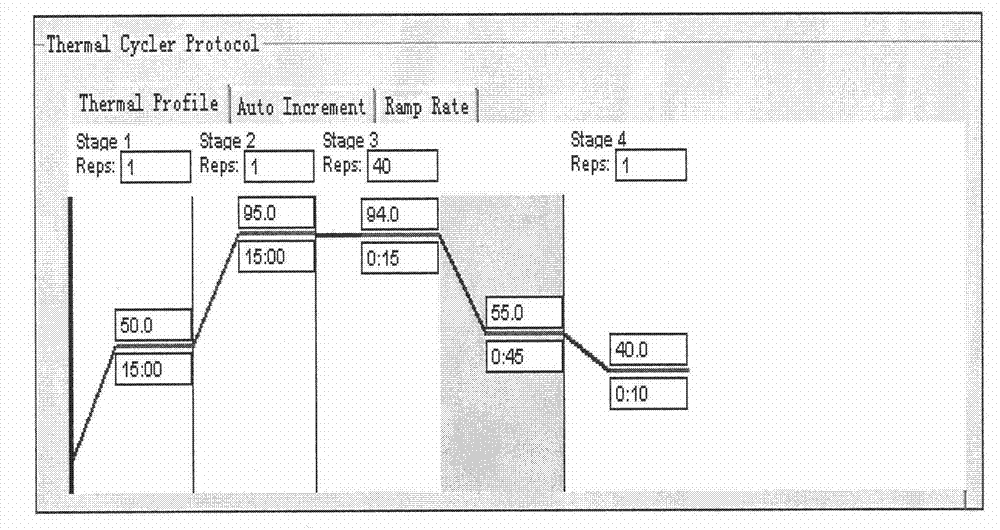

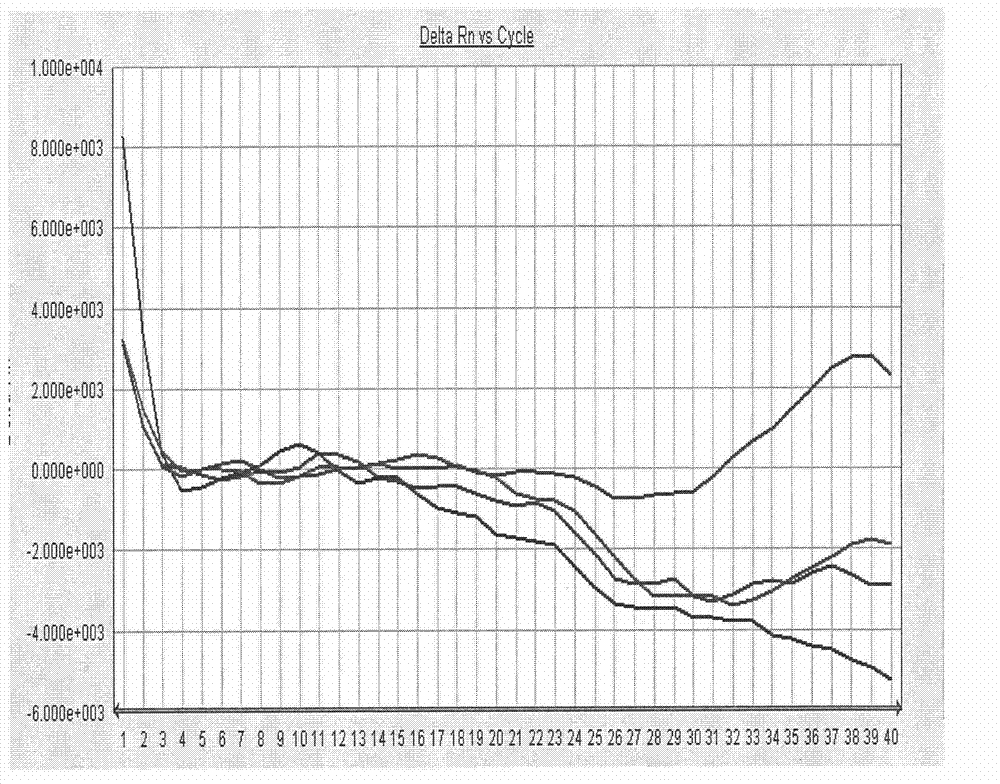

ActiveCN102776297AEasy to operateShort timeMicrobiological testing/measurementFluorescence/phosphorescencePathogenReal-time polymerase chain reaction

The invention relates to a reagent kit for distinguishing and detecting four entomoplily transmitted pathogens, in particular to a reagent kit for distinguishing and detecting dengue virus, yellow fever virus, west nile virus and chikungunya virus by utilizing multiple real-time fluorescent polymerase chain reaction technologies. The reagent kit mainly comprises reverse transcription-polymerase chain reaction (RT-PCR) reaction liquid, primer probe mixed liquid, an RT-PCR reaction enzyme system, diethylpyrocarbonate (DEPC) H2O and packing boxes for separating and packing reagent bottles or tubes. Due to the fact the reagent kit can accurately distinguish the dengue virus, the yellow fever virus, the west nile virus and the chikungunya virus, the reagent kit can be widely applied to the multiple fields of differential diagnosis, inspection & quarantine, prevention and control of epidemic situation and the like of entomoplily transmitted virus.

Owner:DAAN GENE CO LTD +1

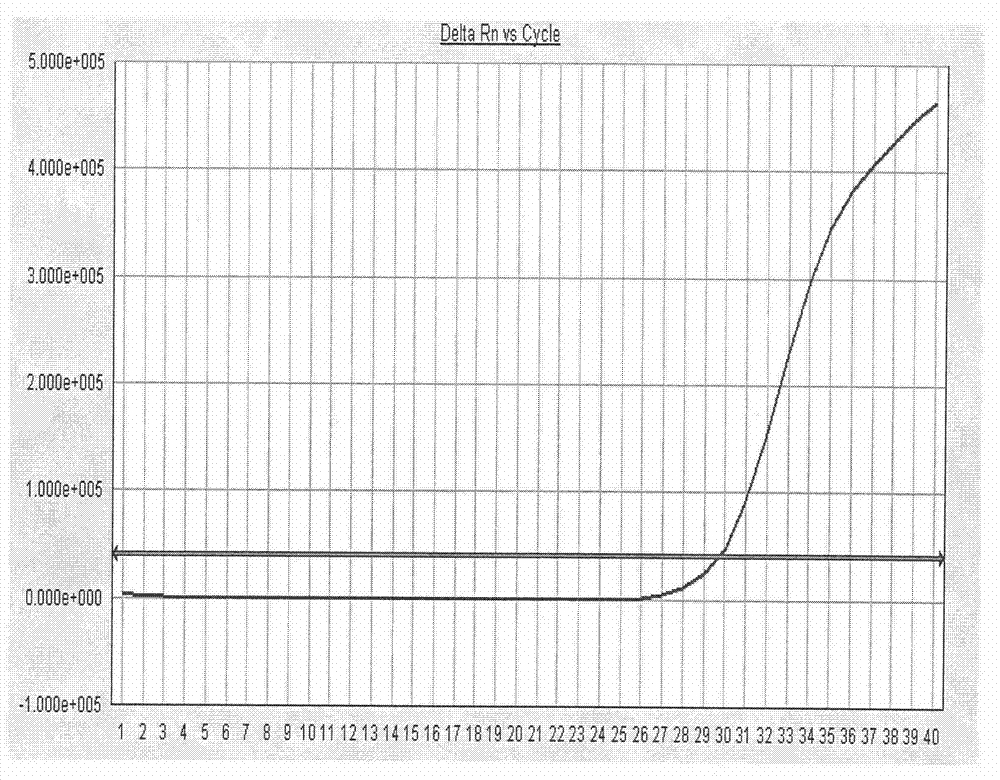

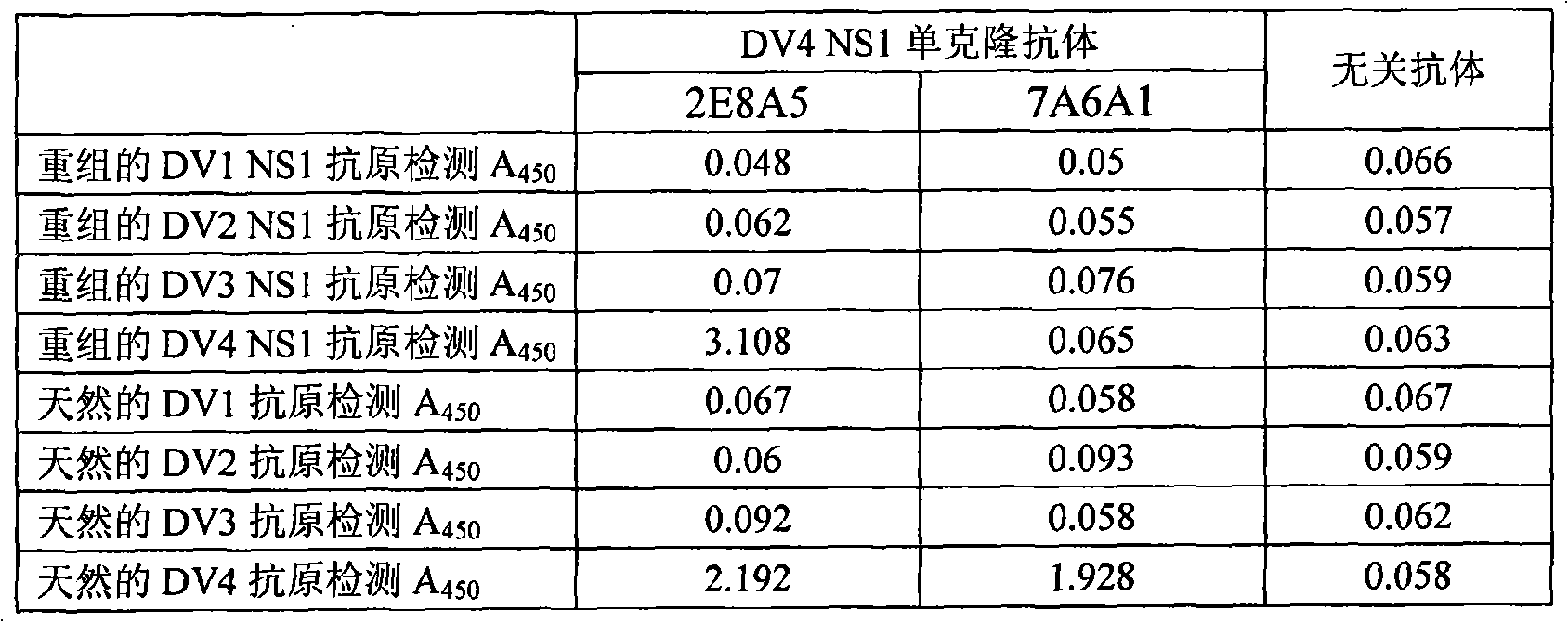

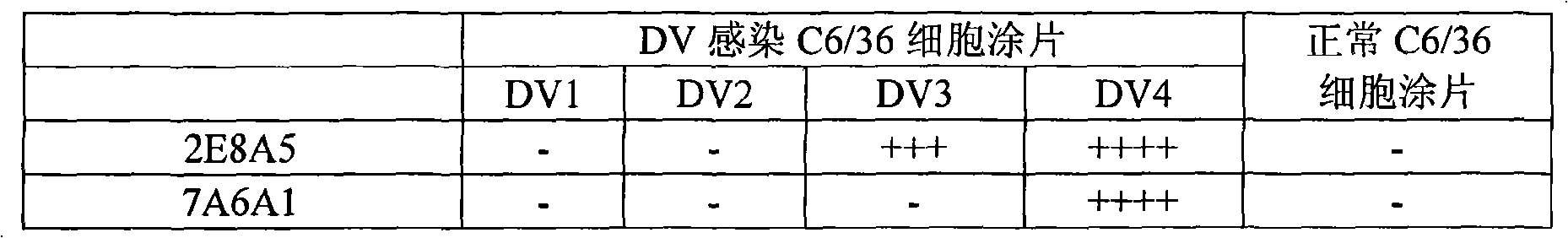

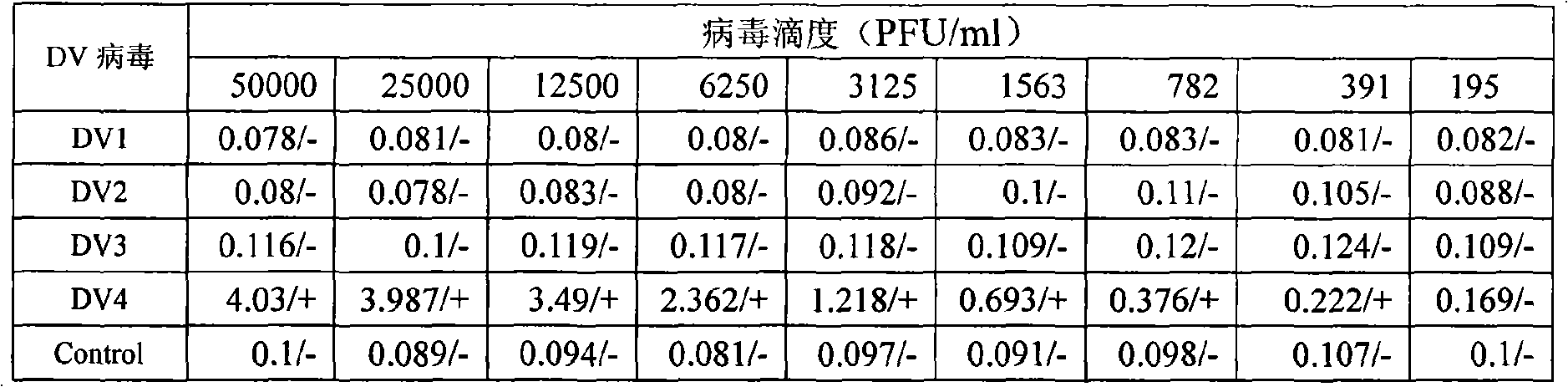

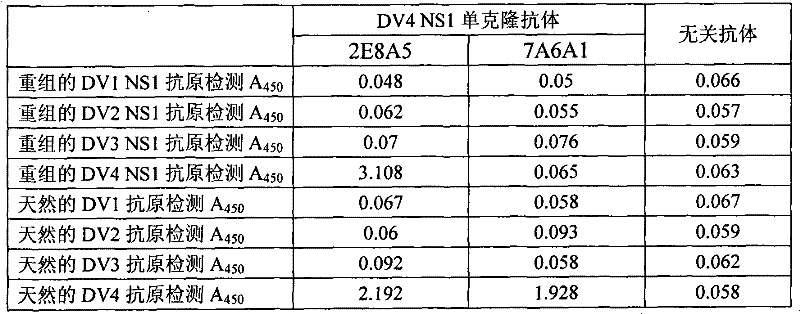

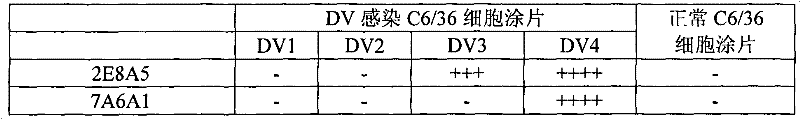

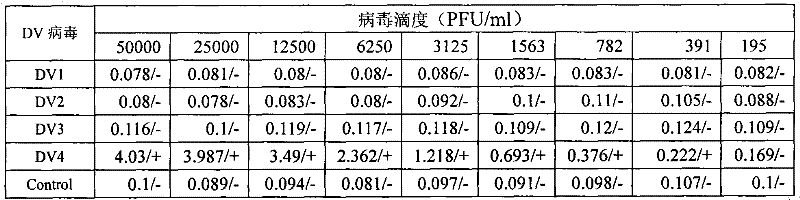

Immunodiagnosis kit for detecting IV-type dengue virus NS1 antigen

ActiveCN101551393AHigh sensitivityReduce the chance of missed detectionMaterial analysisAgainst vector-borne diseasesSerotypeNegative control

The invention discloses an immunodiagnosis kit for detecting specific IV-type dengue virus antigen, comprising a microporous reaction plate coated with monoclonal antibody 2E8A5, sample treatment fluid, monoclonal antibody 7A6A1 combined with markers, positive control, negative control, wash concentrate, color developing solution and stop solution. The kit can detect IV-type dengue virus antigen specifically, does not cross-react with other three types of serotype dengue virus antigens and detects that the supernatant sensitivity of the IV-type dengue virus is 64 times of that of the commercial kit of the same type, namely, the Pan-E Dengue Early ELISA test kit, thus greatly improving the sensitivity of detection of clinical serum samples and simultaneously reducing omission rate in clinical applications.

Owner:SOUTHERN MEDICAL UNIVERSITY

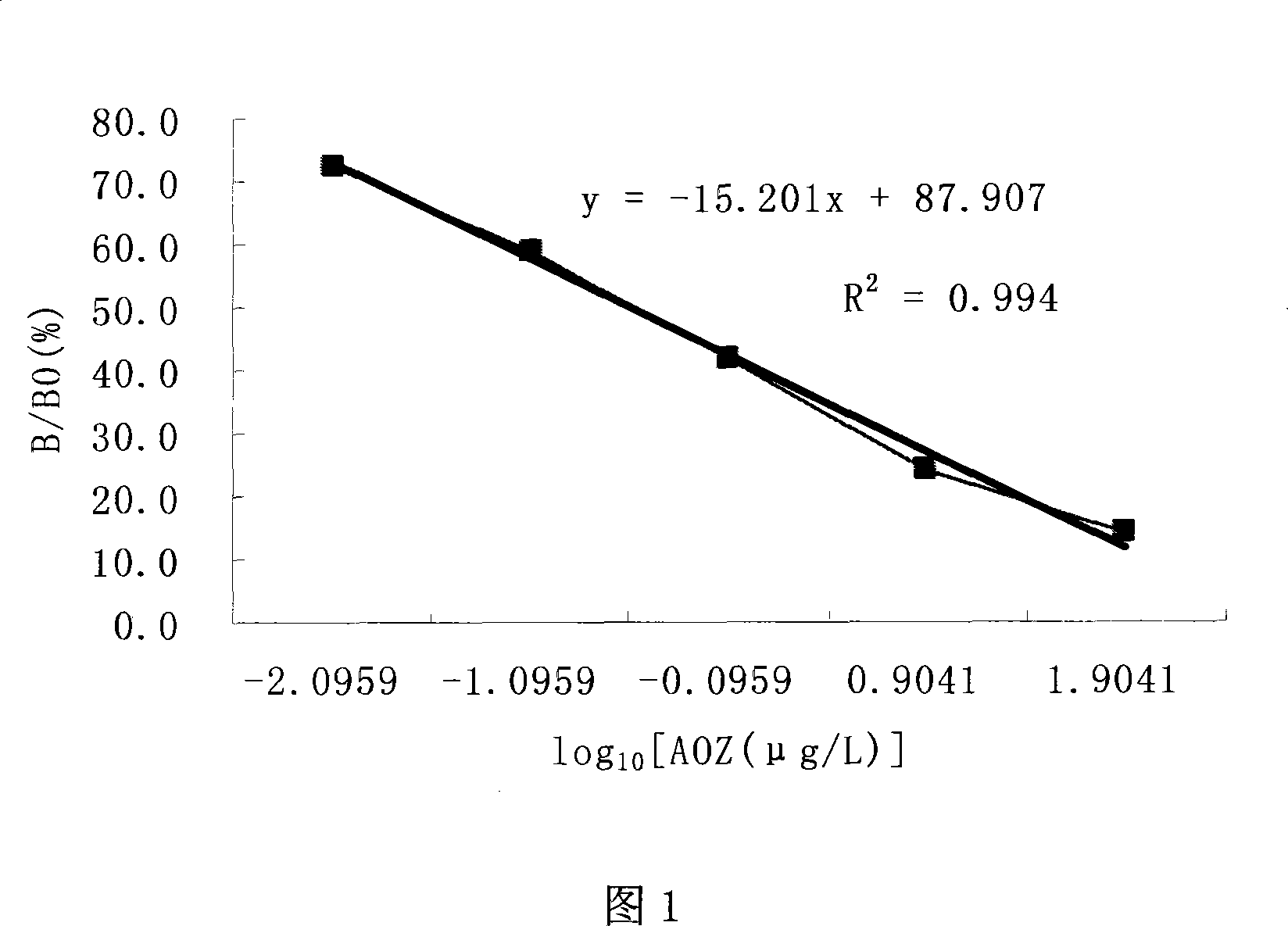

Nitrofurans medicament metabolite residue ELISA kit and use method

ActiveCN101241132AAvoid problems requiring detection multiple timesReduce the chance of missed detectionMaterial analysisAntigenWorking fluid

The present invention discloses enzyme-linked immune kits for detecting nitrofurans metabolite residue including antigenic enzyme label plate coated with nitrofuran meatbolites, enzyme labeled antibody working fluid, standard solution, substrate solution, substrate buffer solution, reaction termination liquid, condense washing liquid and sample diluted concentrated liquid. The present invention also discloses using method for detecting by said kits including steps of pretreatment of sample, detecting with kits, result process and analysis and so on. The kits provided by present invention employ directly competing enzyme-linked immunoadsorption analysis to detect not only multiple nitrofurans metabolite residues at the same time, but also singleness nitrofurans metabolite residue, avoid many times detection of the same sample and reduce miss ratio, has merits of high sensitivity, good stability, less steps and low cost, and suit for screening of a large mount of samples, and has importance practical significance.

Owner:SOUTH CHINA AGRI UNIV

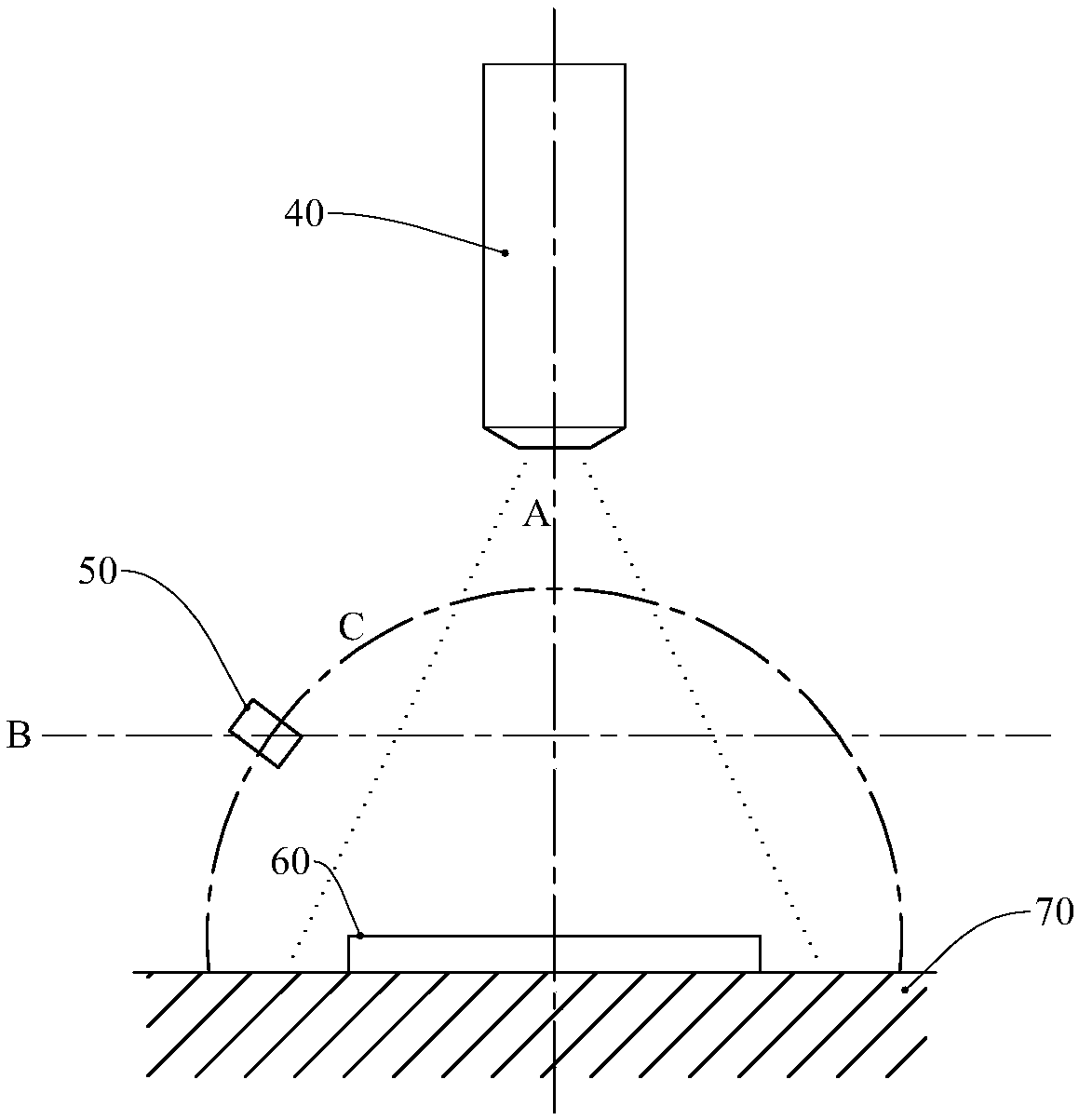

Method for detecting surface defects

PendingCN108827971AImprove accuracyReduce the chance of missed detectionOptically investigating flaws/contaminationImage synthesisMultiple image

Owner:深圳市创科自动化控制技术有限公司

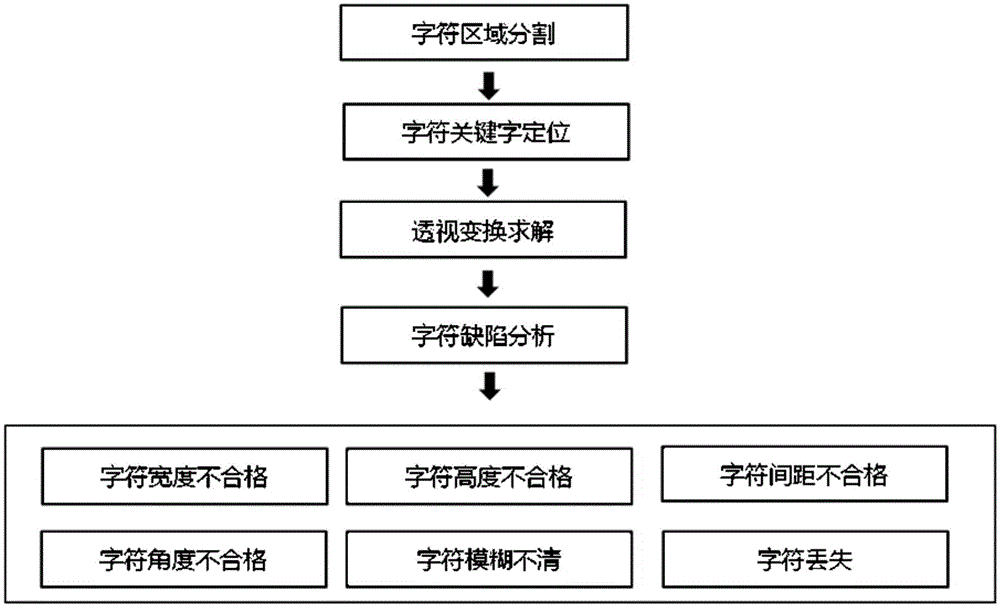

Jet code detection method and system

InactiveCN105023018APrecise positioningAccurate readingCharacter and pattern recognitionAlgorithmEngineering

The invention belongs to the technical field of jet printing and discloses a jet code detection method. The method comprises: setting a character template; and carrying out character region partitioning, character keyword positioning, perspective transformation and solving and character defect analysis, wherein character defects comprise unqualified character width, unqualified character height, unqualified character separation distances, unqualified character angle, blurring characters and loss of the characters; a jet code comprises a keyword and a variable character. According to the method and system disclosed by the invention, the jet code detection efficiency and reliability are enhanced through efficient automatic detection method and system.

Owner:武汉楚锐视觉检测科技有限公司

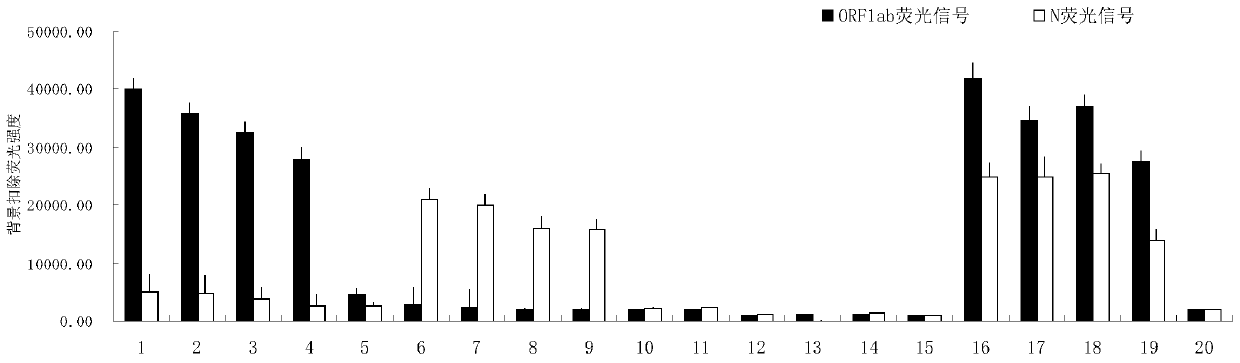

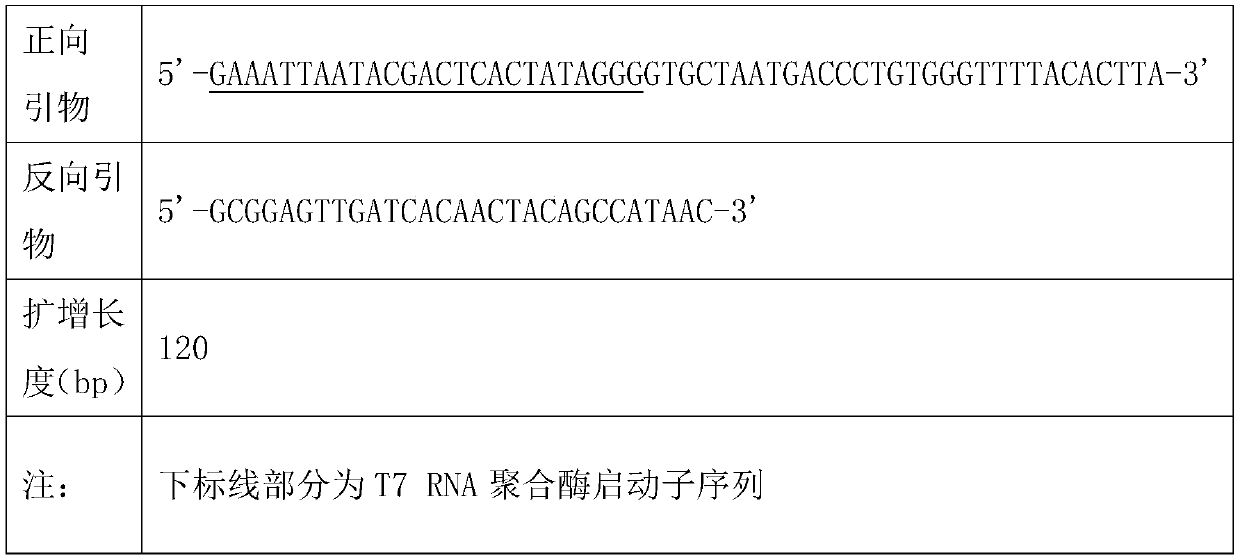

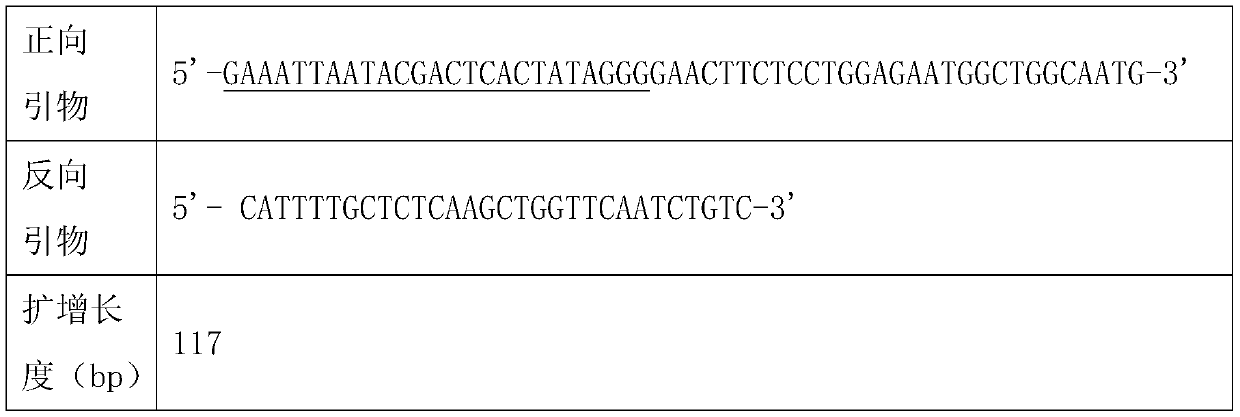

Combination of primers and CRISPR sequence for detecting novel coronavirus gene, and application thereof

PendingCN111560469ASimple and efficient operationReduce the chance of missed detectionMicrobiological testing/measurementMicroorganism based processesMolecular biologyViral gene

The invention provides combination of primers and a CRISPR sequence for detecting novel coronavirus gene comprising two groups of primer pairs for RPA isothermal amplification for respectively detecting virus ORF1ab genes and N genes, and two crRNA sequences capable of respectively detecting RPA amplification products. The ORF1ab gene and the N gene can be detected at the same time through systemdetection, operation is easy and convenient, and each detection sample only needs to be detected through a single tube; the whole reaction process is carried out at the temperature of about 37 DEG C,a fine temperature control element and complex temperature change which are required by PCR amplification are not required, and the combination is suitable for a basic apartment to detect by using relatively cheap instant detection equipment; and the sensitivity reaches 10 copies / uL. Compared with a PCR technology, the advantages are that the speed is higher, an obvious detection signal can be obtained within 30 min, and whether the 2019-nCoV novel coronavirus nucleic acid result of a sample is positive or not can be rapidly judged.

Owner:广州和盛医疗科技有限公司

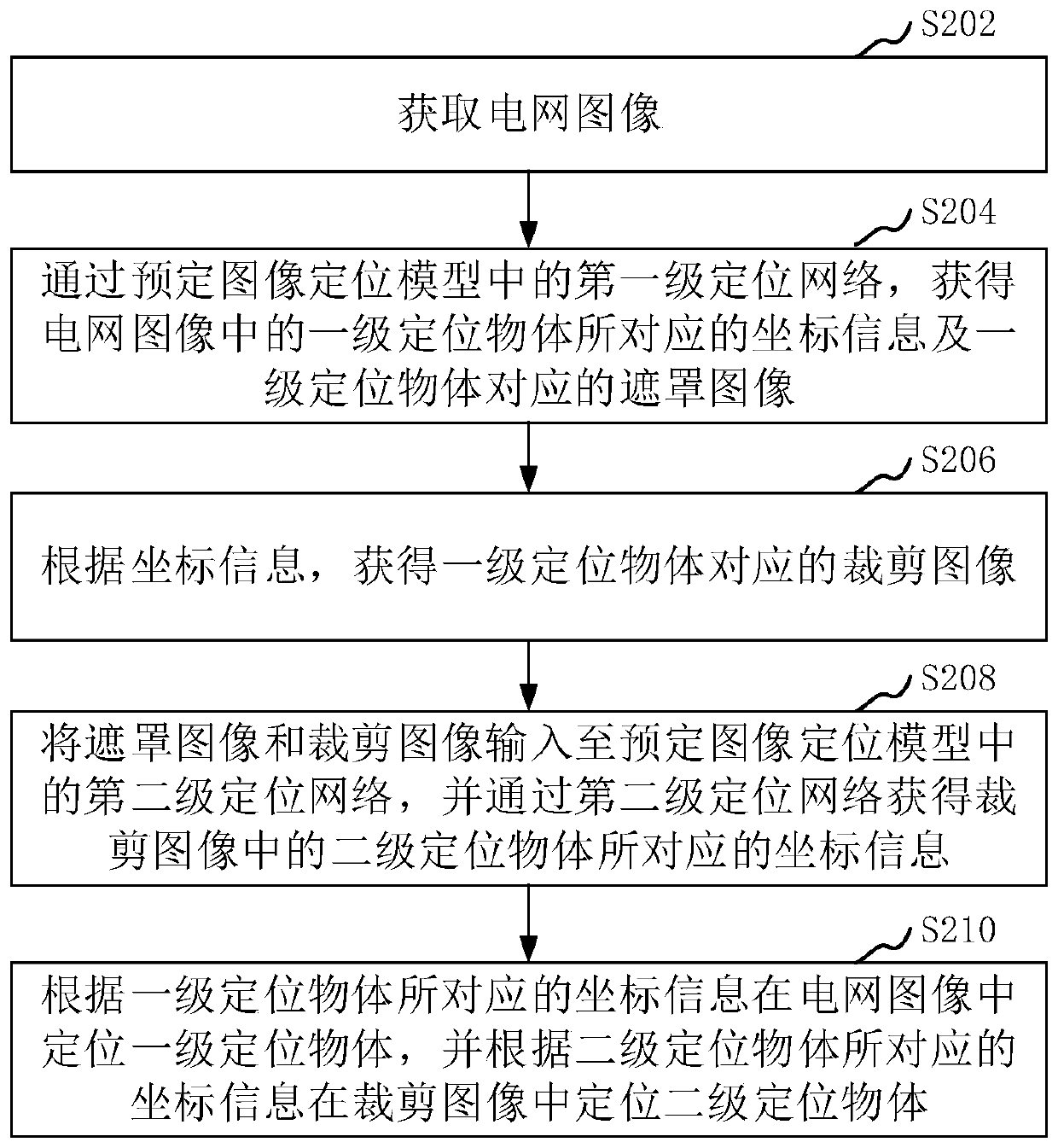

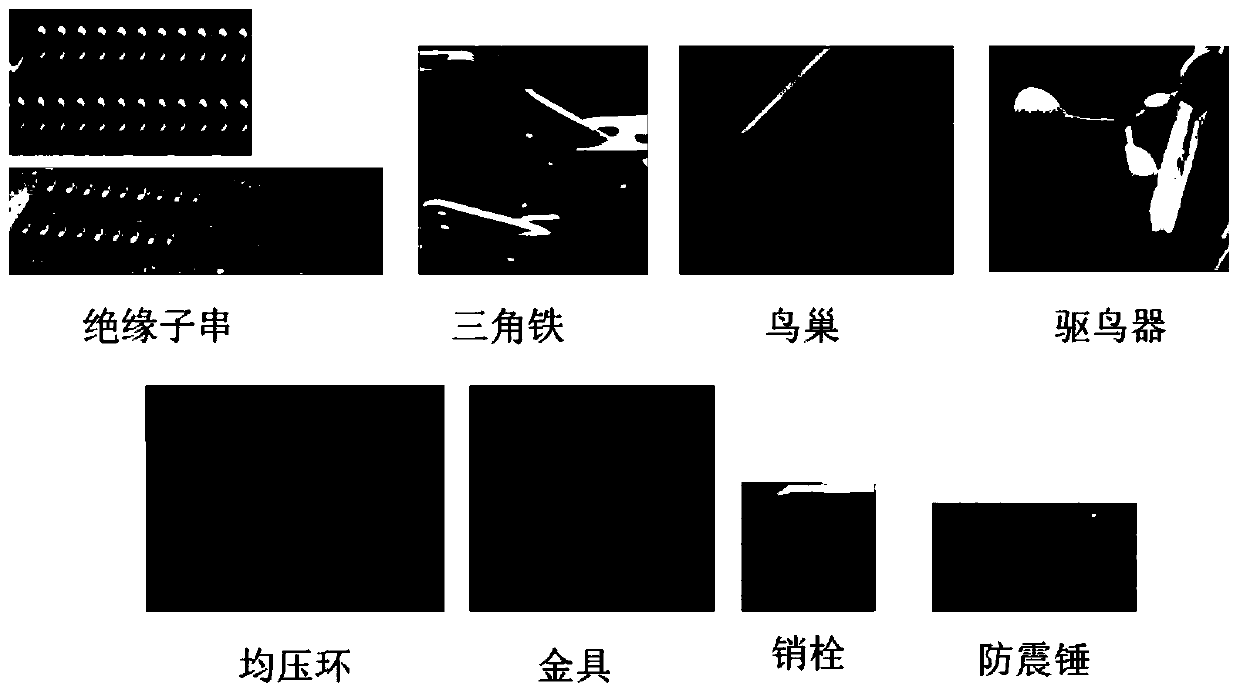

Power grid image positioning method and image positioning model training method

ActiveCN110910360AShorten the timeReduce the chance of missed detectionImage enhancementImage analysisComputer graphics (images)Power grid

The invention relates to a power grid image positioning method and an image positioning model training method. The method comprises: obtaining coordinate information of a first-level positioning object in the power grid image and a corresponding mask image through a first-level positioning network in a predetermined machine learning model; obtaining a cut image of the first-level positioning object according to the coordinate information; jointly determining coordinate information corresponding to a second-level positioning object in the cut image through a second-level positioning network according to the mask image and the cut image; and finally, positioning the object in the power grid image according to the coordinate information. Firstly, a first-level positioning object in a power grid image is positioned through a first-level positioning network in an image positioning model; and then a second-level positioning object in dependence connection with the first-level positioning object in the cut image is positioned through a second-level positioning network, so the method can achieve the positioning from the first-stage positioning object to the second-stage positioning objectunder the condition that the size of the object is smaller, and is very suitable for the object detection and recognition in a scene that the size difference of the object on a power transmission lineis larger.

Owner:TENCENT CLOUD COMPUTING BEIJING CO LTD

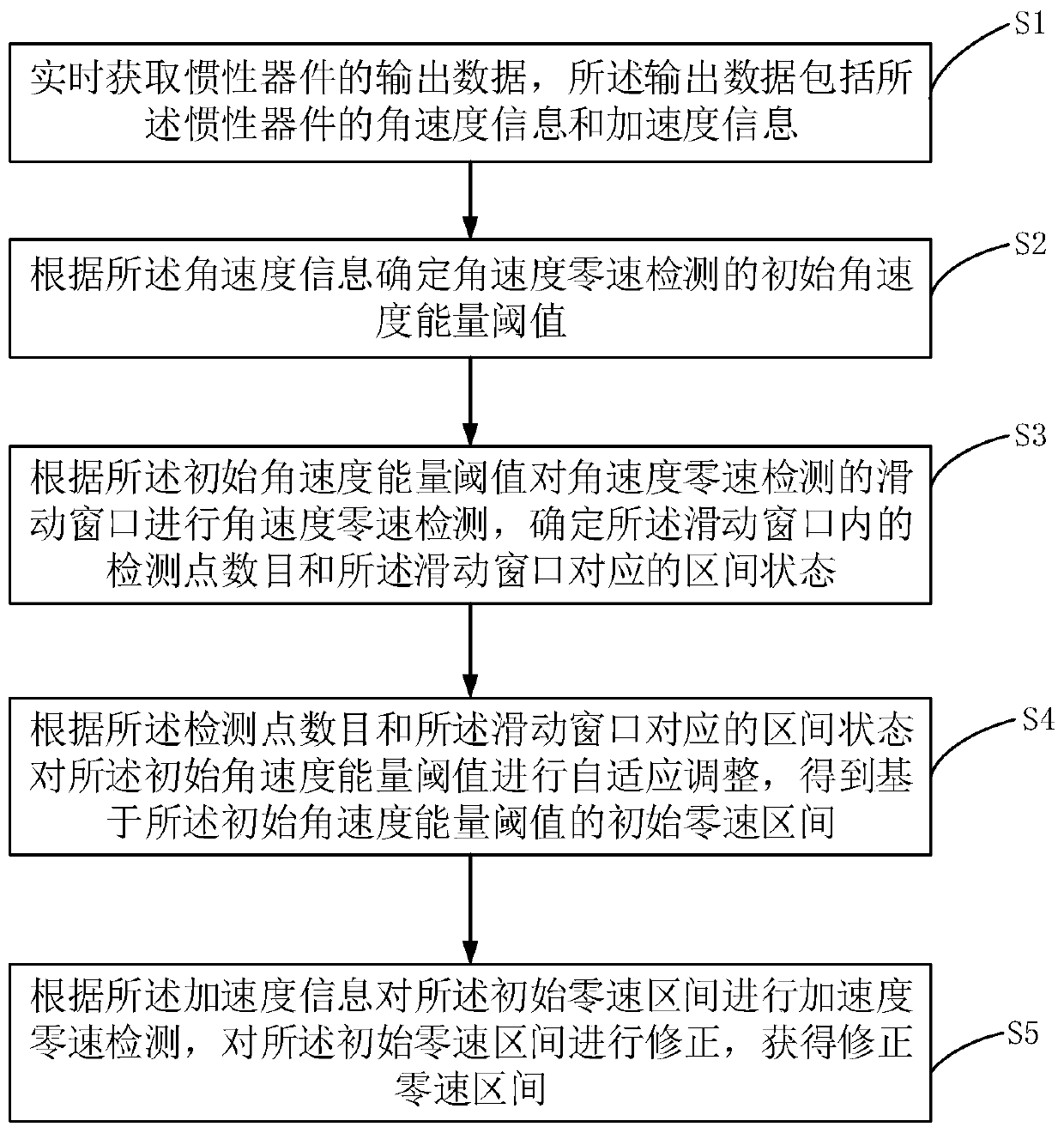

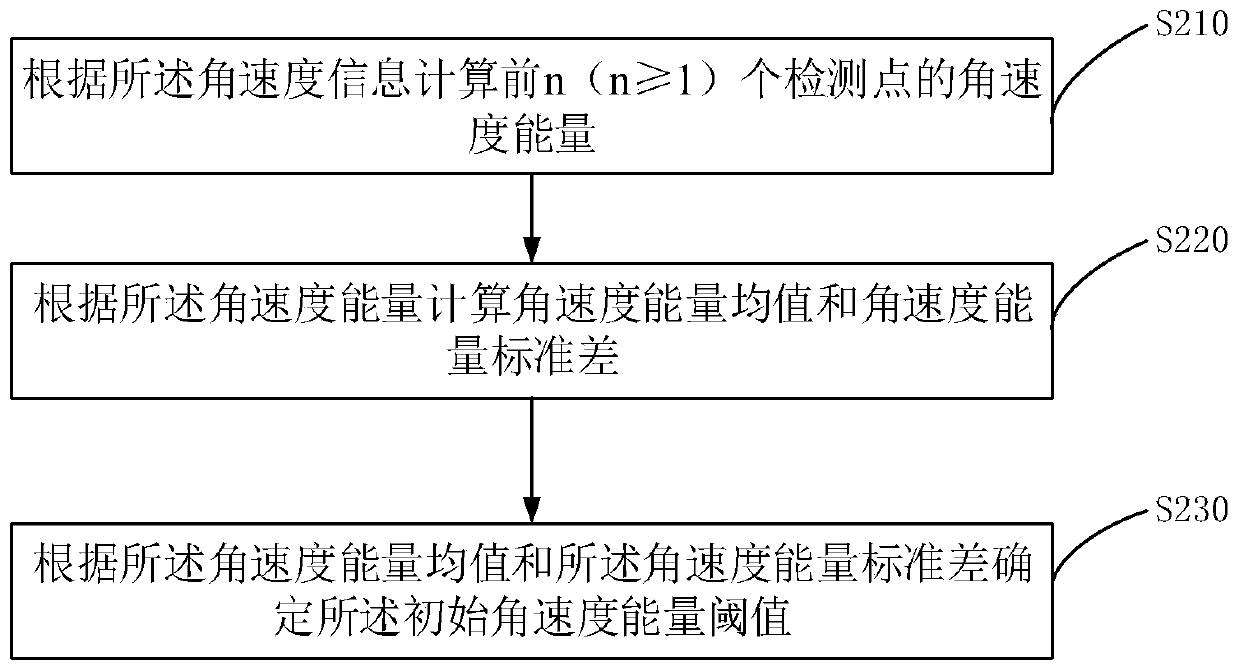

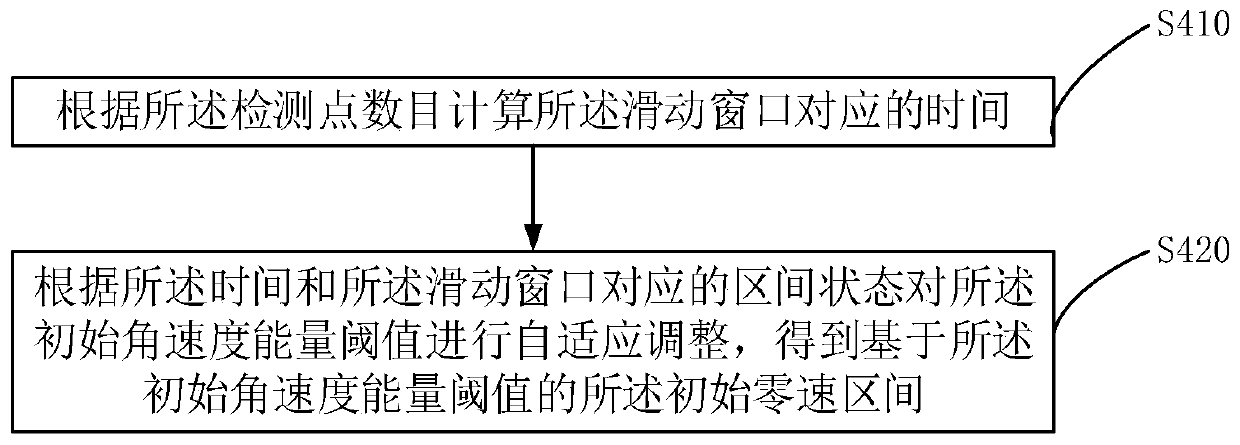

Adaptive zero-speed interval detection method

ActiveCN110455316AReduce the chance of missed detectionImprove detection reliabilityNavigation by speed/acceleration measurementsSelf adaptiveSlide window

The present invention provides an adaptive zero-speed interval detection method, and belongs to the technical field of pedestrian navigation and positioning. The method comprises: S1: acquiring outputdata of an inertial device in real time, wherein the output data comprises angular speed information and acceleration information of the inertial device; S2: determining an initial angular speed energy threshold of the angular speed zero-speed detection according to the angular speed information; S3: according to the initial angular speed energy threshold, performing angular speed zero-speed detection on a sliding window of the angular speed zero-speed detection, and determining the number of detection points in the sliding window and the interval state corresponding to the sliding window; S4: according to the number of the detection points and the interval state corresponding to the sliding window, adaptively adjusting the initial angular speed energy threshold to obtain an initial zero-speed interval based on the initial angular speed energy threshold; and S5: performing acceleration zero-speed detection on the initial zero-speed interval according to the acceleration information, and correcting the initial zero-speed interval to obtain a corrected zero-speed interval.

Owner:HARBIN INST OF TECH

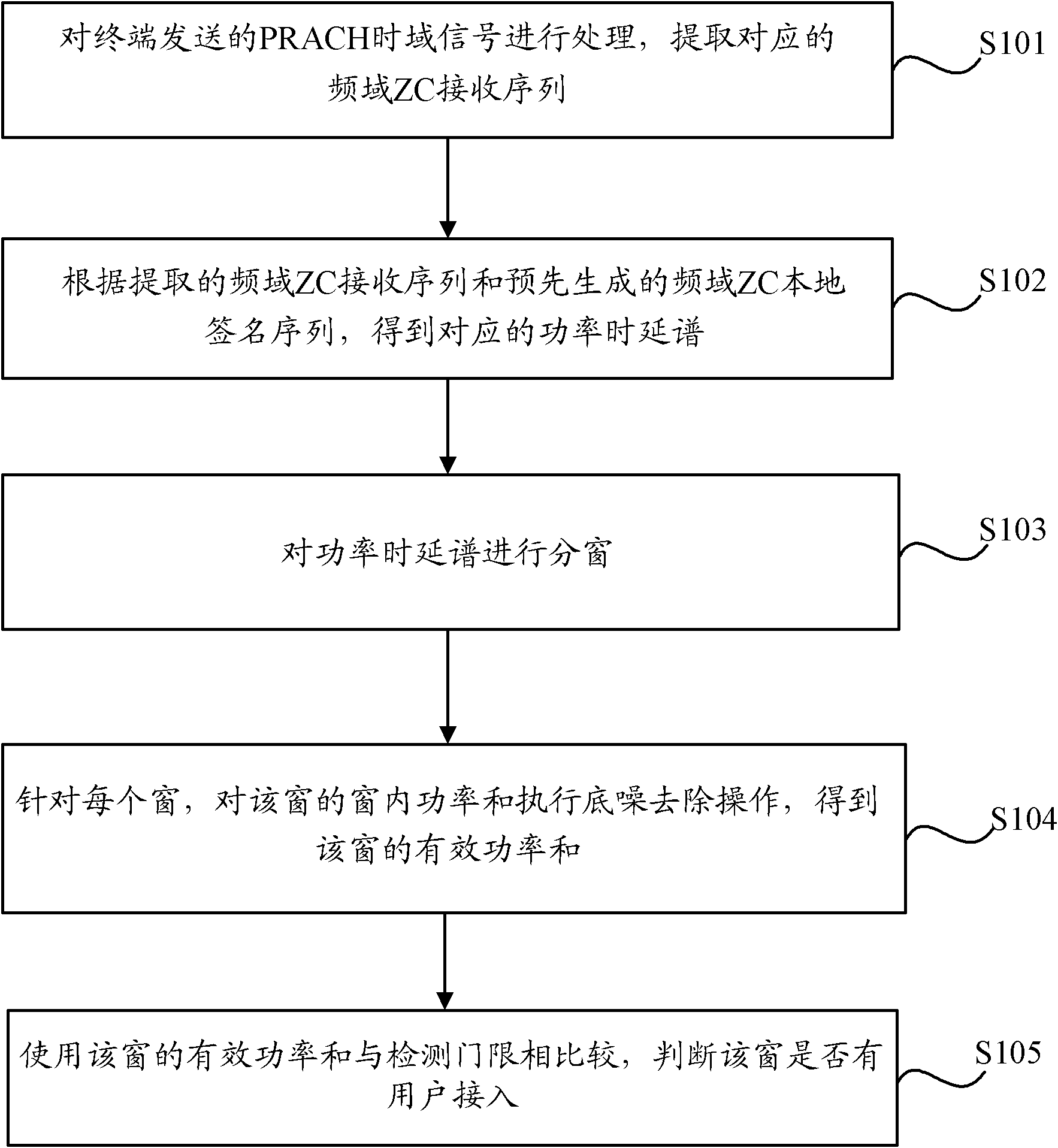

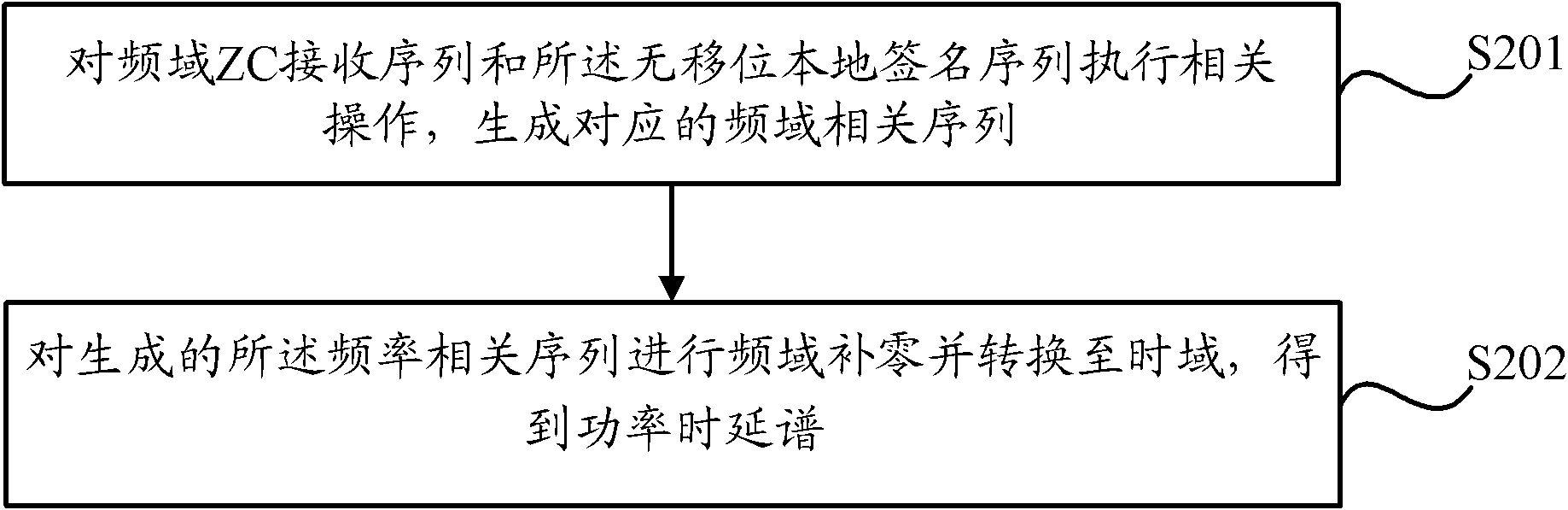

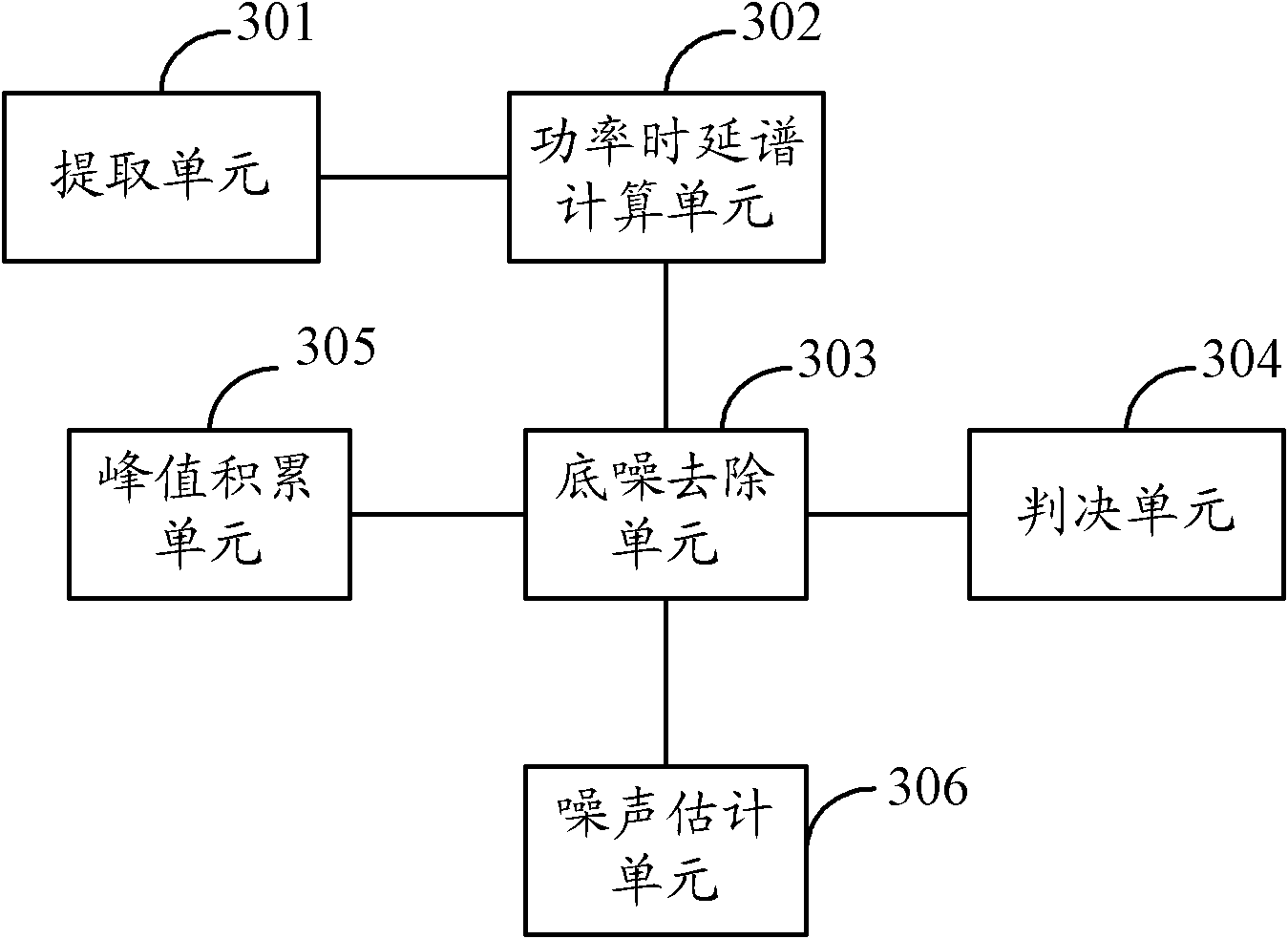

Detection method, device and base station for random access signal

ActiveCN103108337AEasy to detectCompensation for effective power lossEnergy efficient ICTHigh level techniquesTime domainEffective power

The invention provides a detection method, a device and a base station for a random access signal. A physical random access channel (PRACH) time-domain signal sent by a terminal is processed, and a corresponding frequency domain zone code (ZC) receiving sequence is extracted. A corresponding power time delay spectrum is obtained based on the extracted frequency domain ZC receiving sequence and a frequency domain ZC local signature sequence generated in advance. Windowing is performed on the generated power time delay spectrum, for each window, an effective power sum is obtained through internal power of the window and execution of base noise removing operation, and the effective power sum of the window is compared with a detection threshold so as to judge whether a user is accessed or not. According to the internal power in the window and the execution of the base noise removing operation, the effective power of the time delay spectrum is restored, effective power loss due to oversampling is compensated, undetected odds are reduced, and random access signal detection performance is improved.

Owner:COMBA TELECOM SYST CHINA LTD

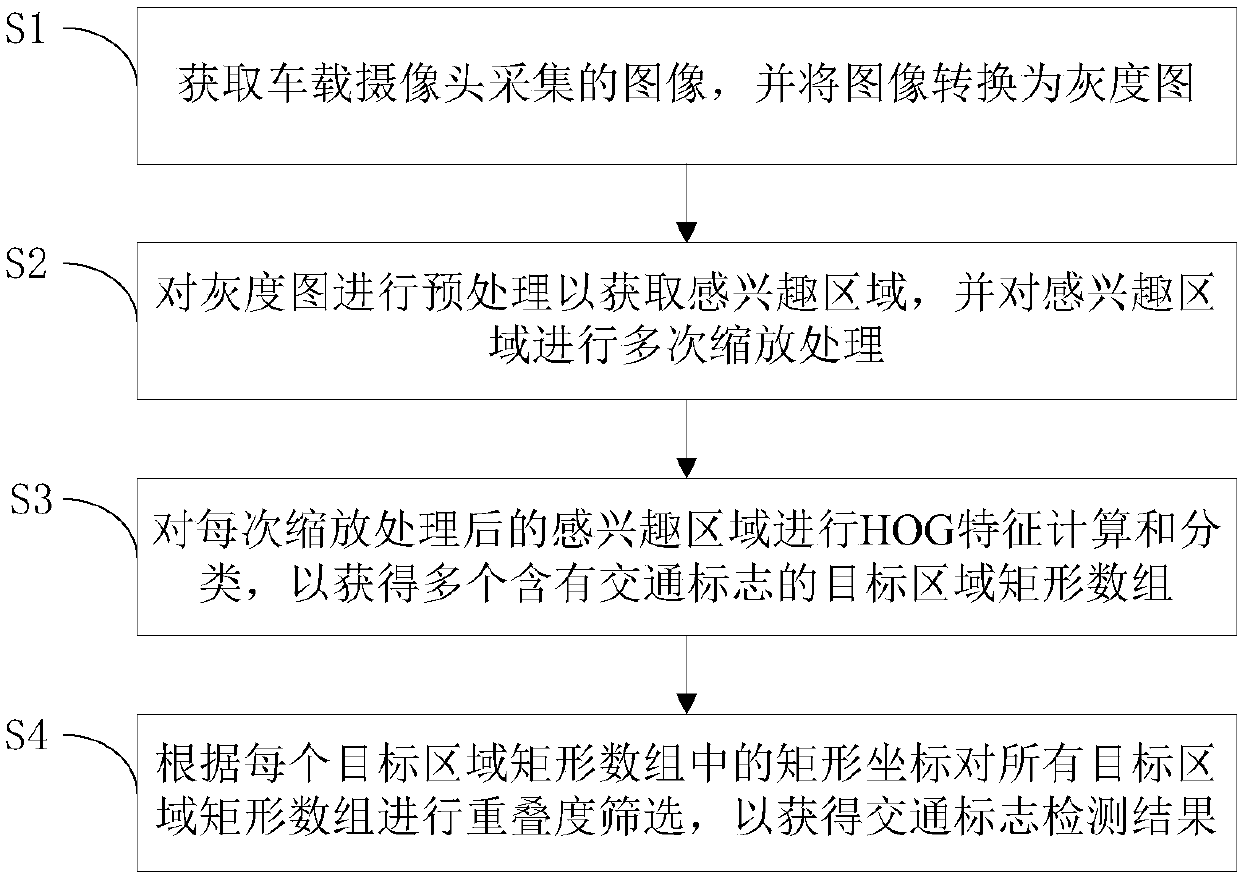

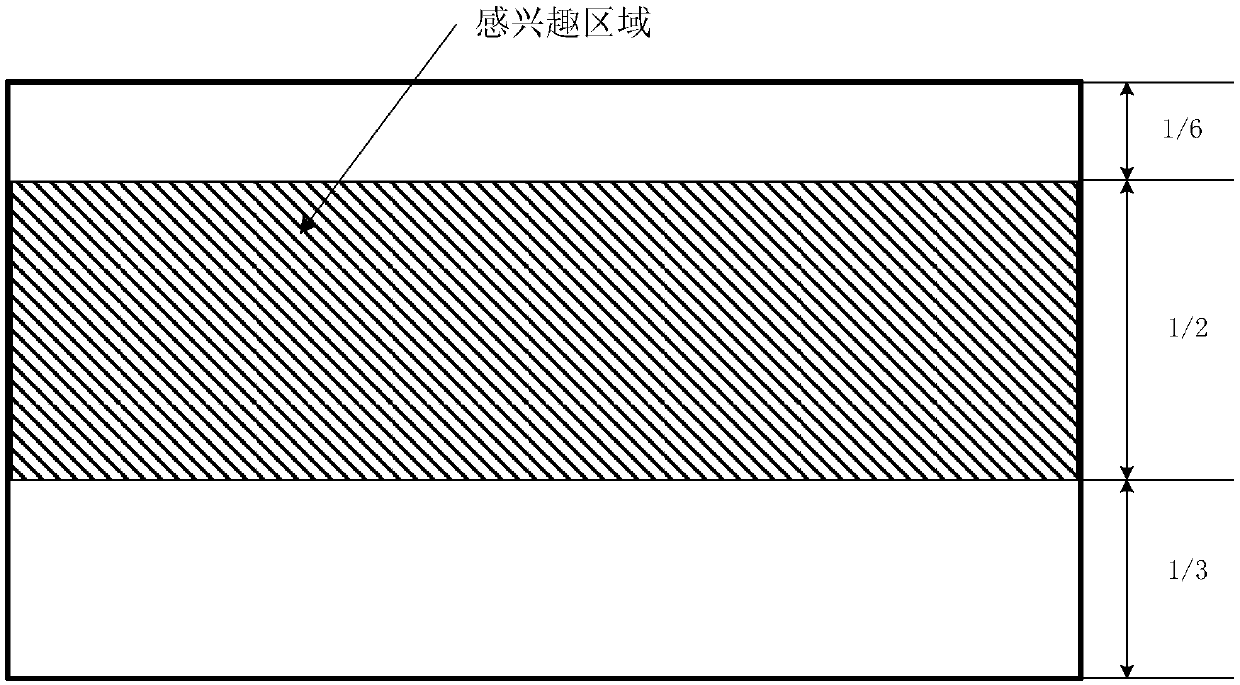

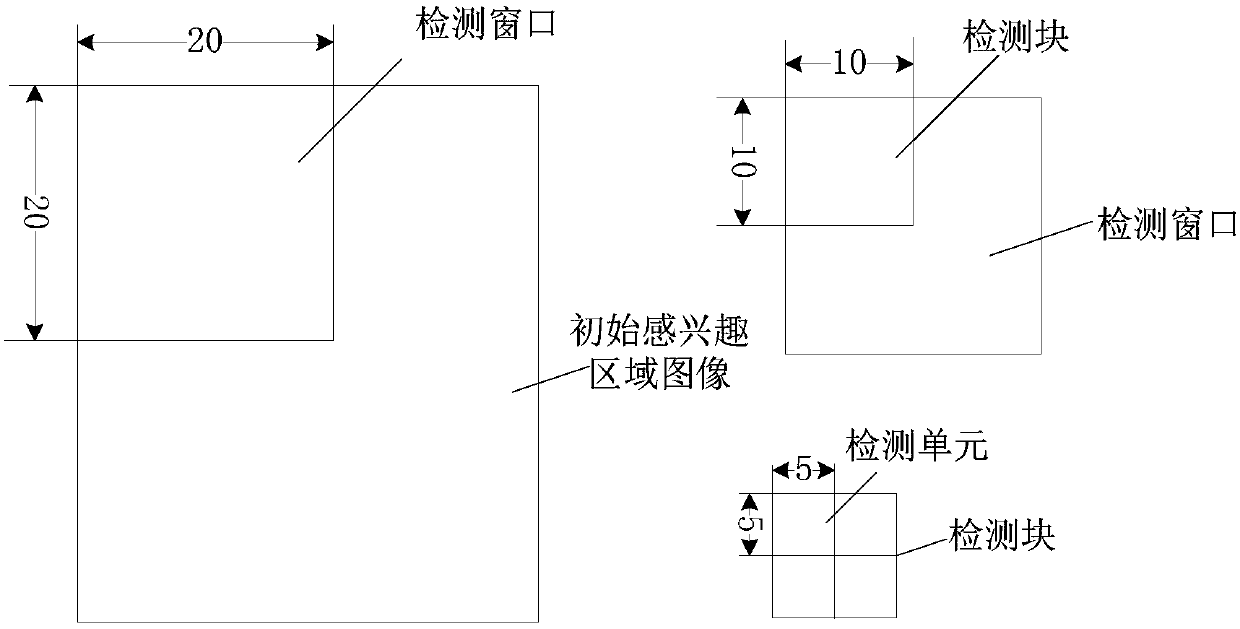

Vehicle and traffic sign detection method

InactiveCN109858310AImprove detection accuracyReduce the chance of missed detectionCharacter and pattern recognitionArray data structureTraffic sign detection

The invention discloses a vehicle and traffic sign detection method, and the method comprises the following steps: obtaining an image collected by a vehicle-mounted camera, and converting the image into a grayscale image; preprocessing the grey-scale image to obtain an interested area, and performing scaling processing on the interested area for multiple times; HOG feature calculation and classification are performed on the region of interest after each time of zooming processing, so that a plurality of target region rectangular arrays containing traffic signs can be obtained; and carrying outoverlapping degree screening on all the target area rectangular arrays according to the rectangular coordinates in each target area rectangular array to obtain a traffic sign detection result. According to the detection method provided by the invention, multi-stage zooming can be carried out on the input image, HOG feature calculation and classification are carried out on each stage of zoomed image to obtain a traffic sign detection result, so that the detection precision is improved, and the probability of missed detection is reduced.

Owner:BYD CO LTD

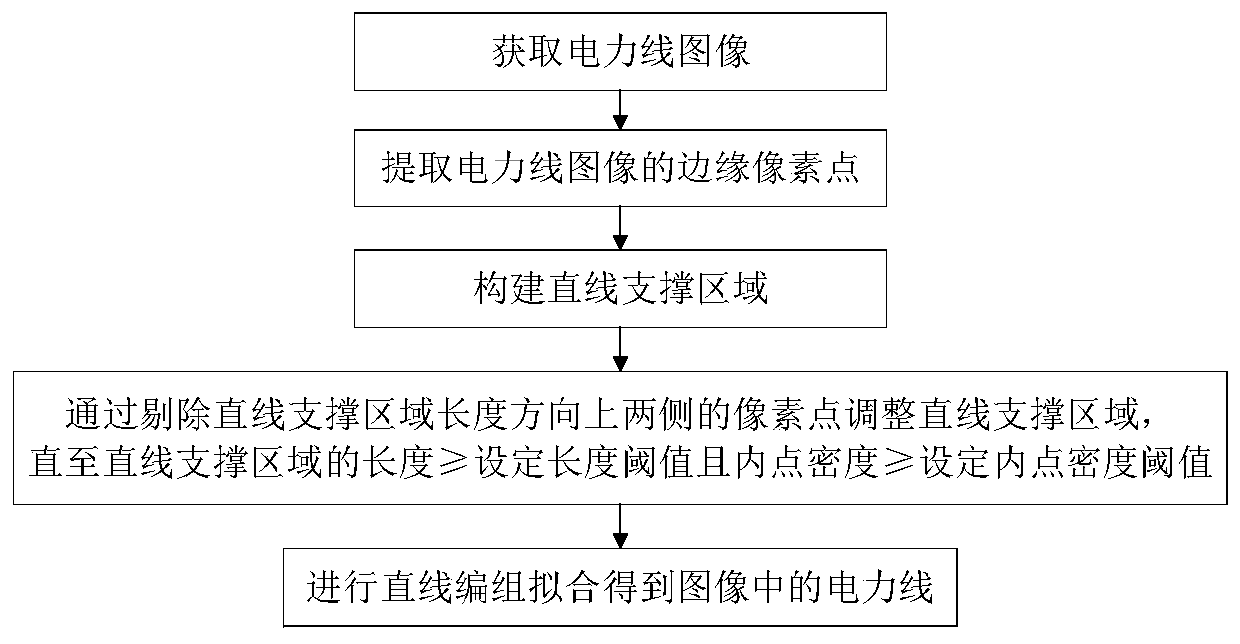

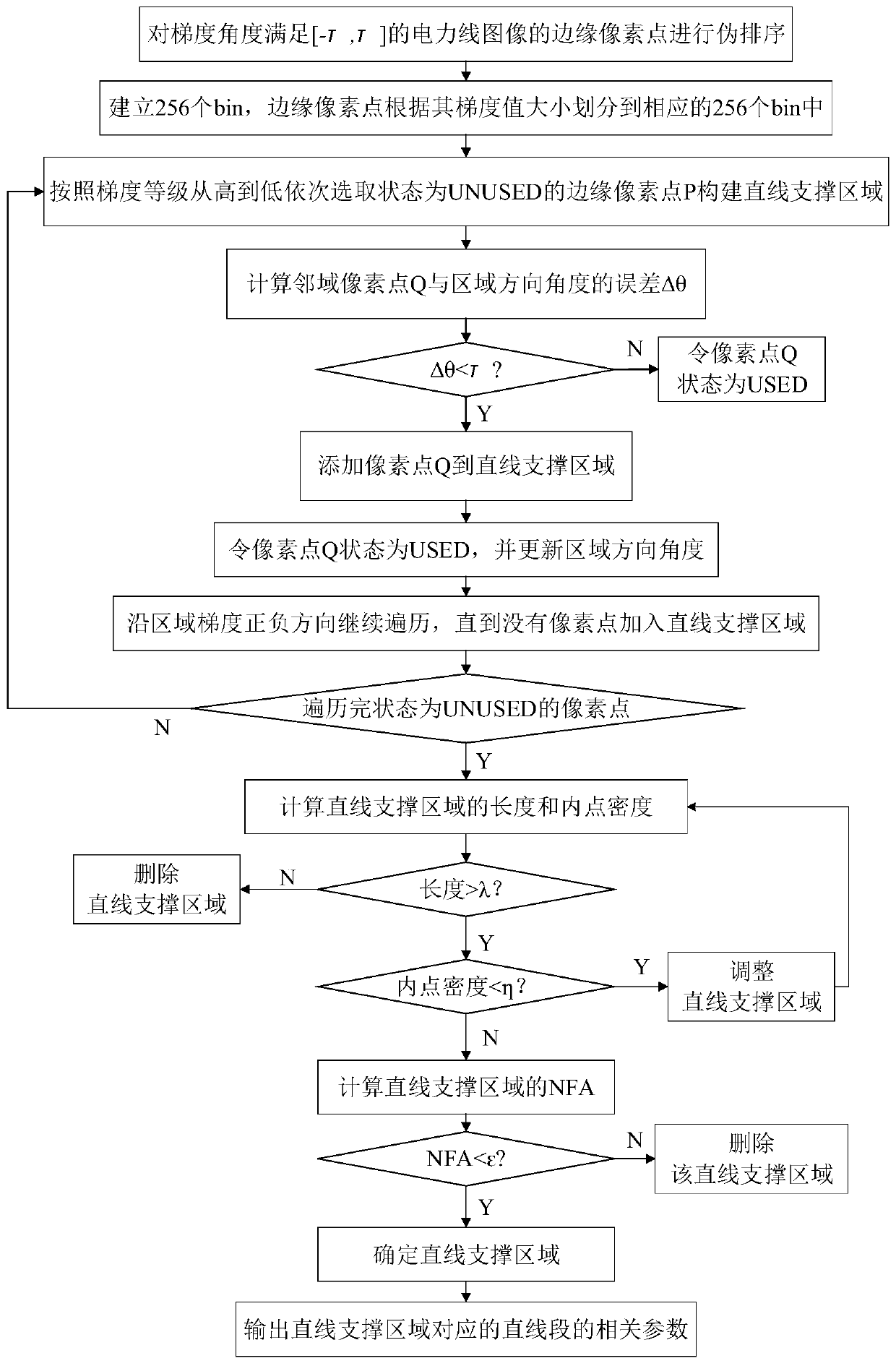

Power line detection method and device

ActiveCN110956078APreserve straight line featuresAvoid undetected situationsCharacter and pattern recognitionInformation technology support systemImage extractionAlgorithm

The invention provides a power line detection method and device, and belongs to the technical field of power line detection. The method comprises the steps of obtaining a power line image; extractingedge pixel points of the power line image; constructing a linear support area by utilizing the edge pixel points of the power line image; adjusting the constructed linear support area, wherein the following steps are iteratively executed: when the length of the linear supporting area is greater than a set length threshold value and the interior point density of the linear supporting area is smaller than a set interior point density threshold value, removing pixel points on two sides of the linear support area in the length direction until the length is greater than or equal to a set length threshold value and the internal point density is greater than or equal to a set internal point density threshold value to obtain an adjusted linear support area; and performing linear grouping fitting to obtain a power line in the image. According to the invention, the linear support area adjusting mode can reduce the probability of power line missed detection.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

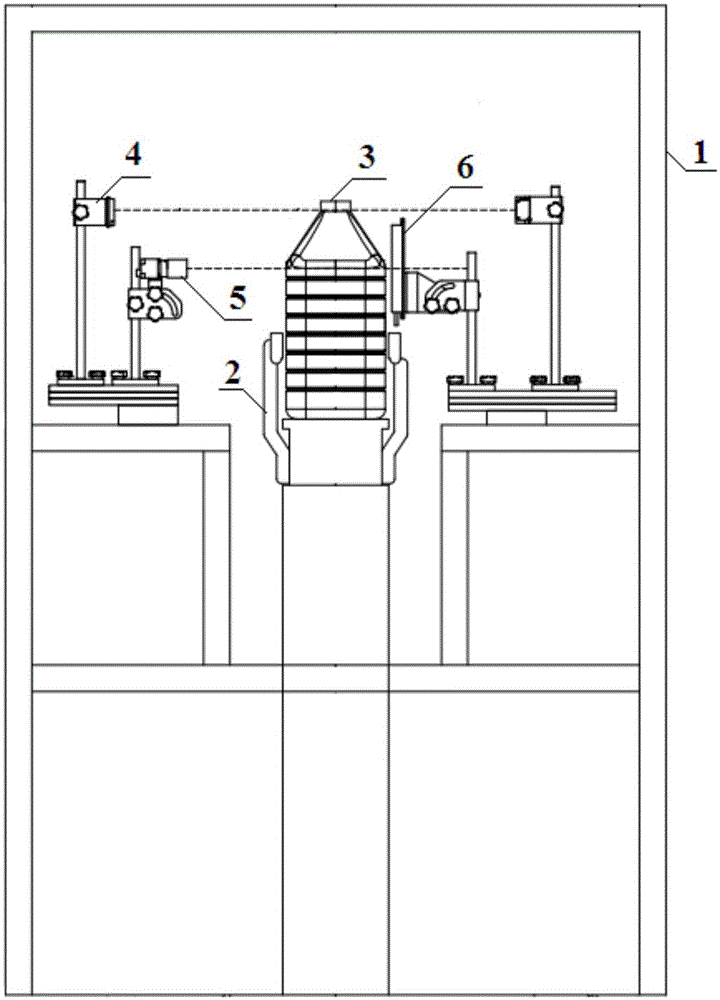

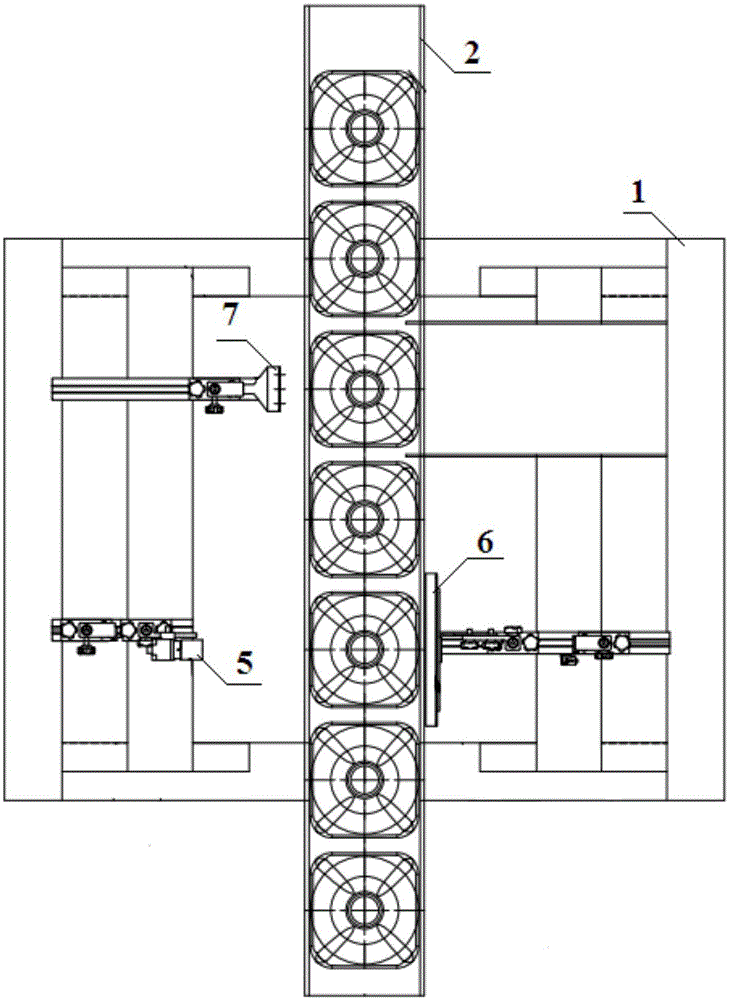

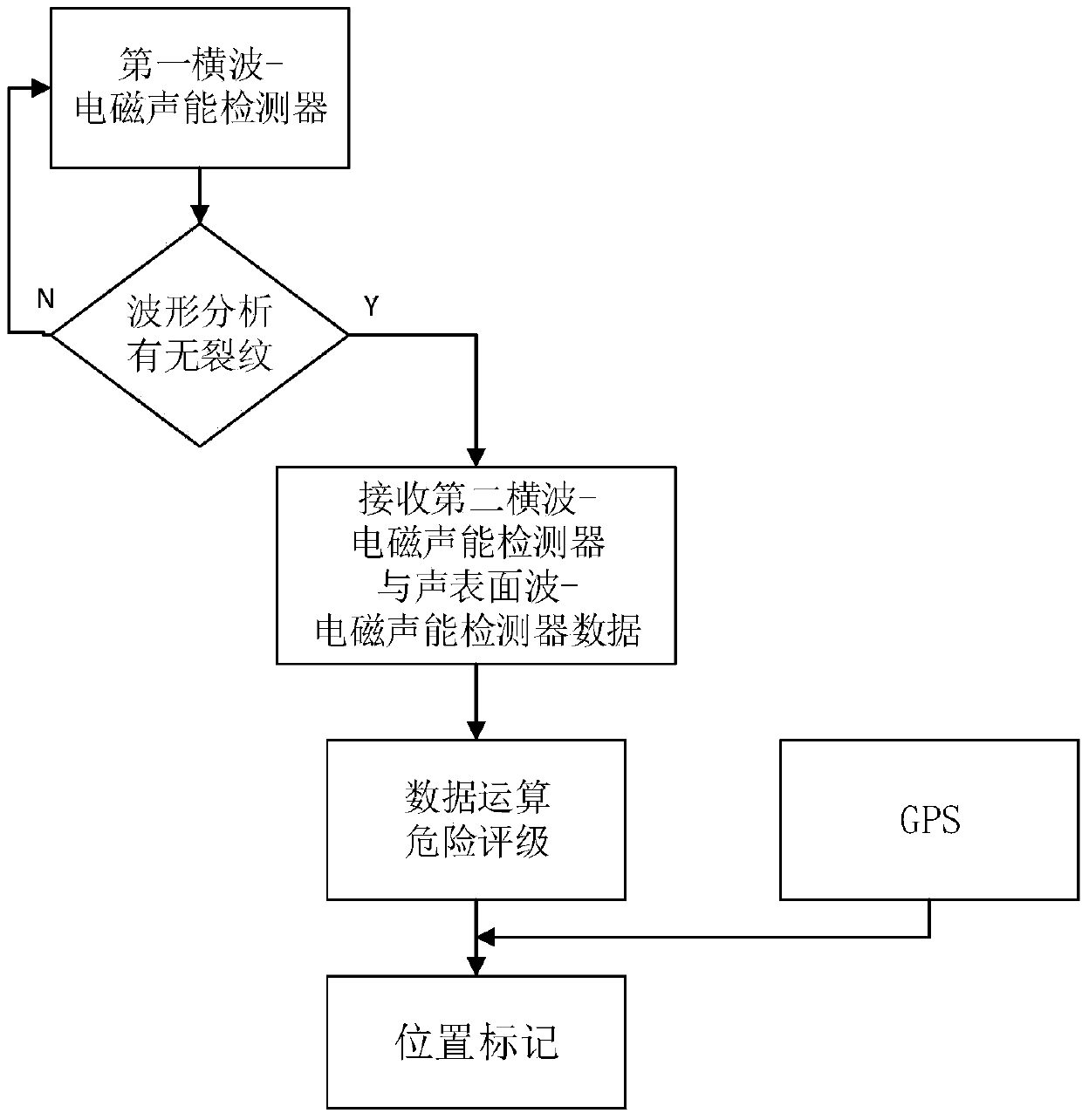

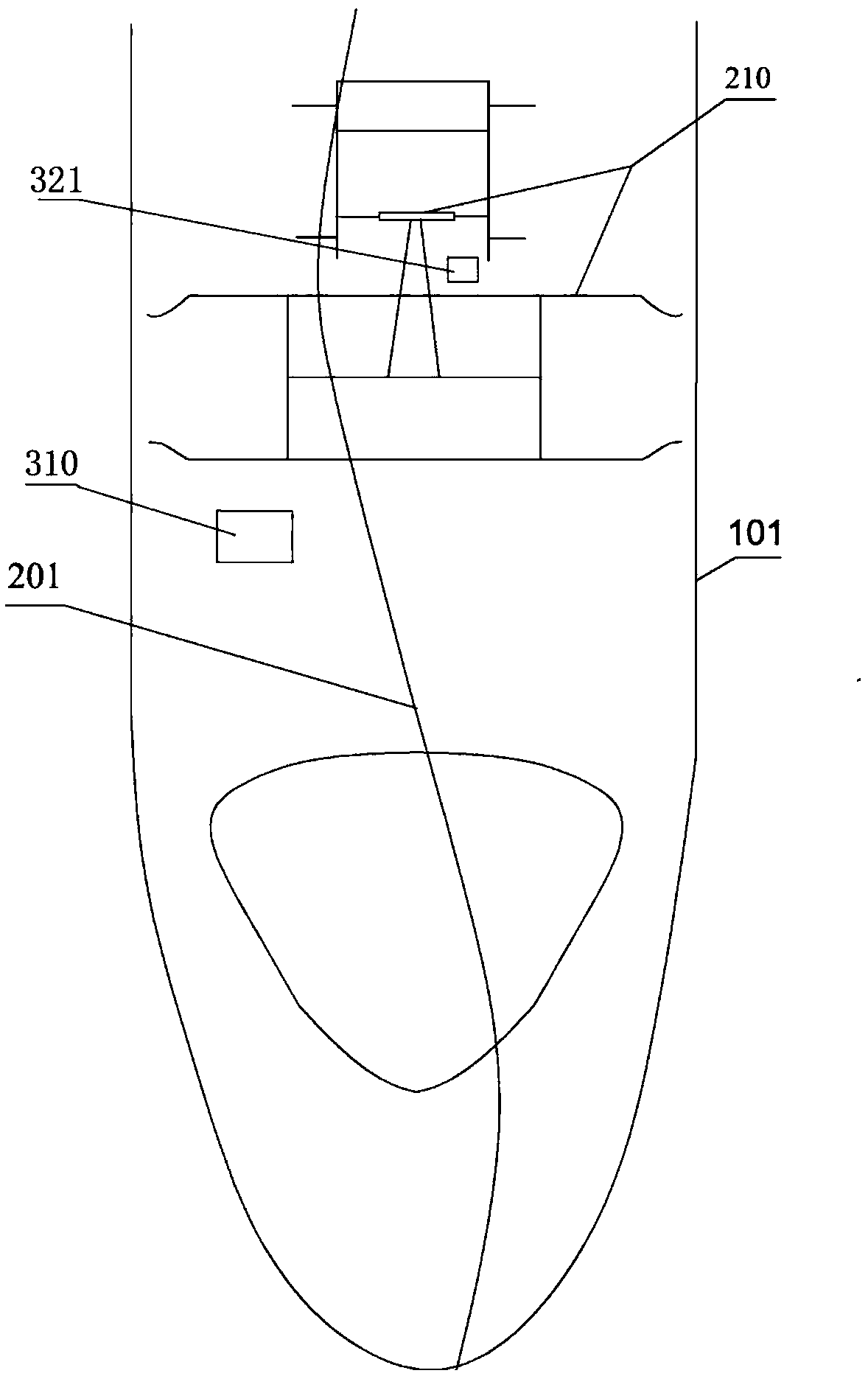

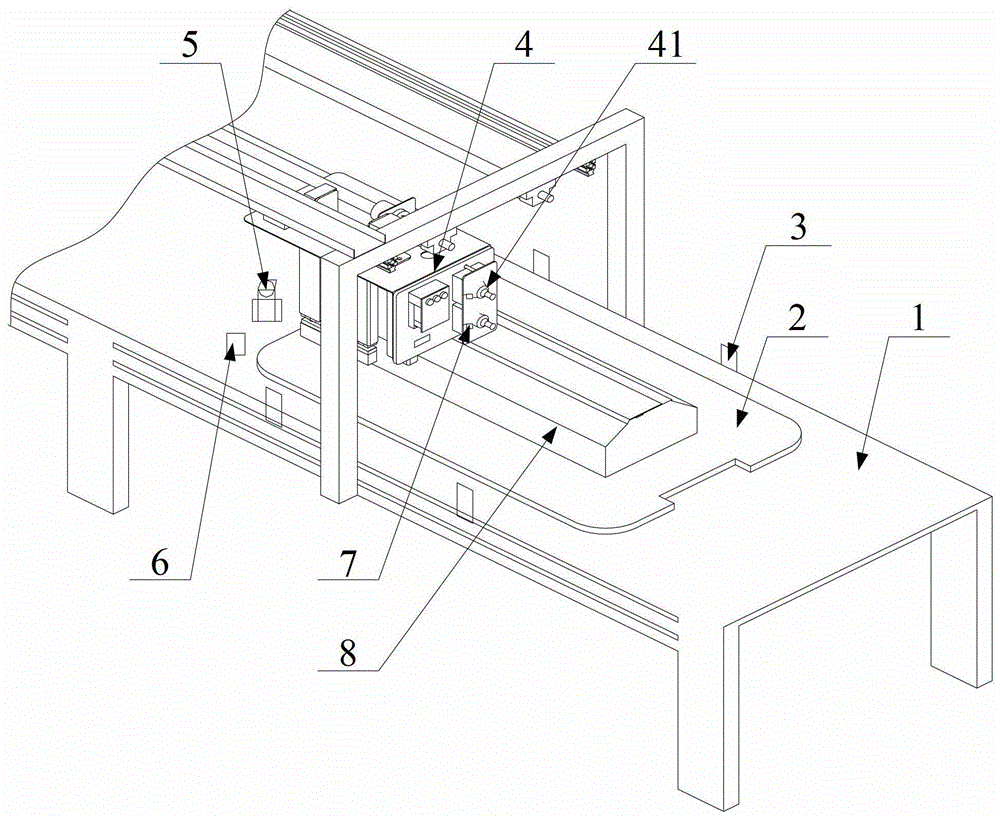

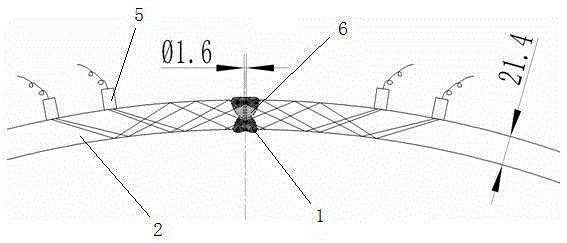

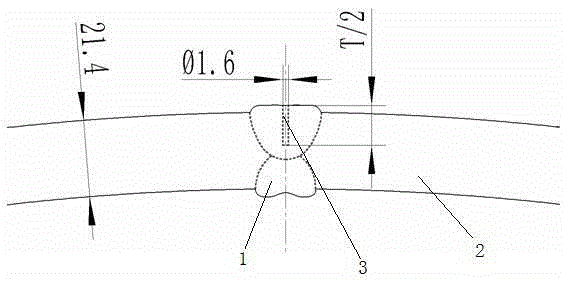

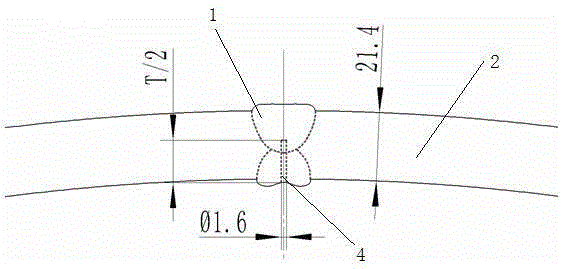

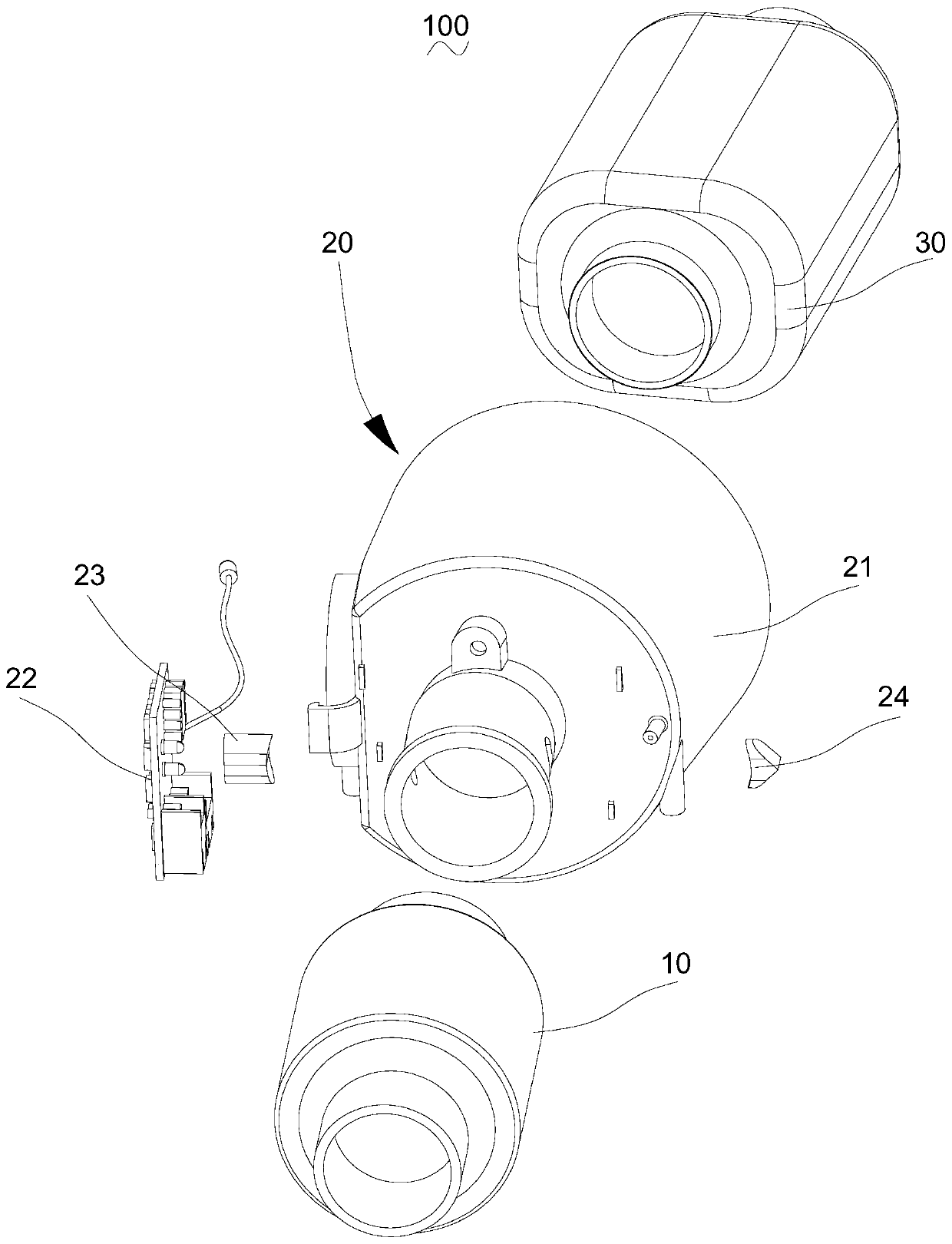

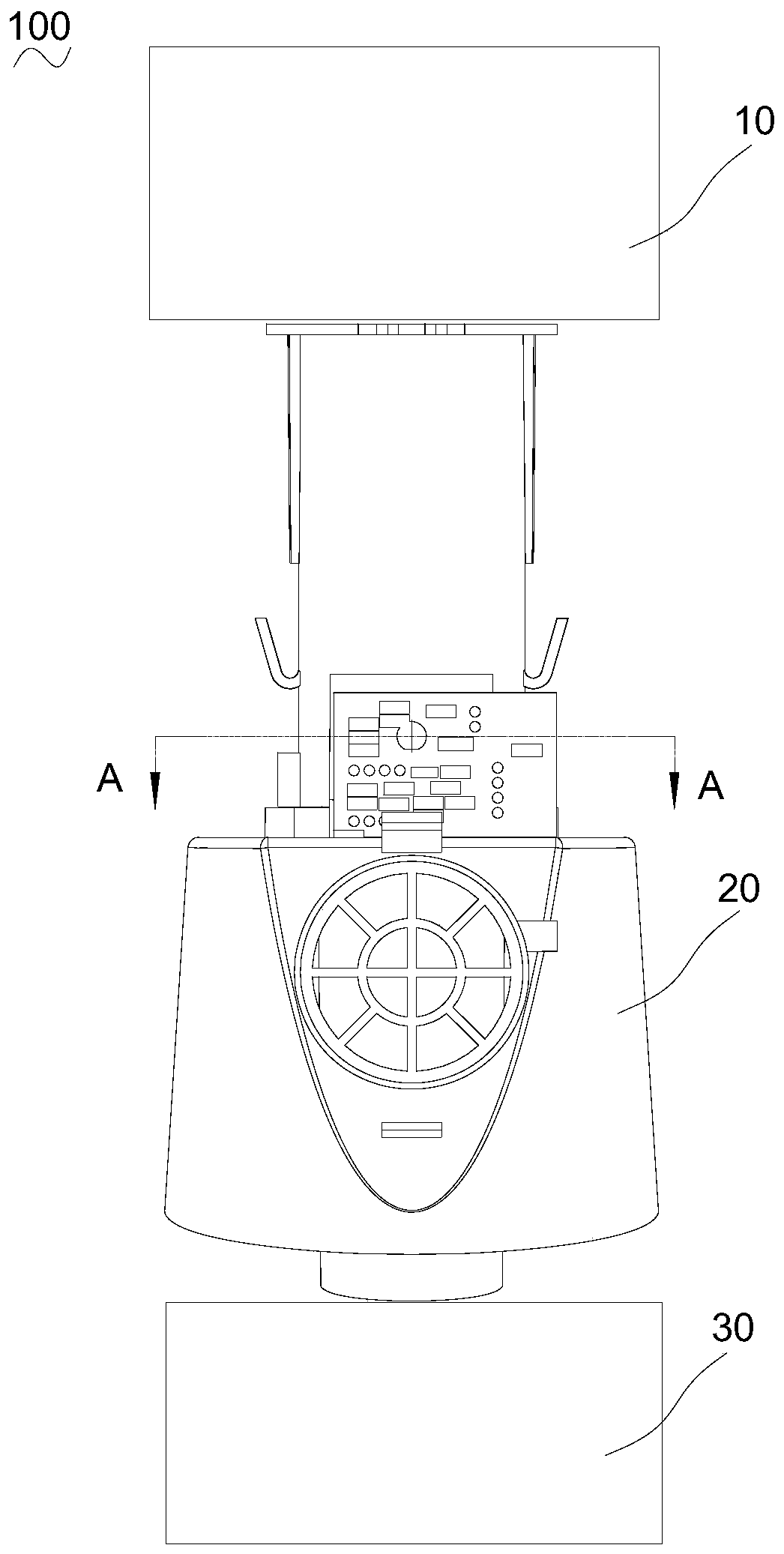

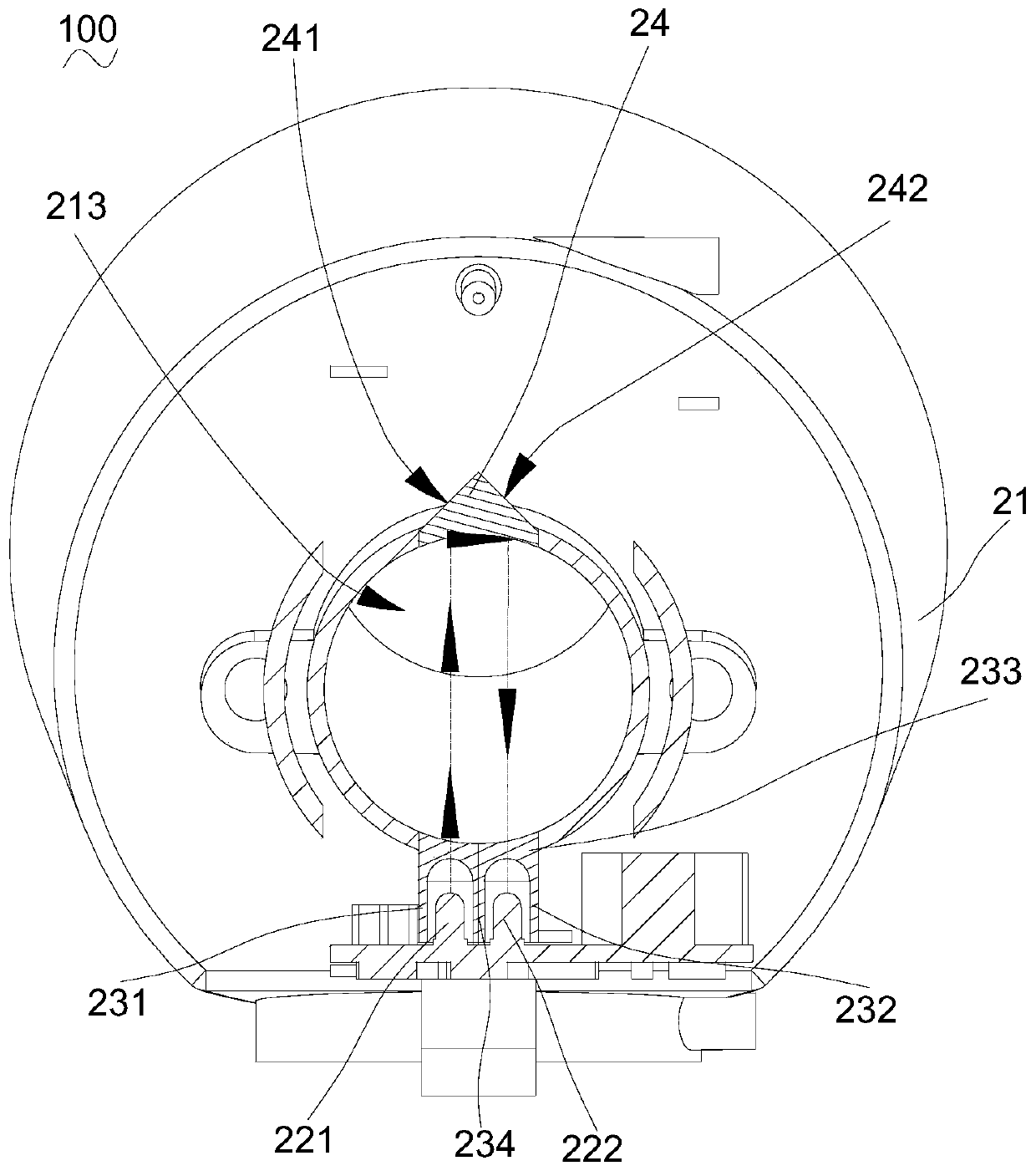

Crack detection system and method for high-speed rail contact line based on laser ultrasound

ActiveCN110907363ASimple structureFeasible and reliableProcessing detected response signalMaterial analysis by optical meansEngineeringLaser ultrasonics

The invention relates to a crack detection system for a high-speed rail contact line based on laser ultrasound. The crack detection system comprises a contact line following device and a laser ultrasonic detection device; the contact line following device comprises a lifting bow, a transmission mechanism and a half-section cavity; the lifting bow is arranged on the roof of the detection train, andtwo sides of the lifting bow are connected with the half-section cavity through two corresponding groups of same transmission mechanisms; the laser ultrasonic detection device is mounted in the half-section cavity and comprises a control processing unit, a laser ultrasonic excitation device and an ultrasonic receiving device; the laser ultrasonic excitation device and the ultrasonic receiving device are installed on the laser ultrasonic detection adjusting mechanism. The contact line following device provided by the invention solves the problem that following detection cannot be carried out during driving due to zigzag and nonlinear laying of the contact line, is simple in structure, high in feasibility and reliability and lower in cost compared with an electrical device, can continue tobe optimized in the directions of weight reduction, vibration reduction and the like, and has a large improvement space.

Owner:常州天策电子科技有限公司

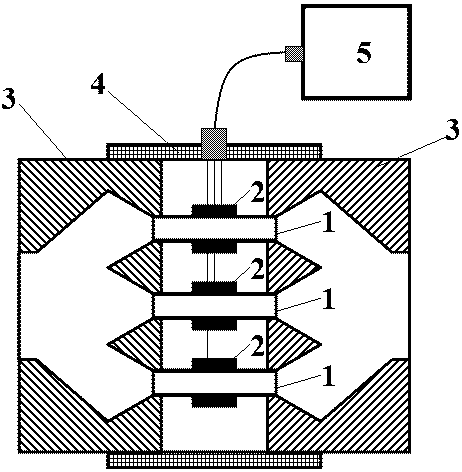

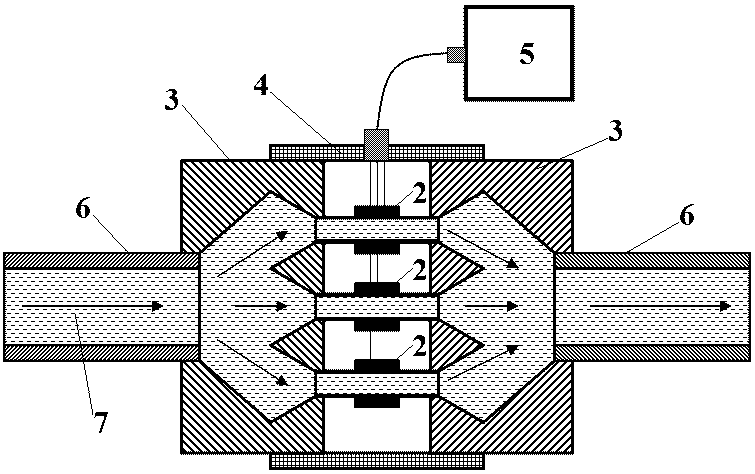

Device and method for online monitoring metal abrasive particles of oil in large-caliber oil return pipe

ActiveCN105738259AReduce resistanceSolve the low sensitivity problemParticle size analysisMaterial magnetic variablesEddy currentSmall caliber

The invention discloses a device and method for online monitoring metal abrasive particles of oil in a large-caliber oil return pipe.The device comprises a plurality of flow dividing guide pipes, a plurality of external-penetration-type eddy current detection probes, two porous end face transferring pipes, a fixing pipe and a multi-channel eddy current detector.The small-pipe-flow-dividing and multi-channel eddy current monitoring method is adopted; as the diameter of the flow dividing guide pipes is smaller than that of the large-caliber oil return pipe, the small-caliber external-penetration-type eddy current detection probes can be adopted for detection, detection accuracy and detection sensitivity are greatly improved, the detection missing probability is reduced, and the low-sensitivity problem of large-caliber external-penetration-type eddy current detection probes is effectively solved.As horn-shaped holes are formed in the porous end face transferring pipes unique in design, the drainage function is achieved, the resistance to flowing of oil is greatly reduced, and meanwhile oil dirt is not prone to accumulation.

Owner:EDDYSUN (XIAMEN) ELECTRONICS CO LTD

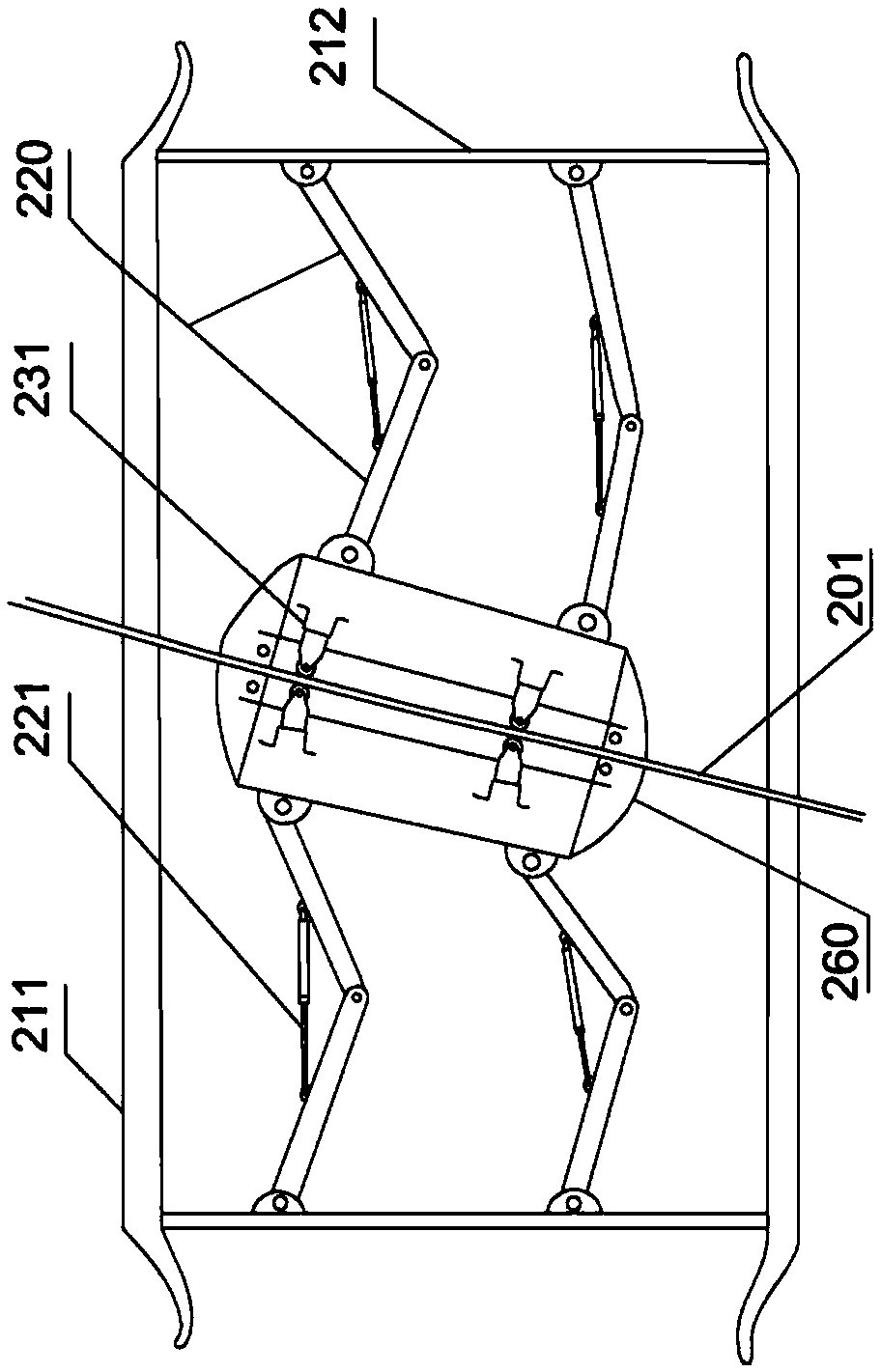

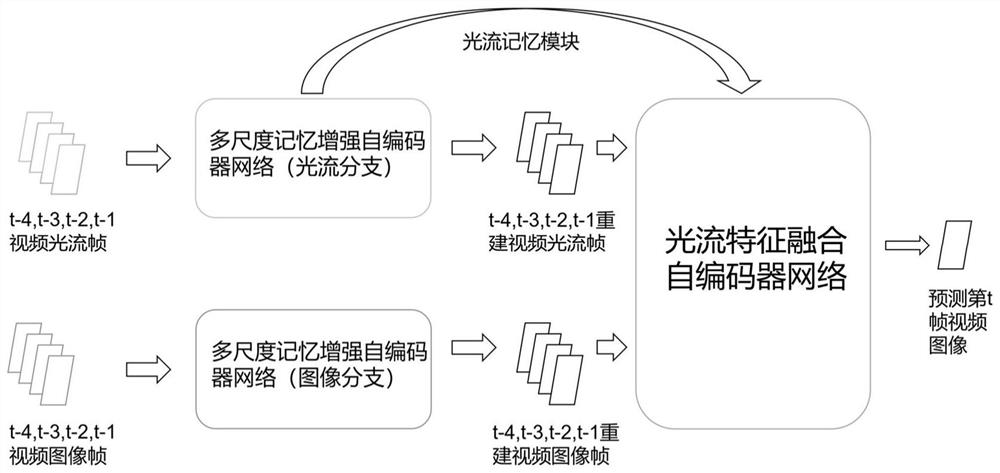

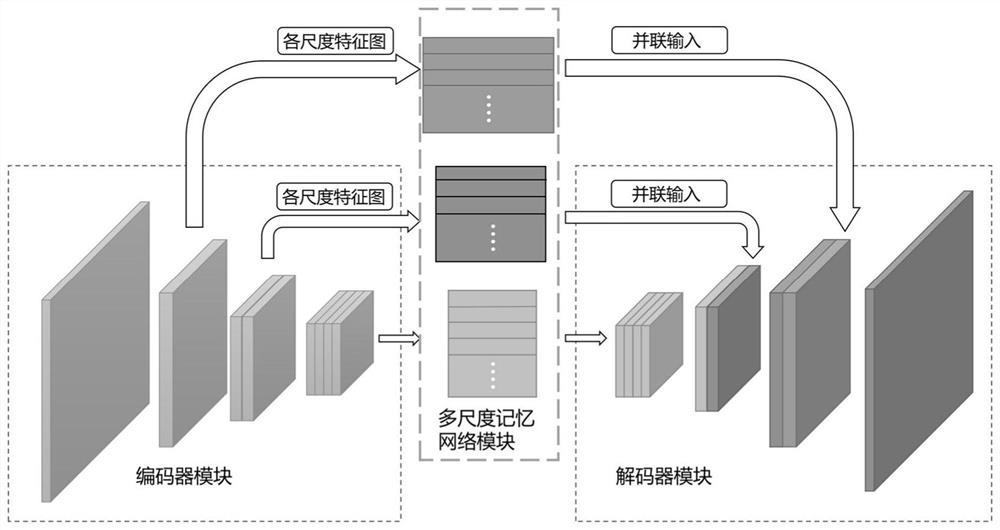

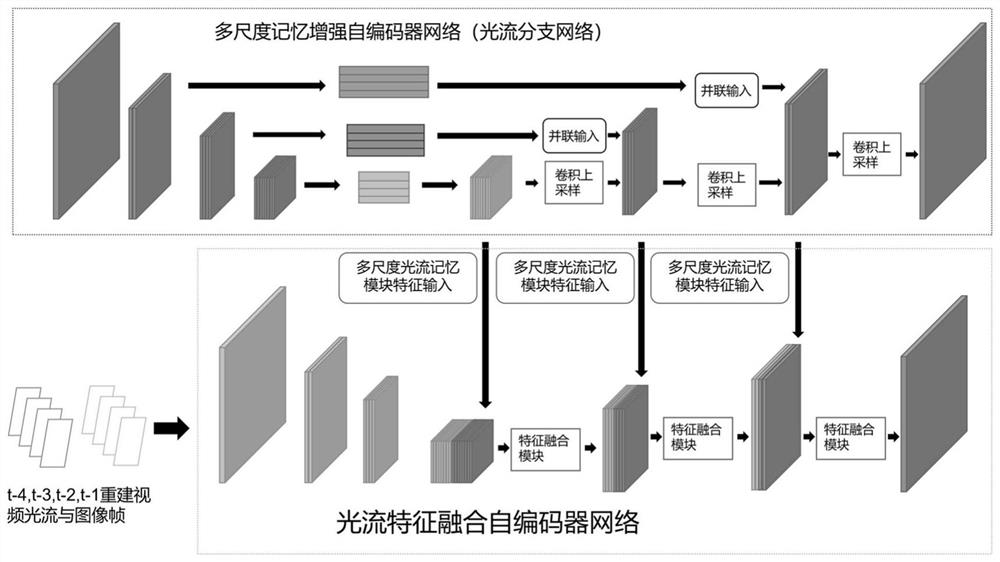

Multi-mode two-stage unsupervised video anomaly detection method

PendingCN114332053AReduce the chance of missed detectionSolve the phenomenon of rebuilding abnormal framesImage analysisNeural architecturesAnomaly detectionOptical flow

The invention discloses a multi-mode two-stage unsupervised abnormal video detection method. According to the method, video optical flow information and a memory network module are fully utilized, and the end-to-end unsupervised video anomaly detection method is realized. In the two stages, firstly, a multi-scale memory enhanced auto-encoder network module is used for respectively inputting an image sequence and an optical flow sequence of a video for reconstruction, and then the reconstructed image sequence, the reconstructed optical flow sequence and memory network feature information of optical flow are input into an optical flow feature fusion auto-encoder network module. And outputting the predicted video image, and detecting the video abnormality according to the error between the predicted image and the real image and the error between the reconstructed optical flow and the real optical flow. According to the method, the common problems of high omission ratio, insufficient robustness and the like of a depth auto-encoder method for video anomaly detection at present are solved.

Owner:SHANGHAI JIAO TONG UNIV

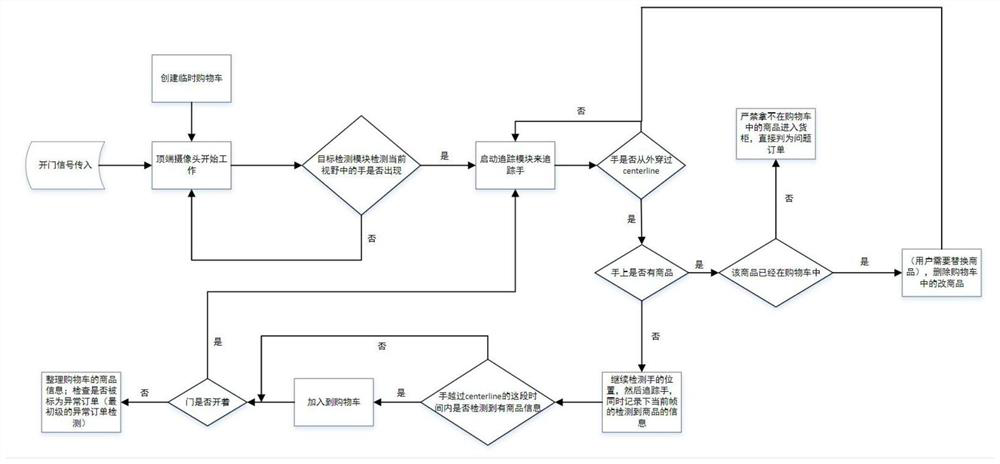

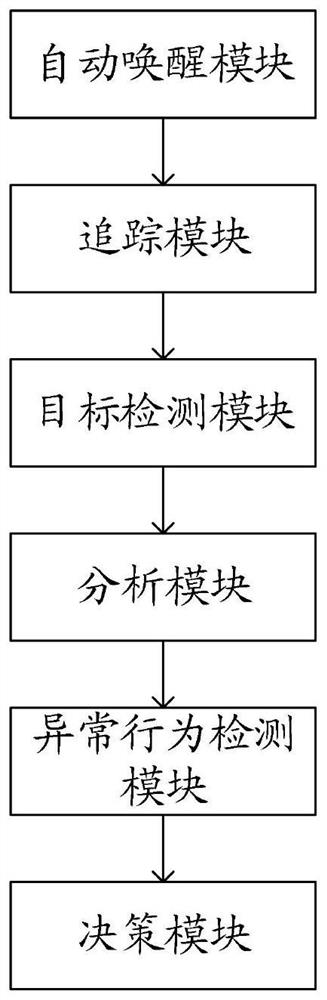

Unmanned vending method and system based on dynamic vision

PendingCN112991379AImprove space utilizationReduce the probability of missed detectionImage enhancementImage analysisReal-time computingOperations research

The invention discloses an unmanned vending method and system based on dynamic vision, and belongs to the technical field of artificial intelligence. The method comprises the following steps: detecting the state of an unmanned vending cabinet door; performing biological recognition on the hand of the user; judging the movement direction of the hand relative to the self-service vending cabinet door; judging a shopping state according to the movement direction, the temporary commodity list information and the updated temporary shopping cart information; and obtaining a final shopping result, and completing shopping. According to the invention, the accuracy of commodity identification is improved, the commodity damage rate is reduced, and the shopping experience is improved.

Owner:SOUTH CHINA UNIV OF TECH

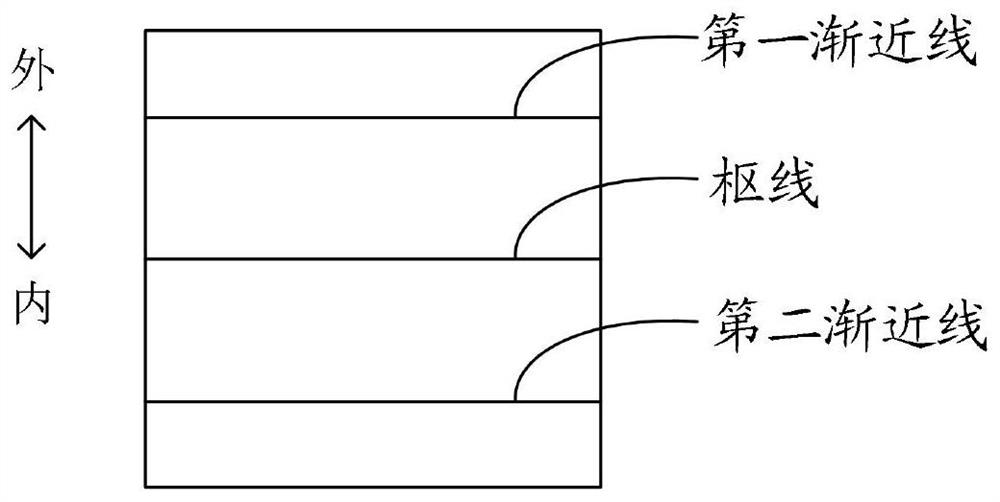

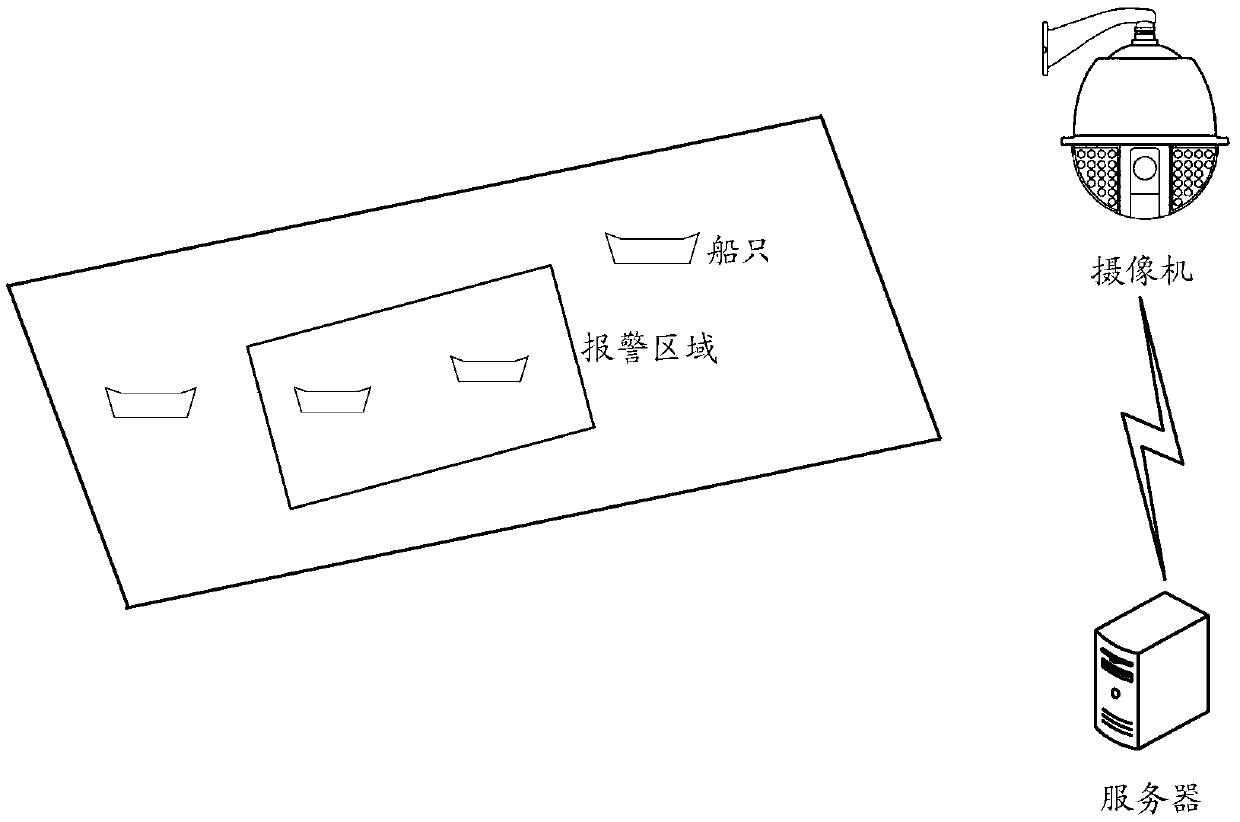

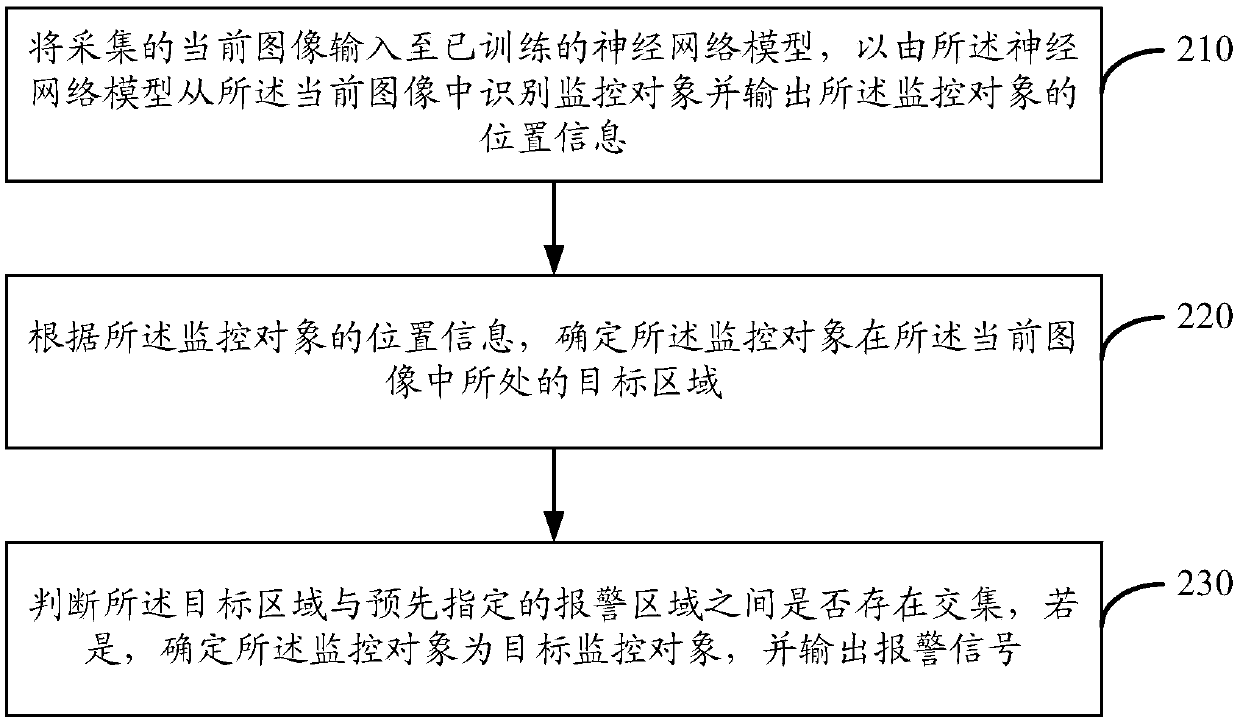

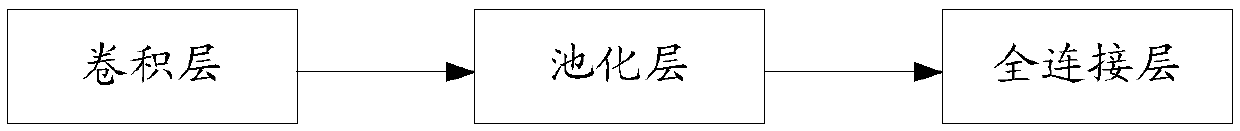

Regional alarm method and device, electronic equipment and readable storage medium

ActiveCN110874953AImprove reliabilityReduce false positivesClimate change adaptationCharacter and pattern recognitionPattern recognitionEngineering

The invention relates to a regional alarm method and device, electronic equipment and a readable storage medium. The method comprises the following steps: inputting a collected current image into a trained neural network model, so that the neural network model identifies a monitored object from the current image and outputs position information of the monitored object; determining a target area where the monitored object is located in the current image according to the position information of the monitored object; and judging whether an intersection exists between the target area and a pre-specified alarm area or not, if so, determining that the monitored object is a target monitored object, and outputting an alarm signal. According to the invention, the neural network model is adopted todetect the monitored object, the accuracy is high, and the accuracy of the regional alarm method can be improved.

Owner:HANGZHOU HIKVISION DIGITAL TECH

Method for monitoring traffic violation of non-motor vehicles

ActiveCN107545727AEnsuring the intensity of violation monitoringRealize monitoringArrangements for variable traffic instructionsDetection of traffic movementTraffic violationSurveillance camera

The invention provides a method for monitoring the traffic violation of non-motor vehicles. The method includes a non-motor vehicle license plate, a pressure sensor, a radio frequency emitter, a monitoring camera, a radio frequency receiver and a road traffic monitoring platform. The method includes the following steps: the pressure sensor detecting the pressure value imposed on a rear seat of thenon-motor vehicle, and transmitting the pressure value to the radio frequency emitter, when the pressure value passes through the road monitoring terminal, uploading the pressure value to the road traffic monitoring platform through the radio frequency receiver; the road traffic monitoring platform comparing the pressure value and a preset upper limit of pressure value, determining whether the non-motor vehicle has been loaded with cargo or carries other passengers, and if the non-motor vehicle has been loaded with cargo or carries other passengers, transmitting a command for acquiring the non-motor vehicle license plate to the monitoring camera; and the monitoring camera acquiring the non-motor vehicle license plate, the road traffic monitoring platform identifying the non-motor vehiclelicense plate in the images, and informing the owner of the non-motor vehicle of the violation through short texts or instant software.

Owner:ZHENGZHOU BLUEEYE TECH CO LTD

Production line monitoring system and production line monitoring method

ActiveCN103885370BAvoid missing detectionReduce the chance of missed detectionProgramme controlComputer controlAutomatic controlTester device

Owner:GREE ELECTRIC APPLIANCES INC

Ultrasonic detection method for defects at middle parts of welding seams of extra-large wall thickness SAWH steel pipe

ActiveCN105301103AImprove Weld Inspection IntegrityGuaranteed pass rateAnalysing solids using sonic/ultrasonic/infrasonic wavesPass rateWeld seam

The invention discloses an ultrasonic detection method for defects at the middle parts of welding seams of an extra-large wall thickness SAWH steel pipe and relates to the technical field of ultrasonic flaw detection devices or methods. The ultrasonic detection method comprises the following steps: manufacturing artificial defects on the upper sides and the lower sides of the welding seams; respectively clamping one ultrasonic detection probe on the outer wall of a steel pipe on each of the left sides and the right sides of the welding seams, adjusting the distances from the probes to an upper side vertical hole or a lower side vertical hole well, slightly adjusting the probes and finding out defect reflection highest waves through an ultrasonic flaw detector; calibrating the ultrasonic flaw detector according to the reflection highest waves; detecting the welding seams of the steel pipe in batches by using the calibrated ultrasonic flaw detector. With the adoption of the method, the possibility of missing detection of defects in the middle region of the welding seams can be effectively reduced, the detection completeness of the steel pipe welding seams is improved, the missing detection probability of welding seams is reduced and the ex factory pass rate of the steel pipe is guaranteed, so that the product quality is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

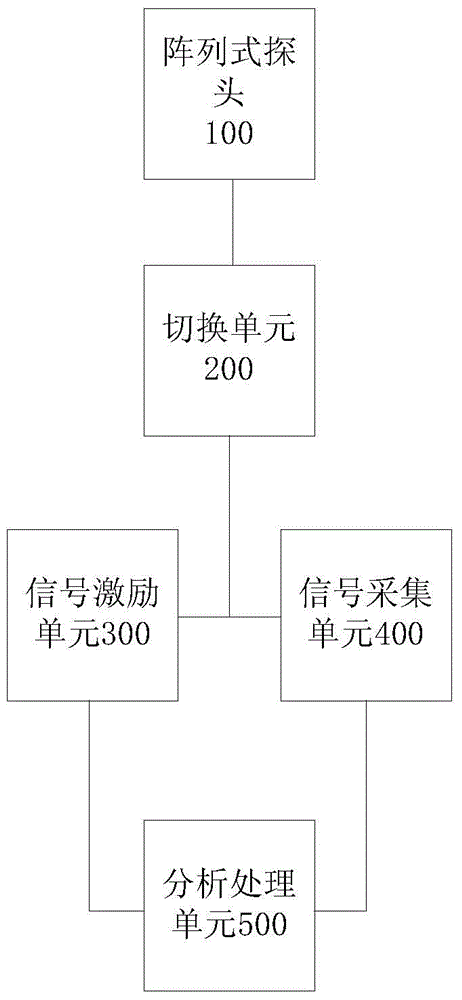

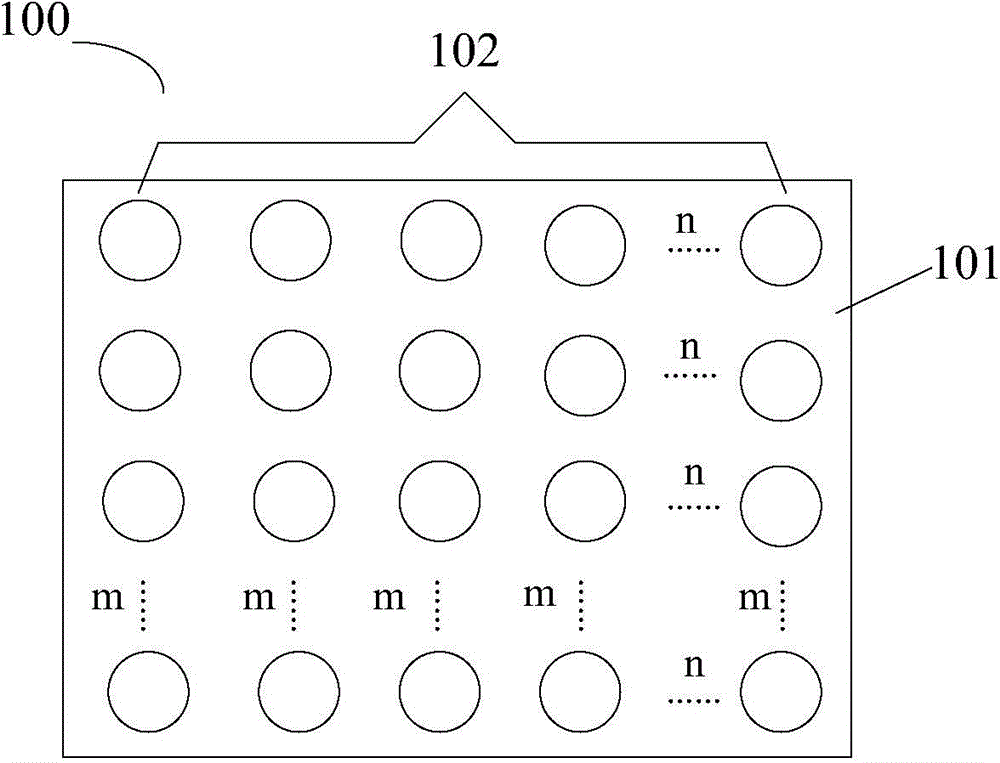

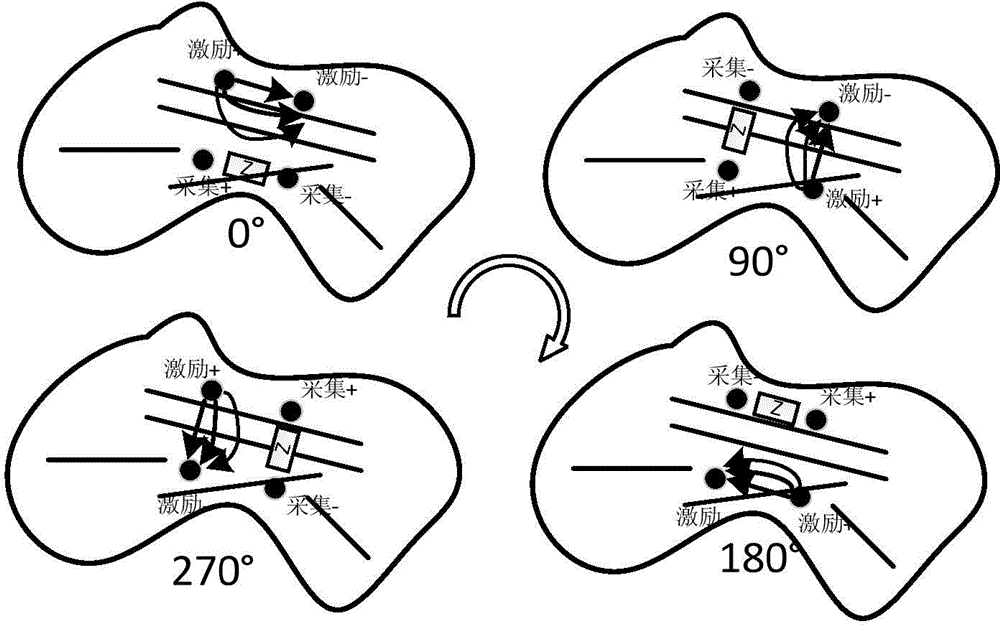

Quick measuring device and quick measuring method on basis of bio-impedance technologies

InactiveCN105286863AImprove measurement accuracyGuaranteed SensitivityDiagnostic recording/measuringSensorsFast measurementMeasurement device

The invention particularly discloses a quick measuring device and a quick measuring method on the basis of bio-impedance technologies. The quick measuring device comprises an array probe, a switching unit, a signal excitation unit, a signal acquisition unit and an analysis and processing unit. An electrode array of the array probe is connected with the signal excitation unit and the signal acquisition unit by the switching unit, the array probe comprises a substrate and the electrode array, the electrode array is embedded in the substrate, N*M micro-electrodes are arranged in an array manner to form the electrode array, and a plurality of detection regions for measuring bio-impedance in a unit of two or four micro-electrodes are formed by the electrode array. The quick measuring device and the quick measuring method have the advantages that the detection regions are increased, the repeated point selection frequencies are reduced, different depths and surfaces of to-be-measure biological tissues can be measured, accordingly, the to-be-measured biological tissues can be omni-directionally measured without dead spaces, and missing detection can be thoroughly prevented.

Owner:SEALAND TECH CHENGDU

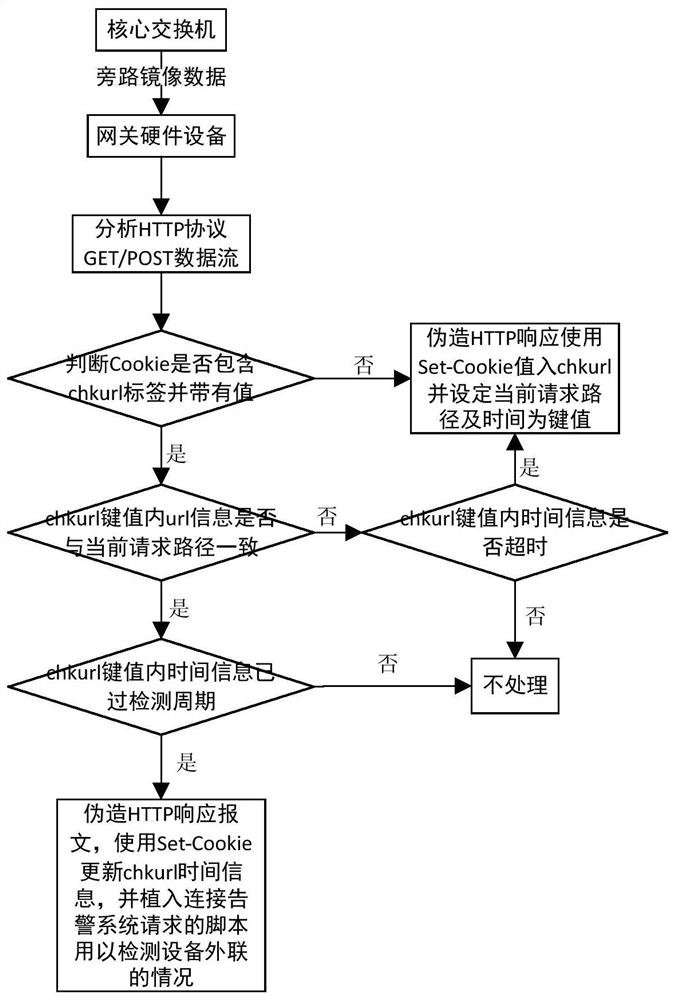

Illegal external connection detection method for NAT access equipment

PendingCN112887264AEasy to deployEasy to handleTransmissionHigh level techniquesTime informationPathPing

The invention provides an illegal external connection detection method for NAT access equipment, which comprises the following steps of: S1, deploying gateway hardware equipment on a bypass of a core switch, and providing network flow information to the gateway hardware equipment; S2, analyzing flow information in real time; S3, if the chkurl information does not exist, turning to the step S4, otherwise, turning to the step S5; S4, enabling the gateway hardware equipment to use a Set-Cookie value to enter a chkurl key and a chkurl key value; S5, judging whether the chkurl key value is consistent with the request path of the current message or not, if not, turning to step S6, and otherwise, turning to S7; S6, judging whether the time information in the chkurl key value is overtime or not, and if the time information is overtime, turning to the step S4; S7, judging whether the time information in the chkurl key value exceeds a detection period or not, if not, ending, otherwise, continuing to execute the step S8; and S8, inputting the gateway hardware equipment value into a script with an alarm system connection request so as to detect the external connection condition of the equipment, thereby solving the problem that the NAT access equipment cannot effectively and comprehensively carry out illegal external connection detection.

Owner:ZHEJIANG YUANWANG INFORMATION CO LTD

Dust detection device and dust collector

PendingCN110613401AReduce the chance of missed detectionReduce processing costsSuction filtersElectric equipment installationDust detectionLight beam

The invention relates to a dust detection device and a dust collector, and the dust detection device comprises the following parts: an air duct structure which is internally provided with a gas channel; an emitting part that is used for emitting first light into the gas channel; a reflection part that is used for enabling the first light to be reflected at least once in the gas channel and formingsecond light which deviates from the first light and can penetrate through the gas channel; a receiving part that is arranged in a staggered manner with the emitting part, and used for receiving thesecond light; the emitting part and the receiving part are integrated into a whole. Due to the fact that the first light is reflected at least once in the gas channel under the action of the reflection part and forms the second light deviating from the first light, dust can be sensed through the at least two light beams, and the probability of dust missing detection is reduced; as the emitting part and the receiving part are integrated, compared with the prior art, the processing cost is reduced, and the assembly efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Immunodiagnosis kit for detecting IV-type dengue virus NS1 antigen

ActiveCN101551393BLow costSimple and fast operationMaterial analysisAgainst vector-borne diseasesPositive controlSerotype

The invention discloses an immunodiagnosis kit for detecting specific IV-type dengue virus antigen, comprising a microporous reaction plate coated with monoclonal antibody 2E8A5, sample treatment fluid, monoclonal antibody 7A6A1 combined with markers, positive control, negative control, wash concentrate, color developing solution and stop solution. The kit can detect IV-type dengue virus antigen specifically, does not cross-react with other three types of serotype dengue virus antigens and detects that the supernatant sensitivity of the IV-type dengue virus is 64 times of that of the commercial kit of the same type, namely, the Pan-E Dengue Early ELISA test kit, thus greatly improving the sensitivity of detection of clinical serum samples and simultaneously reducing omission rate in clinical applications.

Owner:SOUTHERN MEDICAL UNIVERSITY

Reagent kit for distinguishing and detecting dengue virus/yellow fever virus/west nile virus/chikungunya virus

ActiveCN102776297BEasy to operateShort timeMicrobiological testing/measurementFluorescence/phosphorescenceEnzyme systemQuarantine

The invention relates to a reagent kit for distinguishing and detecting four entomoplily transmitted pathogens, in particular to a reagent kit for distinguishing and detecting dengue virus, yellow fever virus, west nile virus and chikungunya virus by utilizing multiple real-time fluorescent polymerase chain reaction technologies. The reagent kit mainly comprises reverse transcription-polymerase chain reaction (RT-PCR) reaction liquid, primer probe mixed liquid, an RT-PCR reaction enzyme system, diethylpyrocarbonate (DEPC) H2O and packing boxes for separating and packing reagent bottles or tubes. Due to the fact the reagent kit can accurately distinguish the dengue virus, the yellow fever virus, the west nile virus and the chikungunya virus, the reagent kit can be widely applied to the multiple fields of differential diagnosis, inspection & quarantine, prevention and control of epidemic situation and the like of entomoplily transmitted virus.

Owner:DAAN GENE CO LTD +1

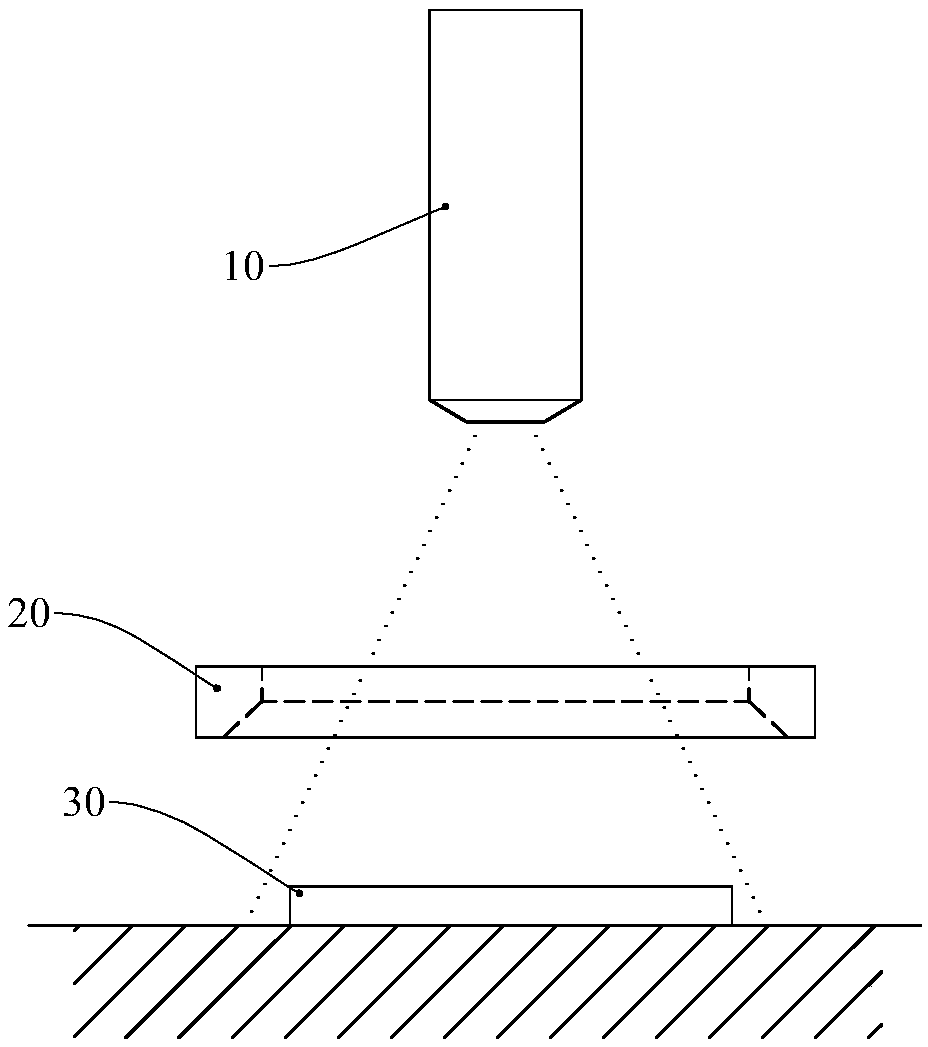

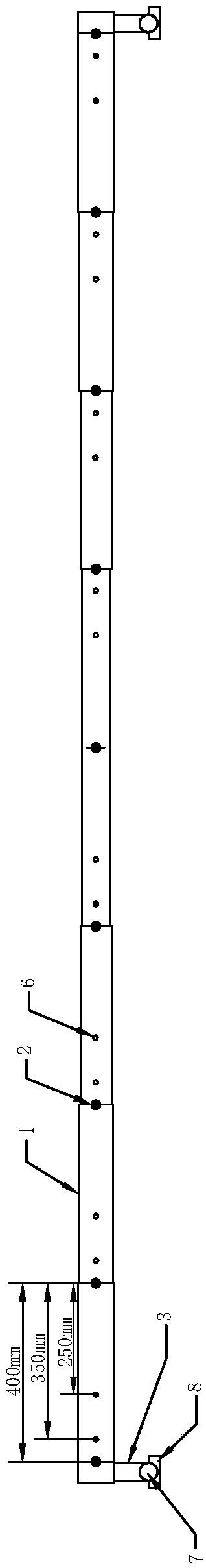

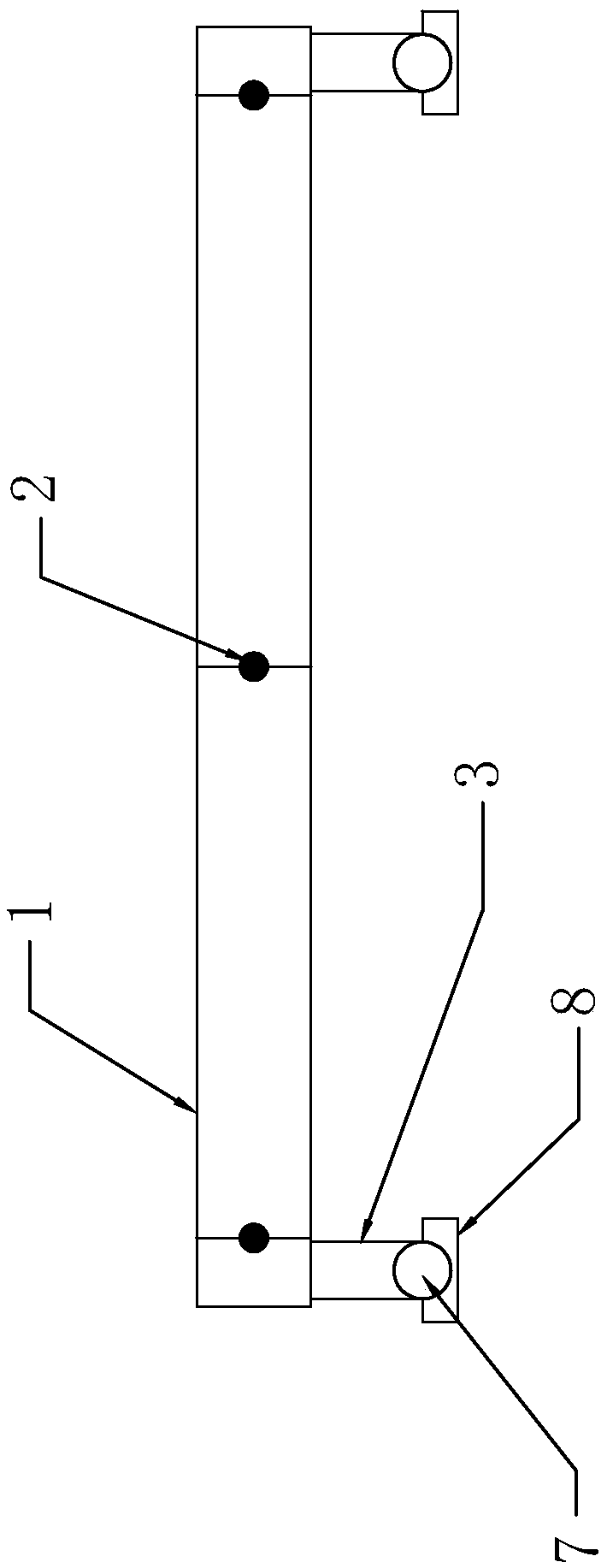

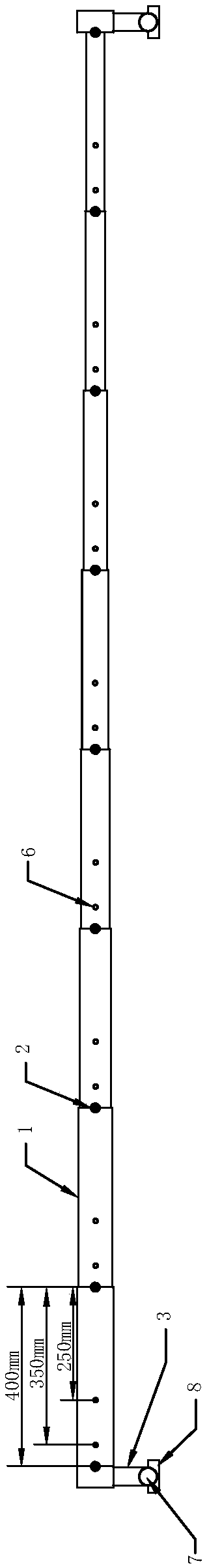

Device for laser positioning method for realizing storage tank bottom plate detection

PendingCN108731651AReduce the chance of missed detectionImprove detection efficiencyReference line/planes/sectorsEngineeringLaser beams

The technical scheme of the invention discloses a device for a laser positioning method for realizing storage tank bottom plate detection. The device comprises a telescopic rod formed by connecting multiple supporting rods in a sleeving manner, wherein a laser emission device is arranged on each supporting rod; a power supply is arranged at one end of the telescopic rod; and the laser emission devices are all connected with the power supply. According to the device, laser beams emitted by the laser emission devices replace artificially drawn auxiliary straight lines, and the distance between the laser beams is controlled by utilizing retraction of the telescopic rod; and the device can shrink to a smaller length, is convenient to be carried by detection personnel and is easy to operate anduse, the emitted laser beams can be clearly seen in a dark environment, and the missing inspection probability can be effectively decreased by an auxiliary detecting instrument.

Owner:GUANGDONG INSPECTION & RES INST OF SPECIAL EQUIP ZHUHAI INSPECTION INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com